Solar photovoltaic panel with self-cleaning function

A solar photovoltaic panel and self-cleaning technology, which is applied in the field of solar photovoltaic panels, can solve problems such as cumbersome processes, and achieve the effect of improving hydrophobic performance, high hydrophobic performance and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The specific preparation process of fluorosilicone resin is as follows:

[0017] Step 1: Add 13.8g of 3,4-dihydroxybenzaldehyde to 70mL of acetone solution, then add 14.14g of sodium trifluorate to it, stir to dissolve, then raise the temperature to 70-75°C, and then add 21g of trifluoroacetic anhydride to it , reflux reaction for 7-8h, and then carry out vacuum distillation to obtain dihydroxy fluorinated benzoic acid;

[0018] Step 2: Add 24.8g of dihydroxyfluorinated benzoic acid prepared in step 1 into 90mL of pyridine solution, stir to dissolve, add 2.6g of sodium hydroxide and 2g of nano-silica to it, heat up to 230-240°C for reflux reaction 15-17h, then distill to remove the solvent, add the obtained solid product into water, stir and mix for 2-3min, then filter, wash and dry to obtain the fluorosilanized monomer;

[0019] Step 3: Add 10 g of the fluorosilylated monomer prepared in Step 2 to 60 mL of acetone solution, and at the same time add 5.6 g of azobisisob...

Embodiment 2

[0021] The specific preparation process of polyfluororesin is as follows:

[0022] Step 1: Add 13.8g of 3,4-dihydroxybenzaldehyde to 70mL of acetone solution, then add 14.14g of sodium trifluorate to it, stir to dissolve, then raise the temperature to 70-75°C, and then add 21g of trifluoroacetic anhydride to it , reflux reaction for 7-8h, and then carry out vacuum distillation to obtain dihydroxy fluorinated benzoic acid;

[0023] Step 2: Add 10g of the dihydroxyfluorinated benzoic acid prepared in step 2 into 60mL of acetone solution, and at the same time add 5.6g of azobisisobutyronitrile to it, raise the temperature to 95-100°C for reflux reaction for 2-3h, then raise the temperature React at 120-125°C for 5-6h to obtain a resin solution.

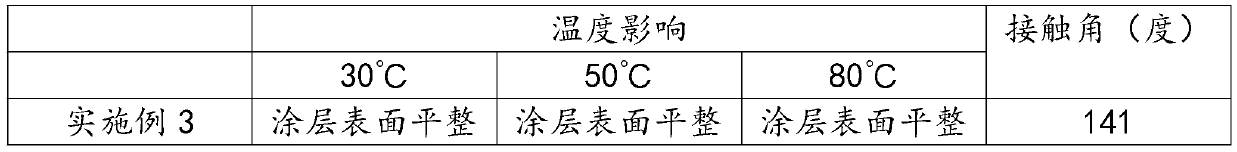

Embodiment 3

[0025] A solar photovoltaic panel with a self-cleaning function. The surface of the photovoltaic panel is coated with a layer of self-cleaning paint. The self-cleaning effect of the solar photovoltaic panel is realized through the performance of the self-cleaning paint. The specific preparation process of the self-cleaning paint is as follows:

[0026] In the first step, add 10 g of butyl titanate to 200 mL of ethanol solution, then add hydrochloric acid to it to adjust the pH to 3, stir and react for 8-10 minutes, then add 10 mL of distilled water to it, and stir and mix for 2-3 minutes to obtain a colloidal solution;

[0027] In the second step, 38 g of the fluorosilicone resin glue solution prepared in Example 1 and 1.1 g of film-forming aid were added to 10 g of the colloidal solution prepared in the first step, and stirred and mixed for 3-5 minutes to obtain a coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com