Patents

Literature

238 results about "Gelcoat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gelcoat or 'Gel Coat' is a material used to provide a high-quality finish on the visible surface of a fibre-reinforced composite. The most common gelcoats are thermosetting polymers based on epoxy or unsaturated polyester resin chemistry. Gelcoats are modified resins which are applied to moulds in the liquid state. They are cured to form crosslinked polymers and are subsequently backed with thermoset polymer matrix composites which are often mixtures of polyester resin and fiberglass, or epoxy resin which is most commonly used with carbon fibre for higher specific strength.

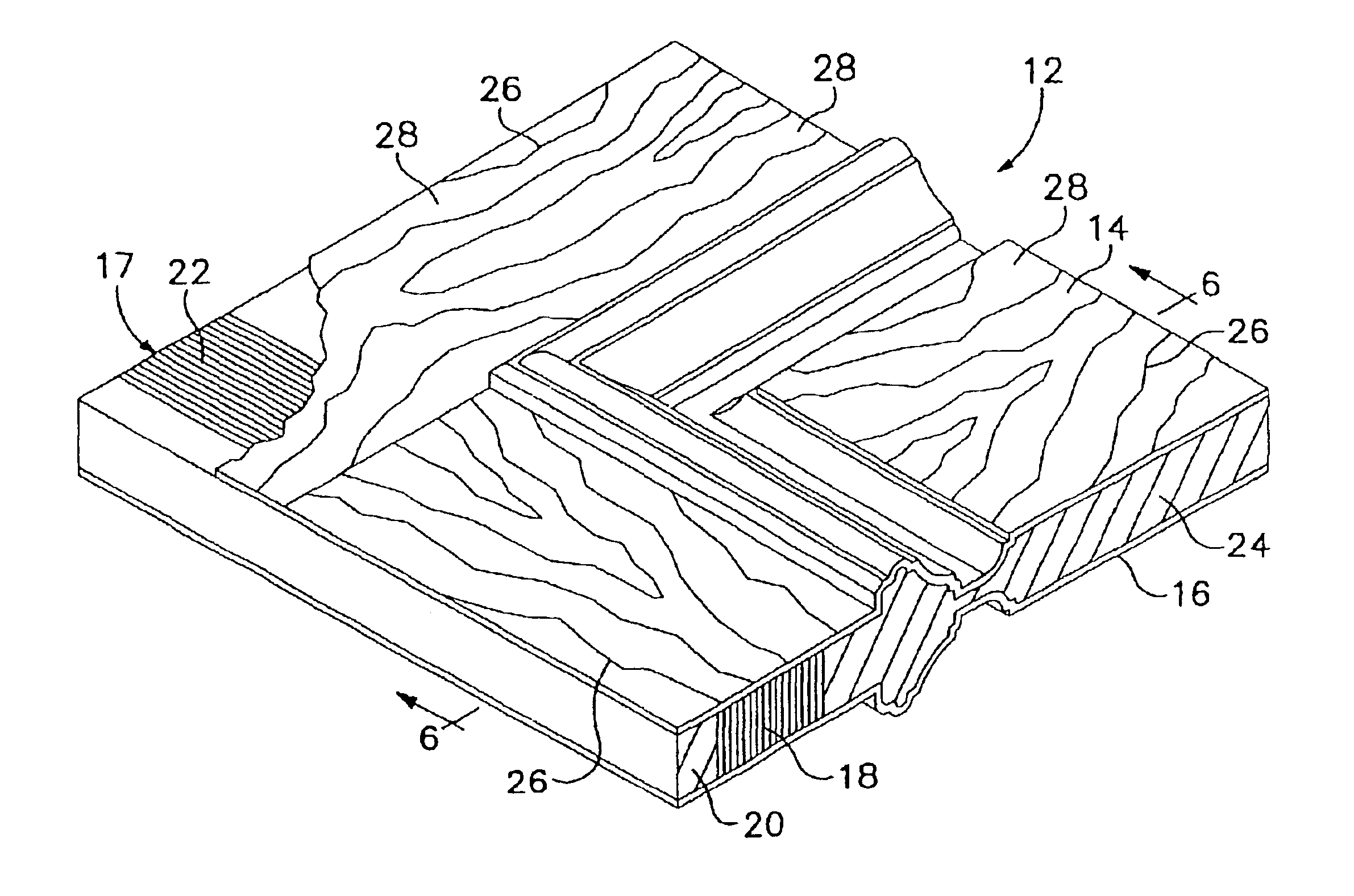

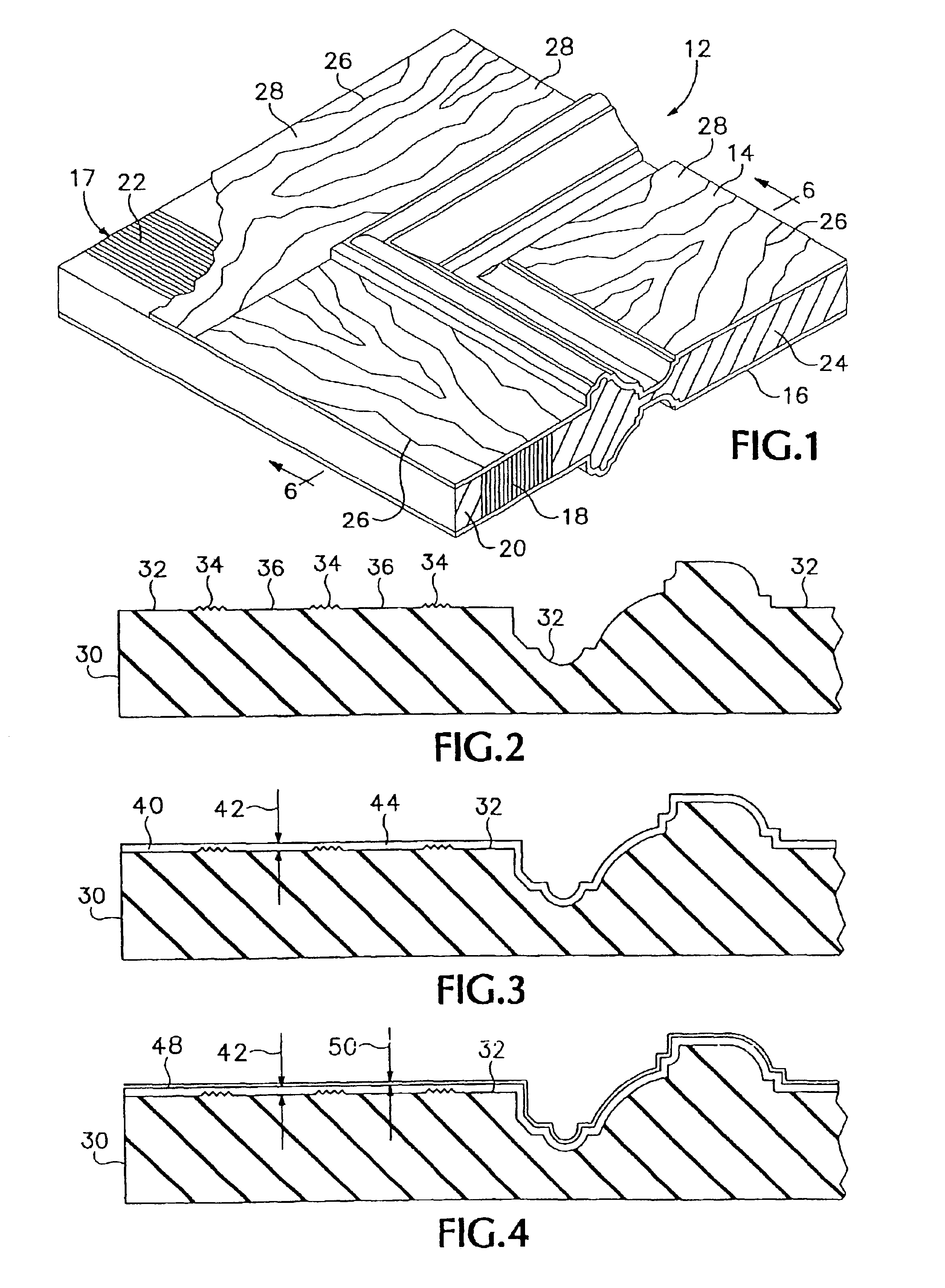

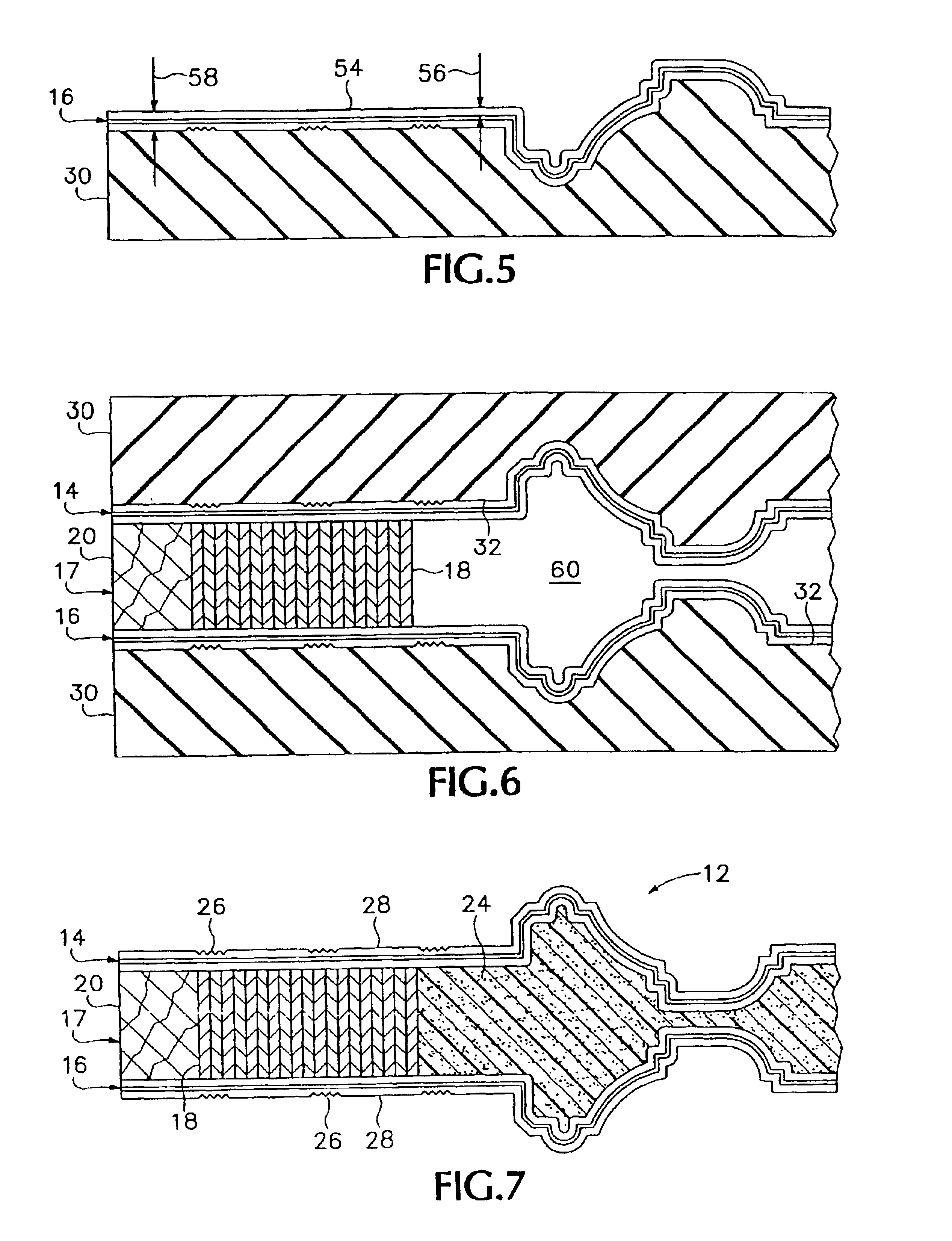

Articles of composite structure having appearance of wood

A door or other entryway component of synthetic resin composite construction and closely resembling the appearance of stained real wood. Skin portions of doors and other structures have a surface layer of clear gel coat resin molded to include the texture of a wood grain surface. A subsurface layer adjacent the clear gel coat layer is of pigmented gel coat resin. A structural support layer of the skin is of reinforced resin. Skins of a door or similar article are mounted on frames, and dense micro porous resin foam is provided between the skins to form a solid structure such as a door. Moldings retaining glass panels in openings defined in the door or similar structure are attached to the skins by adhesively fastening the moldings to the skins. Fasteners mounted in the moldings so that there are no plugged holes in the exterior surfaces of the moldings are used to locate the moldings properly with respect to the skins by inserting the fasteners into predrilled holes in the skins. The assembled doors and other structures can be finished by staining and coating with a finish system such as a urethane varnish to provide an appearance closely resembling real wood.

Owner:JELD-WEN

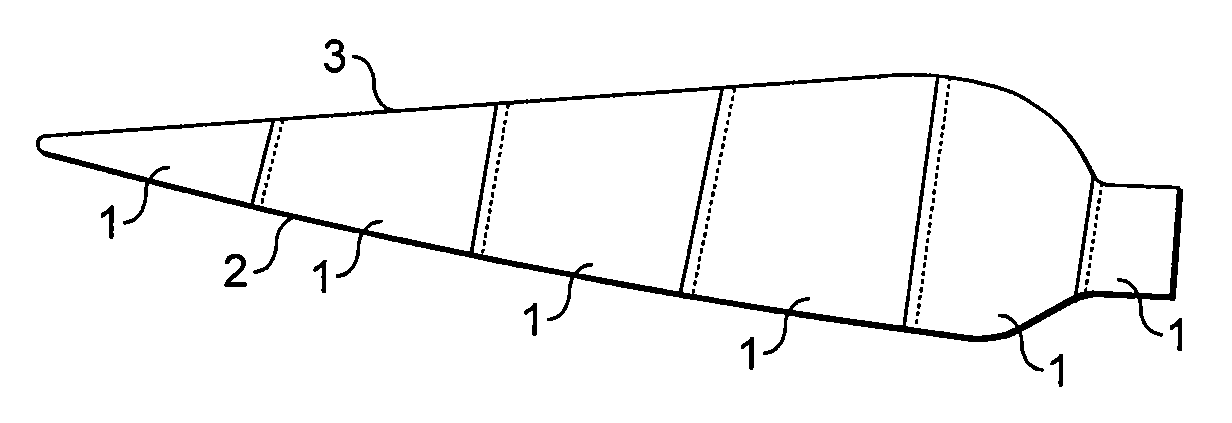

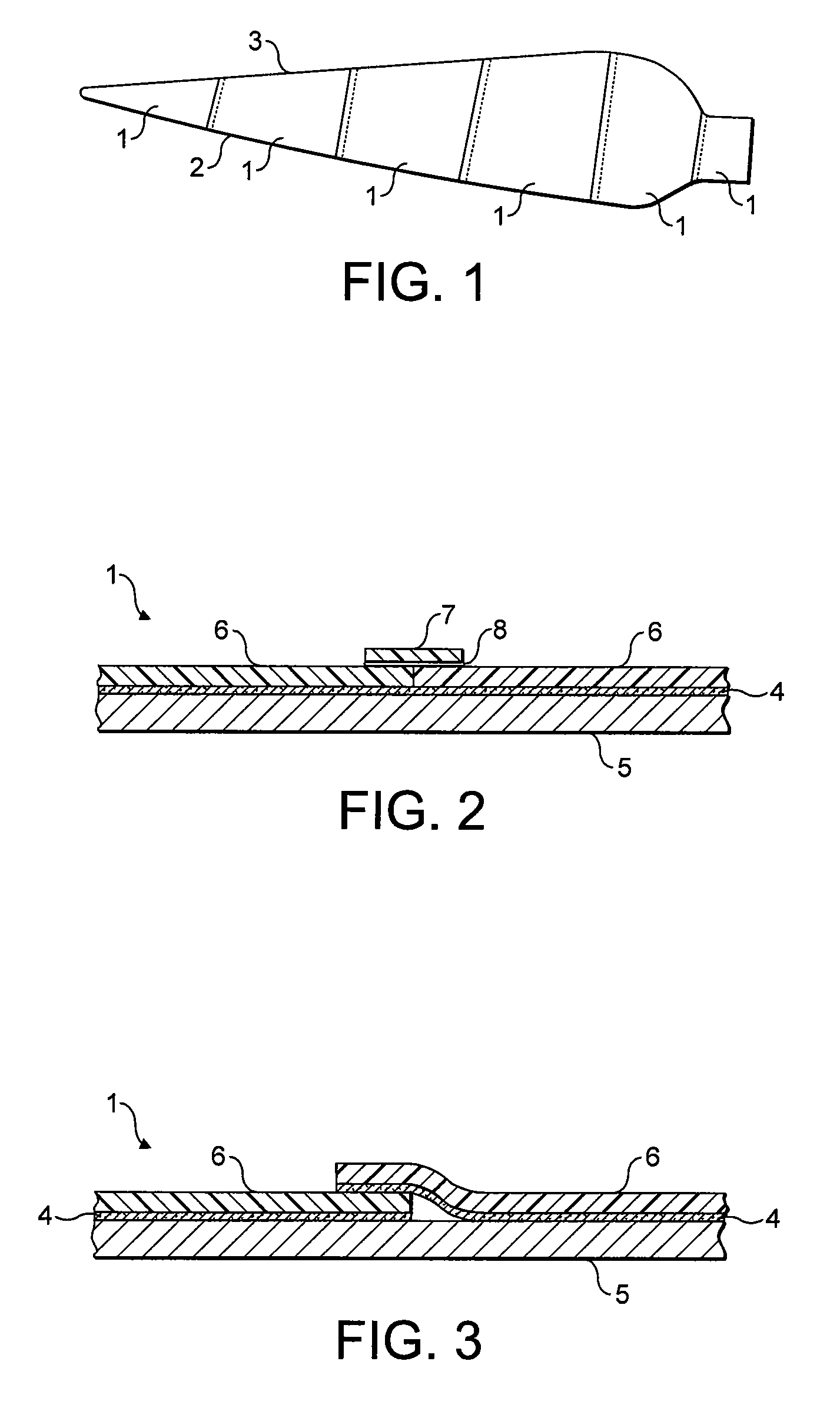

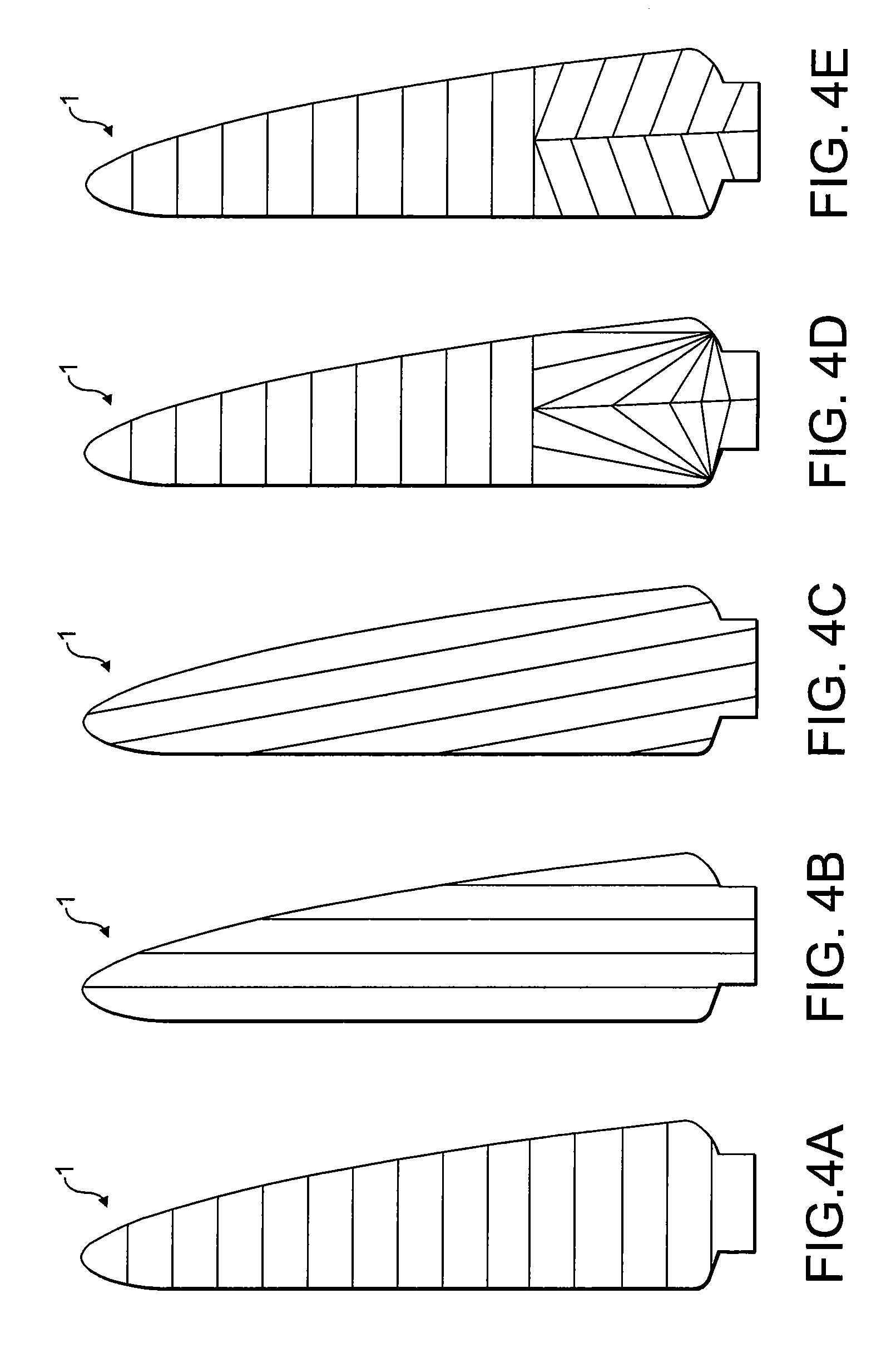

Wind turbine blade

InactiveUS20090246033A1Increase flexibilityEfficient use ofPropellersFinal product manufactureTurbine bladeGelcoat

There is provided a wind turbine blade at least 50% of the surface of which is covered with a self-adhesive thermoplastic film. By applying a self-adhesive thermoplastic film to the blade, the need for a gelcoat or the paint is eliminated. It is estimated that the thermoplastic film will take a similar time to apply as the gelcoat and / or paint. However, it does not require any further treatment once it has been applied thereby reducing significantly the work involved in finishing the blade. Also, the thickness of the film is precisely controlled in advance of its application to the blade ensuring that a surface with a uniform thickness is produced.

Owner:BLADE DYNAMICS LTD

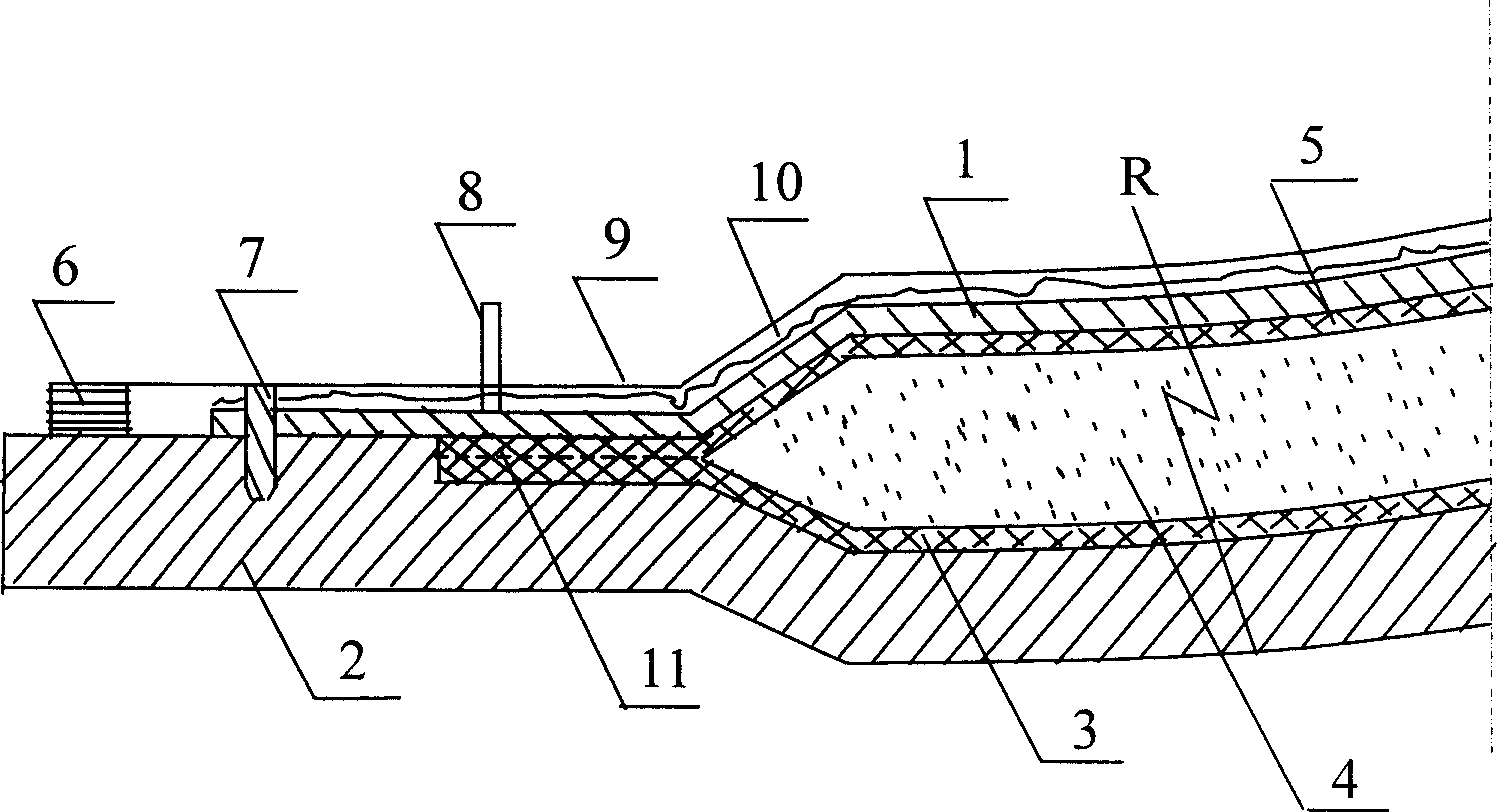

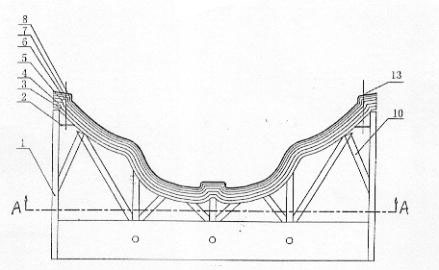

Vacuum forming technique for sandwich structure piece of composite material of fiberglass-reinforced plastics

ActiveCN1915650AFlat surfaceNo stratificationSynthetic resin layered productsGlass fiberOptoelectronics

A composite glass fiber reinforced plastics material with sandwich structure is composed of an external layer made of glass fiber reinforced plastics and coated by water-proof resin, an internal layer made of glass fiber reinforced plastics, and a core layer with cellular structure or made of foam plastics. Its vacuum forming technology includes such steps as respectively preparing mould, external layer, internal layer and core layer, molding, and vacuum solidifying.

Owner:上海之合玻璃钢有限公司

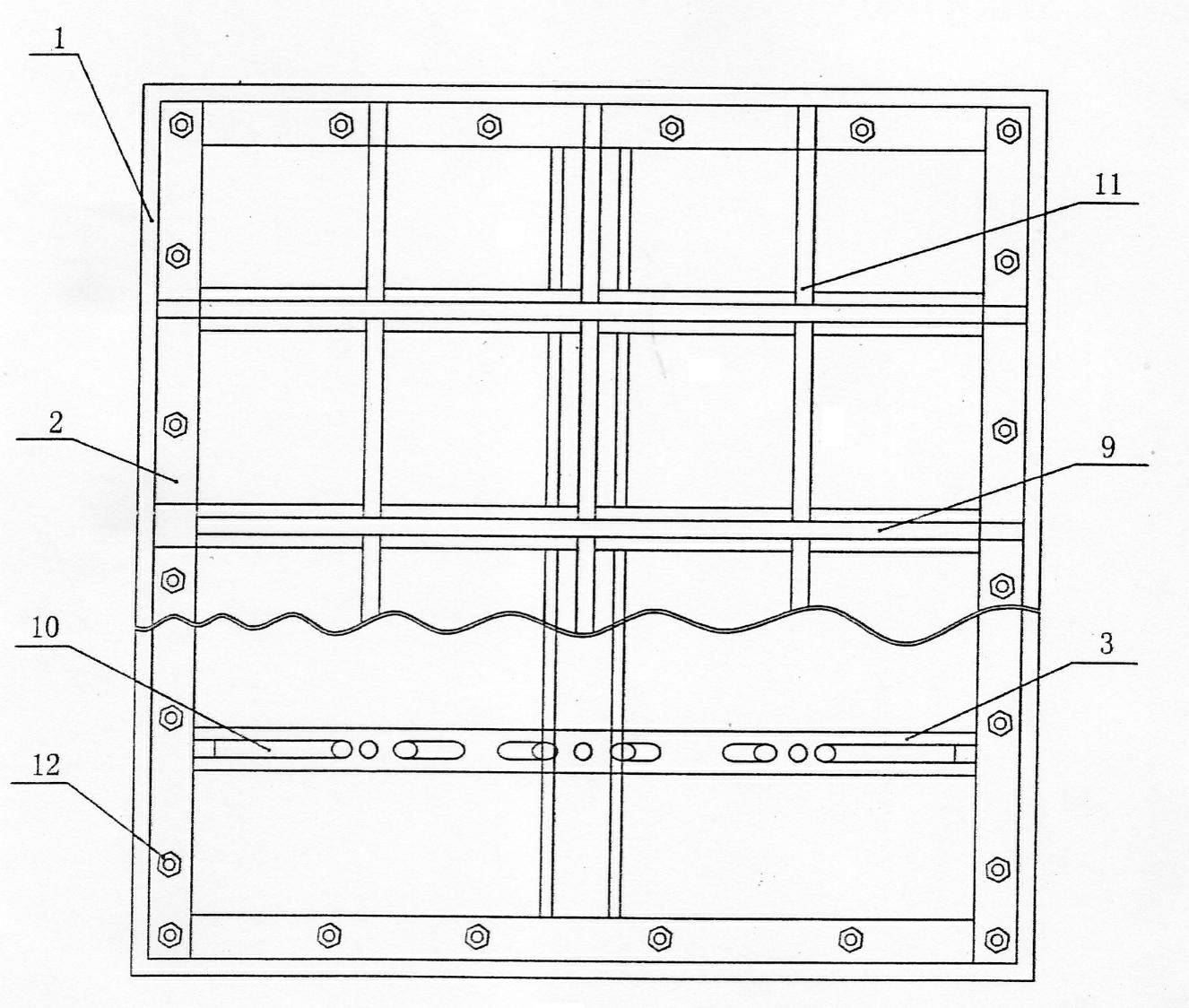

Manufacturing method for glass fiber reinforced plastic pressing mould

The invention provides a manufacturing method for a glass fiber reinforced plastic pressing mould. Unsaturated polyester resin and glass fibers are used as main materials for the pressing mould, and steel is used as a framework to fix the pressing mould. The manufacturing method comprises the following steps: fabricating a wood mould or a plaster mould according to product design requirements; brushing a gel coating on the waxed mould; pasting alkali-free surfacing mat, with an impregnating compound being an S-904 resin mixture; pasting alkali-free chopped strands of the glass fibers; pasting medium-alkali glass fiber plaid; pasting a plurality of layers of medium-alkali glass fiber plaid, with an impregnating compound being an S-685 resin mixture; pasting a plurality of layers of medium-alkali glass fiber plaid again, with an impregnating compound being an S-191 resin mixture, so as to finish fabrication of the glass fiber reinforced plastic pressing mould. According to needs of the mould, the framework for the mould is welded, flat steel and support are installed, and the glass fiber reinforced plastic pressing mould is fixed on the framework for the mould by using countersink bolts. According to the invention, manufacturing cost for the glass fiber reinforced plastic pressing mould is low, readjusting and remodification of the mould can be carried out, and products capable of satisfying current performance requirements for interior decorative parts for automobiles can be produced.

Owner:GUIZHOU HUAYUN AUTOMOBILE DECORATING PART MFG CO LTD

Glass reinforced plastic boat production method

ActiveCN101417510AReduce labor intensityReduce pollutionWaterborne vesselsDomestic articlesVacuum pumpingEngineering

The invention relates to ships, in particular to a method for manufacturing glass reinforced plastic ships. The steps are as follows: mould manufacture, waxing, gel coat spraying, hull moulding, hull strengthening, first column laying, demoulding cloth paving and compressing, guide cloth paving and compressing, spiral tube laying, vacuum tube laying, vacuum film packaging and compressing, vacuum pumping, resin guiding, and the like. The method has the advantages of unique technology, smooth ship surface, short production cycle, low labor intensity, and the like, and environmental pollution can be reduced further.

Owner:WEIHAI ZHONGFU XIGANG SHIP

Production technology for glass reinforced plastic hand washer and face washing cabinet

ActiveCN102837346AReduce manufacturing costShorten the production cycleWood working apparatusEngineeringPutty

The invention discloses a production technology for a glass reinforced plastic hand washer and a face washing cabinet. A method comprising the steps of split pasting, cutting, polishing and then assembling is mainly adopted. The production technology comprises the following steps: (1) manufacturing a hand washer / face washing cabinet wood mould: firstly selecting materials, dividing the product into three parts, namely, a hand washer / face washing cabinet platform, a vertical surface and a check surface, according to the dimension of the product, respectively manufacturing the wood mould, coating putty and polishing; (2) manufacturing a glass reinforced plastic mould: coating release agent and gel coat, and then pasting; (3) treating the surface of the glass reinforced plastic mould: performing water sand grinding and surface polishing; (4) pasting; (5) de-molding; and (6) cutting and assembling. The production technology is low in production cost and shorter in production period. The produced glass reinforced plastic hand washer and face washing cabinet are highly polished.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

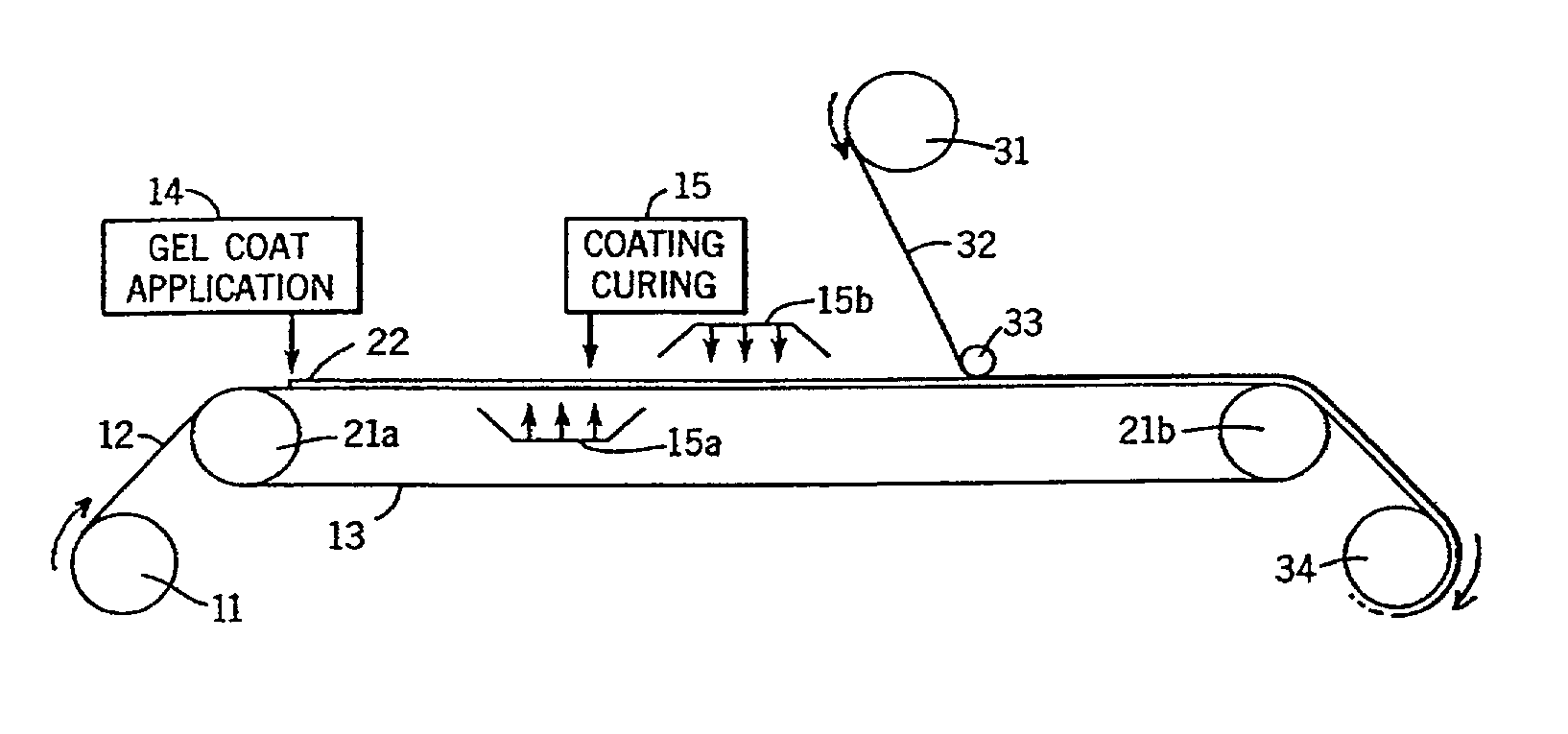

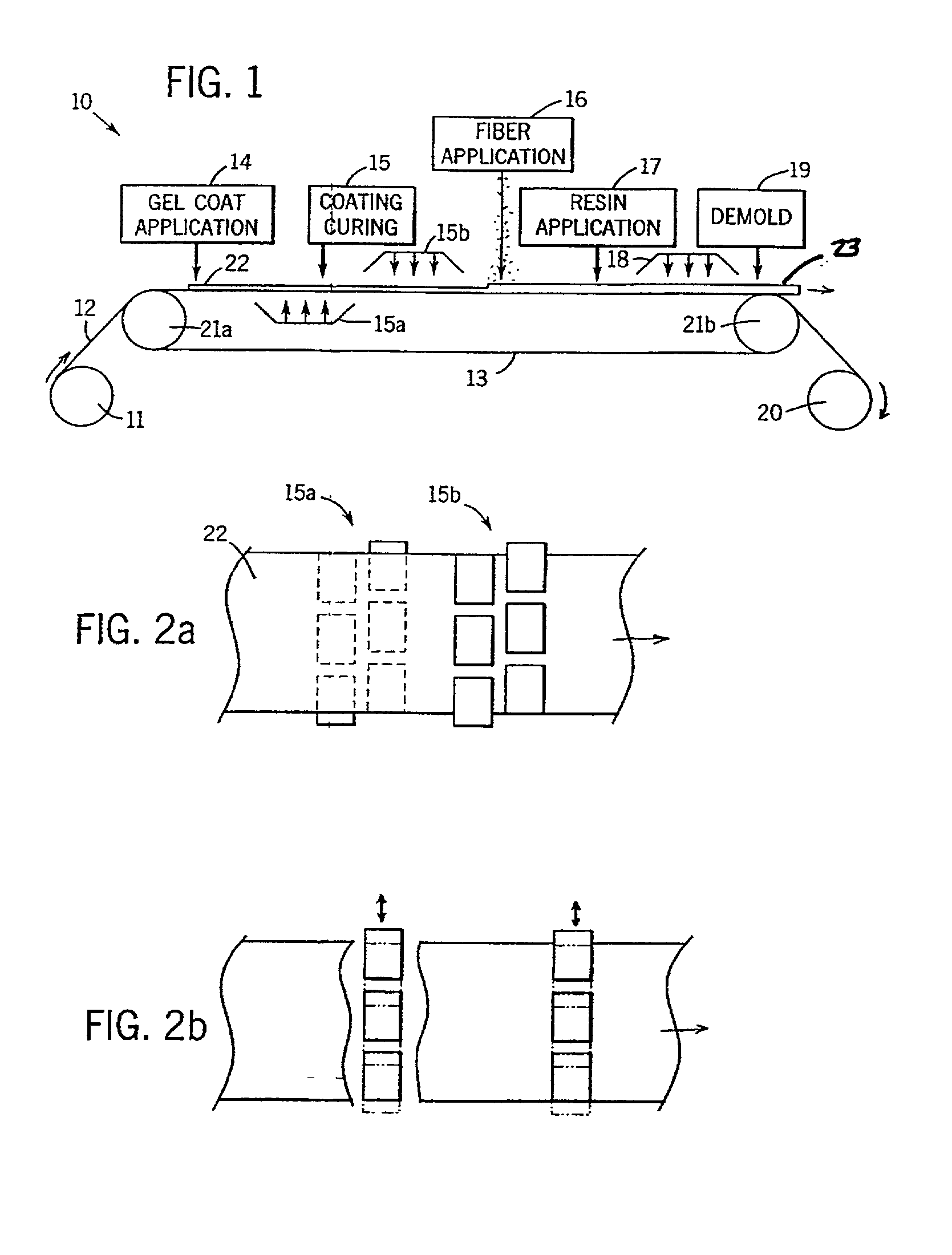

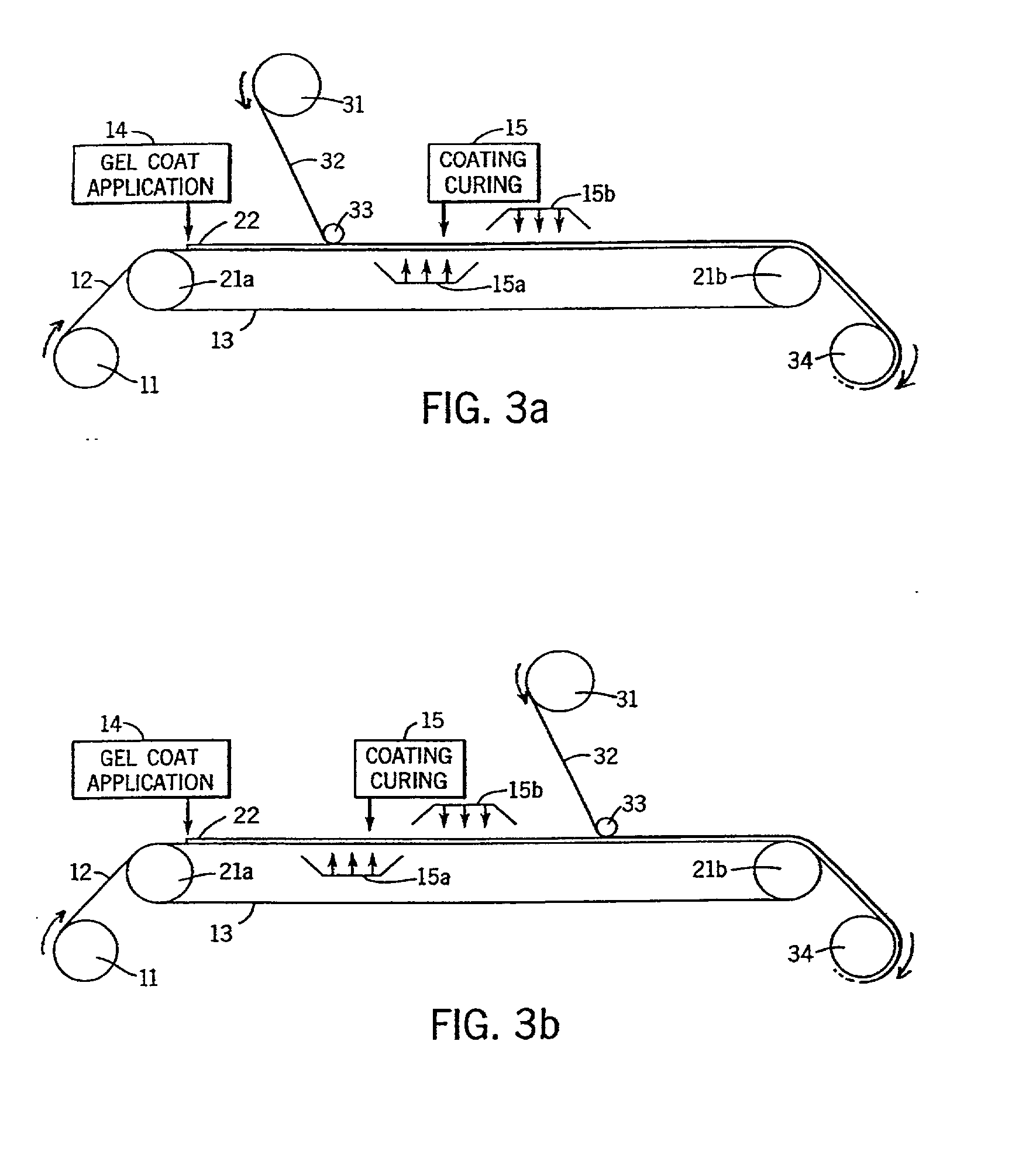

Curing of a gel coat on a mold

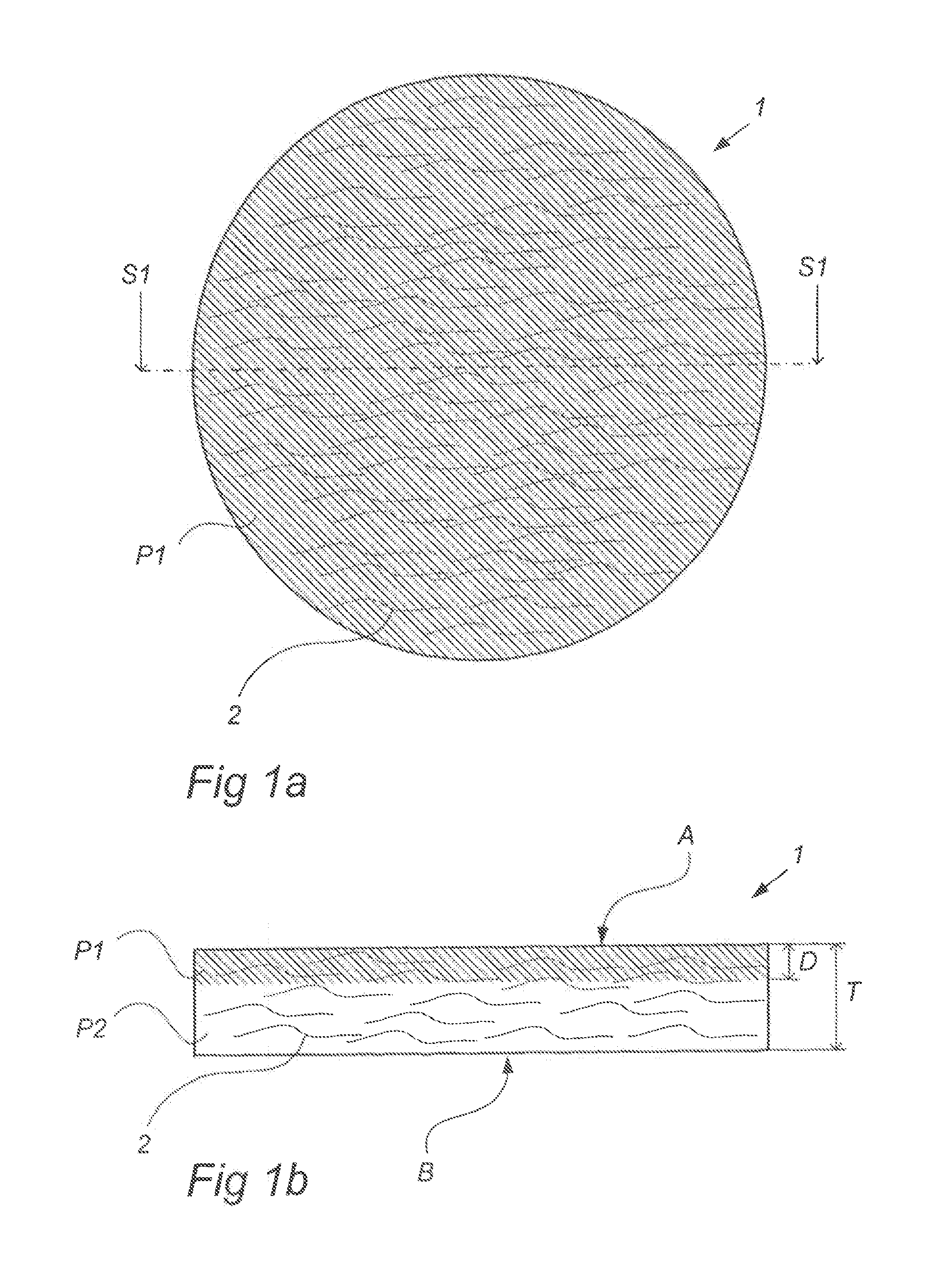

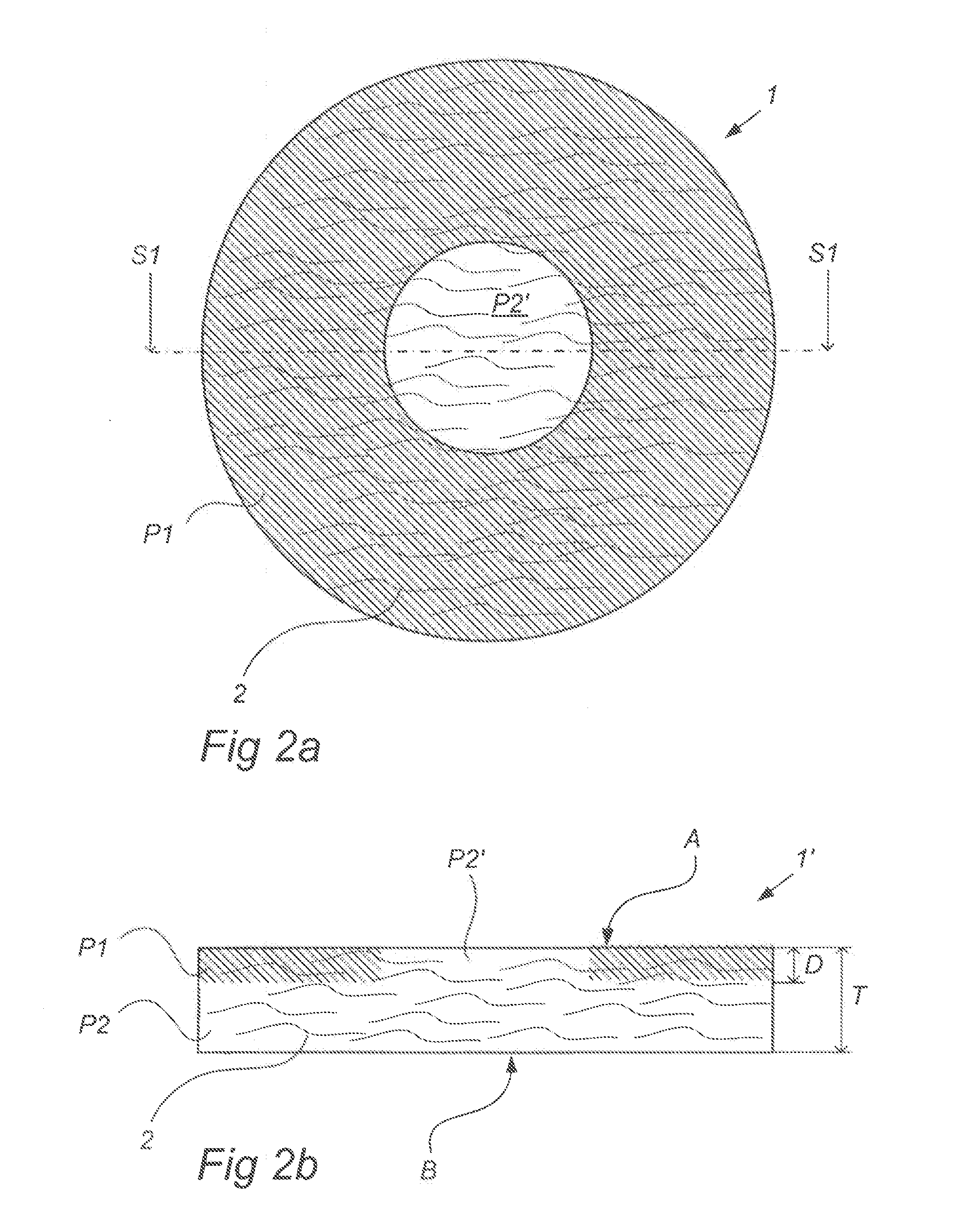

InactiveUS20020000290A1Maintain good propertiesLow viscosityLamination ancillary operationsLaminationCoated surfacePolyester

Partially cured gel coats are prepared in a manner for subsequent application to a substrate, e.g. a reinforcing polymer matrix, by a process comprising the steps of: A. Applying a gel coat, e.g., an unsaturated polyester resin, to a nonporous mold, e.g., a polyester film, which is at least partially transparent to actinic radiation, e.g. UV light; and B. Exposing the surface of the gel coat that is in contact with the film, i.e., the bottom surface, to actinic radiation that has first passed through the mold. In certain embodiments of the invention, the surface of the gel coat opposite the bottom surface, i.e., the top surface, is exposed to actinic radiation shortly after the bottom surface is exposed to the actinic radiation to effect a bi-directional cure of the gel coat. The gel coat produced by the process of the invention is nonporous and essentially defect-free.

Owner:COOK COMPOSITES & POLYMERS CO

Low styrene volatilization unsaturated polyester gel coat resin and preparation method thereof

The invention relates to a low styrene volatilization unsaturated polyester gel coat resin used for the surface of a composite material, and a preparation method thereof. The gel coat resin which is prepared by carrying out high speed dispersion on an unsaturated polyester resin, a thixotropic agent, a filler, styrene, a defoamer, a styrene volatilization inhibitor and the like is suitable for spraying. The unsaturated polyester resin for preparing the gel coat resin, which has the characteristics of low viscosity, high solid content and high strength, is a special unsaturated polyester resin developed for the low styrene volatilization unsaturated polyester gel coat resin. The low styrene volatilization unsaturated polyester gel coat resin of the invention, which can be widely applied to the surface of the composite material, can decorate and protect the composite material; and simultaneously the gel coat resin can greatly reduce the styrene volatilization in the gel coat construction process, so the gel coat resin is in favor of the environmental protection.

Owner:CHANGZHOU HUAKE POLYMERS

Method of making hull of fishing boat and yacht with basalt fiber reinforced material

InactiveCN1421351AIncrease loading capacityReduce resistanceNon-magnetic metal hullsHeat stabilityFishing

The present invention is the method of making hull of fishing boat and yacht with basalt fiber reinforced material. The material used includes twist-less basalt rove or fabric, unsaturated polyester resin or epoxy resin, promoter and other supplementary material. The making process includes spreading the basalt material, spraying resin, curing, demolding and other steps. The basalt fiber has acidand alkali resistance, heat stability, tensile strength and other mechanical performance superior to those of common glass fiber. Making hull of fishing boat and yacht with basalt fiber reinforced material can result in improved performance and lowered cost.

Owner:周献刚 +1

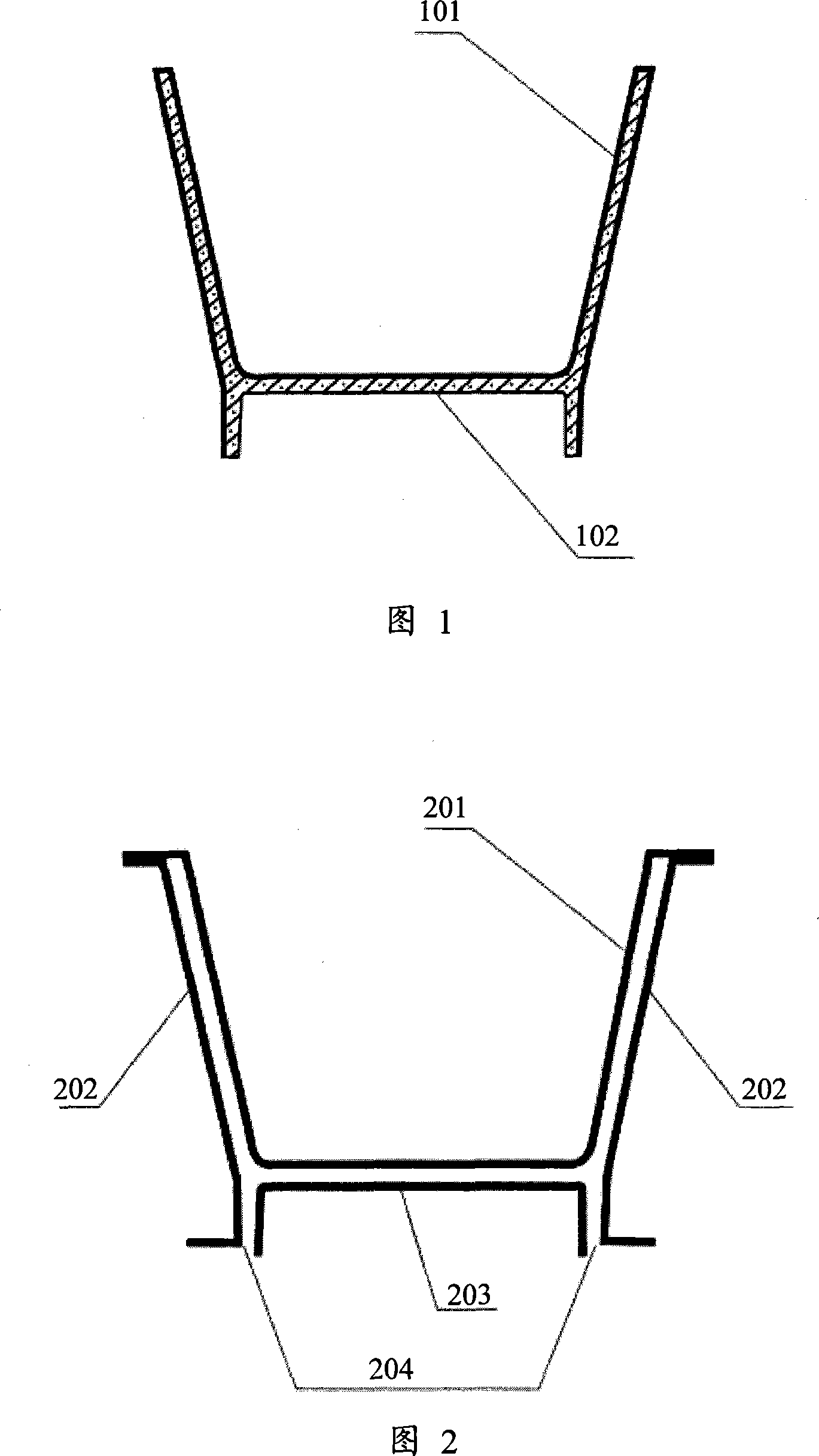

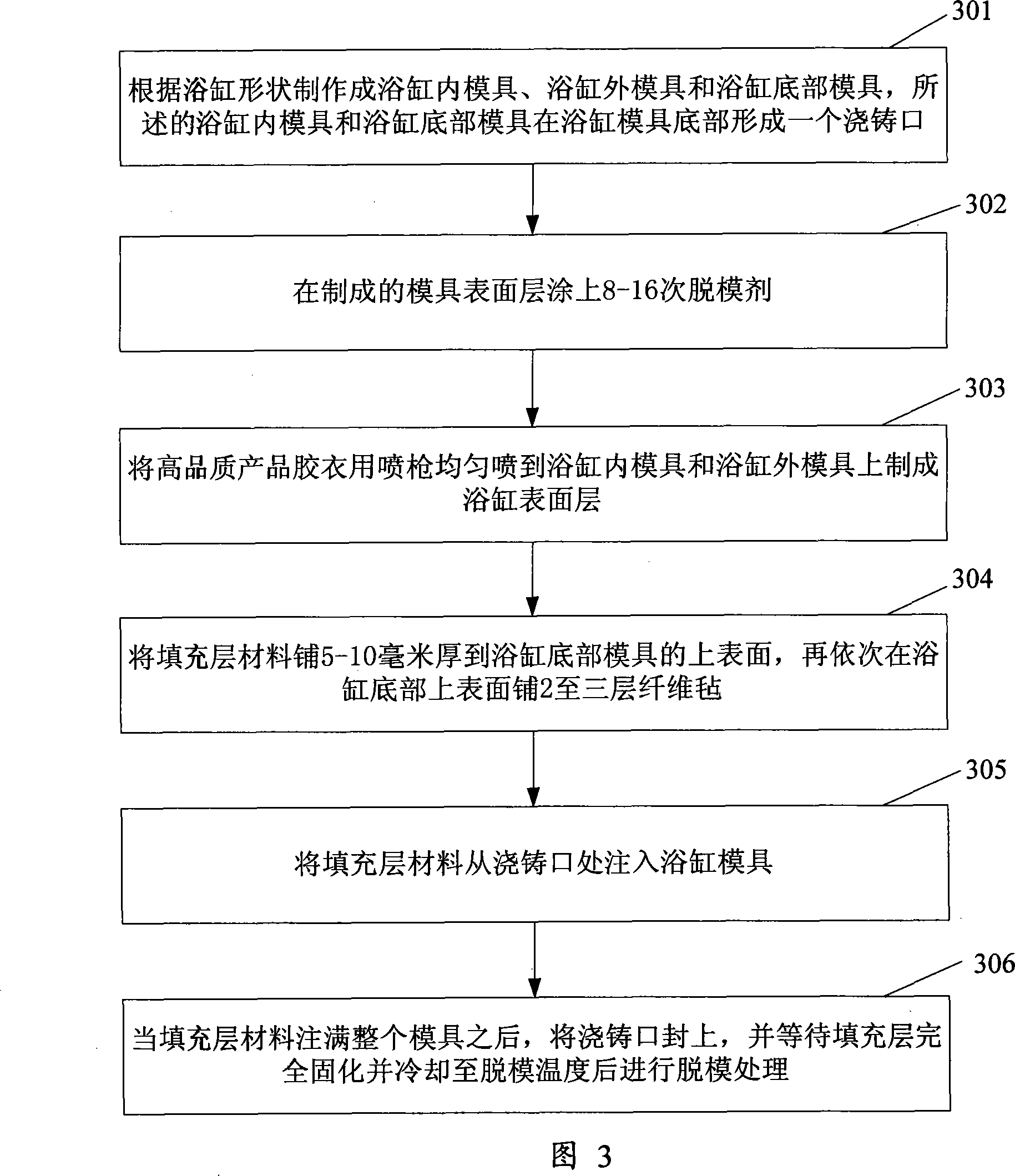

Artificial stone integral bathtub and method for making same

InactiveCN101181823AGood insulation performanceStrong ability to withstand pressureBathsDouchesFilling materialsBathtub

The invention discloses a manufacturing method of an artificial stone integrated bathtub, the method comprising the following steps: making a bathtub inner mold, a bathtub outer mold and a bathtub bottom mold according to the shape of the bathtub, and the bathtub inner mold and the bathtub bottom mold are located at the bottom of the bathtub mold Form a casting port; apply a release agent on the inner surface of the bathtub mold; spray the high-quality product gel coat evenly on the inner surface of the inner mold of the bathtub and the outer mold of the bathtub to form the surface layer of the bathtub; Spread the filling layer material on the upper surface of the mold at the bottom of the bathtub, and then spread the fiber felt on the filling layer material at the bottom of the bathtub in turn; inject the filling layer material into the bathtub mold from the casting port; when the filling layer material fills the entire mold, put The casting mouth is sealed, and the demoulding process is performed after the filling layer is completely solidified and cooled to the demoulding temperature. The invention also discloses an artificial stone integral bathtub, which has a simple manufacturing method and good thermal insulation performance of the bathtub.

Owner:罗桂华

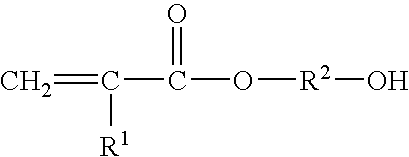

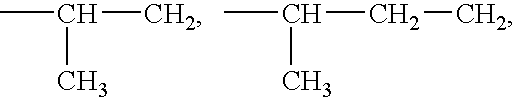

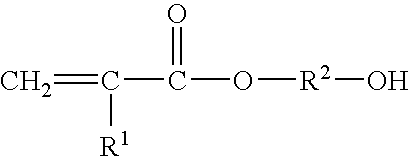

Urethane acrylate gel coat resin and method of making

InactiveUS20060167208A1Improved color stabilityGood weather resistancePolyurea/polyurethane coatingsPolyesterMeth-

An improved urethane acrylate gel coat resin, its method of manufacture, and its use in gel coat compositions are disclosed. The urethane acrylate gel coat resin contains terminal acrylate moieties and is the reaction product of an oligoester of weight average molecular weight about 200 to about 4000, a diisocyanate, and a hydroxyalkyl (meth)acrylate. The gel coat resin is used in gel coat compositions that exhibit good weatherability and color stability after cure.

Owner:VALSPAR SOURCING INC

Shell of anticorrosion distribution box and preparation method thereof

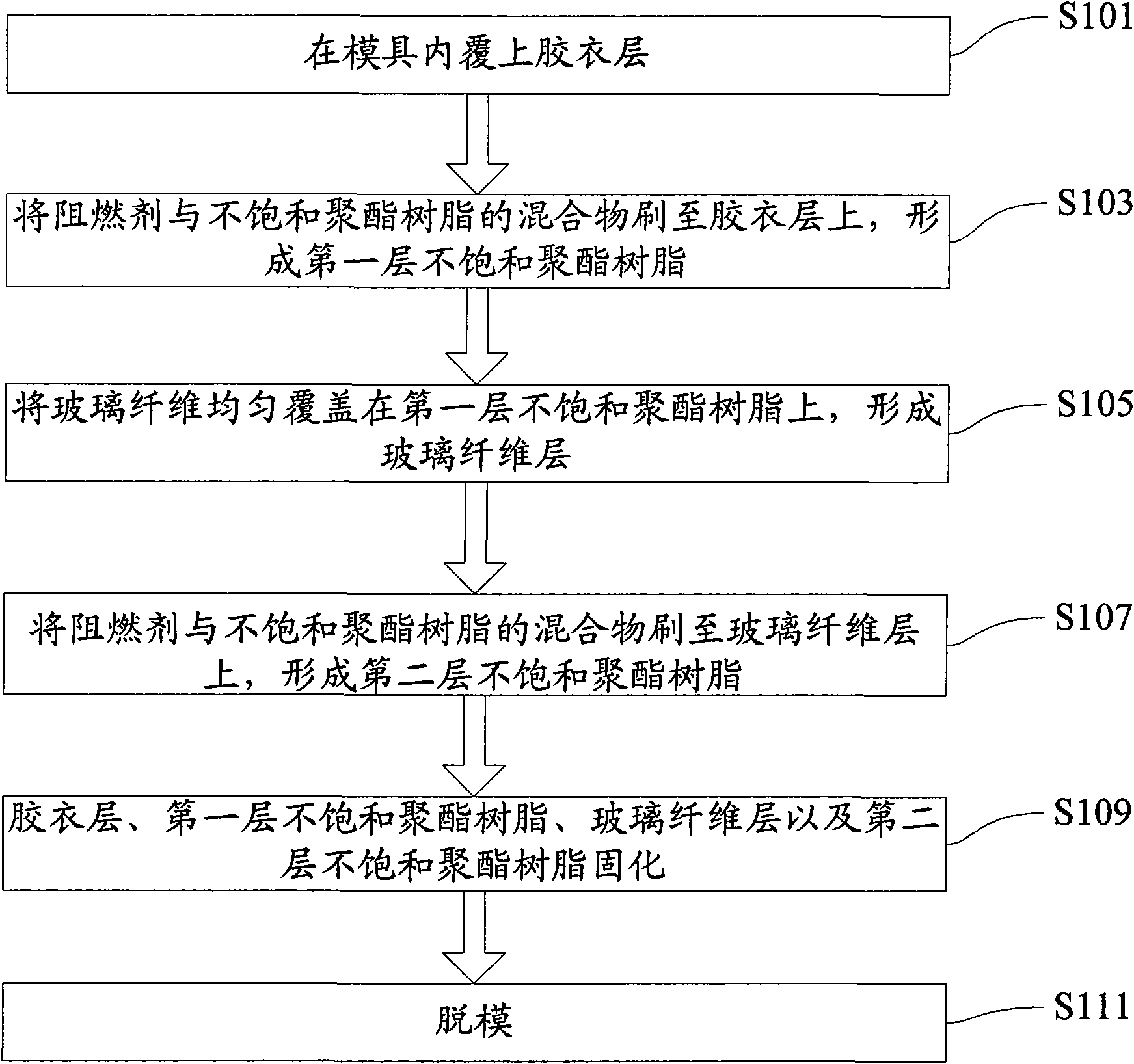

The invention provides a shell of an anticorrosion distribution box and a preparation method thereof. The method for preparing the shell of the anticorrosion distribution box comprises the steps: a) covering a gel coat layer in a mold; b) brushing a mixture of a fire-retardant agent and an unsaturated polyester resin onto the gel coat layer to form a first layer of the unsaturated polyester resin; c) evenly covering glass fiber on the first layer of the unsaturated polyester resin to form a glass fiber layer; d) brushing the mixture of the flame retardant and the unsaturated polyester resin onto the glass fiber layer to form a second layer of the unsaturated polyester resin; e) solidifying the gel coat layer, the first layer of the unsaturated polyester resin, the glass fiber layer and the second layer of the unsaturated polyester resin; and f) demolding. Components according to the mass ratio are as follows: 28 to 32 percent of the glass fiber, 63 to 67.5 percent of the unsaturated polyester resin, and 4.5 to 5 percent of the fire-retardant agent. The shell of the anticorrosion distribution box has the advantages of paint-free property, bright and clean appearance, light weight, corrosion resistance, ultraviolet resistance, fire retardance and long service life.

Owner:JIANGSU HENGKAI ELECTRIC

Unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and paint preparation method thereof

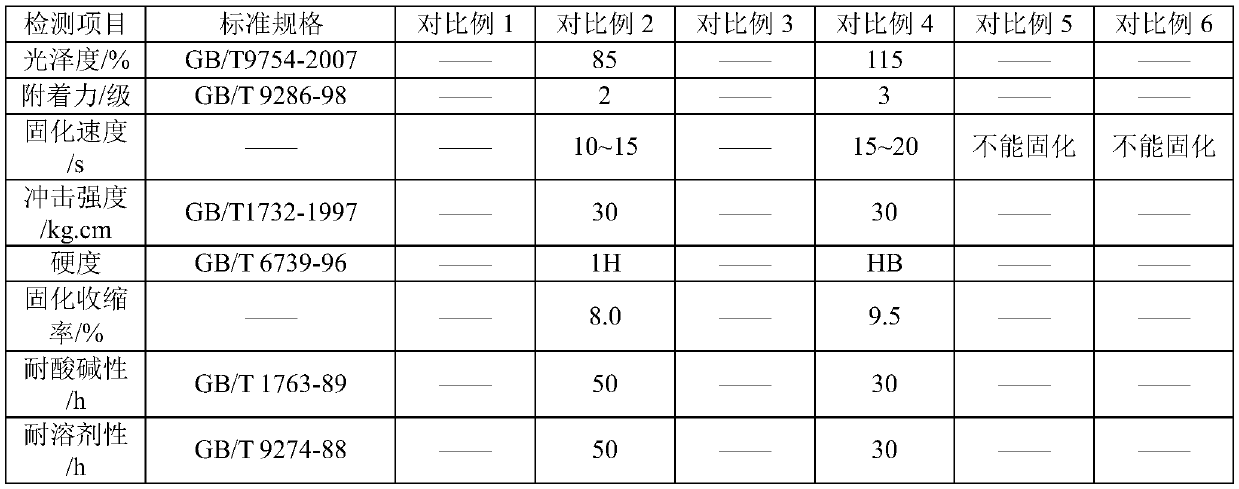

ActiveCN105504245AImprove performanceImprove corrosion resistancePolyester coatingsPolyesterShrinkage rate

The invention discloses unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and a paint preparation method thereof. The unsaturated polyester paint is prepared from 90-100 parts of unsaturated polyester gel coat resin, 10-30 parts of activated thinner, 1-5 parts of photoinitiator, 1-3 parts of coinitiator, 0-20 parts of talcum powder, 0-0.5 part of dispersing auxiliary and 0.5-3 parts of other auxiliaries. The weight ratio of photoinitiator to coinitiator is (1-5):(1-3), and unsaturated polyester gel coat resin is a mixture of acrylate-terminated unsaturated polyester and activated thinner. A coating can be prepared from the paint through the UV-LED photocuring technology, deep solidification of a film 200 micrometers thick on a woodware base material can be achieved, and the coating is low in shrinkage rate, good in acid resistance and alkaline resistance, high in luster and good in adhesive force.

Owner:GUANGDONG UNIV OF TECH +1

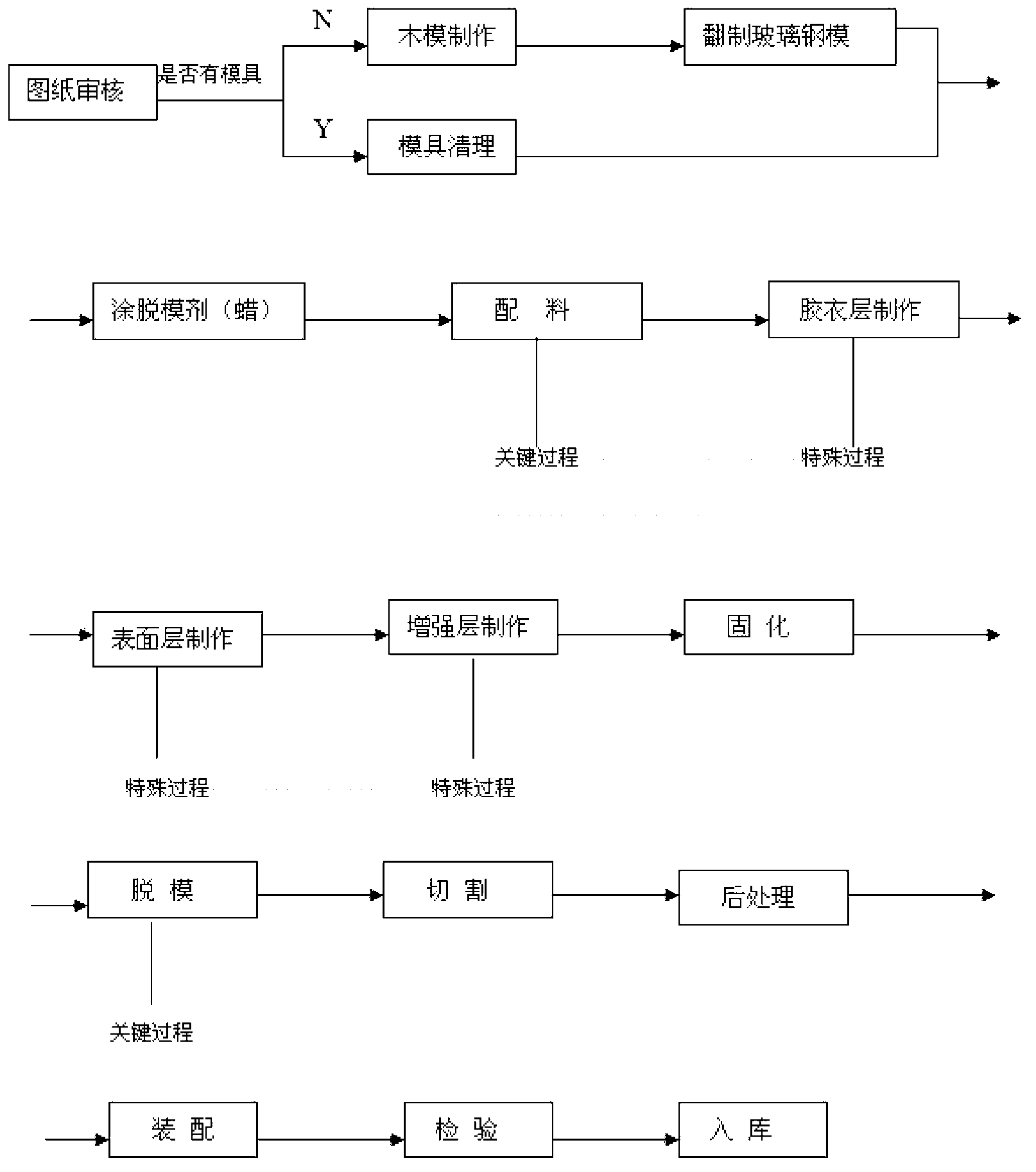

Glass fiber reinforced plastic processing technology

ActiveCN102001212AReduce pollutionReduce manufacturing costLamination ancillary operationsSynthetic resin layered productsGlass fiberFiber

The invention relates to the field of composite materials, in particular to glass fiber reinforced plastic processing technology. The following technical scheme adopted in the invention is that: the glass fiber reinforced plastic processing technology mainly comprises the following steps of: spraying an unsaturated polyester gel coat on a die; gelling the unsaturated polyester gel coat at normal temperature; laying a resin glass fiber layer on the unsaturated polyester gel coat; wrapping the outer part of the resin glass fiber layer with nylon cloth and flatly compacting; curing and molding at a high temperature; and cooling at normal temperature after the curing and forming, and uncovering the nylon cloth. Through the technical scheme, a glass fiber reinforced plastic product can solve the surface quality problem at one time during machine shaping, later grinding and repairing are not needed, the production cost and pollution to air are reduced.

Owner:ANHUI JINCEN COMPOSITES

Artificial carved stone as decoration

InactiveCN1363475AImprove permeabilityEasy to glueNatural patternsOrnamental structuresControl layerSurface layer

An artificial carved stone as decoration is composed of the surface layer prepared from resin and pigment, the central layer prepared from unsaturated polyester resin, pigment and heavy calcium carbonate, and skeleton layer prepared from unsaturated polyester resin, pearlite, and pigment. It is made up through coating demoulding agent on the inner surface of mould, sequentially coating surface layer, control layer and skeleton layer, natural solidifying, demoulding and trimming. Its advantages include light weight, low cost and beautiful appearance.

Owner:郭旭清

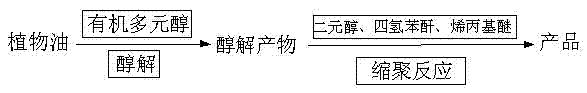

Unsaturated polyester resin for machine-made or hand-pasted plane skylight and preparation method thereof

InactiveCN102181017AGood water and weather resistanceGood water and aging resistanceGelcoatUnsaturated polyester

The invention relates to the technical field of preparation of high polymer materials, in particular to unsaturated polyester resin for a machine-made or hand-pasted plane skylight and a preparation method thereof. The preparation method comprises the following steps of: undergoing an esterification reaction on organic polylol, saturated or unsaturated polyatomic acid or acid anhydride and a monofunctional compound in the presence of catalyst; and dissolving a polymer prepared by condensing in inhibitor-containing cinnamene to obtain the unsaturated polyester resin. The invention has the advantages that the unsaturated polyester resin is prepared from lower-cost raw materials and has low preparation cost; and lower viscosity and good glass fiber wetting property are achieved while the strength is ensured. The resin and the compound of the resin can be widely applied to products, such as automobile parts, gel coatings, artificial stones and the like with higher requirements on weather resistance, in particular to weather-resistant plates.

Owner:CHANGZHOU HUAKE POLYMERS

Manufacturing process for glass fiber-reinforced plastic product

The invention discloses a manufacturing process for a glass fiber reinforced plastic product. The manufacturing process comprises the following steps: S1, material selection: selecting an appropriateamount of unsaturated resin, glass fibers and a gel coat; S2, mold preparation: cleaning the mold, wiping the mold with soft gauze to thoroughly eliminate impurities on the surface of the mold, and then carrying out drying to remove water stains; S3, coating of a release agent: uniformly coating the interior of the mold with the release agent, wherein it is ensured that every corner is coated, polyvinyl alcohol has to be thoroughly dried, and two-hour standing is needed for polishing wax, non-silicone oil paste and other release agents so as to allow solvents to volatilize; and S4, coating ofgel coat resin, wherein a hairbrush may be used for brushing, and the gel coat is cured to the extent that the gel coat feels slightly sticky in contact but does not stain the fingers. Compared with other production processes, the manufacturing process of the invention is low in price, reduced in needed space and mature in technology; and the prepared glass fiber-reinforced plastic product has good processability and good comprehensive performance after curing, is more and more widely applied to construction, corrosion prevention, shipbuilding, transportation, the automobile industry, the electric appliance industry, etc., and is greatly improved in quality.

Owner:NANAN CHUANGPEI ELECTRONICS TECH CO LTD

Air-drying unsaturated polyester resin for easy-polishing gel coat, and preparation method thereof

The present invention relates to the technical field of polymer material preparation, and especially to an air-drying unsaturated polyester resin for an easy-polishing gel coat, and a preparation method thereof. The resin is prepared by the following steps, wherein the steps comprise that: an organic polyol and a renewable vegetable oil are subjected to an ester exchange reaction, and then are subjected to a condensation polymerization with a small molecule dihydric alcohol or a dibasic acid, tetrahydrophthalic anhydride and allyl ether; the formed polymer is dissolved in styrene to prepare the resin. The air-drying unsaturated polyester resin of the present invention has the following advantages that: (1) the renewable vegetable oil is selected as the main component, such that the use of the toxic and harmful chemical engineering raw materials is reduced so as to meet the green environmental protection concept; (2) the vegetable oil, the tetrahydrophthalic anhydride, the allyl ether and the like in the resin component provide good air-drying properties, such that the resin can be widely applicable for the fields with high air-drying requirements. The resin of the present invention is mainly applicable for the easy-polishing gel coat with the high air-drying requirements, and has characteristics of excellent toughness, excellent adhesion, excellent weather resistance, excellent polishing property and the like. In addition, the resin of the present invention has good air-drying property, and the gel coat prepared by the resin of the present invention has characteristics of good adhesion, low porosity, easy polishing and the like.

Owner:CHANGZHOU HUAKE POLYMERS

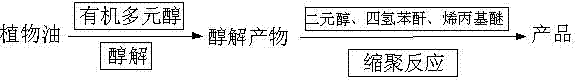

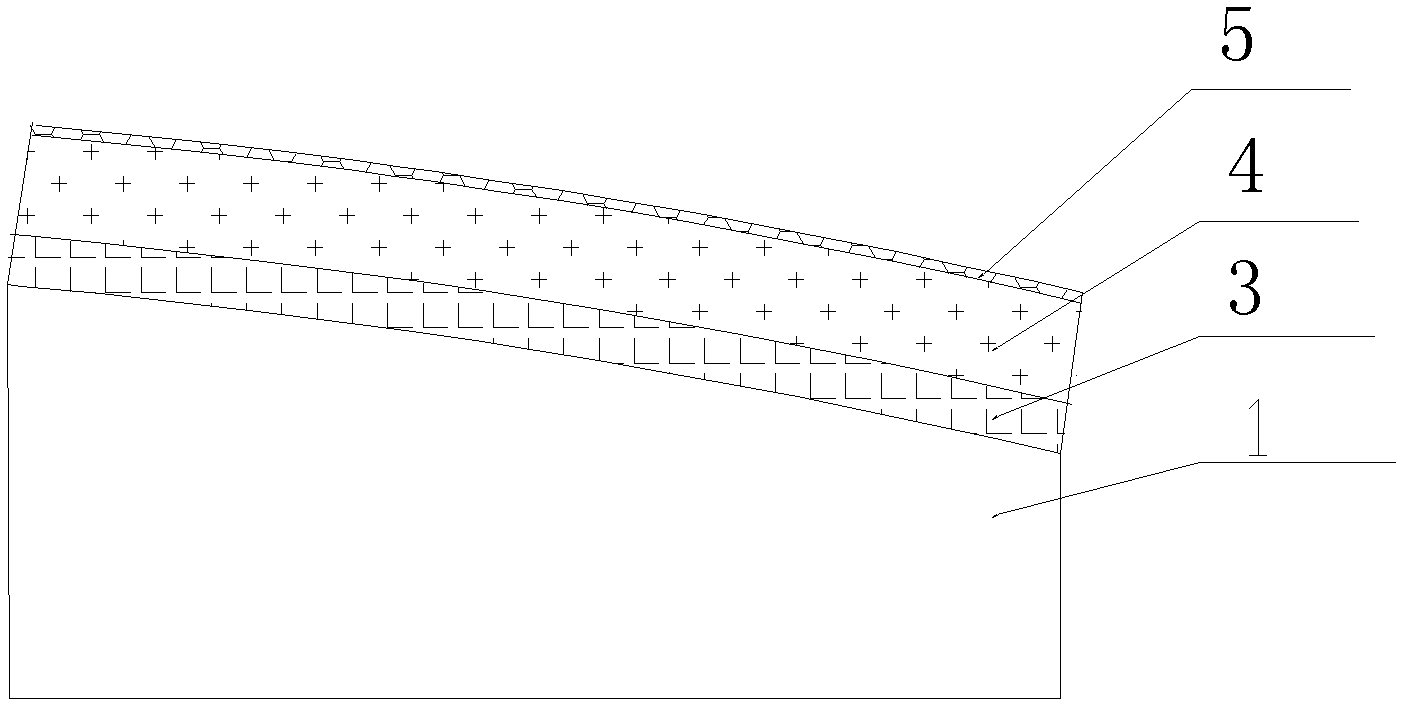

Making process of wind-power blade main model

The invention discloses a making process of a wind-power blade main model, which belongs to the technical field of wind-power blade molding. The process comprises the following steps of: 1) making a metal steel frame platform at the bottom; 2) laying a wood plate; 3) coating epoxy resin white carbon black filler on the surface of the wood plate, placing multiple EPS (Expandable Polystyrene) polystyrene solid foams according to the shape of the designed main model in a laminated way, and bonding and fixing the EPS polystyrene solid foams; 4) machining profiles of the EPS polystyrene solid foams; 5) pasting glass fiber reinforced plastic airtight layers on the machined profiles in the step 4); 6) detecting the vacuum degrees of the glass fiber reinforced plastic airtight layers; 7) uniformly spreading wood substituted epoxy resin layers on the surfaces of the glass fiber reinforced plastic airtight layers which satisfy the vacuum degree requirements, controlling the spreading thicknesses at about 15-35 mm and curing the wood substituted epoxy resin layers at normal temperature; and 8) machining the surfaces of the wood substituted epoxy resin layers; and then coating gel coat layers on the wood substituted epoxy resin layers and curing and molding the wood substituted epoxy resin layers to obtain the main model. The main model made by using the process disclosed by the invention has the advantages of high profile precision, easiness for construction operation, low making cost as well as contribution to promotion and application.

Owner:北玻院(滕州)复合材料有限公司

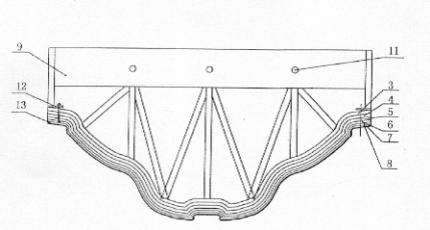

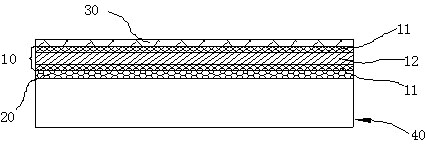

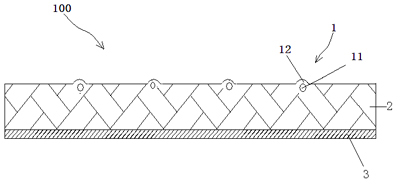

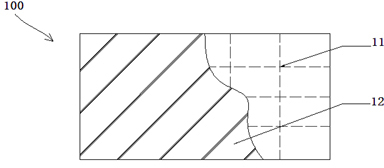

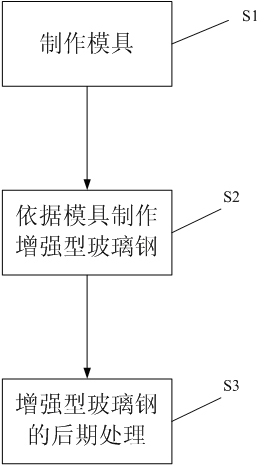

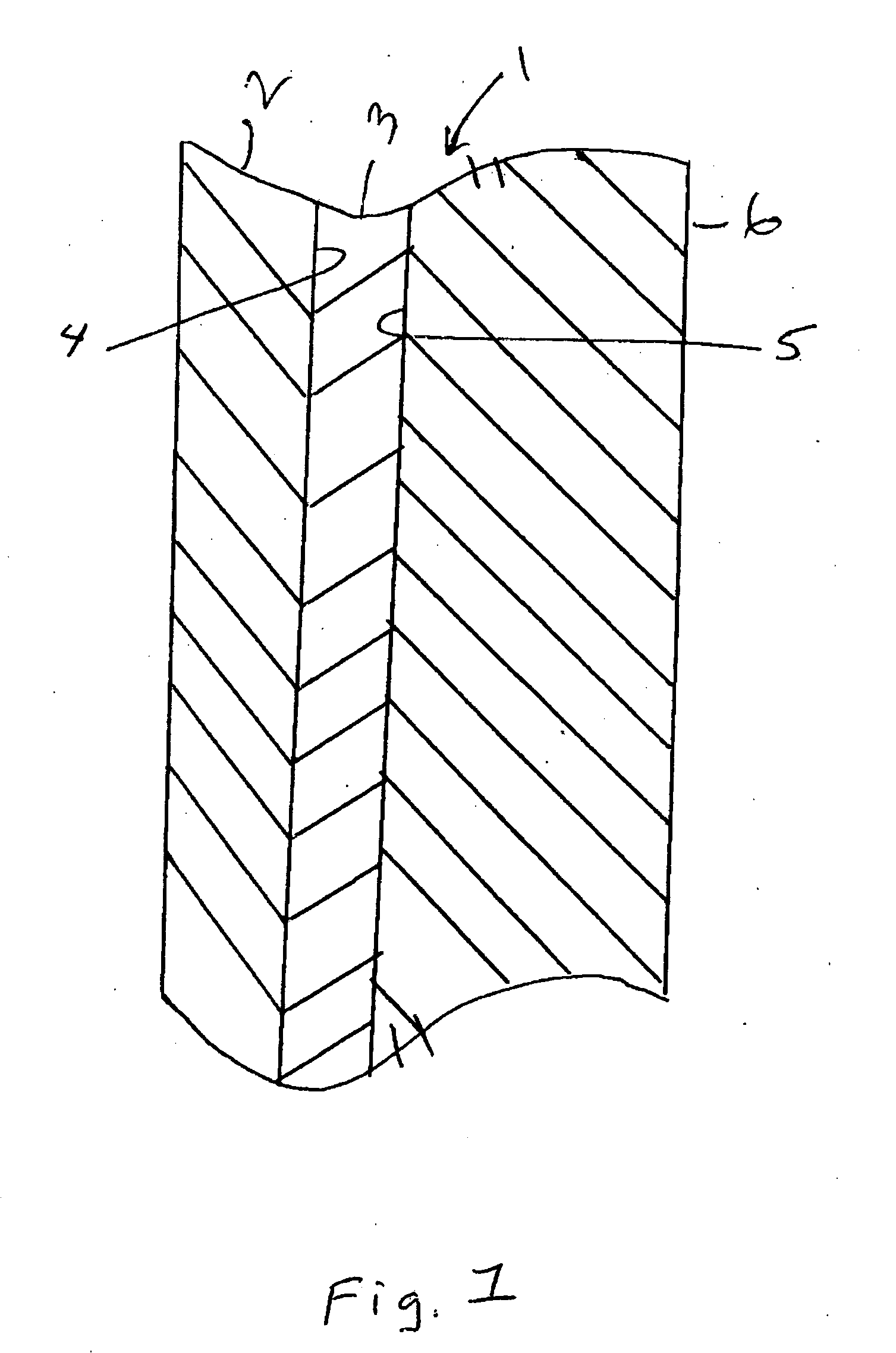

A kind of reinforced fiberglass and its manufacturing method

InactiveCN102275345AHigh tensile strengthStrong toughnessGlass/slag layered productsGlass fiberGelcoat

The invention discloses a method for manufacturing reinforced FRP, which includes the following steps: S1: making a mold; S2: making reinforced FRP according to the mold, the reinforced FRP includes: a gel coat layer on the surface and a glass fiber layer in the middle , the reinforcement layer positioned at the bottom surface; the glass fiber layer is laid on the gel coat layer, which includes several layers of glass fibers; the reinforcement layer is laid on the glass fiber layer, which includes several reinforcement ribs, and is used for wrapping Several layers of glass fiber for reinforcing ribs; S3: post-processing of reinforced FRP; among them, S2 further includes: S21: spray gel coat on the mold, and wait for it to cure to complete the production of the gel coat layer; S22: in the gel coat layer Laying several layers of glass fiber completely soaked by resin on top, and waiting for it to be solidified and formed, to complete the production of glass fiber layer; S23: laying a reinforcement layer on the basis of S22. Compared with the prior art, the enhanced FRP produced by the invention is not easily deformed, has strong toughness and excellent performance.

Owner:EVERGROW INT TRADING SHANGHAI

Weather-resistant nano-composite gel coat and preparation method thereof

ActiveCN103937388APigment treatment with organosilicon compoundsPolyester coatingsCooling towerAccelerant

The invention discloses a weather-resistant nano-composite gel coat. The weather-resistant nano-composite gel coat consists of the following components in parts by weight: 100 parts of unsaturated polyester resin, 10-30 parts of styrene, 10-25 parts of modified nano ZnO, 5-8 parts of talcum powder, 3-5 parts of titanium dioxide, 1-3 parts of thixotropic agent, 0.1-0.2 part of thixotropic stabilizer, 0.4-1 part of surface additive, 0-10 parts of mill base and 0.1-0.4 part of accelerant. The invention also provides a preparation method of the weather-resistant nano-composite gel coat. The method comprises the following step of 1) adding the talcum powder, the titanium dioxide, the thixotropic stabilizer and the thixotropic agent sequentially to the unsaturated polyester resin; 2), adding the modified nano ZnO into styrene, dispersing at a high speed and adding to the mixture obtained in the step 1); and 3), adding the mill base, the surface additive and the accelerant into the mixture obtained in the step 2). The weather resistant nano-composite gel coat is mainly used for the surface of the glass reinforced plastics of the cooling tower.

Owner:浙江倍斯特制冷科技有限公司

Halogen-free flame retardant gel coat resin and preparation method thereof

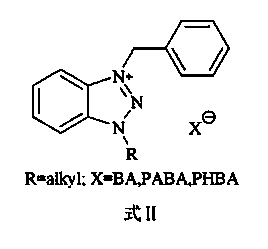

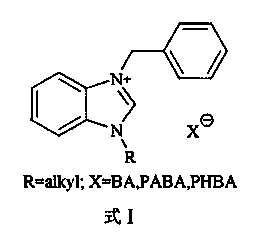

The invention discloses a halogen-free flame retardant gel coat resin which comprises a matrix resin, a thixotropic agent, a liquid additive, color paste, and a flame retardant, wherein the flame retardant is composed of more than three of 1-alkyl-3-benzylbenzimidazole mesylate ionic liquid or 1-alkyl-3-benzyl benzotriazole ionic liquid, and aluminium hydroxide, magnesium hydroxide, ammonium polyphosphate, phosphate and derivatives thereof, silicon nitride, nano montmorillonite, barium sulfate, metal oxides and nano hydrotalcite. According to the halogen-free flame retardant gel coat resin disclosed by the invention, the ionic liquids are used in a flame retardant gel coat, and the addition amount of the ionic liquids is less, but the flame retardant properties of the coat are significantly enhanced. The prepared gel coat resin has the advantages of moderate viscosity, high thixotropy, high solid content, high strength, high flame retardant properties and the like, and is applicable to the surfaces of base resins or laminating materials with high flame retardant requirements for chemical engineering, yachts, textiles and rail transit and the like.

Owner:CHANGZHOU TIANMA GROUP CO LTD

Acrylate-modified aspartates and gel coat compositions made therefrom

A coating composition is provided. The composition comprises as component I, a) a polyaspartic acid ester comprising the reaction product of one more diamines, one or more difunctional acrylate-containing compounds and one or more maleic / fumaric acid esters; b) at least one moisture scavenger; c) at least one deaerator; d) at least one plasticizer; and e) optionally additives; and as component II, one or more polyisocyanates. Methods of making and applying the composition to a substrate are also provided. The coating is particularly suitable for use as a gel coat.

Owner:COVESTRO LLC

Sprayable hardtop coating

A coating suitable for spraying onto a substrate comprises a gel coat and a filler. Preferably the weight of filler exceeds the weight of the gel coat. Preferably the filler is unground, that is, no secondary grinding operation is required to be performed on the filler prior to mixture with the gel coat. Preferably the coating has less than 17.5% by weight reactive monomer.

Owner:R J MARSHALL COMPANY THE

Accelerated curing of epoxy gelcoats

InactiveUS20030130481A1Reduced room temperature gel timeDecrease room temperature gelling timePretreated surfacesCoatingsVitrificationAccelerated curing

Aqueous solutions of inorganic nitrate salts are used to accelerate the gelling of epoxy gelcoat resins without adversely affecting the glass transition temperature of the finally cured gelcoat. The aqueous accelerants may be used to accelerate gelling of gelcoats that are formed during initial fabrication of composite parts. The aqueous acclerants are also useful for shortening the gel time of gelcoats that are intended for use in repairing damaged structures.

Owner:HEXCEL COMPOSITES LTD (GB)

Vacuum infusion machining method for weather-resistant fiberglass reinforced plastics (FRP) products

The invention provides a vacuum infusion machining method for weather-resistant fiberglass reinforced plastics (FRP) products. The method comprises the steps of preparing a mould - applying gel coat - laying at least three layers of fiberglass - laying an isolating membrane with holes - laying and arranging guide pipes - laying a guide net - laying a vacuum bag - vacuum pumping - resin leading-in - demoulding; the laying sequence of the guide pipes and the guide net in the traditional vacuum infusion machining method is changed, and the inside surfaces of the FRP products prepared are free of pipe pressure traces; the gel coat resin prepared is made of raw material constituents which are excellent in performance and able to coordinate with each other, and the gel coat prepared is excellent in weatherability and able to prevent early aging of the FRP products in high temperature, severe cold or other environments; the basic resin in the invention is able to infiltrate the fiberglass properly, and the FRP products prepared finally is high in quality and stability, excellent in weatherability, and applicable for outdoor use.

Owner:CHONGQING HAIQING NEW MATERIAL

Regenerating surface properties for composites

ActiveUS20110129646A1Reduce noiseReduce fluid resistanceMouldsFinal product manufacturePolyresinGelcoat

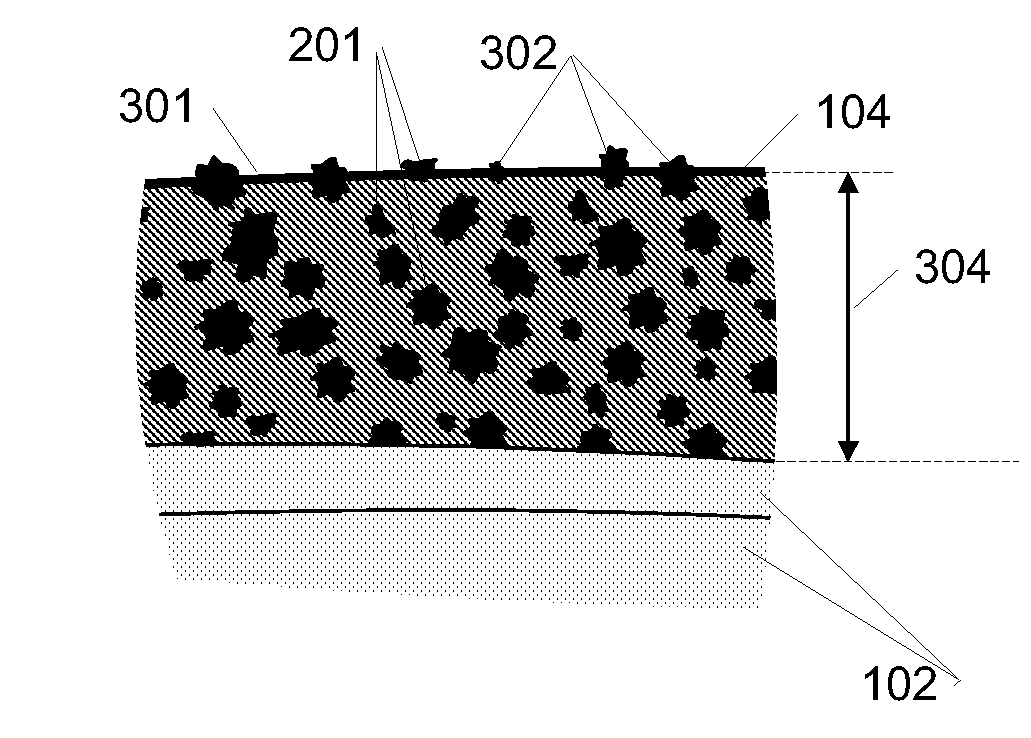

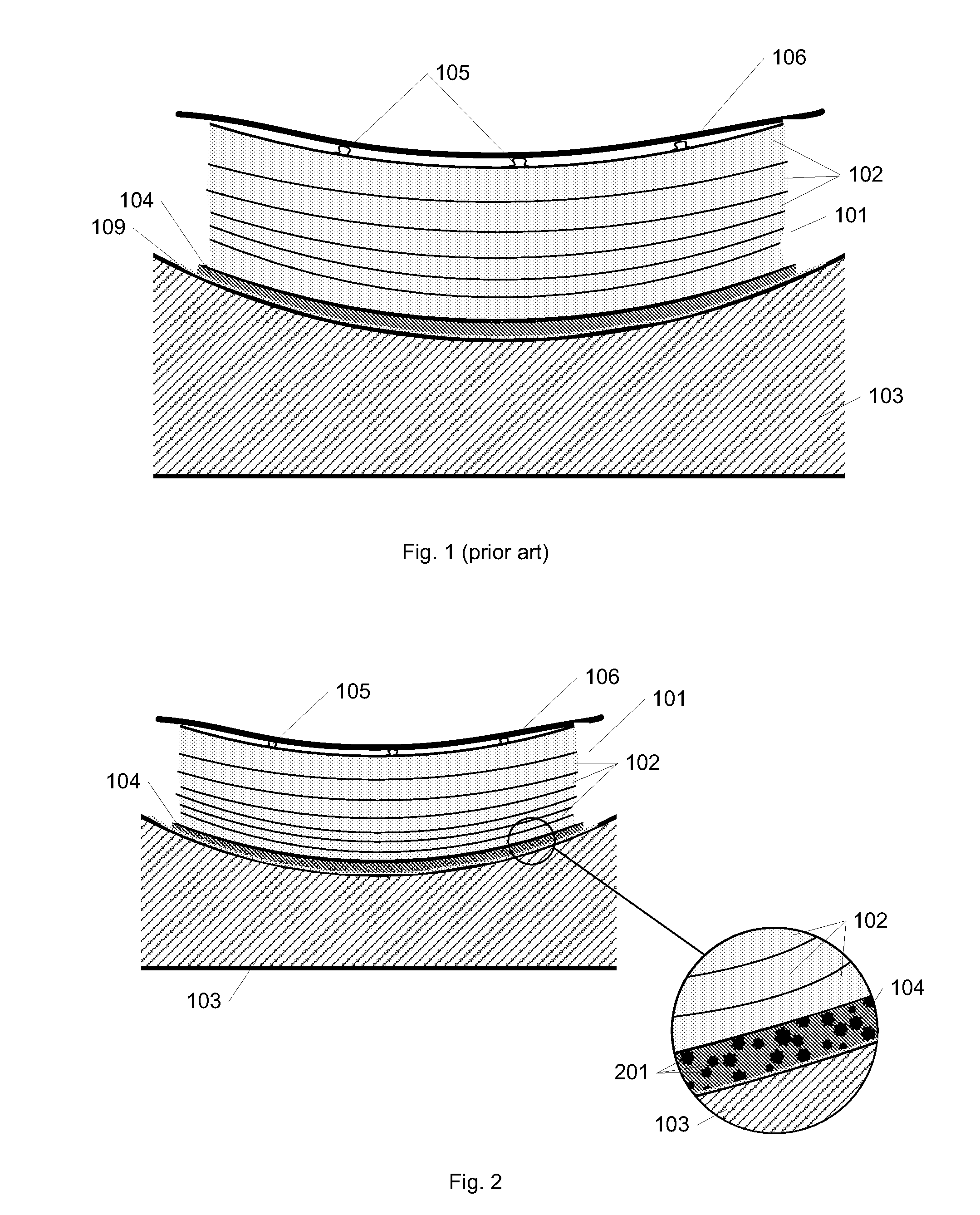

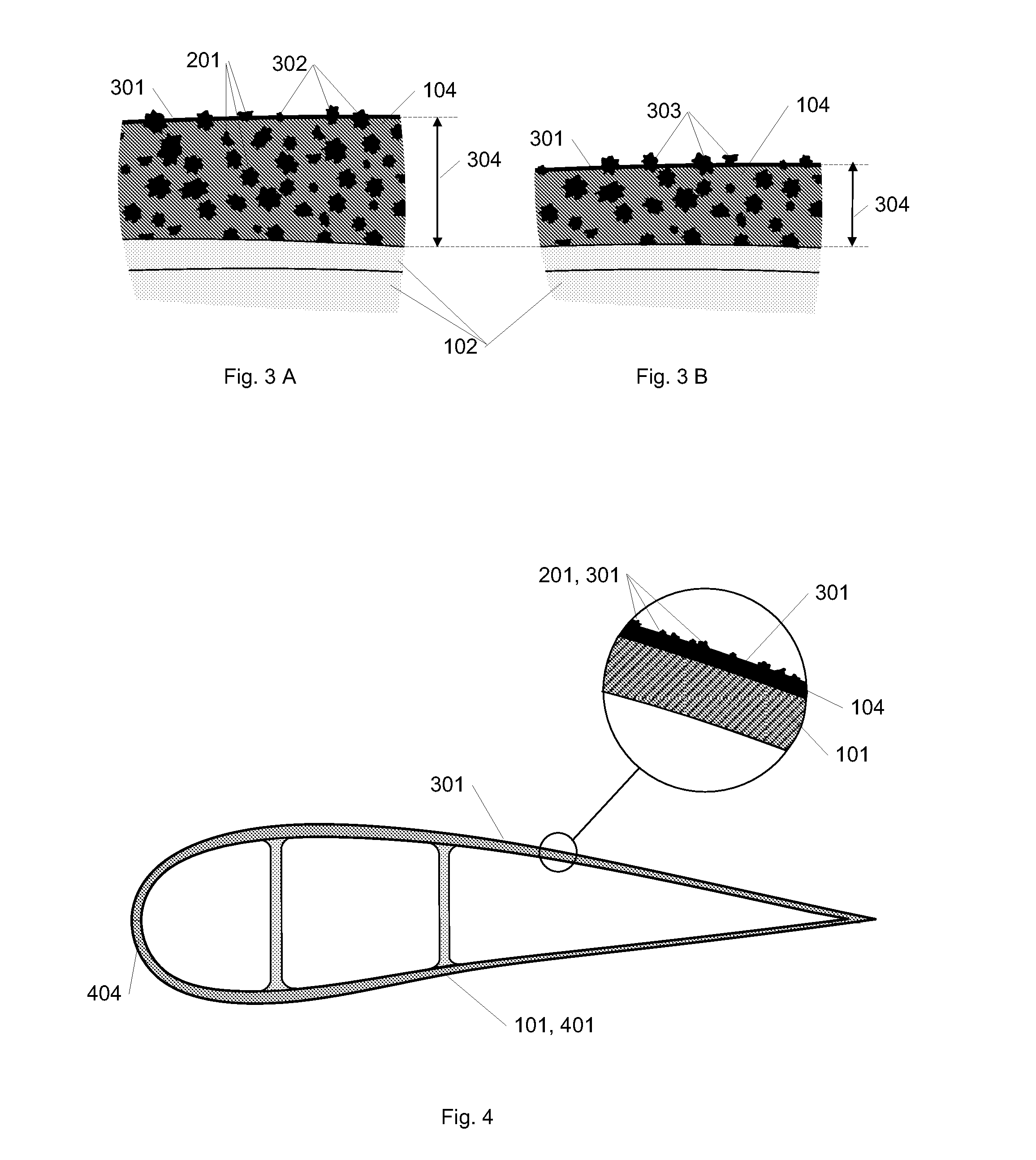

This invention relates to a method for manufacturing a composite member, where a number of different material layers including at least one layer of gelcoat are applied in a mould, and where resin is applied for joining of the layers. The method is new in that particles are added to the gelcoat, whereby the gelcoat comprising such particles forms an outermost layer on at least a part of the manufactured composite member. Hereby is obtained a composite with a hydrophobic and lotus-like surface yielding good self-cleaning properties and which is on the same time self-regenerating. The invention furthermore relates to composite members comprising such a gelcoat layer with particles and to the use of gelcoat comprising particles for giving regenerating self-cleaning properties.

Owner:LM GLASSFIBER

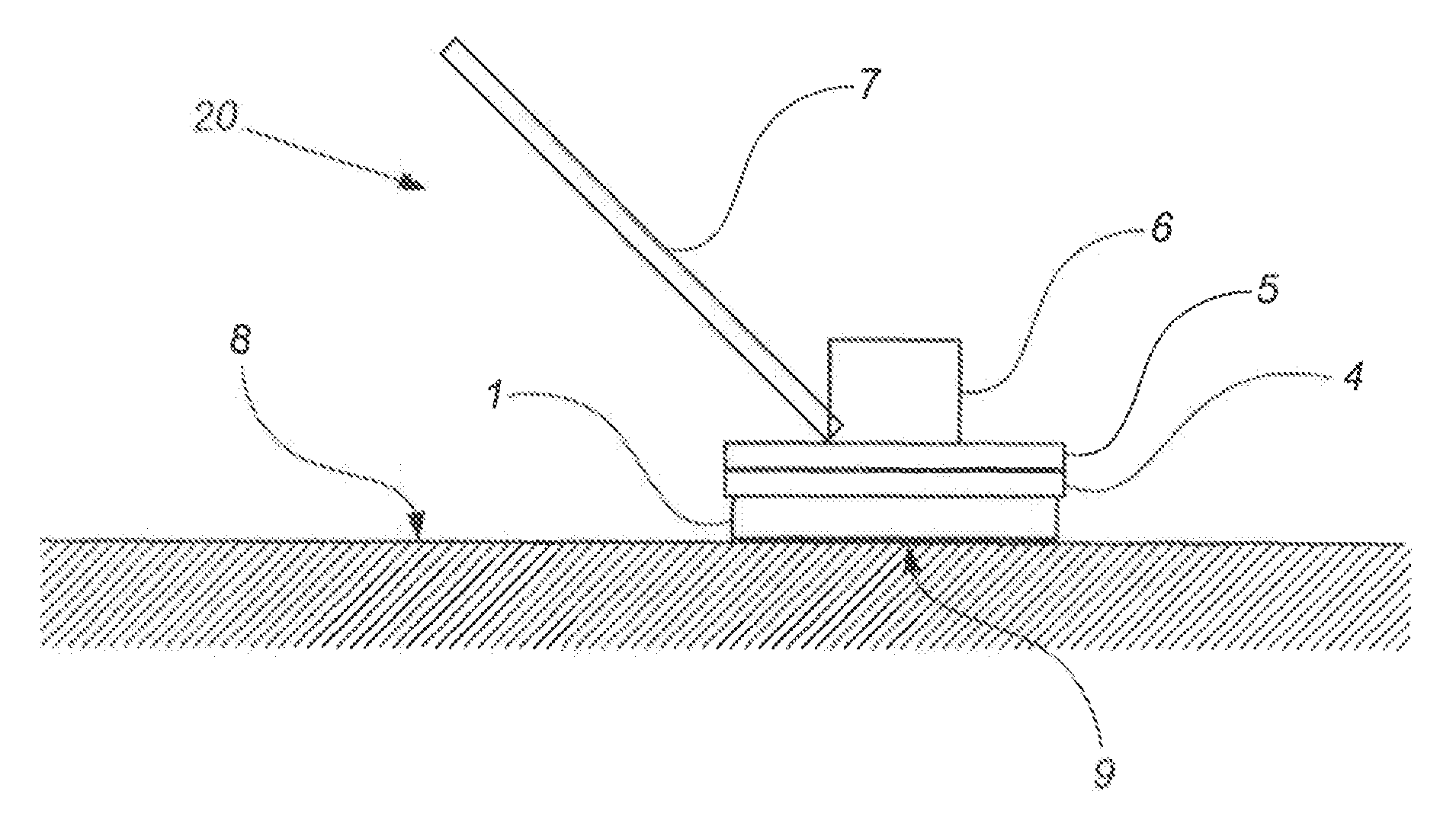

Methods and tool for maintenance of hard surfaces, and a method for manufacturing such a tool

A method is disclosed for treating or maintaining a hard surface comprising a stone or stone-like material, the method comprising treatment of the surface with a flexible pad, in the presence of abrasive particles, bonded to the pad, on a contact surface between the pad and the hard surface, wherein the abrasive particles comprise diamond particles, and the treatment is performed in the absence of an effective amount of crystallization agent on the contact surface. The treatment is performed on a substantially regular basis, such as daily, weekly or monthly, and the treatment is performed using a pad comprising an open, lofty, three dimensional non-woven webs of fibers. A tool for use in the method is also provided, as well as a floor-surfacing machine comprising such a tool and a method for manufacturing such a tool. Furthermore, methods for treating or maintaining hard, smooth surfaces such as wood, polymer material, lacquer, linoleum, gelcoat, glass and automotive enamel are disclosed.

Owner:TWISTER CLEANING TECH AB

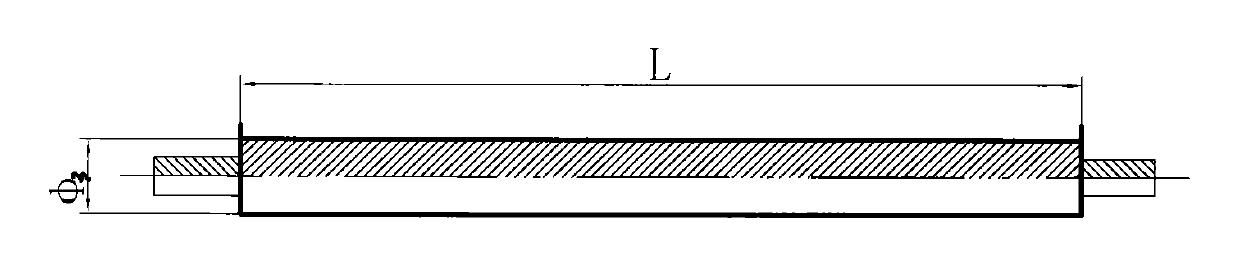

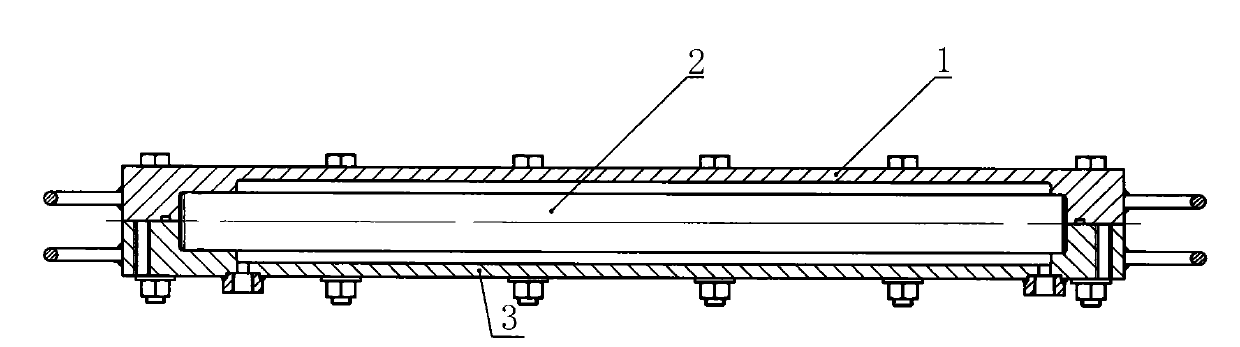

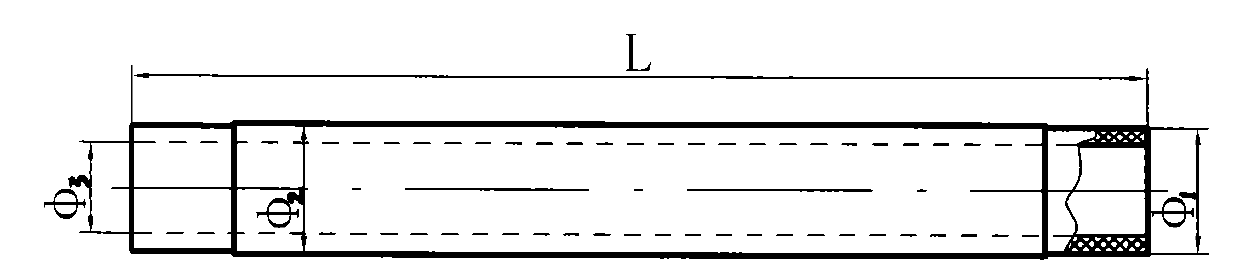

Manufacturing method of insulating support rod

The invention discloses a manufacturing method of an insulating support rod, and the method comprises the following steps: spraying a certain thickness of gel-coating resin on the surface of a male mole of a resin transfer mold, curing in an oven, then using a dry preform which is not dipped with glue for winding the well cured male mold of the resin transfer mold according to the designed number of layers, assembling the resin transfer mold, sealing and carrying out vacuum pumping during the assembly process, finally using an injection machine for injecting special injection resin into the well sealed resin transfer mold, placing into the oven for curing, demolding, trimming rough selvedges and obtaining the insulating support rod. The insulating support rod product has the advantages of good quality of the inner surface and the outer surface, light weight, high dimensional precision, excellent electric insulation performance and mechanical properties; and the manufacturing method of the insulating support rod has the advantages of low cost, short cycle and high reliability.

Owner:XIAN CHAOMA COMPOSITE MATERIALS

Low blush gelcoats having high color fastness

Gelcoat compositions comprising a base resin, a reactive diluent component, a pigment and more than about 2% by weight inorganic extended fillers wherein the reactive diluent component either a) comprises styrene and one or more alternative reactive diluents or b) consists of one or more alternative reactive diluents. Also, disclosed is watercraft made with these gelcoat compositions. Further, a process for making gelcoat compositions is disclosed wherein some or all of the styrene in the reactive diluent component is replaced with one or more alternative reactive diluents.

Owner:ASHLAND LICENSING & INTPROP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com