Composite concrete material and preparation method thereof

A technology of concrete and mixture, which is applied in the field of new composite concrete materials and its preparation, can solve the problems of poor comprehensive performance of semi-flexible pavement, hot construction and short construction period, poor durability, etc., and achieve the elimination of adverse effects and interface compatibility Good, reasonable gravel grading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

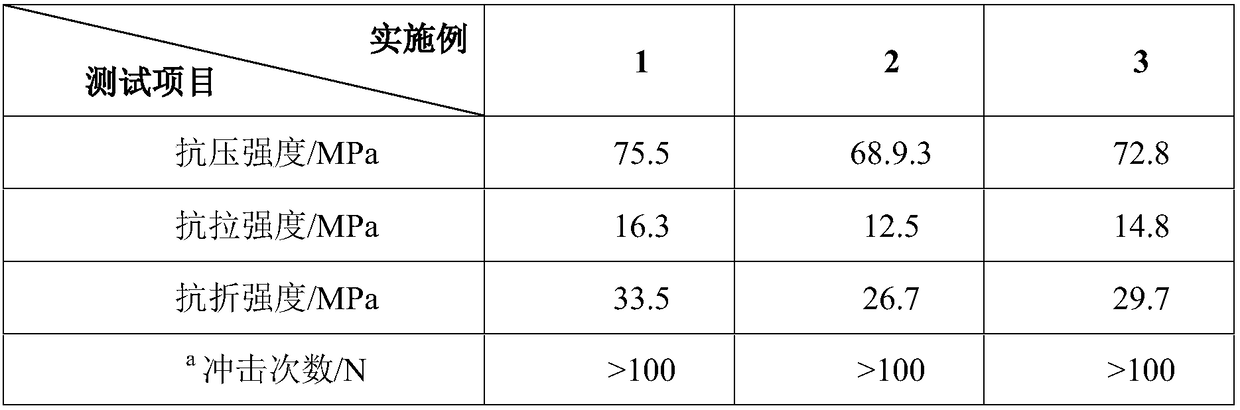

Examples

Embodiment 1

[0040] The new composite concrete material is composed of high-porosity epoxy resin gravel mixture and high-fluidity polymer-modified cement mortar. The specific composite method is that high-fluidity polymer-modified cement mortar is filled The internal pores of the crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0041] The high-porosity epoxy resin crushed stone mixture is composed of two-component epoxy resin adhesive and crushed stone, the porosity is 20%, and the mass ratio of crushed stone to adhesive is 100:6. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 2:1.

[0042] The two-component epoxy resin adhesive is composed of two components, A and B, and the mass ratio is A component: B component = 2:1. After the components A and B are accurately weighed according to the mass ratio, they are stirred and mixed evenly ...

Embodiment 2

[0060]The new composite concrete material is composed of high-porosity epoxy resin gravel mixture and high-fluidity polymer-modified cement mortar. The specific composite method is that high-fluidity polymer-modified cement mortar is filled The internal pores of the crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0061] The high-porosity epoxy resin crushed stone mixture is composed of two-component epoxy resin adhesive and crushed stone, the porosity is 30%, and the mass ratio of crushed stone to adhesive is 100:3. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 1:1.

[0062] The two-component epoxy resin adhesive is composed of A and B components, and the mass ratio is A component: B component = 3:1; A component and B component are accurately weighed according to the mass ratio, and then stirred Mix evenly to obtain the...

Embodiment 3

[0080] The new composite concrete material is composed of high-porosity epoxy resin gravel mixture and high-fluidity polymer-modified cement mortar. The specific composite method is that high-fluidity polymer-modified cement mortar is filled The internal pores of the crushed stone mixture form a dense composite structure after the two are consolidated and formed.

[0081] The high-porosity epoxy resin crushed stone mixture is composed of two-component epoxy resin adhesive and crushed stone, the porosity is 25%, and the mass ratio of crushed stone to adhesive is 100:4.5. Crushed stone is a mixture of basalt rock with a particle size of 3-5mm and basalt rock with a particle size of 5-10mm, and the mass ratio of the two is 1.5:1.

[0082] The two-component epoxy resin adhesive is composed of A and B components, and the mass ratio is A component: B component = 3:1; A component and B component are accurately weighed according to the mass ratio, and then stirred Mix evenly to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com