Membrane distillation device for seawater desalination

A technology of membrane distillation and membrane distillation, which is applied in the field of membrane separation, can solve problems such as low utilization rate of low-temperature waste heat, discharge of low-temperature waste heat, environmental heat pollution, etc., and achieve the effects of improving driving force and efficiency, promoting self-repair, and improving hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

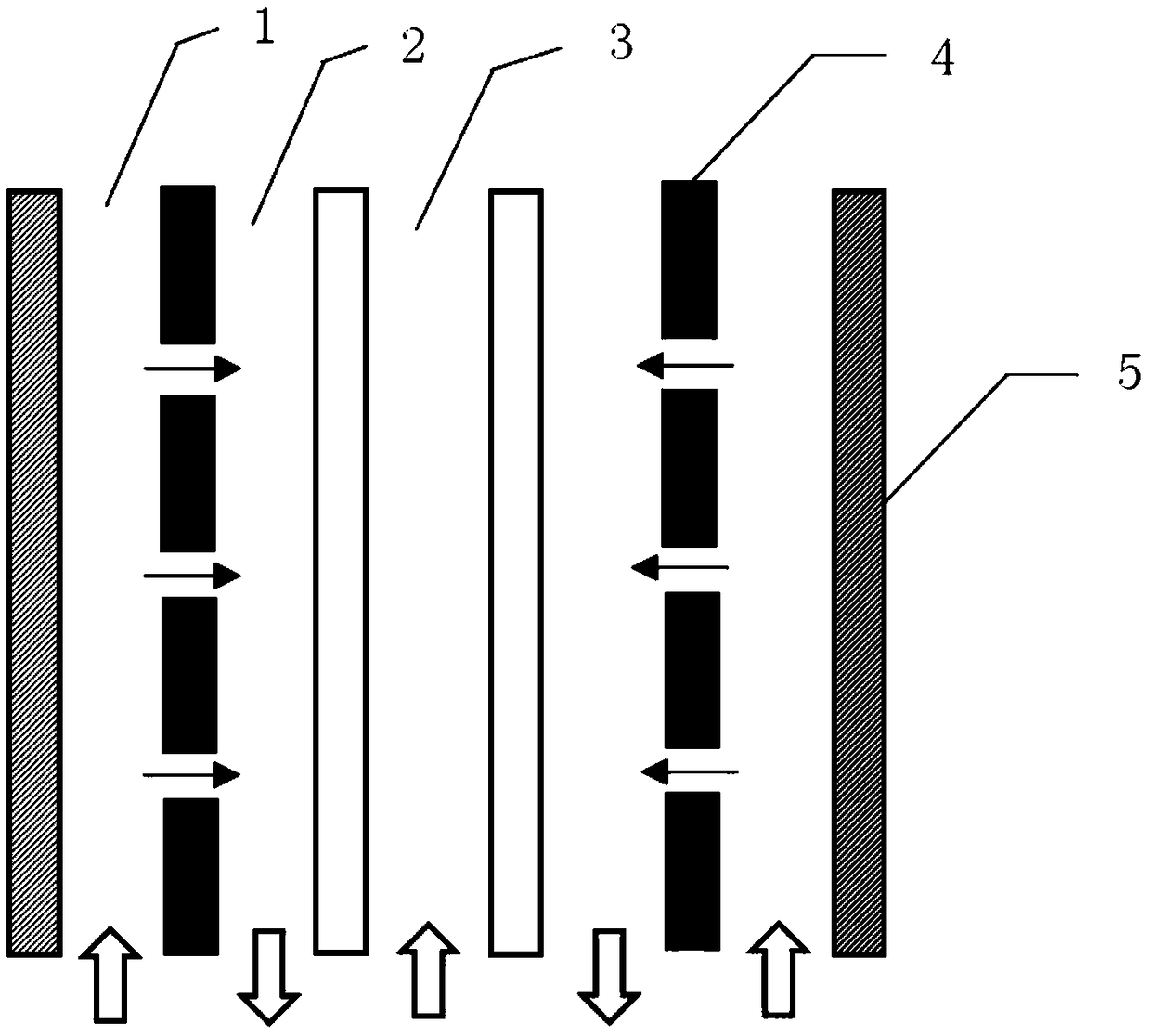

[0041] In this embodiment, a membrane distillation device for seawater desalination includes a hot liquid input chamber, a vacuum cooling chamber and a condenser tube. The outer layer of the device is a shell wall, and a distillation film layer is arranged inside the device. There is a hot liquid input chamber in between, and a vacuum cooling chamber inside the distillation film layer, and a condensation pipe is installed in the vacuum cooling chamber;

[0042]The shell wall is heat-resistant and light-transmitting material, cold fluid is passed through the condensation pipe, and the distillation film layer is a photothermal self-repairing superhydrophobic film; the photothermal self-repairing superhydrophobic film includes a base film, a photothermal layer, a self-repairing Repairing the superhydrophobic layer and the silver nanowire layer, the basement membrane is provided with a photothermal layer, the photothermal layer is provided with a self-repairing superhydrophobic lay...

Embodiment 2

[0057] In this embodiment, a membrane distillation device for seawater desalination includes a hot liquid input chamber, a vacuum cooling chamber and a condenser tube. The outer layer of the device is a shell wall, and a distillation film layer is arranged inside the device. There is a hot liquid input chamber in between, and a vacuum cooling chamber inside the distillation film layer, and a condensation pipe is installed in the vacuum cooling chamber;

[0058] The shell wall is heat-resistant and light-transmitting material, cold fluid is passed through the condensation pipe, and the distillation film layer is a photothermal self-repairing superhydrophobic film; the photothermal self-repairing superhydrophobic film includes a base film, a photothermal layer, a self-repairing Repairing the superhydrophobic layer and the silver nanowire layer, the basement membrane is provided with a photothermal layer, the photothermal layer is provided with a self-repairing superhydrophobic la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com