Method for preparing super-hydrophobic flame retardant fabric through one pot method

A textile and super-hydrophobic technology, applied in textiles and papermaking, physical treatment, fiber treatment, etc., can solve the problems of non-waterproof, cumbersome, and time-consuming reactions of flame-retardant textiles, and achieve improved hydrophobicity and flame-retardant properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

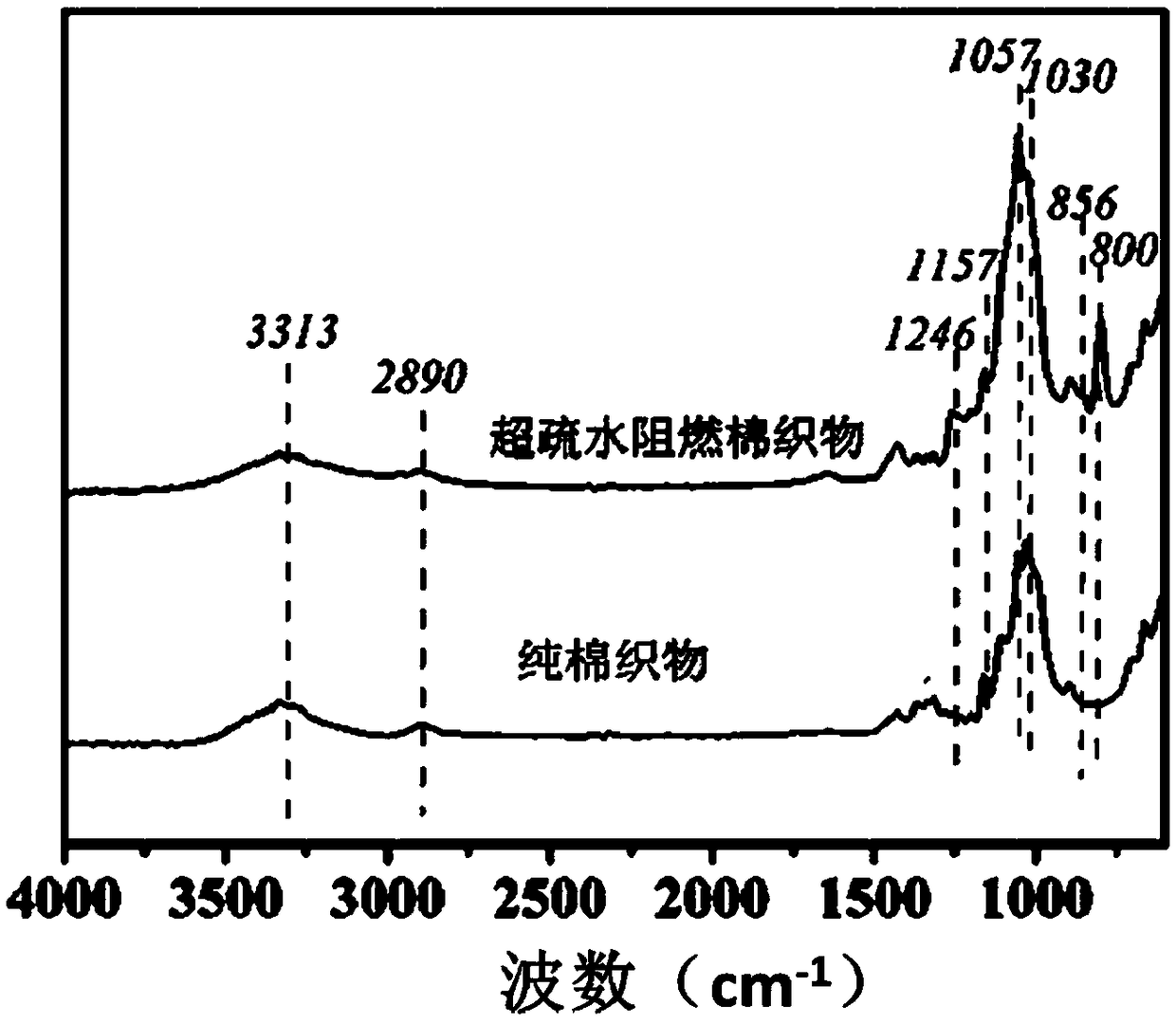

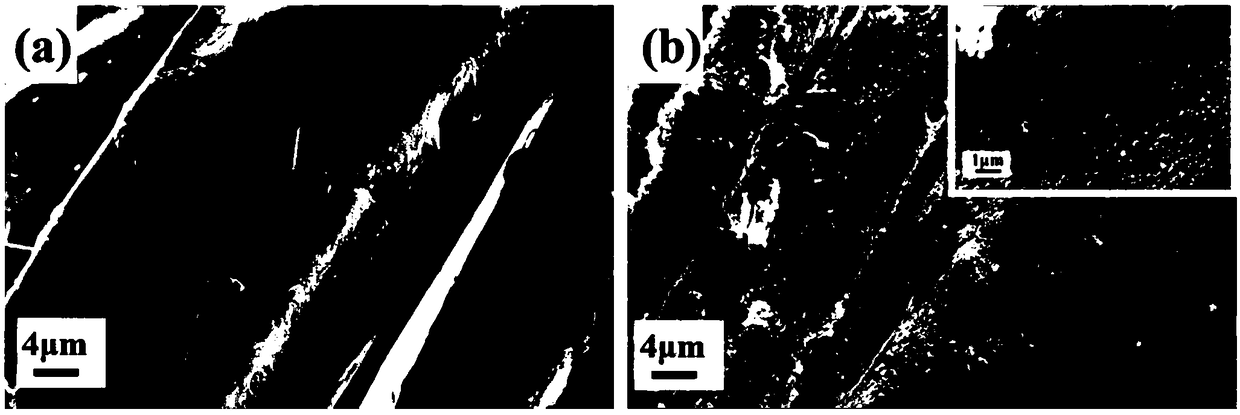

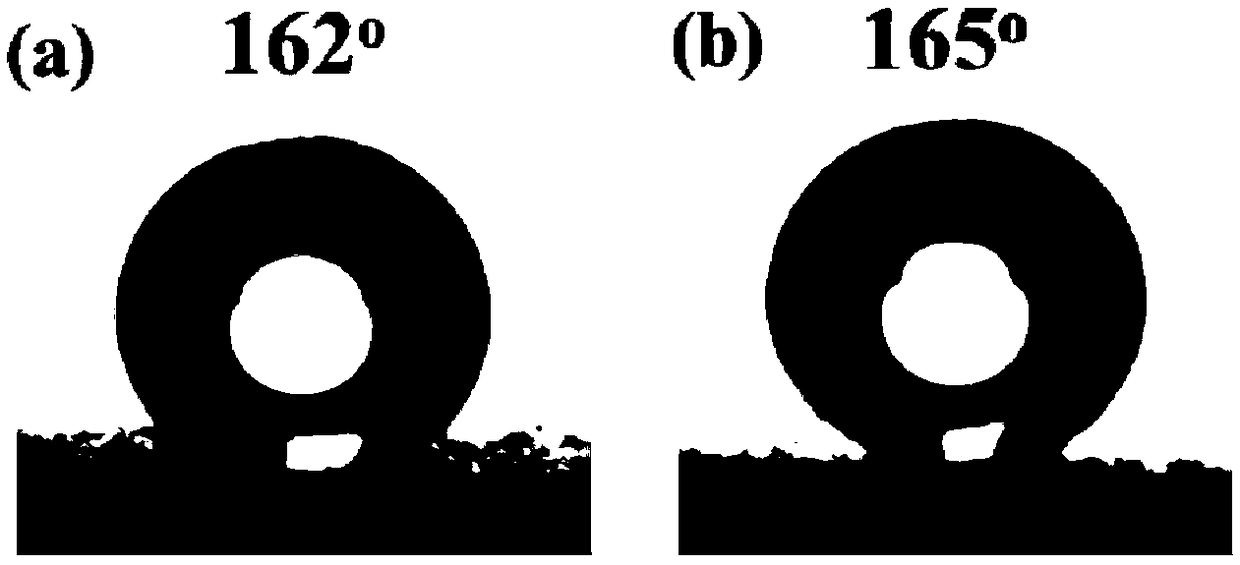

Embodiment 1

[0035] The cotton fabric was first treated with 200W oxygen plasma for 1 min. Measure 100mL of absolute ethanol in a 250mL beaker with magnetic stirring, add 4.00g of ammonium polyphosphate, 2.00g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 560, 4.00g of ethyl orthosilicate and The cotton fabric treated with oxygen plasma (the cotton fabric is completely immersed in the solution) was magnetically stirred at 30° C. for 30 minutes, so that ammonium polyphosphate was deposited on the surface of the cotton fabric through hydrogen bond interaction. Then, 1M ammonia water was added dropwise into the beaker, the pH value of the mixed solution was adjusted to 9, and the stirring reaction was continued for 1 hour, so that the surface of the cotton fabric was coated with a composite coating with a micro-nano structure. Then the cotton fabric was taken out from the beaker, rinsed twice with ethanol and dried at 60°C to obtain a superhydrophobic flame-retardant ...

Embodiment 2

[0043] Corona treatment was first performed on the polyester fabric with a corona discharge apparatus at a voltage of 10kV for 45s. Measure 100mL of acetone into a 250mL beaker with magnetic stirring, add 8.00g of ammonium polyphosphate, 1.00g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 400, 2.00g of tetraethyl orthosilicate and corona The treated polyester fabric was magnetically stirred at 25° C. for 20 minutes, so that ammonium polyphosphate was deposited on the surface of the polyester fabric through hydrogen bond interaction. Then, 1M ammonia water was added dropwise to the above-mentioned beaker to adjust the pH value of the mixed solution to 8, and the stirring reaction was continued for 2 hours, so that the surface of the polyester fabric was coated with a composite coating with a micro-nano structure. Then the polyester fabric was taken out from the beaker, rinsed twice with ethanol and dried at 50°C to obtain a superhydrophobic flame-retard...

Embodiment 3

[0047] The ramie fabric was first treated with 200 watts of oxygen plasma for 2 minutes. Measure 100mL of absolute ethanol into a 250mL three-neck flask with a magnetic stirring and reflux device, add 2.00g of ammonium polyphosphate, 2.40g of hydroxyl-terminated polydimethylsiloxane with a molecular weight of 800, ethyl orthosilicate The ramie fabric treated with 1.20 g of ester and oxygen plasma was magnetically stirred at 50° C. for 60 min, so that ammonium polyphosphate was deposited on the surface of the ramie fabric through hydrogen bond interaction. Then, 1M ammonia water was added dropwise to the above-mentioned flask, the pH value of the mixed solution was adjusted to 8.5, and the stirring reaction was continued for 0.5h, so that the surface of the ramie fabric was covered with a composite coating with a micro-nano structure. Then the ramie fabric was taken out from the flask, rinsed twice with ethanol and dried at 90°C to obtain a superhydrophobic flame-retardant rami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com