Patents

Literature

73results about How to "Improve hydrophobic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

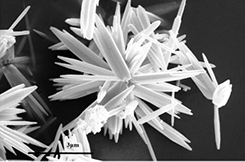

Method for preparing hydrophobic silica aerogel from rice husk ash based aquagel

The invention provides a method for preparing hydrophobic silicon dioxide aerogel by rice hull ash based water gel. The silicon dioxide water gel obtained by taking rice hull ash as materials is subjected to solvent replacement, surface finish in the siloxane phase and normal-pressure drying treatment to prepare the silicon dioxide aerogel with hydrophobic characteristics. For the aerogel prepared, the specific surface area reaches between 500 and 1000m<2> / g, the volume density is between 0.08 and 0.3g / cm<3>, and the sizes of the micropores are mainly distributed in the range of between 1 and 100nm. The method adopts advanced technologies of the solvent replacement, the surface finish and the preparation of the normal-pressure aerogel, thereby unnecessarily using expensive organic resources, avoiding the use of supercritical drying equipment which is commonly used in the convention preparation of the silicon dioxide aerogel and has problems of high price, low efficiency and high risk and the technological investment, and obviously lowering production risk and production cost. Moreover, the method also has the advantages of simple process, strong manageability and suitable mass production and application.

Owner:TONGJI UNIV

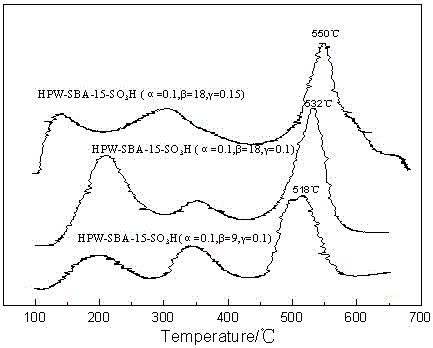

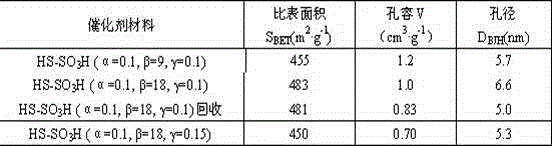

Method for preparing sulfonic acid group-modified mesoporous material-loaded heteropolyacid catalyst and application thereof during esterification reaction

ActiveCN105854942AImprove hydrophobic propertiesEasy to prepareOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFormic acidOxidizing agent

The present invention discloses a method for preparing a sulfonic acid group-modified mesoporous material-loaded heteropolyacid catalyst and the application thereof during the esterification reaction. 3-mercapto propyl trimethoxy silane is adopted as an organic silicon source, and tetraethoxysilane is adopted as an inorganic silicon source. A tri-block copolymer is adopted as a template agent, and H2O2 solution is adopted as an oxidant. Phosphotungstic acid is added as an active ingredient and the sulfonic acid group-modified mesoporous material-loaded heteropolyacid catalyst is obtained through the one-step hydro-thermal synthesis process based on the copolycondensation method in the acidic condition. According to the technical scheme of the invention, the catalyst has the advantage of strong acidity, and the specific surface area thereof is 300-600 m2 / g. The pore volume of the catalyst is 0.4-1.4 cm3 / g, and the pore diameter of the catalyst is 3-7 nm. When the catalyst is used for catalyzing the esterification reaction of cyclohexene and formic acid, the catalyst exhibits good catalytic activity. The conversion rate of cyclohexene can reach 87% and the selectivity of cyclohexyl formate is up to 99%. Moreover, even after the catalyst is recycled, the catalyst is still good in activity. Therefore, the catalyst can be recycled and used repeatedly, and has a considerable industrial application prospect.

Owner:XIANGTAN UNIV

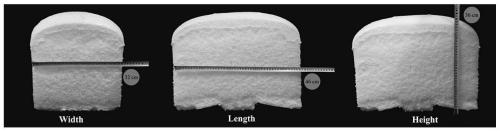

Silk fibroin porous support made from polyvinyl alcohol, and preparation method and application thereof

ActiveCN102743796AEasy to useReduce porosityMacromolecular non-active ingredientsProsthesisFiberPolymer science

The present invention relates to a silk fibroin porous spongy support made from polyvinyl alcohol, and a preparation method and application thereof. The support is made from 60-80 wt% of silk fibroin fiber and 20-40 wt% of polyvinyl alcohol particles; and the support is provided with uniformly distributed micropores, and has a porosity of 85-95%. The preparation method comprises the steps of: 1) extracting silk fibroin from silk to form a silk fibroin aqueous solution; 2) mixing a polyvinyl alcohol solution with the silk fibroin solution; 3) transferring the mixed solution of silk fibroin and polyvinyl alcohol into a dialysis bag, and placing in a polyethylene glycol solution for dialysis concentration; 4) placing the concentrated blend in a plastic mold, and conducting freeze drying; 5) rinsing the dried blend with water, and removing polyvinyl alcohol to form a spongy silk fibroin porous material; and 6) drying the prepared porous support material at room temperature to obtain a finished product. The support is used in tissue engineering, soft tissue repair and drug release.

Owner:SUZHOU SIMEITE BIOTECH CO LTD

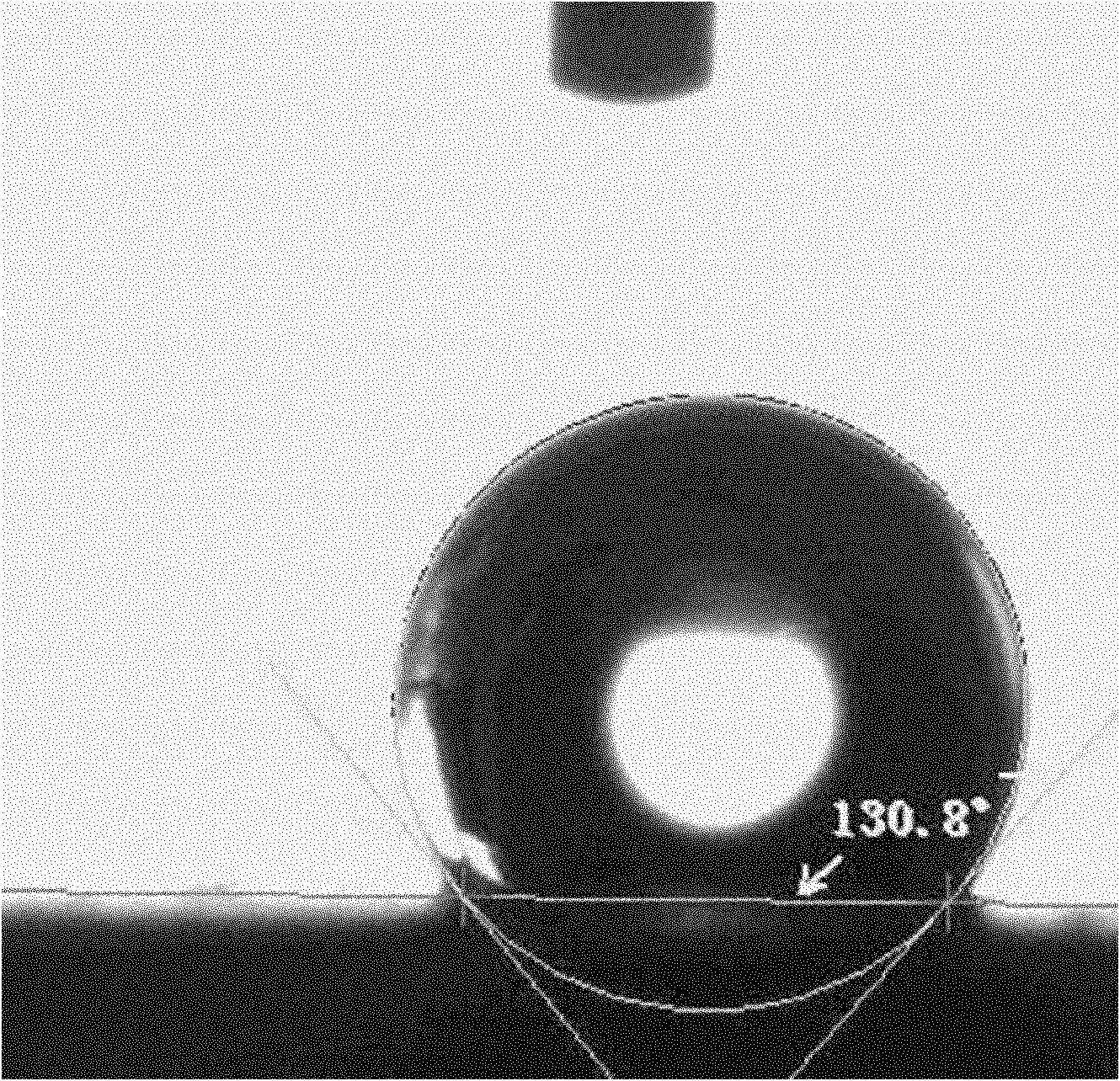

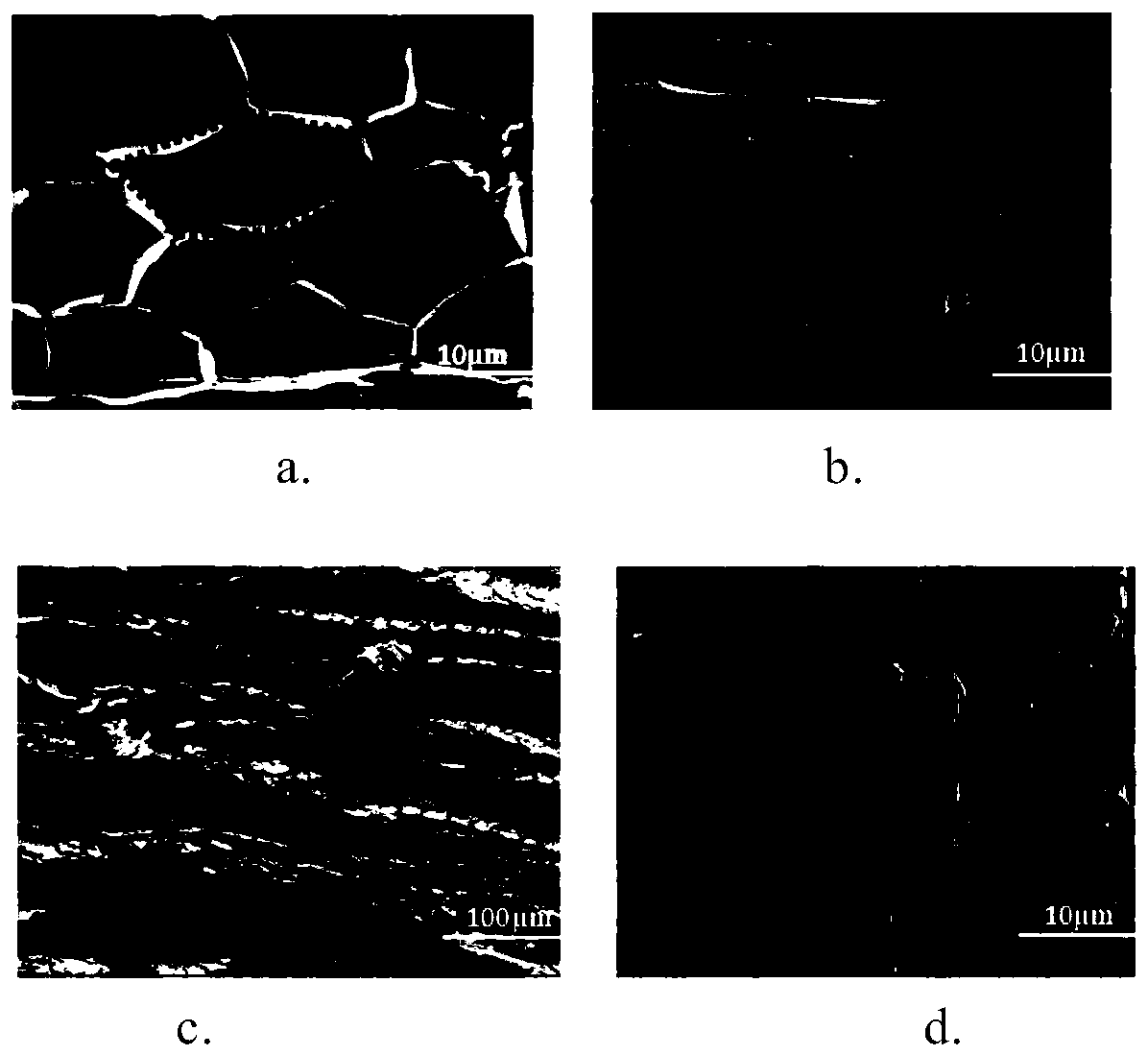

Preparation method of bionic hydrophobic coating on surface of magnesium alloy

ActiveCN101962761AImprove hydrophobic propertiesReduce contact areaLiquid/solution decomposition chemical coatingChemical platingEtching

The invention relates to a metal material surface modification technology, in particular to a preparation method of a bionic hydrophobic coating on the surface of a magnesium alloy, which aims at improving the surface hydrophobicity of a coating and further improving the corrosion resistance. The method comprises the following steps: carrying out pretreatment by alkali wash and acid wash, and then immersing a sample in a chemical etching solution to change the appearance characteristics of the surface of the sample and enable the surface to contain chemical element substances different from the matrix; and after the reaction, placing the magnesium alloy sample subjected to chemical etching in a chemical plating solution with nickel sulfate as a main salt. Thus, because of the coupling effect of different structure and foreign substance, the adsorptive deposition position and distribution of metal cations in the chemical plating solution are changed, and a chemical coating having typical biologic hydrophobic surface characteristics can be gradually formed in the deposition process.

Owner:JILIN UNIV

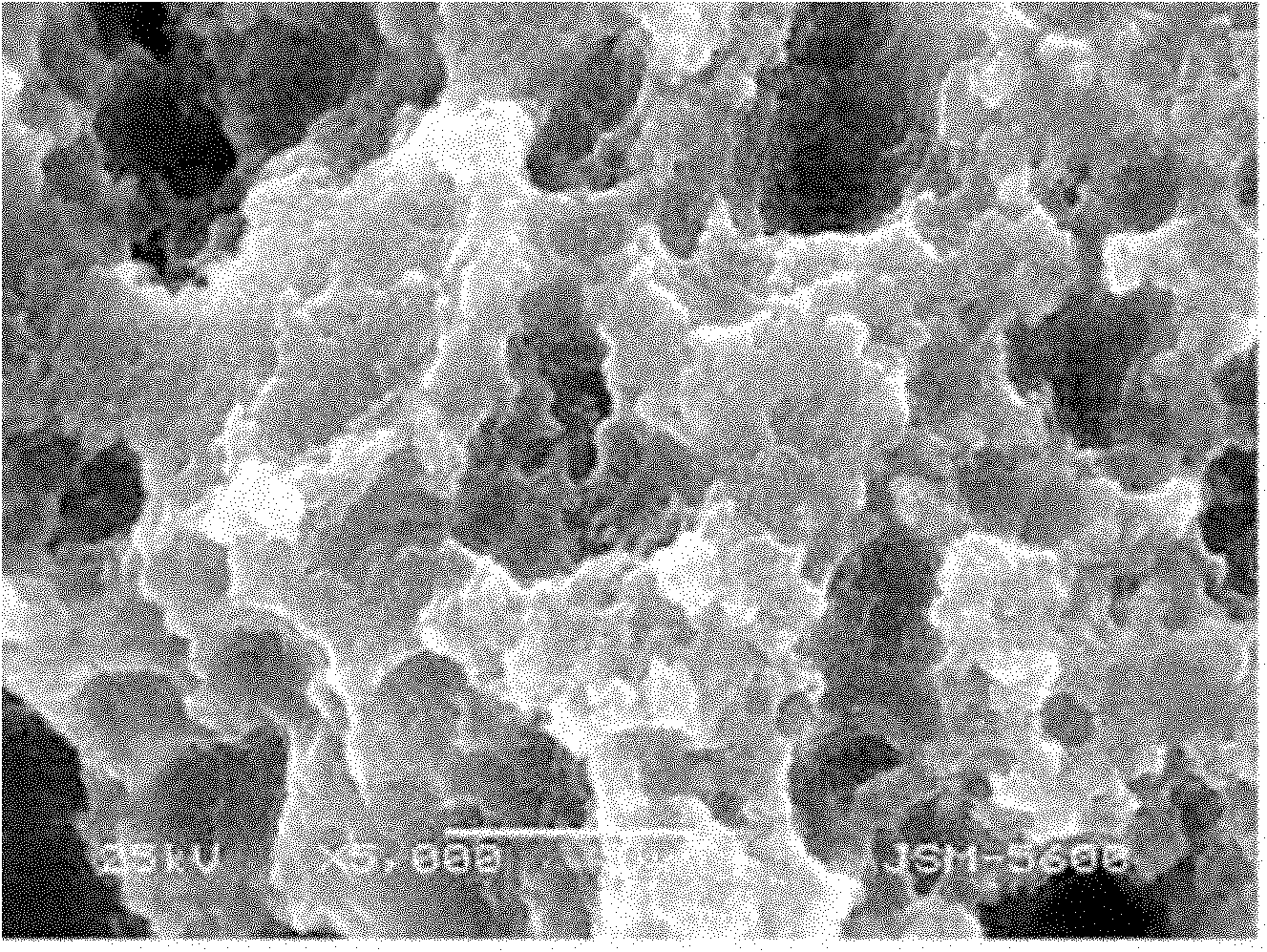

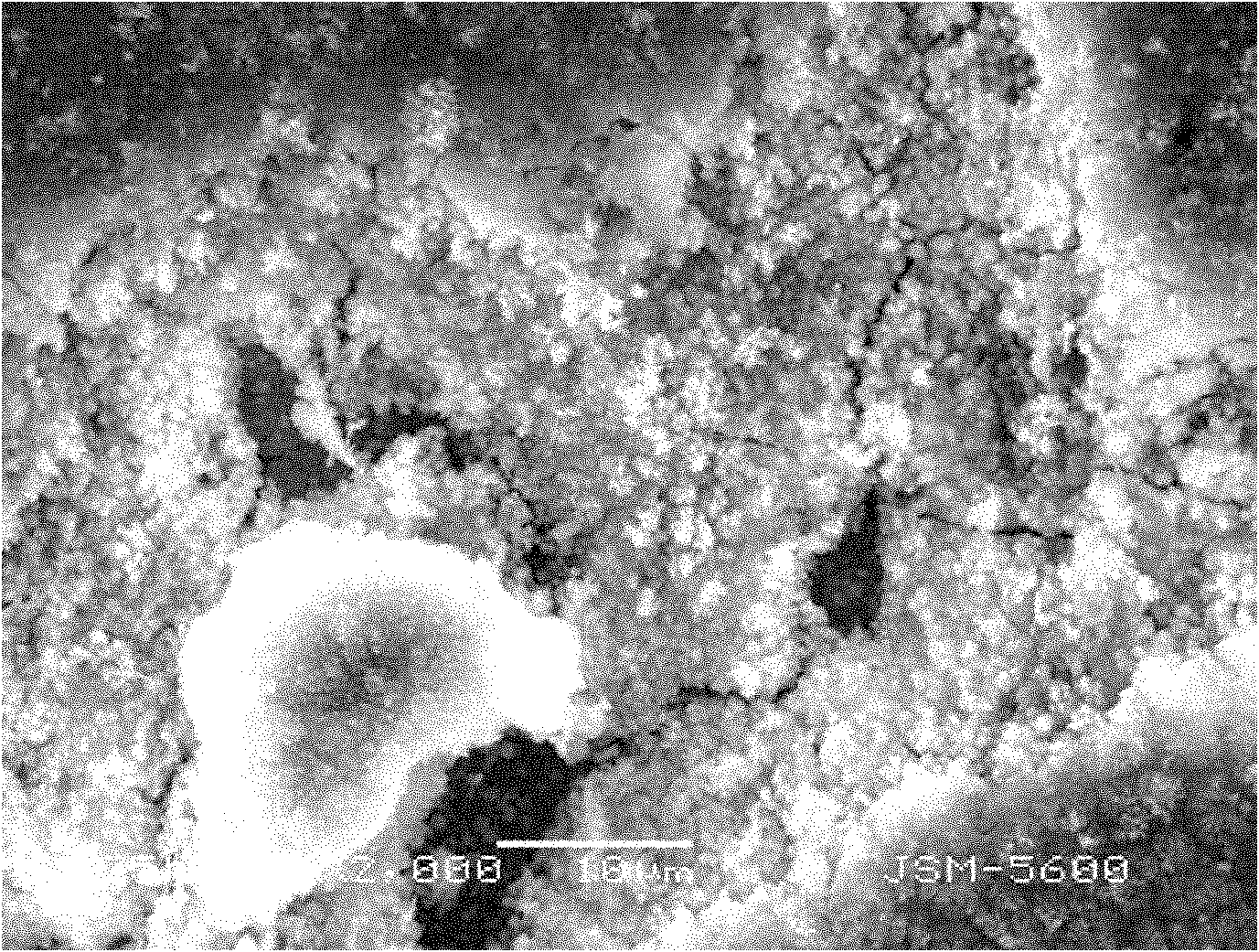

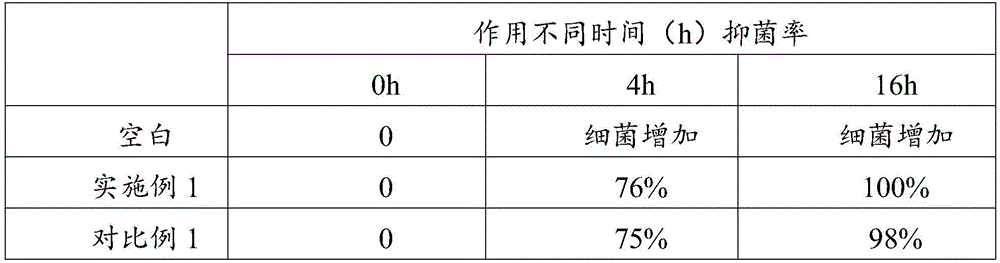

Mildew-preventing antibacterial hydrophobic coating

InactiveCN106752554AEnvironmental protection is goodImprove hydrophobic propertiesAntifouling/underwater paintsPaints with biocidesNano zinc oxideAntibacterial effect

The invention discloses a mildew-preventing antibacterial hydrophobic coating and belongs to the technical field of coatings. According to the mildew-preventing antibacterial hydrophobic coating disclosed by the invention, a coarse surface shape can be formed on a substrate by adding polymeric particles, so that the hydrophobic property of the coating is greatly improved; and meanwhile, by taking nano-zinc oxide modified chitosan as an antibacterial agent, the mildew-preventing antibacterial hydrophobic coating disclosed by the invention has a good antibacterial effect and overcomes the defects that silver oxide which serves as the antibacterial agent is active in property, is easily oxidized in air to lead to discolor and is high in cost.

Owner:FOSHAN LANRUI OUTE INFORMATION SERVICES CO LTD

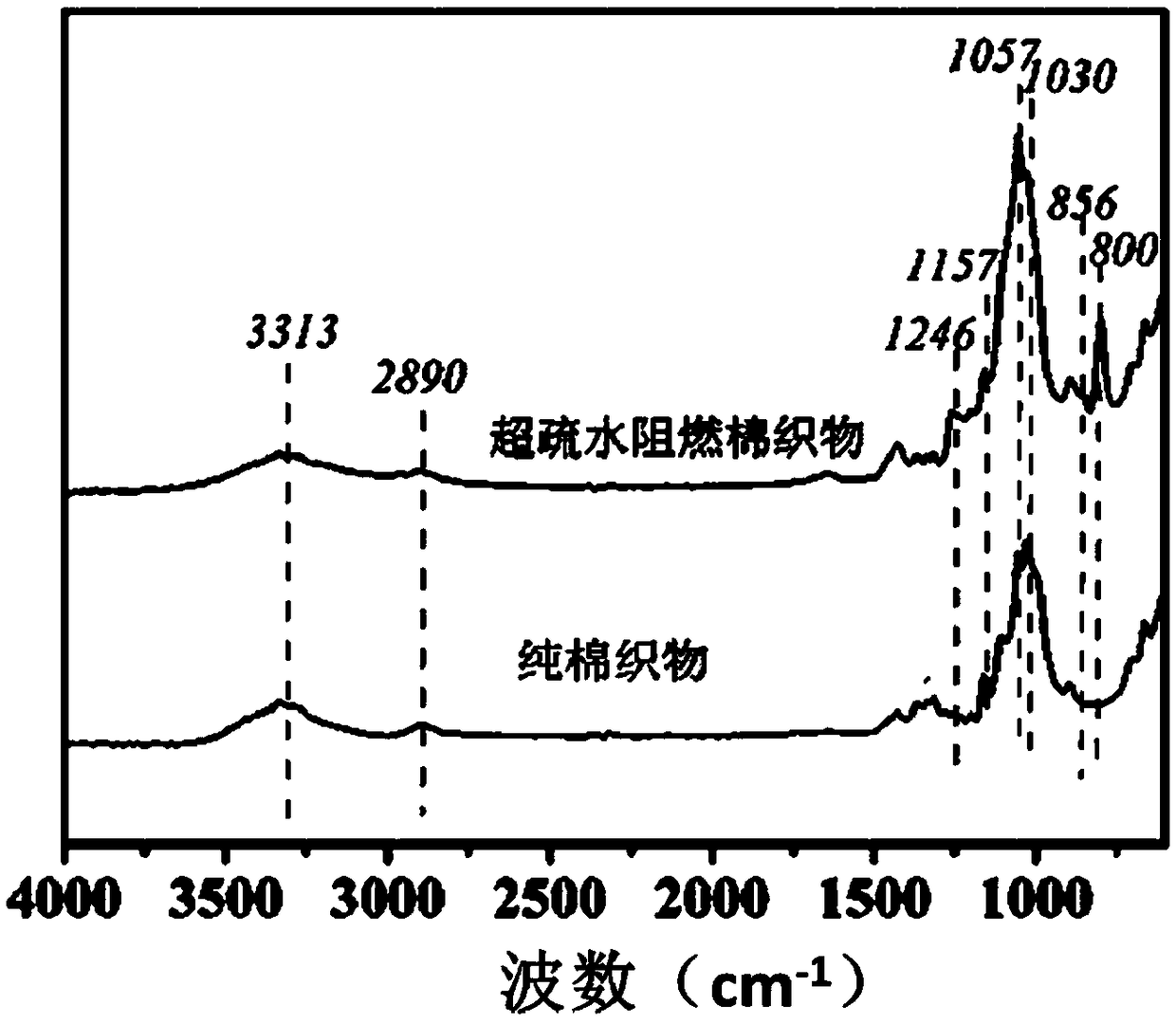

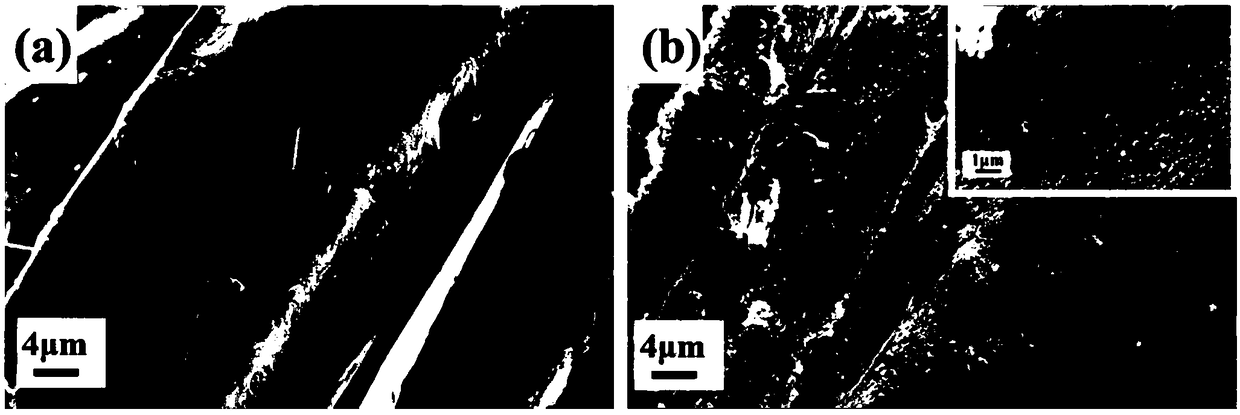

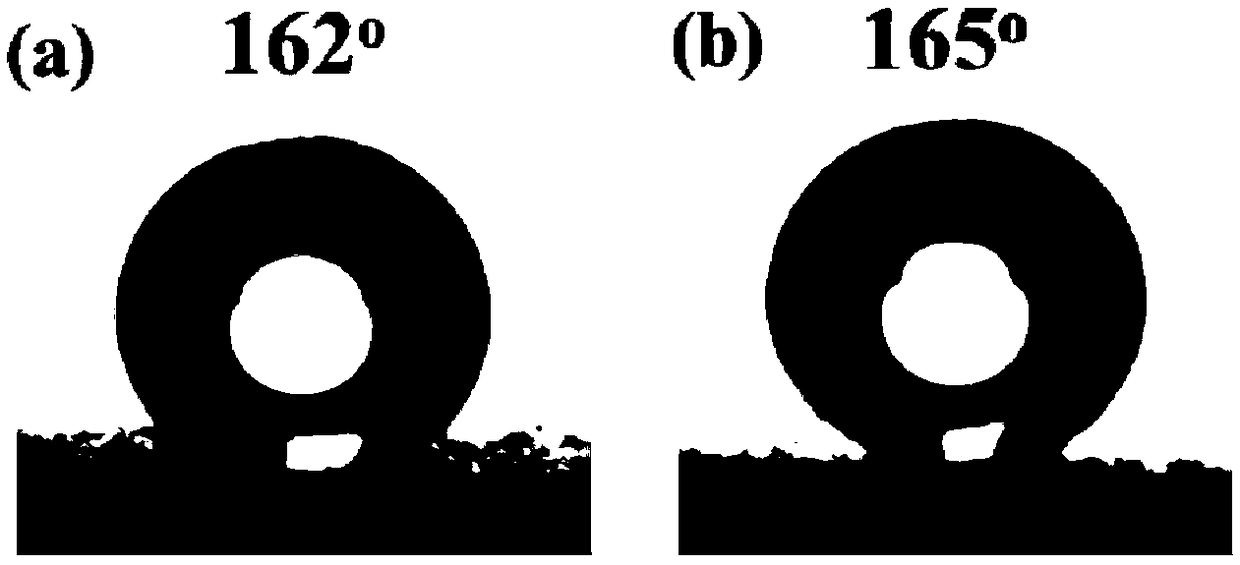

Method for preparing super-hydrophobic flame retardant fabric through one pot method

ActiveCN109137467AImprove flame retardant performanceImprove hydrophobic propertiesPhysical treatmentAmmonium polyphosphateChemistry

The invention discloses a method for preparing super-hydrophobic flame retardant fabric through a one pot method. The method comprises the steps that oxygen plasma corona is adopted for treating the fabric; at 25-50 DEG C, organic solvent, tetraethoxysilane, hydroxyl-terminated polydimethylsiloxane and ammonium polyphosphate are mixed, mixed liquid is obtained, the fabric is added, stirring is conducted, and ammonium polyphosphate is deposited on the surface of the fabric through hydrogen-bond interaction; the pH value of the mixed liquid is adjusted to be 8-9; stirring continues to be conducted, tetraethoxysilane and hydroxyl-terminated polydimethylsiloxane are subjected to a dehydration condensation reaction, a generated polysiloxane-silicon dioxide hybrid and ammonium polyphosphate forma composite coating with a micro-nano structure, and the surface of the fabric is wrapped by the composite coating; rinsing and drying are conducted, and the obtained fabric has excellent super-hydrophobic property and flame retardant property. Accordingly, the simple one pot method is adopted, the technology is simple, the condition is mild, the source of raw materials are wide, the price is low, and large-scale industrial production is facilitated.

Owner:SOUTH CHINA UNIV OF TECH

Boehmite sol type wear-resisting concrete sealing hardening agent and preparation method of boehmite sol type wear-resisting concrete sealing hardening agent

The invention discloses a boehmite sol type wear-resisting concrete sealing hardening agent. The boehmite sol type wear-resisting concrete sealing hardening agent is prepared from the following components in percentage by weight: 30 percent to 60 percent of boehmite sol, 3 percent to 8 percent of nano particles, 5 percent to 10 percent of a silane coupling agent, 1 percent to 5 percent of wax powder, 0.1 percent to 0.5 percent of a surfactant, 5 percent to 11 percent of ethanol and the balance of de-ionized water, wherein the silane coupling agent is selected from tetraethoxysilane, 3-aminopropyltriethoxy silane, gamma-glycidyloxypropyltrimethoxysilane, gamma-(methacryloxy)propyltrimethoxysilane, bi-(trimethoxysilicylpropyl)amine, bi-(triethoxysilylpropyl)amine, 1,2-bi(trimethoxysilyl)ethane and the like. The invention further discloses a preparation method of the boehmite sol type wear-resisting concrete sealing hardening agent.

Owner:集纳(温州)新材料科技有限公司

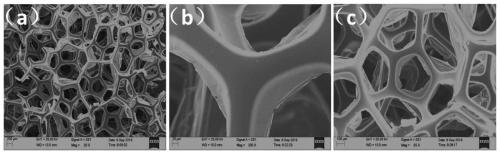

Super-hydrophobic oleophilic sponge material and preparing method and oil-water separation application thereof

InactiveCN109621923AImprove hydrophobic propertiesLow priceOther chemical processesAlkali metal oxides/hydroxidesOil waterLong chain

The invention discloses a super-hydrophobic oleophilic sponge material and a preparing method and oil-water separation application thereof, and belongs to the preparation of high-performance oil-waterseparation composites. The preparing method includes the steps of cleaning a sponge to remove impurities, putting the sponge in roughening liquid for surface roughening treatment, and adding a fattyacid solution for hydrophobic modification treatment to obtain the super-hydrophobic oleophilic sponge material. The super-hydrophobic oleophilic sponge material is a sponge material obtained after anon-polarity long-chain alkane group conducts hydrophobic modification on the surface of a substrate with a polyurethane or melamine sponge as the substrate. The preparing process is simple, the priceis low, and the oil absorption performance is excellent and stable. The material can be widely applied for leaking oil recovery, oil-containing wastewater treatment and oil-water mixture separation;the super-hydrophobic oleophilic sponge material solves the problem that an oil-water separation porous material is low in mechanical strength, low in separation efficiency, poor in repeatability andthe like in the current stage.

Owner:SHENYANG JIANZHU UNIVERSITY

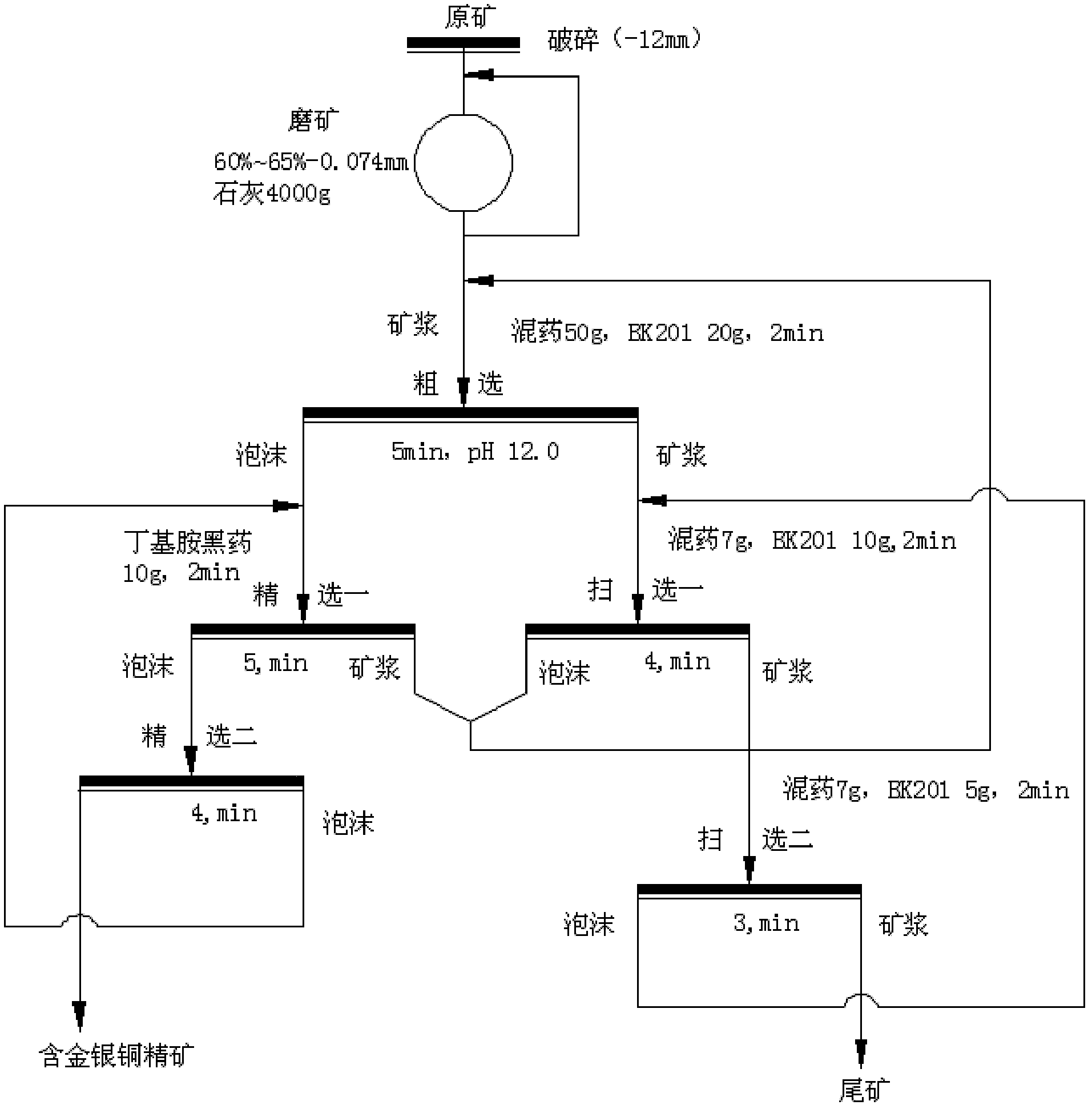

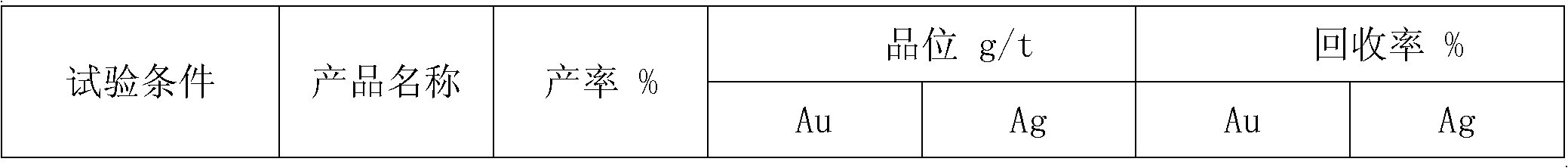

Method for improving recovery rates of gold and silver from chalcopyrite

InactiveCN102600990AImprove hydrophobic propertiesHigh recovery rate of gold and silverFlotationChemical regulationBrass

The invention discloses a method for improving recovery rates of gold and silver from chalcopyrite. The method comprises the steps of: firstly crushing raw ore until the granularity is smaller than 12mm, adding quicklime, grinding, adding water to obtain ore pulp, then adding a collector and a foaming agent for chemical regulation, stirring, entering rough concentration for copper floatation, and carrying out scavenging, concentration and other steps on the ore pulp after rough concentration to obtain gold-silver-containing copper concentrate with high gold and silver grades. According to the invention, on the basis of ensuring traditional copper concentration economic and technical norms, the gold and silver recovery rates are improved by improving gold and silver grades in the copper concentrate, and the recovery rates of the accompany gold and silver in the chalcopyrite reach 85.11% and 89.97%, respectively; and the method is simple, the onsite production is easy to operate and the comprehensive utilization rate of ore resources is improved.

Owner:安徽金联地矿科技有限公司

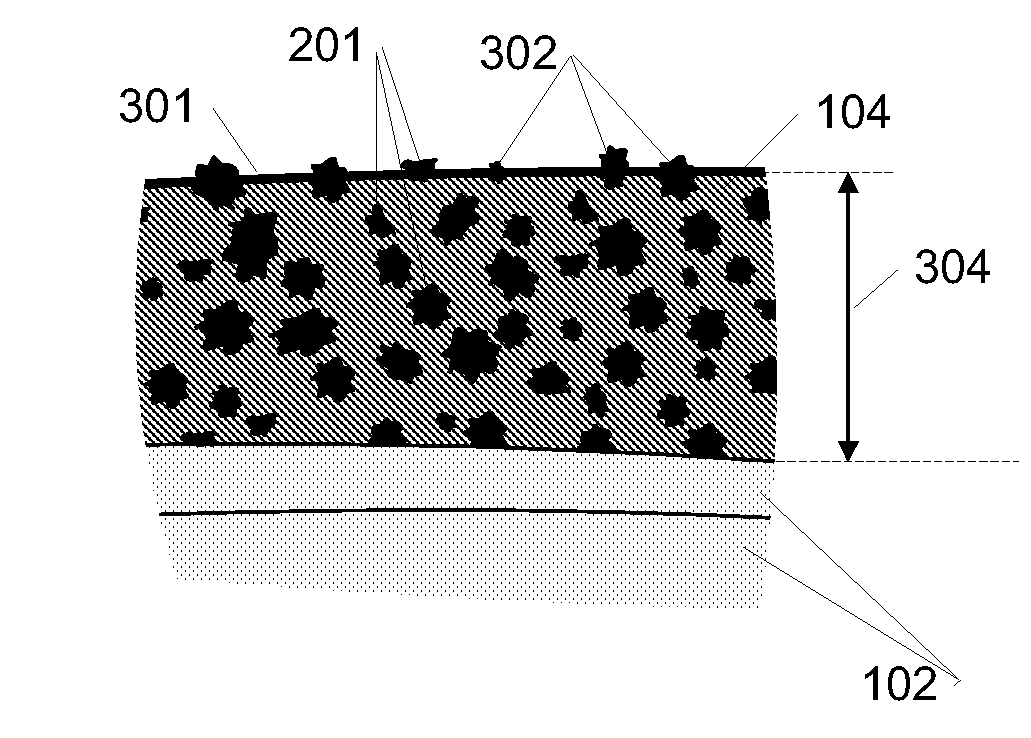

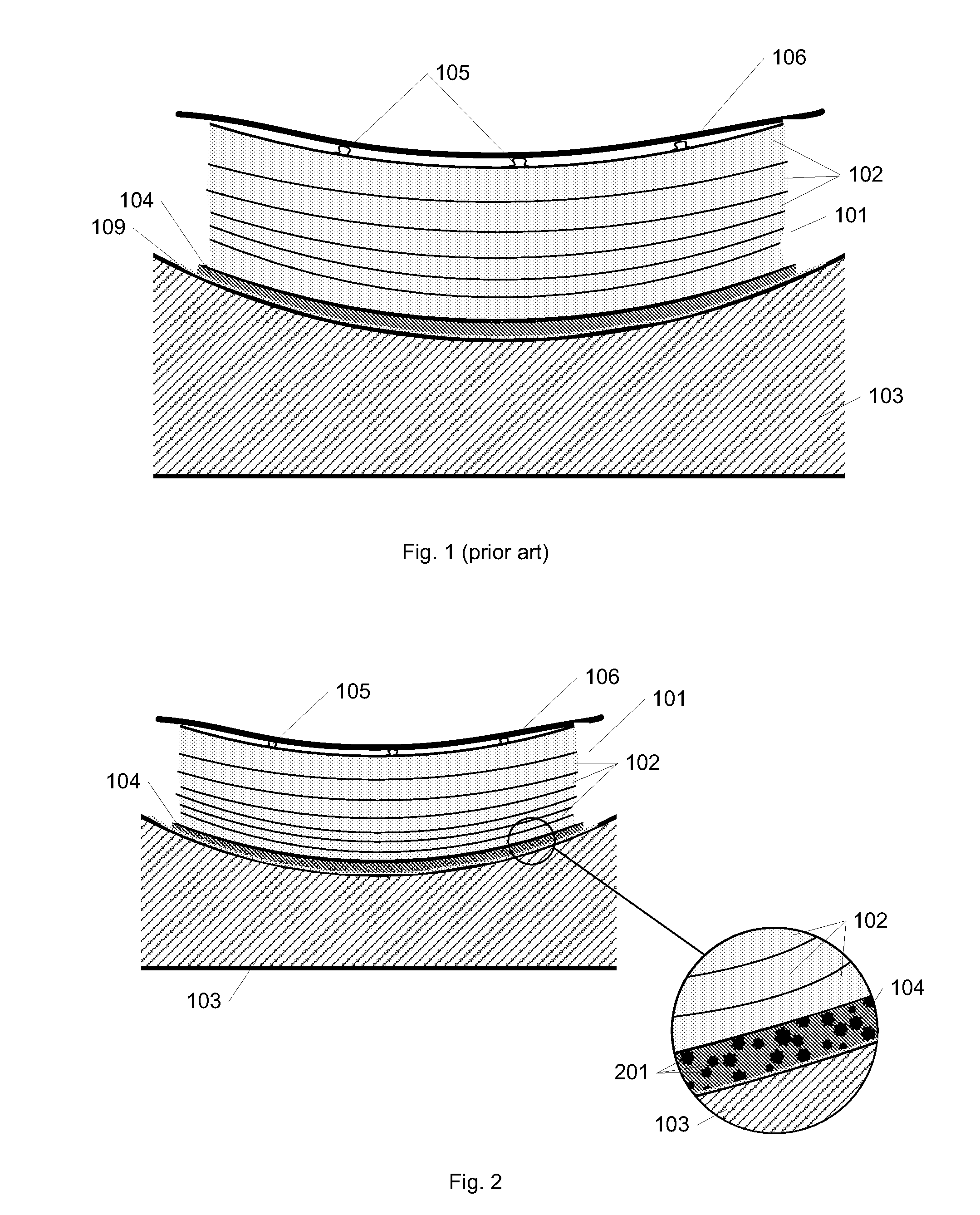

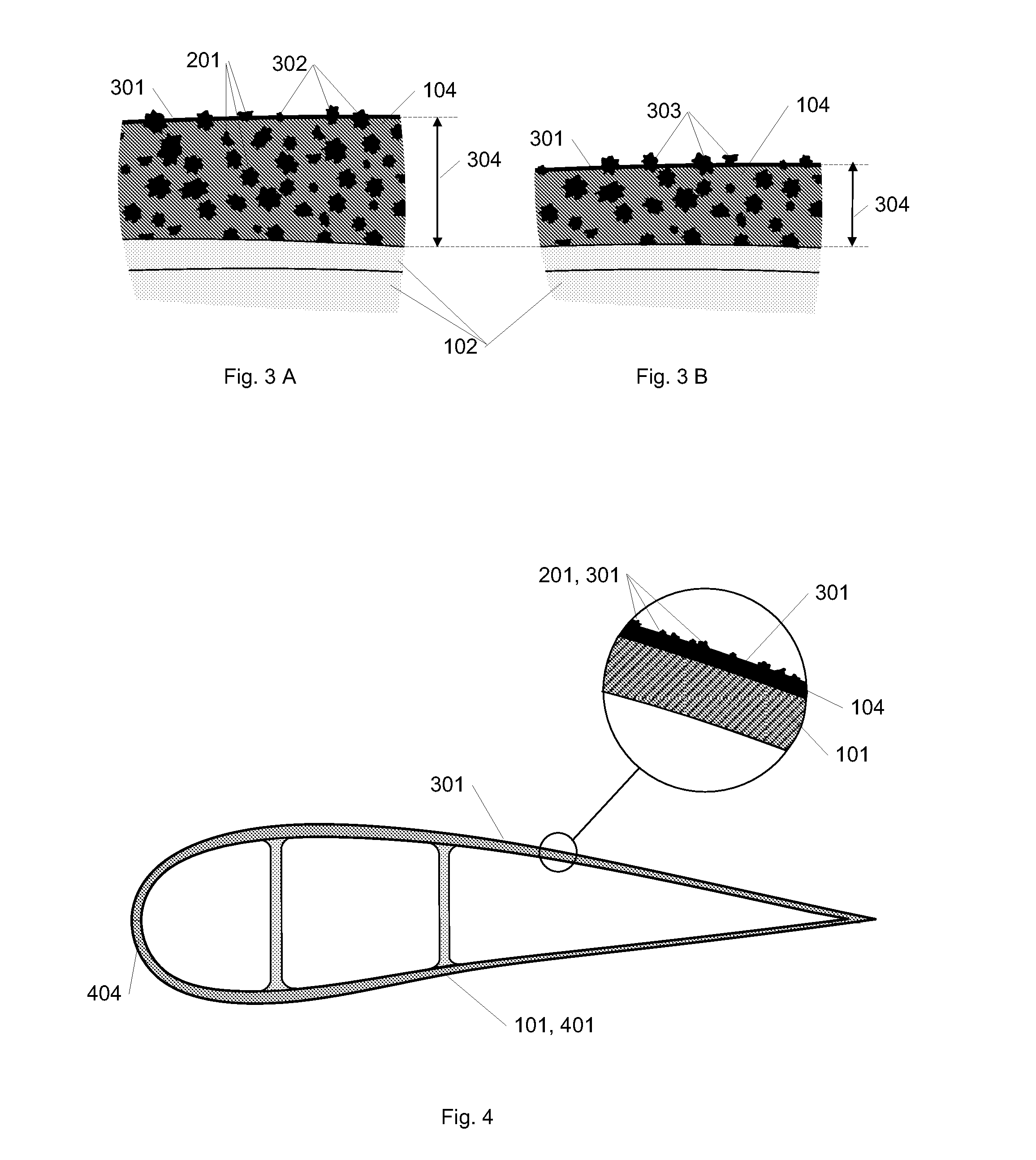

Regenerating surface properties for composites

ActiveUS20110129646A1Reduce noiseReduce fluid resistanceMouldsFinal product manufacturePolyresinGelcoat

This invention relates to a method for manufacturing a composite member, where a number of different material layers including at least one layer of gelcoat are applied in a mould, and where resin is applied for joining of the layers. The method is new in that particles are added to the gelcoat, whereby the gelcoat comprising such particles forms an outermost layer on at least a part of the manufactured composite member. Hereby is obtained a composite with a hydrophobic and lotus-like surface yielding good self-cleaning properties and which is on the same time self-regenerating. The invention furthermore relates to composite members comprising such a gelcoat layer with particles and to the use of gelcoat comprising particles for giving regenerating self-cleaning properties.

Owner:LM GLASSFIBER

Membrane distillation device for seawater desalination

InactiveCN108862478AReasonable structureImprove hydrophobic propertiesMembranesGeneral water supply conservationSeawaterVacuum cooling

The invention relates to a membrane distillation device for seawater desalination. The membrane distillation device comprises a hydrothermal input chamber, a vacuum cooling chamber and a condensationtube, the outer layer of the device is a shell wall, a distillation membrane layer is arranged in the device and is a superhydrophobic membrane, the hydrothermal input chamber is arranged between theshell wall and the distillation membrane layer, the vacuum cooling chamber is arranged inside the distillation membrane layer, and the condensation tube is arranged in the vacuum cooling chamber in apenetrating manner. The membrane distillation device is of a reasonable structure and has the characteristics of high distillation efficiency, good energy saving performance and stable operation.

Owner:梧州市兴能农业科技有限公司

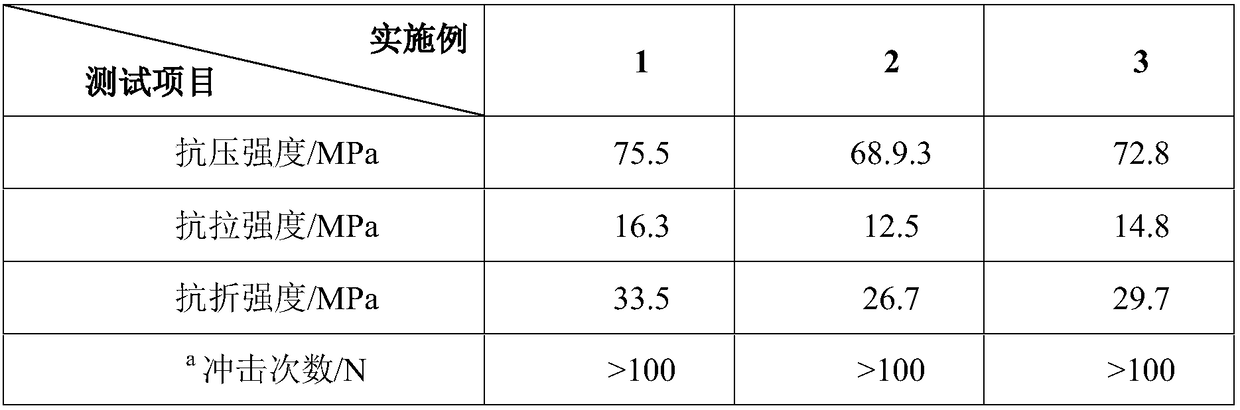

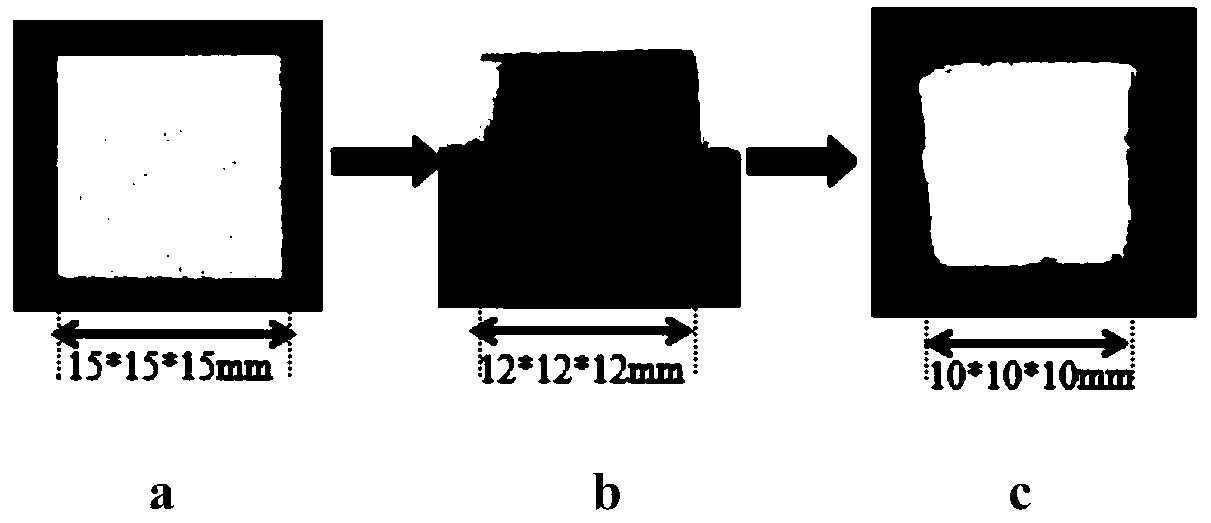

Composite concrete material and preparation method thereof

The invention discloses a composite concrete material belonging to the technical field of preparation of road materials and a preparation method of the composite concrete material. The composite concrete material is prepared by compounding a high void ratio epoxy resin gravel mixture with high fluidity polymer modified cement mortar; a specific compounding mode is to fill internal pores of the high void ratio epoxy resin gravel mixture with the high fluidity polymer modified cement mortar; a dense composite structure is formed by consolidating the high fluidity polymer modified cement mortar and the high void ratio epoxy resin gravel mixture. The preparation method comprises the following steps: firstly, preparing the high void ratio epoxy resin gravel mixture; secondly, pouring the high fluidity polymer modified cement mortar; thirdly, curing concrete. Compared with the prior art, the composite concrete material disclosed by the invention has the advantages of high comprehensive performance, good stability and durability, high price performance cost ratio, convenience in construction, long construction period and the like; the composite concrete material is more suitable for semi-flexible pavement paving engineering.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Method for quickly preparing super-hydrophobic surface on matrix based on 3D printing

ActiveCN108099185AImprove hydrophobic propertiesSave raw materialsAdditive manufacturing apparatusNon-macromolecular adhesive additivesAqueous solutionHydrophobic surfaces

The invention relates to the technical field of 3D printing, and discloses a method for quickly preparing a super-hydrophobic surface on a matrix based on 3D printing. The preparation method comprisesthe following steps of: (1) drawing a geometric lattice array surface through graphics software, thereby obtaining a two-dimensional geometric structural model map; (2) taking the matrix, cleaning liquid on the surface of the matrix by an aqueous solution of ethanol, naturally drying in air to obtain a clean dried matrix surface, and uniformly coating a layer of an adhesive base film on the surface of the matrix, and naturally drying in air; (3) filling a printing raw material into a printer, and guiding the two-dimensional geometric structural model map in the step (1) into a 3D printer; and(4) putting the matrix onto a printing platform, and spraying raw materials on the adhesive base film to form the two-dimensional geometric lattice array through a printing spray head on the 3D printing platform. The super-hydrophobic matrix surface has relatively good super-hydrophobic properties.

Owner:ZHEJIANG OCEAN UNIV

Super-hydrophobic wood sponge and application thereof

InactiveCN110527132AIntensifies the silanization reactionImprove hydrophobic propertiesIon-exchange process apparatusIon-exchanger regenerationChemistryMethyltrimethoxysilane

Owner:BEIJING FORESTRY UNIVERSITY

Anti-efflorescence magnesium oxychloride cement and preparation method thereof

The invention discloses anti-efflorescence magnesium oxychloride cement which comprises the following components in parts by weight: 0.1-0.5 parts of an anti-efflorescence agent, 1.5-2.5 parts of magnesium chloride, 4-5 parts of a cementing agent and 2-3 parts of water, wherein the cementing agent is one or more of caustic calcined magnesia, fly ash, microsilica and latex powder; the anti-efflorescence agent is an ultrathin hydrotalcite nanosheet prepared by using a microchannel reactor for coprecipitation reaction; the ultrathin hydrotalcite nanosheet is further modified with a surfactant specifically by the following modification process: dispersing the ultrathin hydrotalcite nanosheet in 0.001-0.5 mol / l of a surfactant solution. An LDH nanosheet prepared by the microreactor has an ultrathin structure and a relatively large specific surface area after dispersion, can effectively capture free chloride ions in the cement material, forms LDH of a chloride ion intercalation layer, and avoids migration of chloride ions to a cement surface to cause efflorescence; and hydrotalcite-like nanosheets are further modified with the surfactant.

Owner:QINGDAO UNIV OF SCI & TECH

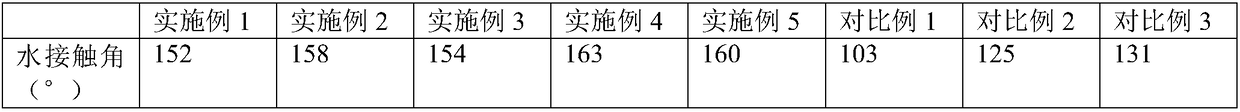

Highly hydrophobic anti-ultraviolet inorganic artificial stone and preparation method thereof

ActiveCN107473644AImprove hydrophobic propertiesImprove the strength of UV resistanceEmulsionWater reducer

The invention provides a highly hydrophobic anti-ultraviolet inorganic artificial stone and a preparation method thereof. The highly hydrophobic anti-ultraviolet inorganic artificial stone is prepared from the following components in parts by mass: 60-70 parts of quartz sand, 5-10 parts of quartz powder, 18-23 parts of cement, 2-5 parts of an active additive, 4-6 parts of an emulsion, 0.8-1.2 parts of a water reducer, 2-4 parts of water, 0.36-0.46 part of a fluorine group-containing additive and 0.5-1 part of an ultraviolet additive. The hydrophobic property and the anti-ultraviolet strength of the inorganic artificial stone are improved, so that the inorganic artificial stone can achieve a self-cleaning effect, an inorganic artificial stone curtain wall project is cleaned conveniently, and the anti-ageing performance of the inorganic artificial stone is enhanced, so that the cost of the curtain wall project cleaning is reduced effectively, and the service life of the wall body is prolonged.

Owner:东莞环球经典新型材料有限公司

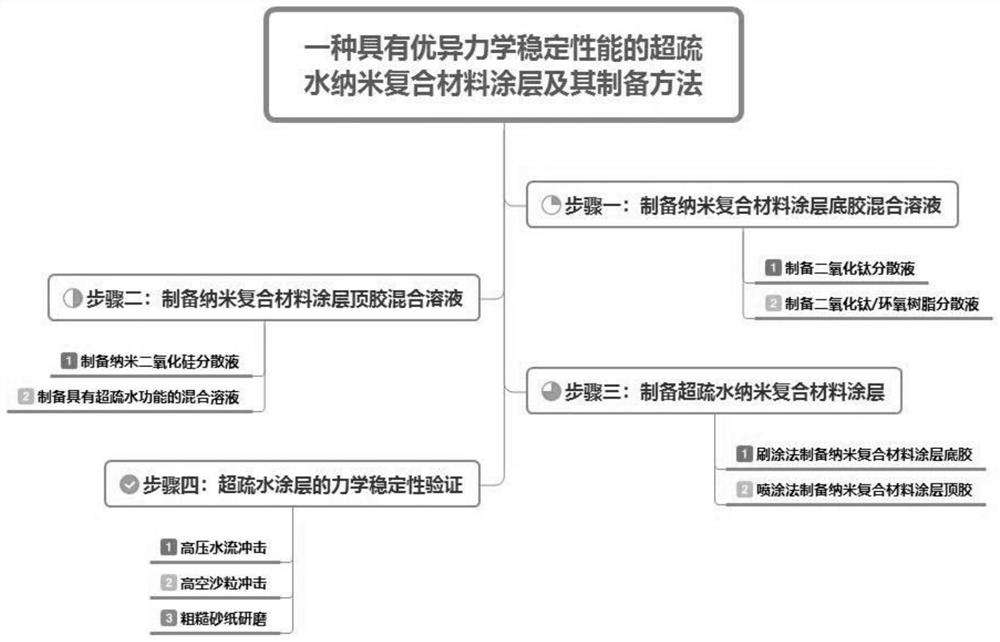

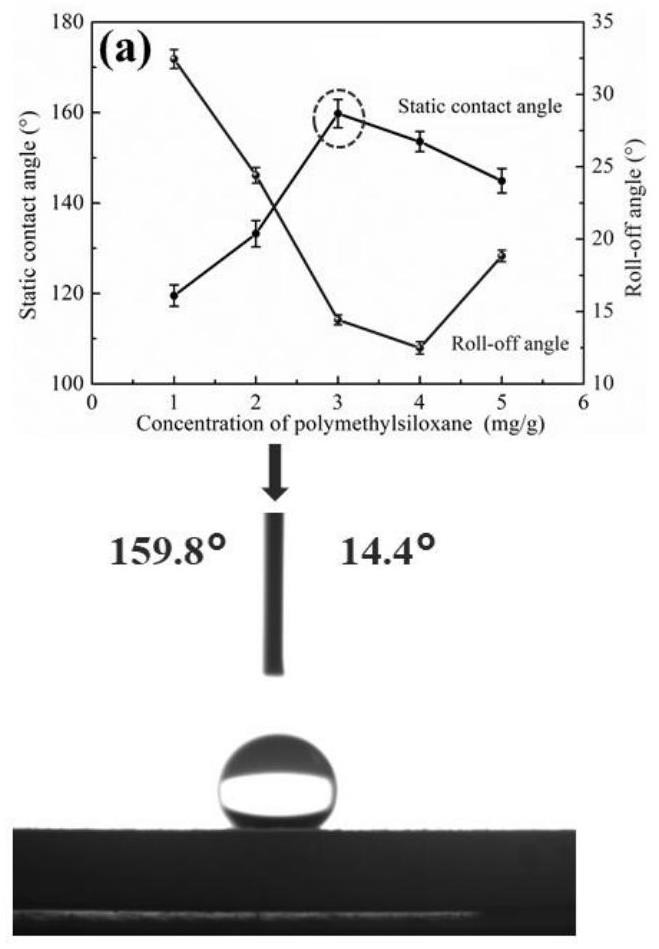

Super-hydrophobic nanocomposite coating with excellent mechanical stability and preparation method thereof

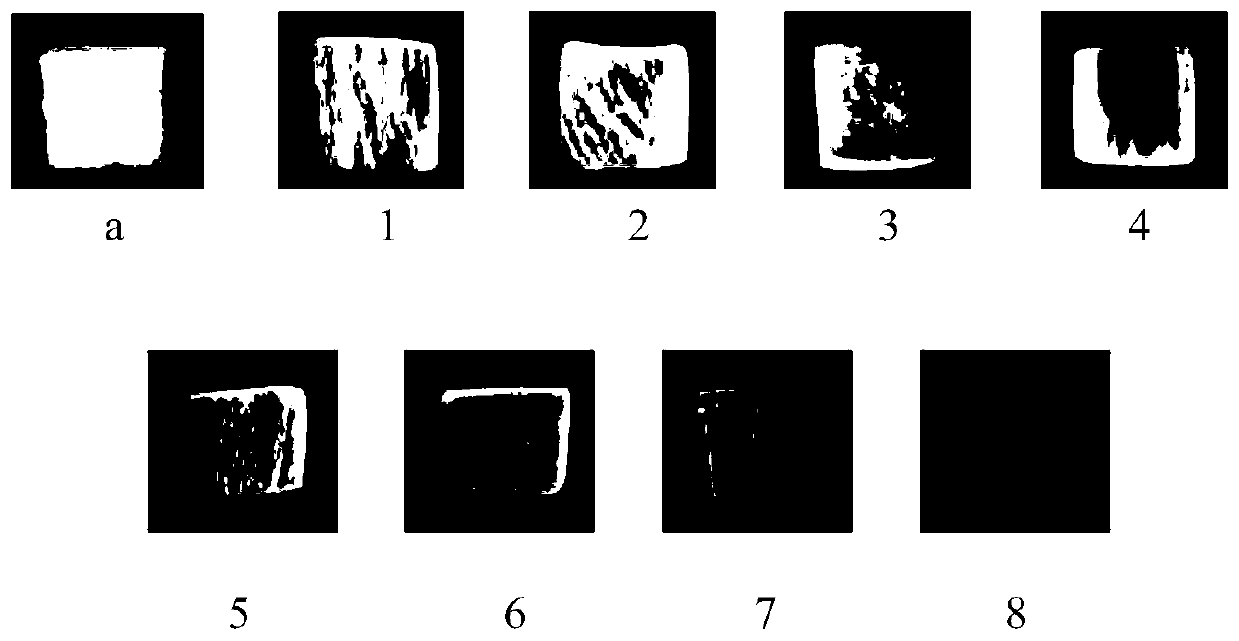

ActiveCN114686076AAvoid debondingReinforced Ultra-Sturdy" WeldingSpecial surfacesEpoxy resin coatingsEpoxyMicro nano

The invention discloses a super-hydrophobic nano composite material coating with excellent mechanical stability and a preparation method of the super-hydrophobic nano composite material coating, and belongs to the technical field of preparation of super-hydrophobic composite coating materials. The super-hydrophobic nano composite material coating comprises a bottom film and a top film, the bottom film is an epoxy resin film layer doped with titanium dioxide and attached to the surface of a substrate, and the top film is an epoxy resin film layer doped with modified silicon dioxide and polymethylsilsesquioxane and located on the bottom film. The epoxy resin in the top film of the composite coating not only can coat micro / nano particles to prevent the micro / nano particles from falling off during long-term realization of a super-hydrophobic function, but also can form three-dimensional spatial crosslinking with the epoxy resin in the bottom coating, so that interface debonding of the upper coating and the lower coating is prevented, super-stable'welding 'of an interface is enhanced, and the service life of a super-hydrophobic coating system is prolonged.

Owner:HARBIN INST OF TECH

Preparation method of modified polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane

InactiveCN105327624AImprove hydrophobic propertiesImprove overall performanceSemi-permeable membranesPolyvinylidene fluorideCarboxylation

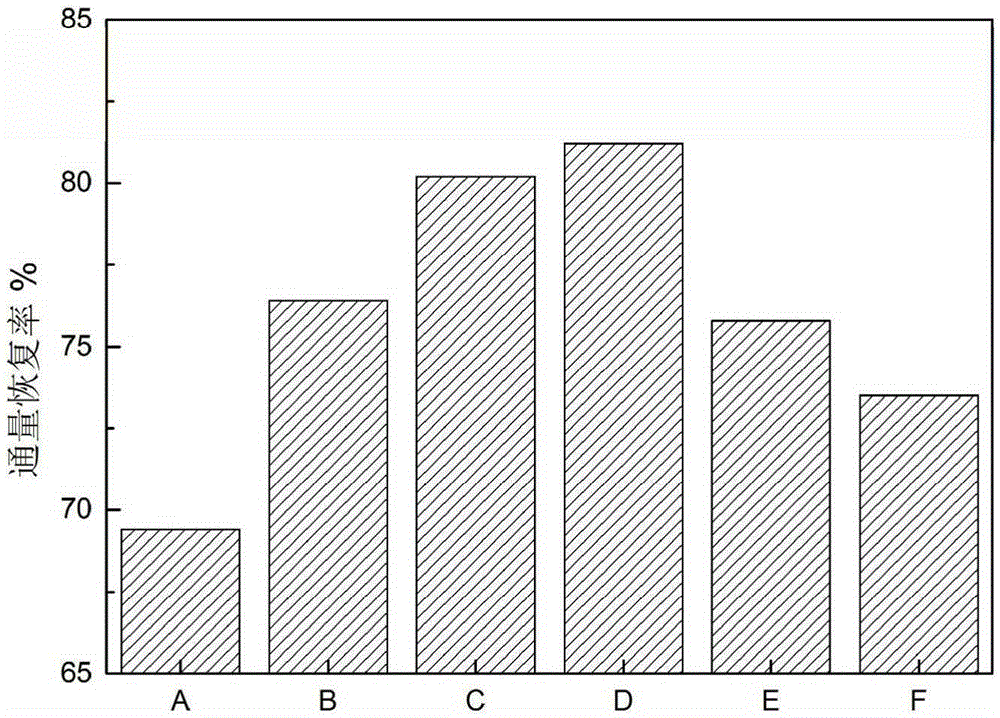

The invention relates to a preparation method of a modified polyvinylidene fluoride-polyvinyl alcohol binary composite ultrafiltration membrane. The preparation method comprises the following steps of preparing membrane casting solution, wherein the membrane casting solution is prepared by polyvinylidene fluoride powder, polyvinyl alcohol powder, carboxylation multiwalled carbon nanotubes and dimethyl sulfoxide solvent; fully dispersing the carboxylation multiwalled carbon nanotube in the dimethyl sulfoxide solvent, then sequentially adding binary membrane materials prepared by the polyvinylidene fluoride powder and the polyvinyl alcohol powder, controlling the temperature to be 95 to 105 DEG C, mechanically stirring and dissolving, and obtaining uniform membrane casting solution; then after fully defoaming the obtained membrane casting solution at the temperature of 40 to 60 DEG C, scraping the membrane on a glass plate; immersing the glass plate with a membrane casting solution thin layer into coagulation bath with the temperature of 25 to 35 DEG C to split phases to form the membrane, taking out after soaking in deionized water for 5 to 7 days, naturally drying, and storing. According to the binary composite ultrafiltration membrane provided by the invention, the flux recovery rate can achieve 81.2 percent, and the binary composite ultrafiltration membrane has good hydrophilic and antifouling property.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Preparation method of heat-resistant optical fiber filling agent

InactiveCN108034266ATrickle temperature increaseImprove hydrophobic propertiesAntioxidantFire retardant

The invention discloses a preparation method of a heat-resistant optical fiber filling agent, and belongs to the technical field of high polymer materials. The method comprises the following steps inparts by weight: sequentially weighing 70-80 parts of basic oil, 10-15 parts of modified rotary steam substance, 10-16 parts of micro-capsules, 8-15 parts of polyallyl amine, 3-5 parts of organobentonite, 3-4 parts of an antioxidant, 5-8 parts of thermoplastic elastomer, 2-3 parts of a flame retardant, 2-4 parts of dicyclohexyl carbon imine, and 3-5 parts of polydimethylsiloxane; mixing the basicoil and the modified rotary steam substance; sequentially adding the micro-capsules, the polyallyl amine, the organobentonite, the flame retardant, the thermoplastic elastomer, the antioxidant, the dicyclohexyl carbon imine and the polydimethylsiloxane; and stirring and mixing to obtain the heat-resistant optical fiber filling agent. According to the technical scheme, the prepared heat-resistant optical fiber filling agent has the characteristics that the consistency is further improved under high temperature, so that the drip resistance of optical fibers is further improved, as a result, theheat resistance of the optical fibers is improved.

Owner:汪逸凡

Method for preparing super-hydrophobic high-intensity thin ceramic glaze layer based on 3D printing and surface micron/ nanoparticles coating

InactiveCN108249961AIncrease roughnessImprove hydrophobic propertiesAdditive manufacturing apparatusCeramic shaping apparatusCeramicCeramic glaze

The invention relates to the technical field of ceramics, and discloses a method for preparing a super-hydrophobic high-intensity thin ceramic glaze layer based on 3D printing and surface micron / nanoparticles coating. The method comprises the following steps: scanning the outer shape of a formed ceramic blank through a three-dimensional canner to obtain a ceramic blank model; constructing a ceramic glaze 3D thin-layer model on the outer surface of the ceramic blank model; inputting the model data into a 3D printer; depositing the thin ceramic glaze layer on the surface of the ceramic glaze by3D printing; dipping micron / nano sizing; and then sintering to obtain the super-hydrophobic high-intensity thin ceramic glaze layer. The thin ceramic glaze layer is super-hydrophobic, and capable ofsaving raw materials.

Owner:QINGDAO UNIV OF SCI & TECH

Composite multi-layer hydrophobic and anti-corrosion film as well as preparation method and application thereof

ActiveCN110551975AImprove hydrophobic propertiesImprove corrosion resistanceVacuum evaporation coatingSputtering coatingFilm structureElectrically conductive

The invention discloses a composite multi-layer hydrophobic and anti-corrosion film as well as a preparation method and an application thereof. The film comprises a first metal adhesion layer, a hydrogen-containing amorphous carbon film layer and a hydrogen-free amorphous carbon film layer from bottom to top and is prepared through magnetron sputtering with control on the ratio of argon to hydrogen. Physical and chemical characteristics of different hybridization composition types of carbon are considered, the amorphous carbon film adopting the dual-layer structure is designed, the a-C:H filmis used as a conductive substrate, and thin-layer a-C with the surface covered is used as the anti-corrosion and hydrophobic medium. Through the structural design, the amorphous carbon film can effectively improve the anti-corrosion performance of the film structure on the basis that the conductivity is guaranteed. The design concept has the great prospect for application in the field of metal corrosion resistance and bipolar plates and has the very positive promotion significance for application of metal bipolar plates to hydrogen cells.

Owner:FOSHAN UNIVERSITY

Preparation method of multifunctional super-hydrophobic coating with mechanical stability

PendingCN113122040AEasy to prepareImprove hydrophobic propertiesAntifouling/underwater paintsPaints with biocidesBeakerPhoto catalysis

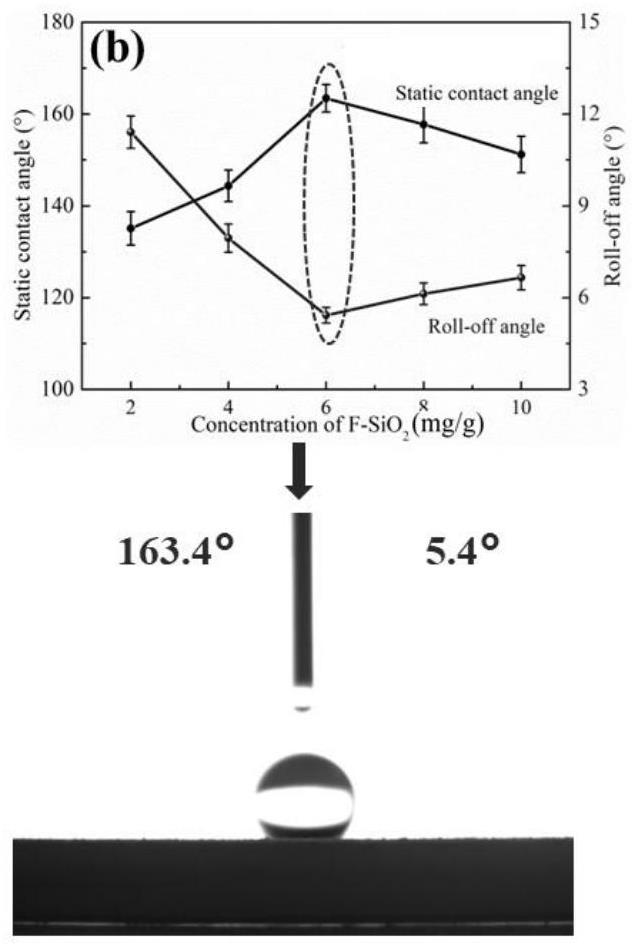

The invention discloses a preparation method of a multifunctional super-hydrophobic coating with mechanical stability, and belongs to the field of multifunctional application coatings. The method comprises the following steps: respectively dissolving zinc nitrate and potassium hydroxide in deionized water, slowly dropwise adding the zinc nitrate solution into the potassium hydroxide solution under magnetic stirring, transferring the obtained solution into a high-pressure kettle, reacting for 5 hours under mild conditions, centrifuging and drying to obtain zinc oxide with special morphology, and performing hydrophobic modification on the zinc oxide particles obtained by the method by using tridecafluorooctyltriethoxysilane, adding n-hexane, polydimethylsiloxane and absolute ethyl alcohol into a beaker according to a certain proportion, fully stirring, adding modified zinc oxide into the mixed solution, carrying out ultrasonic treatment for half an hour, and finally spraying by using a spray gun to obtain the super-hydrophobic coating. The contact angle of the prepared super-hydrophobic coating reaches 157 degrees, the rolling angle is 4 degrees, and the super-hydrophobic coating has good mechanical stability, photocatalysis and antibacterial ability.

Owner:HEILONGJIANG UNIV

Functionalized polyimide molded body and functionalized polyimide membrane

InactiveUS7273551B2Small under-water contact angleEasy to wetSemi-permeable membranesOther chemical processesPolyimide membraneAmount of substance

In a polyimide molded body, in particular a polyimide membrane which is functionalized with a chemical group and a method for production thereof, a molded body or membrane is obtained, whereby a pre-prepared polyimide body, as starting material, is brought into contact with an aqueous modifier solution for a period of 1 second to 1 hour. The modifier solution contains at least one modifier substance at least partially dissolved therein, which comprises a primary or secondary amino group, or a similar amino group and additionally at least one further functional group per molecule. The polyimide molded body is brought to an elevated temperature, either during the contact period with the modifier solution or thereafter and then purified and dried. The membrane obtained according to the invention may be functionalized in a targeted adjustable manner and has a high functionalization degree. The functionalization may be achieved simply and economically in an aqueous medium. The membranes obtained are suitable for use in the technical, biotechnological and medical fields and as starter membranes for the production of affinity membranes.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

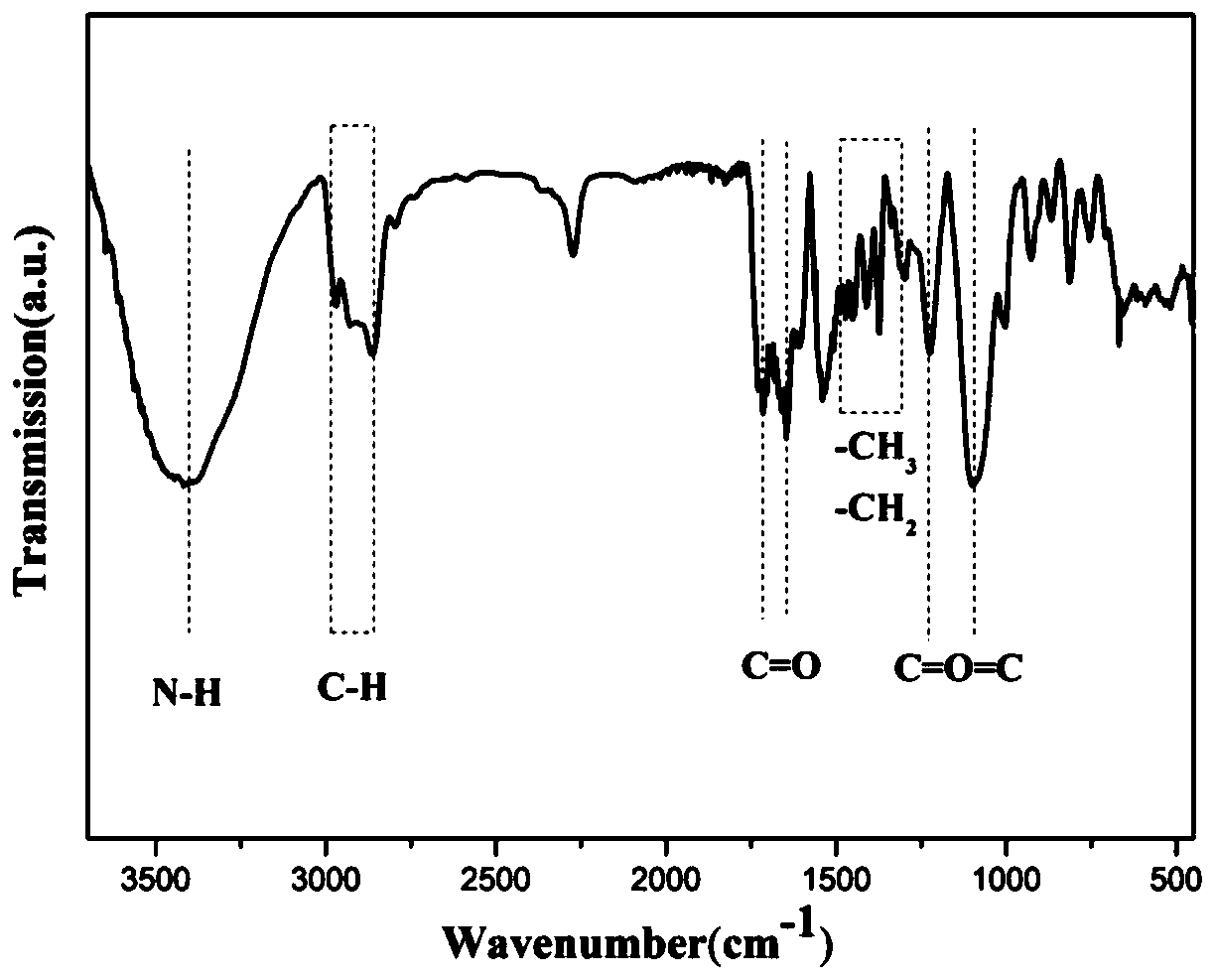

Efficient oil-water and emulsion separation polyurethane foam material and preparation method thereof

InactiveCN111171260AHigh strengthLow densityFatty/oily/floating substances removal devicesOther chemical processesPolymer sciencePtru catalyst

The invention discloses an efficient oil-water and emulsion separation polyurethane foam material which comprises the following components in parts by mass: 100 parts of a polyether polyol, 7 to 25 parts of a foaming agent, 0.3 to 0.6 part of a catalyst, 1.2 to 2.5 parts of a foam stabilizer, 0.6 to 1.2 parts of a polyether auxiliary agent and 60 to 90 parts of toluene diisocynate. The efficient oil-water and emulsion separation polyurethane foam material has good oil-water selective adsorption capacity, can quickly and selectively adsorb oil and organic matters on the water surface or under the water surface, can effectively realize separation of emulsion containing a surfactant, has high adsorption multiplying power, and has good practical application value and popularization value; andthe hydrophobic property has very good stability, the efficient oil-water and emulsion separation polyurethane foam materialis suitable for various complex environments, can be rapidly recovered to the original shape after being extruded,has very good resilience, can be continuously put into use and has very good recycling performance.

Owner:SOUTHWEST PETROLEUM UNIV

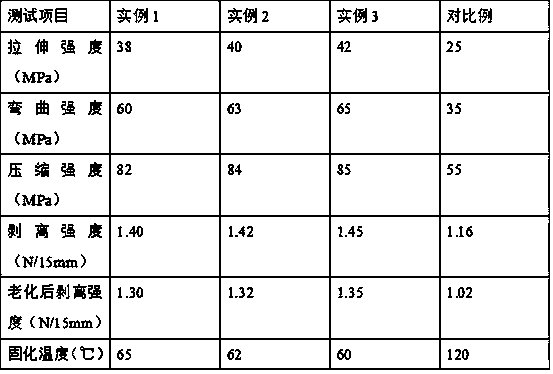

Preparation method of high-temperature-resistant high-humidity-resistant binder for packaging

InactiveCN108977156AImprove hydrophobic propertiesImprove toughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMaleic anhydrideEpoxidized soybean oil

The invention discloses a preparation method of a high-temperature-resistant high-humidity-resistant binder for packaging, belonging to the technical field of preparation of binders. According to thepreparation method, the soybean oil is oxidized under acidic conditions to obtain epoxidized soybean oil, the silicon hydroxyl of asbestos fiber is exposed by acid etching, the asbestos fiber is grafted by maleic anhydride, and the asbestos fiber is subjected to surface modification through the epoxidized soybean oil, high temperature, high humidity resistance and toughness are improved, and the water droplets formed by liquefaction of the surface of the film in high temperature and high humidity air will be quickly dried. According to the invention, the modified epoxy resin is toughened by polybutadiene rubber powder, the toughened modified epoxy resin is composed of epoxy resin and rubber particles, the rubber particles are of a core-shell structure, and the rubber particles of the core-shell structure are evenly distributed. The improvement effect on the toughness and strength is remarkable, the activation energy per unit volume of the epoxy glue is reduced, and the maleic anhydridecan be cured and crosslinked with the epoxy resin at a low temperature, so that the binder can be cured at a lower temperature. Therefore, the preparation method has a broad prospect.

Owner:FOSHAN GAOMING DISTRICT ZHUAHE NEW MATERIAL TECH CO LTD

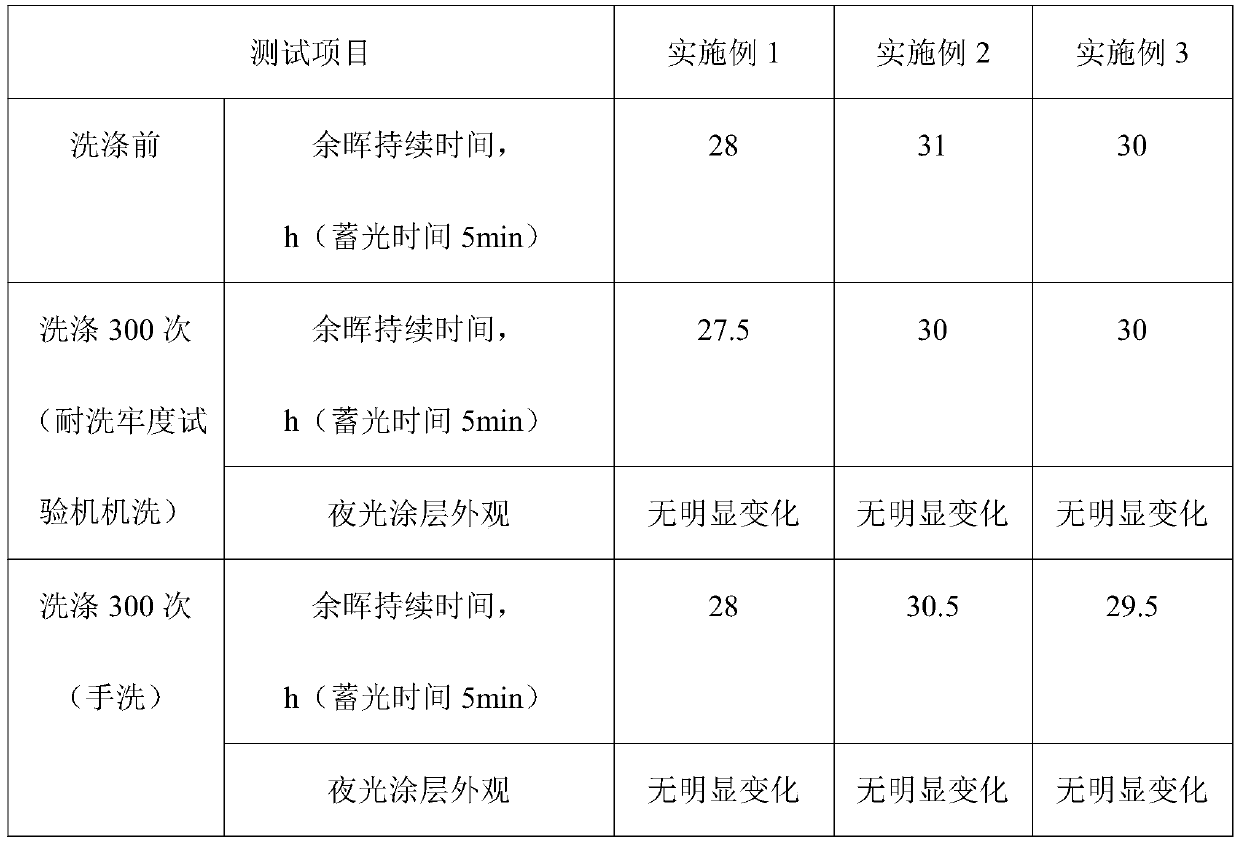

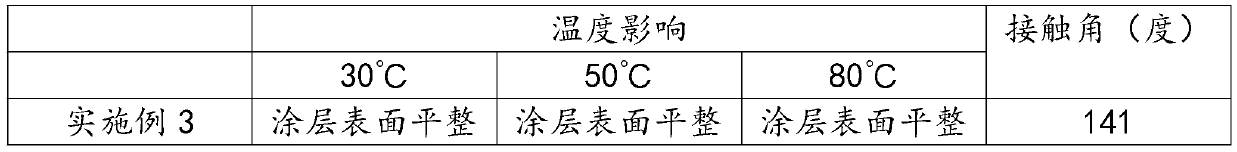

Post-finishing technology of aluminous water-repellent polyester fabric

InactiveCN109853225AImprove hydrophobic propertiesGood compound performanceFibre typesPolyesterPre treatment

The invention provides a post-finishing technology of a luminous water-repellent polyester fabric, and belongs to the technical field of textiles. The post-finishing technology of the luminous water-repellent polyester fabric comprises the steps of pretreatment, water-repellent finishing, luminous coating preparation, coating, dipping, rolling, drying and the like. The technology further comprisesthe step of coating under the action of ultrasonic waves after a luminous coating is prepared. The finally prepared fabric has a good luminous function and good water-repellent performance; meanwhile, the technology is environmentally friendly, so that the prepared fabric has relatively good market prospects.

Owner:吉祥三宝高科纺织有限公司

Solar photovoltaic panel with self-cleaning function

InactiveCN110317537AHigh hydrophobicity and stain resistanceImprove hydrophobic propertiesAntifouling/underwater paintsPaints with biocidesChemistryColloidal Solution

The invention discloses a solar photovoltaic panel with a self-cleaning function. The surface of the photovoltaic panel is coated with a layer of a self-cleaning coating, and through the performance of the self-cleaning coating, the self-cleaning effect of the solar photovoltaic panel is achieved. The self-cleaning coating is prepared through the specific steps of adding a certain amount of butyltitanate into an ethyl alcohol solution, then adding hydrochloric acid into the ethyl alcohol solution to adjust the PH to be 3, adding distilled water into the mixture after a stirring reaction is conducted for 8-10 minutes, and then conducting stirring and mixing for 2-3 minutes to obtain a colloidal solution; adding a fluorosiloxane resin gel solution and a film-forming auxiliary agent into thecolloidal solution, and conducting stirring and mixing for 3-5 minutes to obtain the coating. According to the solar photovoltaic panel, the surface of the photovoltaic panel is coated with the self-cleaning coating, the self-cleaning coating is prepared by compounding resin containing a large quantity of siloxane bonds and fluorine element and titania gel, has high hydrophobicity and fouling resistance, and can achieve the self-cleaning effect.

Owner:安徽三优光电科技有限公司

Preparation method for anticorrosive antibacterial wood fiber composite

PendingCN109731747AImprove flame retardant and smoke suppressionImprove hydrophobic propertiesSpecial surfacesCoatingsTitanium dioxideOxide

The invention discloses a preparation method for an anticorrosive antibacterial wood fiber composite. The preparation method for the anticorrosive antibacterial wood fiber composite comprises the steps that a layer of nanometer oxide suspension liquid is sprayed onto the surface of the wood fiber composite and dried; then a layer of poly-dimethyl siloxane treatment fluid is sprayed onto the surface of the wood fiber composite and dried; and finally, a layer of nanometer oxide suspension liquid is sprayed onto the surface of the wood fiber composite again and dried, and the anticorrosive antibacterial wood fiber composite is prepared. The nanometer oxide suspension liquid is one or several of nanometer aluminum oxide suspension liquid, nanometer titanium dioxide suspension liquid and nanometer zinc oxide suspension liquid. According to the preparation method for the anticorrosive antibacterial wood fiber composite, the surface of the wood fiber composite is subjected to spraying treatment; the inflaming-retarding, smoke-suppressive, anticorrosive and antibacterial properties of the composite are improved, and meanwhile, the hydrophobic property of the surface of the composite is strengthened significantly; and moisture is prevented from entering the interior of the composite and destroying the living environment of microorganism, and the service life and the anticorrosive antibacterial durability of wood are improved significantly.

Owner:贵州省林业科学研究院 +1

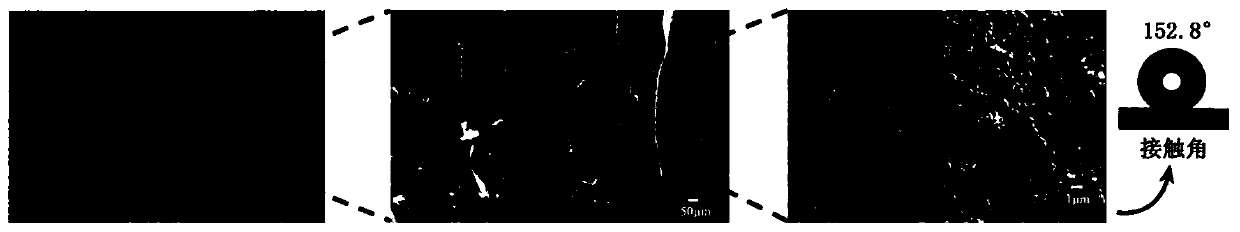

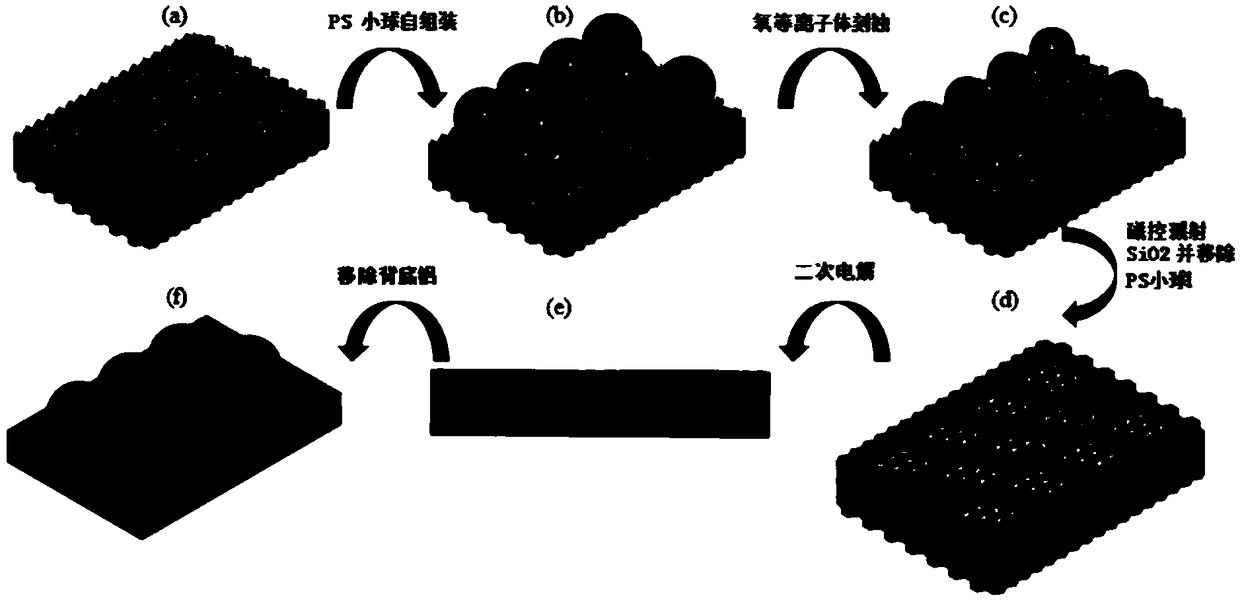

Preparation method of novel anodic oxidation aluminium template and nano array

ActiveCN109504994AImprove hydrophobic propertiesSurface reaction electrolytic coatingVacuum evaporation coatingElectrolysisPolystyrene

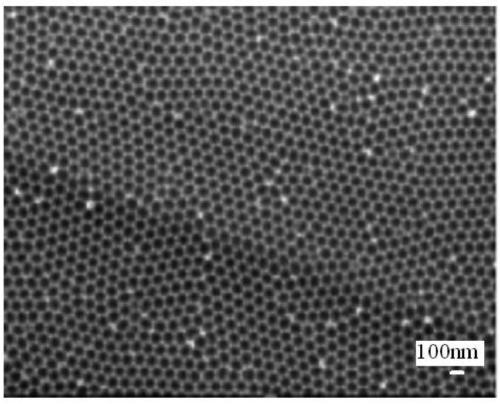

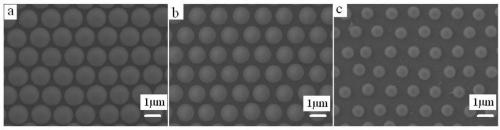

The invention relates to the technical field of electrochemistry, in particular to a preparation method of an anodic oxidation aluminium template and a nano array. The preparation method of the anodicoxidation aluminium template comprises the following steps: carrying out primary electrolysis treatment on a polished aluminium sheet; removing an aluminium oxide layer generated by primary electrolysis; preparing a polystyrene pellet on the surface of an aluminium substrate; etching the polystyrene pellet; depositing a silicon dioxide film on the etched aluminium substrate and removing the polystyrene pellet; and carrying out secondary electrolysis treatment on the aluminium substrate to obtain an aluminium oxide template, and carrying out pore-enlarging on the aluminium oxide template. Withadoption of the template, an insect compound eye nano array and a nanoflower array are prepared, and the prepared insect compound eye nano array is excellent in hydrophobic property.

Owner:SHANGHAI TECH UNIV

Polypeptide fishy-smell-removing method

InactiveCN108642112AImprove content and purityImprove hydrophobic propertiesPeptide preparation methodsFermentationChemistryKetone

The invention discloses a polypeptide fishy-smell-removing method. The polypeptide fishy-smell-removing method comprises the steps of dialysis, ultra-filtration fishy smell removing, shielding fishy smell removing and alcohol-soluble fishy smell removing. Firstly, a chlamys farreri enzymatic hydrolysate is dialysed to remove ash content; then the enzymatic hydrolysate is subjected to ultra-filtration fishy smell removing through a polysulfone hollow fiber ultra-filtration membrane; then ethyl maltol, beta-cyclodextrin and pantolactone are added into a peptide solution subjected to ultra-filtration for shielding fishy smell removing; and finally, an ethanol solution is added for centrifuging to take sediment, and then polypeptides from chlamys farreri are obtained. The polypeptide fishy-smell-removing method has the beneficial effects that the polypeptide fishy-smell-removing method is easy to operate, fishy smell substances of amine, aldehyde, ketone and the like in a polypeptide solution are removed thoroughly, adsorption and wrapping of the beta-cyclodextrin for the aldehyde, ketone and amine type substances can be greatly improved through the pantolactone, 3-hydroxy-5-methyl-2,4-imidazolone in alcohol-soluble fishy smell removing facilitates acceleration separating of the aldehyde and amine type substances, and meanwhile degradation of the polypeptides and proteins can be lowered.

Owner:金华市铁骑士生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com