Efficient oil-water and emulsion separation polyurethane foam material and preparation method thereof

A polyurethane foam and emulsion separation technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of difficult separation of oil-water emulsions, harsh reaction conditions, complex treatment processes, etc., and is conducive to large-scale production and preparation. The effect of mild conditions and a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

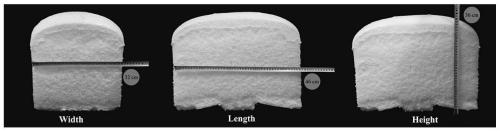

[0037] 40 parts of polypropylene oxide triol, 60 parts of polypropylene oxide diol, 2.5 parts of foam stabilizer, 0.8 part of polyether additive, 0.22 part of stannous octoate, 0.28 part of triethylenediamine, 5.2 parts of ultrapure water, Mix 14 parts of dichloromethane, stir at 1000r / min for 30s, then add 70 parts of toluene diisocyanate, stir rapidly at a stirring speed of 2200r / min, after stirring for 10s, quickly transfer the mixture to a foaming mold, let it foam freely Bubble, the whole foaming process will last about a minute. After the foaming is finished, let it mature at room temperature for 6-24 hours and then cut it according to the required ratio to test the performance of the material.

Embodiment 2

[0039] 40 parts of polypropylene oxide triol, 50 parts of polypropylene oxide diol, 10 parts of polytetrahydrofuran diol, 2.2 parts of foam stabilizer, 0.85 part of polyether additive, 0.18 part of stannous octoate, 0.22 part of triethylenediamine , 5.5 parts of ultrapure water and 10 parts of dichloromethane were mixed, stirred at 1000r / min for 30s, then 73 parts of toluene diisocyanate was added, and stirred rapidly at a stirring speed of 2200r / min, after stirring for 10s, the mixture was quickly transferred to the foaming Let it foam freely in the mold, and the whole foaming process will last for about a minute. After the foaming is finished, let it mature at room temperature for 6-24 hours and then cut it according to the required ratio to test the performance of the material.

Embodiment 3

[0041] 40 parts of polypropylene oxide triol, 40 parts of polypropylene oxide diol, 20 parts of polytetrahydrofuran diol, 2.2 parts of foam stabilizer, 0.85 part of polyether additive, 0.18 part of stannous octoate, 0.22 part of triethylenediamine , 5.5 parts of ultrapure water and 10 parts of dichloromethane were mixed, stirred at 1000r / min for 30s, then 77 parts of toluene diisocyanate was added, and stirred rapidly at a stirring speed of 2200r / min, after stirring for 10s, the mixture was quickly transferred to the foaming Let it foam freely in the mold, and the whole foaming process will last for about a minute. After the foaming is finished, let it mature at room temperature for 6-24 hours and then cut it according to the required ratio to test the performance of the material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com