Method for improving recovery rates of gold and silver from chalcopyrite

A recovery rate, chalcopyrite technology, applied in solid separation, flotation and other directions, can solve the problem of low recovery rate of gold and silver in associated ores, and achieve the effect of improving recovery rate of gold and silver and improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

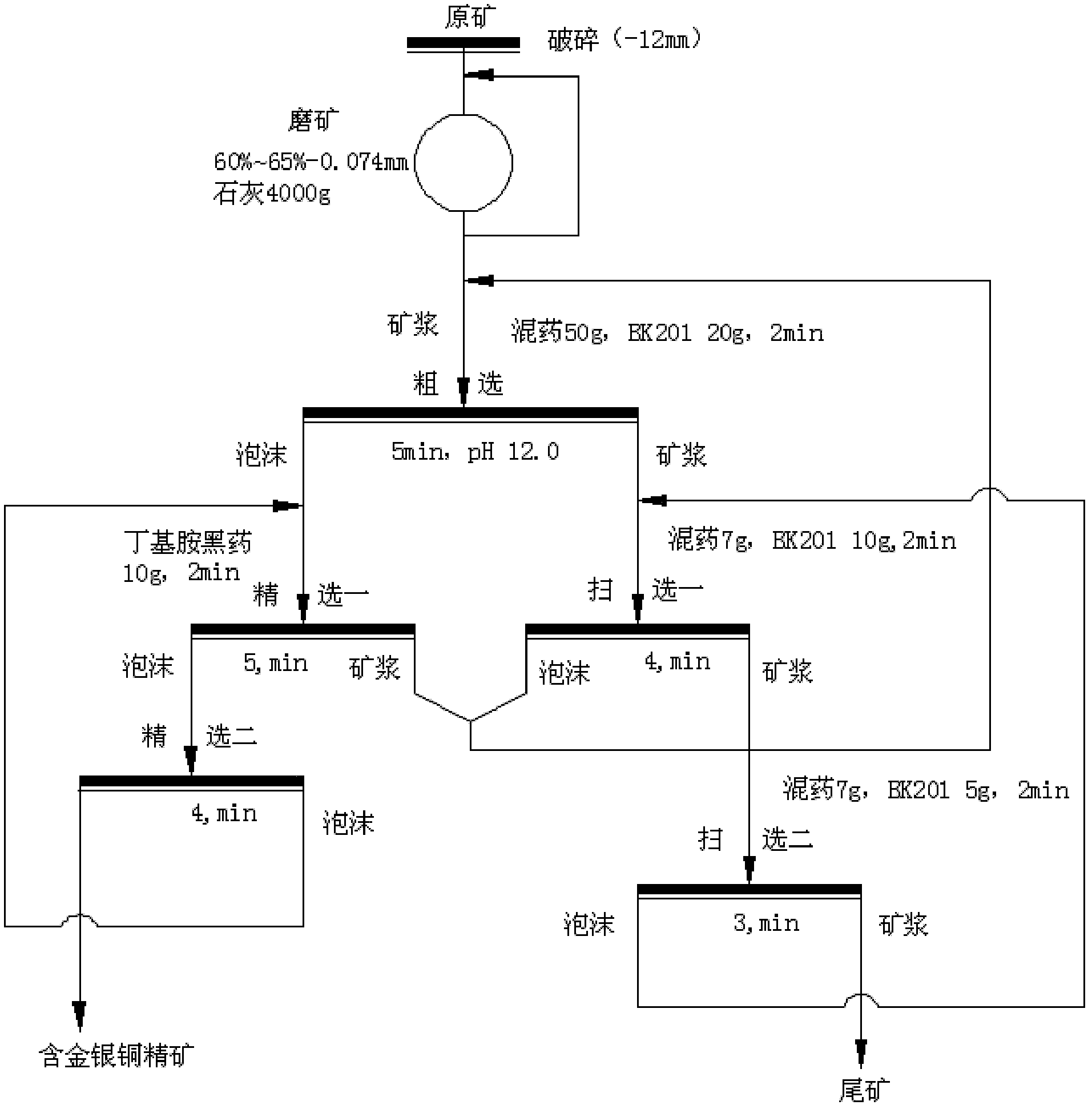

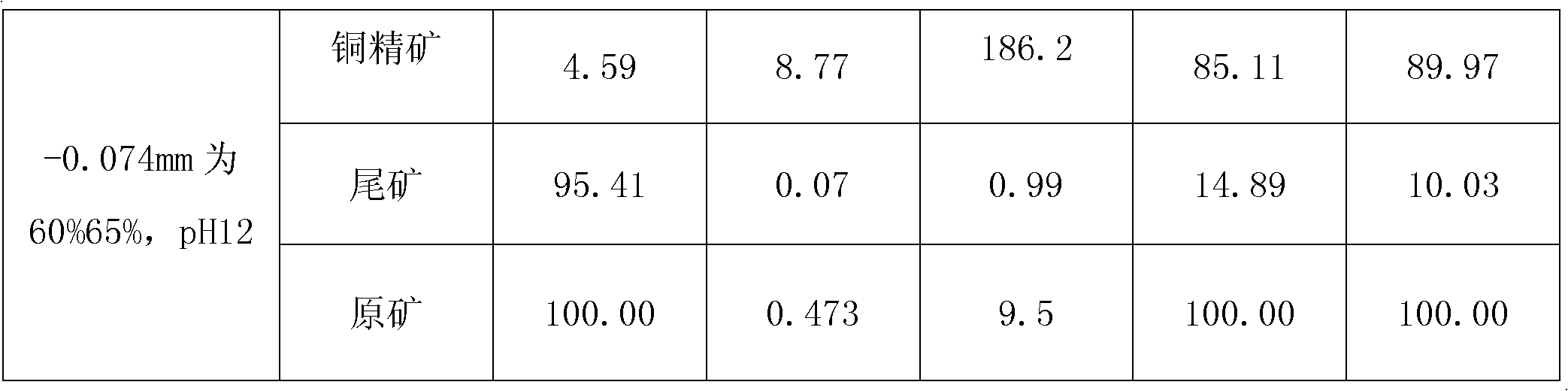

[0018] Such as figure 1 Shown, reclaim the method for gold and silver in the chalcopyrite, former ore is the chalcopyrite containing associated gold and silver, comprises the following steps:

[0019] (1) The raw ore is crushed to make the ore particle size less than 12mm, and then enters the powder silo, and lime is added to the crushed ore. The amount of ore added per ton is 4000g, and the ore is ground to a fineness of -0.074mm, which is 60%~ 65%, its ore pulp is adjusted by adding chemicals, and the added chemicals and dosage are per ton of raw ore plus butylamine black drug ((C4H 9 O) 2 PSSNH 4 ) and butyl xanthate (C 4 h 9 OCSSNa) mixed collector 50g, foaming agent 20g; Control pulp pH to be 12, stirring time 2min, enter the roughing operation of flotation copper, roughing time 5min;

[0020] (2) Dosing is added to the ore pulp again after roughing. The added medicament and dosage are 7g of mixed collector of butylamine black medicine and butyl xanthate per ton of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com