Preparation method of bionic hydrophobic coating on surface of magnesium alloy

A water-based coating, magnesium alloy technology, applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of restricting the use of magnesium alloys, the lack of protection of the substrate, and poor corrosion resistance, so as to reduce contact Enhancement of area, water repellency, and improvement of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the biomimetic hydrophobic coating on the surface of magnesium alloy is carried out according to the following specific steps:

[0032] Step 1, pretreatment of the magnesium alloy sample: first, the magnesium alloy sample is soaked in an alkaline cleaning solution heated in a water bath and cleaned by ultrasonic vibration to remove the grease on the surface of the sample, wherein the cleaning time is 40 minutes, The composition of the alkaline washing solution is: NaOH: 45g / l, Na 3 PO 4 12H 2 O: 10g / l; then, soak the magnesium alloy sample after alkali washing in pickling solution at room temperature to remove oxides and other metal dirt on the surface of the sample. The composition of the lotion is: CrO 3 : 125g / L, HNO 3 : 110ml / l;

[0033] Step 2, chemical etching: immerse the pretreated magnesium alloy sample in a chemical etching solution, so that the morphology and characteristics of the sample surface are changed, and the surface con...

Embodiment 1

[0037] Taking the magnesium alloy AZ91D as the research object, the magnesium alloy is processed into a sample of 10mm×10mm×5mm, and 1000 # , 1500 # and 2000 # Polish the surface of the sample with metallographic sandpaper, and then use 1.5 # Diamond abrasive paste was used to polish the sample surface.

[0038] Soak the magnesium alloy sample in an alkaline cleaning solution with a water bath temperature of 60°C and clean it with ultrasonic vibration to remove the grease on the surface of the sample. The cleaning time is 40 minutes, and the composition of the alkaline cleaning solution is: NaOH: 45g / l, Na 3 PO 4 12H 2 O: 10g / l; then, soak the magnesium alloy sample after alkali washing in pickling solution at room temperature to remove oxides and other metal dirt on the surface of the sample. The composition of the lotion is: CrO 3 : 125g / L, HNO 3 : 110ml / l.

[0039] Immerse the pretreated magnesium alloy sample in the chemical etching solution to change the morphol...

Embodiment 2

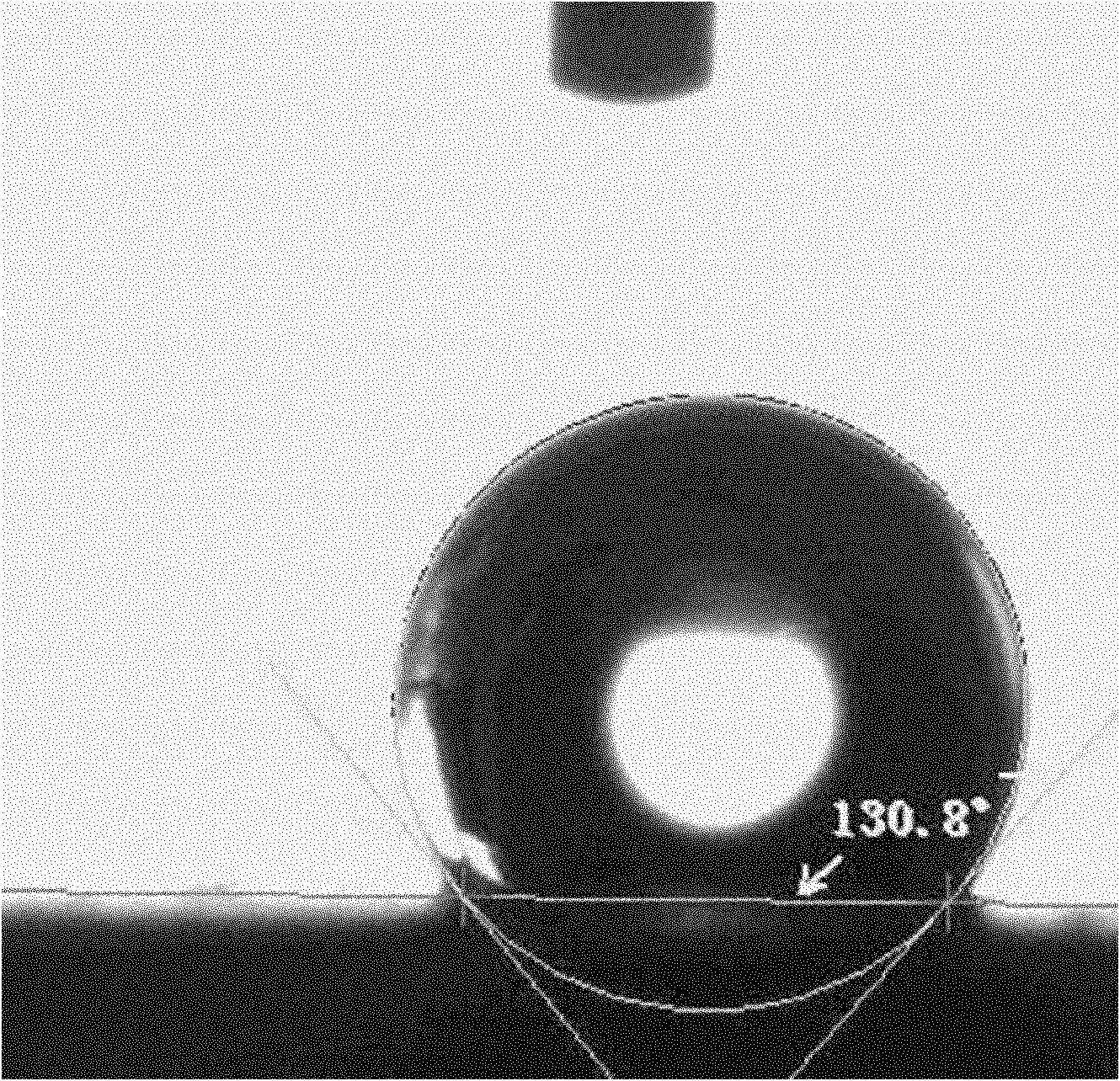

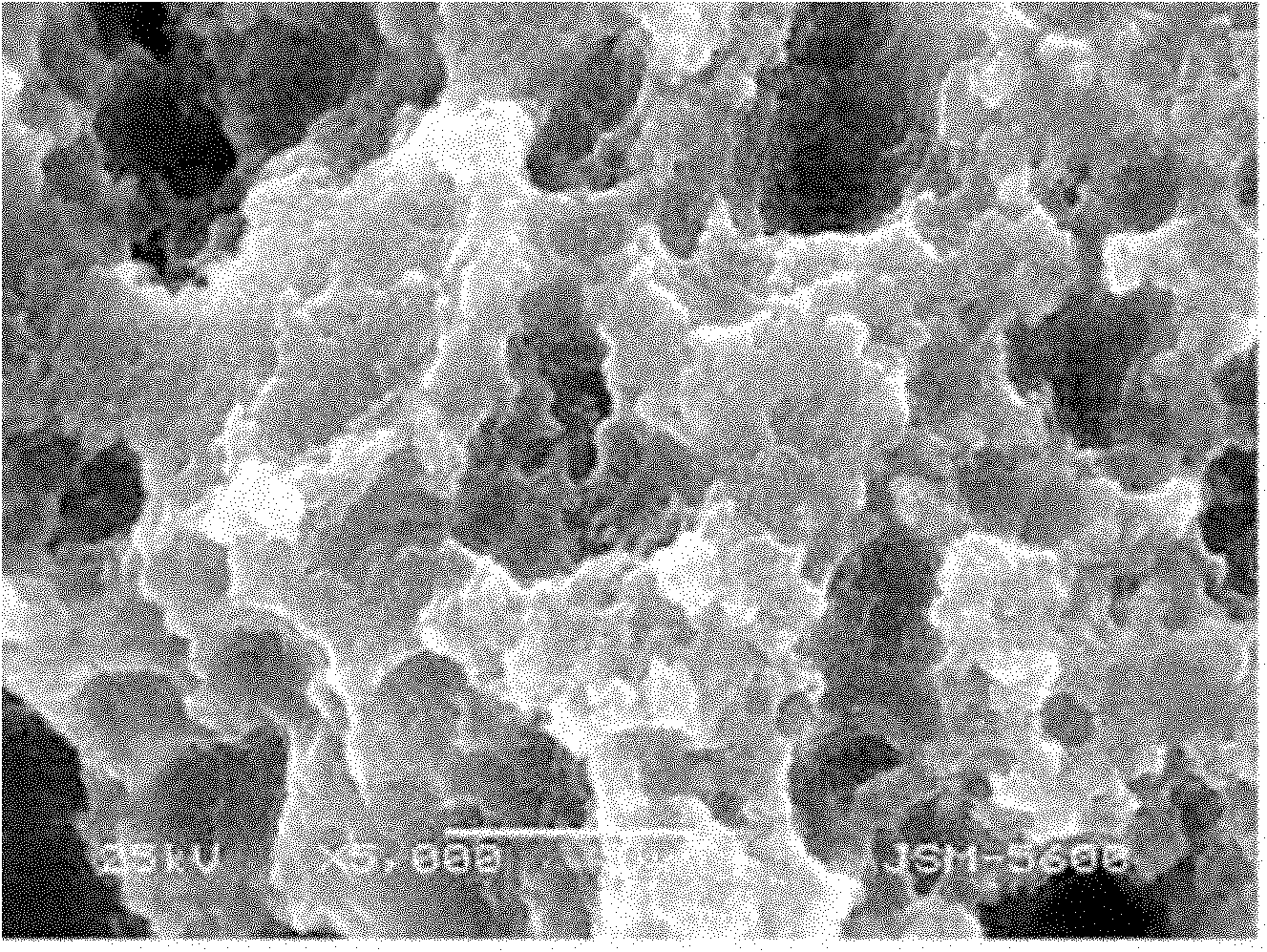

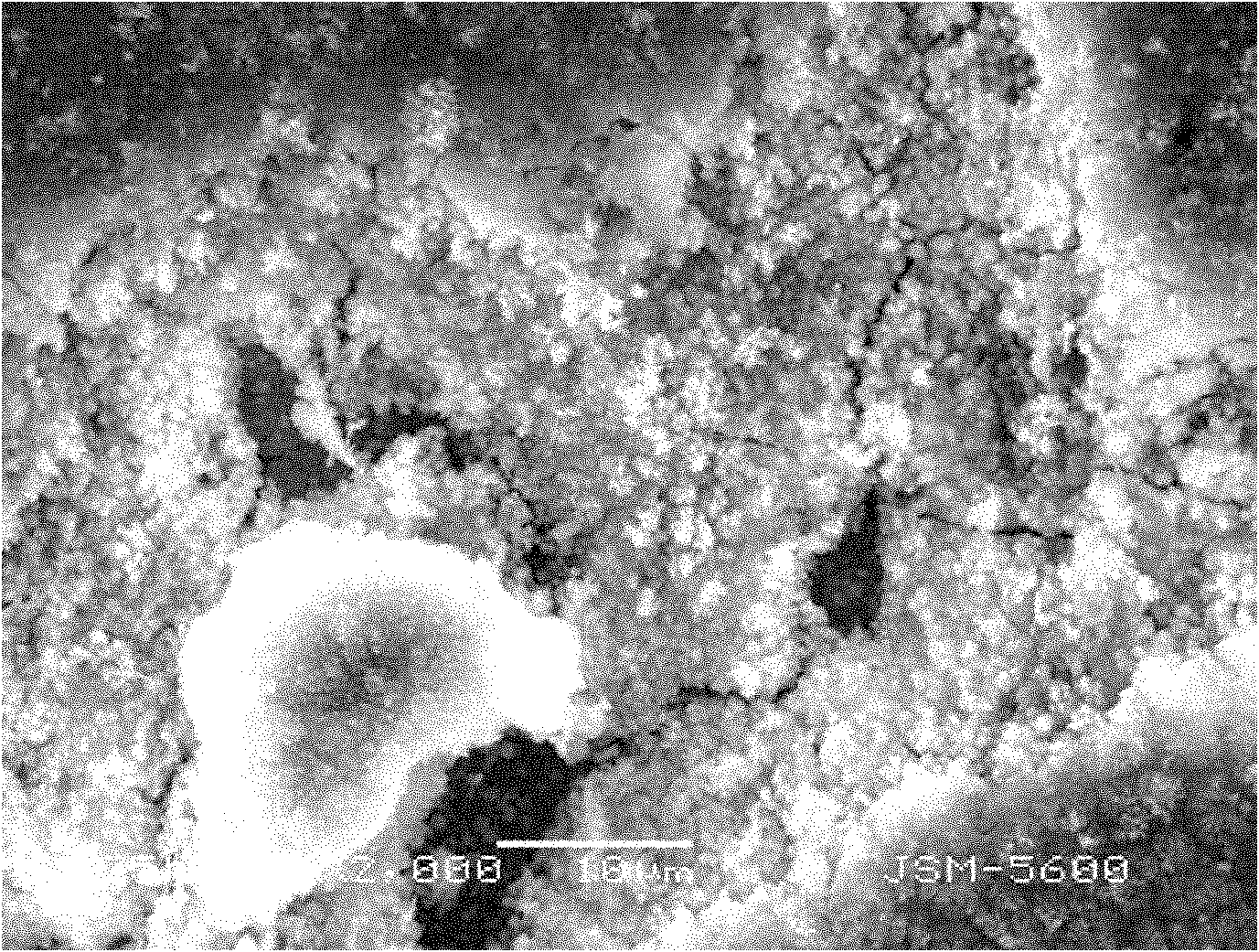

[0043] Embodiment 2, embodiment 3 remove the nitrate solution AgNO that carries out chemical etching 3 Concentrations were 10mmol / l and 50mmol / l, soaking time were 60s and 10s, respectively, and the same process flow as in Example 1 was adopted except that the above parameters were changed. The sample was observed and measured by a scanning electron microscope and a wetting angle measuring instrument. The results showed that when the sample was chemically etched, due to the nitrate solution AgNO 3 With different concentrations, the biomimetic hydrophobic coating formed on the surface has significant differences in surface characteristics (see Figure 5 , Image 6 , Figure 7 ), and there are obvious regular changes in the hydrophobic properties (see Figure 8 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com