Manufacturing method of insulating support rod

A manufacturing method and technology for support rods, which are applied to insulators, coil manufacturing, electrical components, etc., can solve the problems of scrapping, easily broken, and no insulating support rods of transformer devices, and achieve high production efficiency, good quality, and excellent electrical Effect of insulating properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

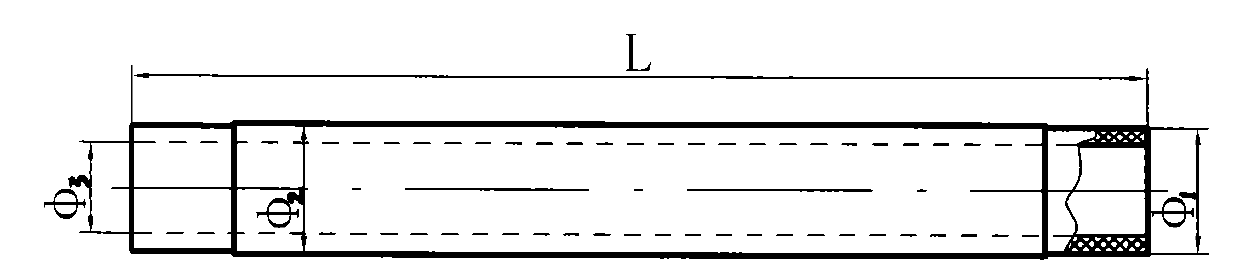

[0022] for 50mm, 52mm, It is manufactured for an insulating support rod of 36mm and L is 466mm (the schematic diagram of its structure is shown in image 3 shown)

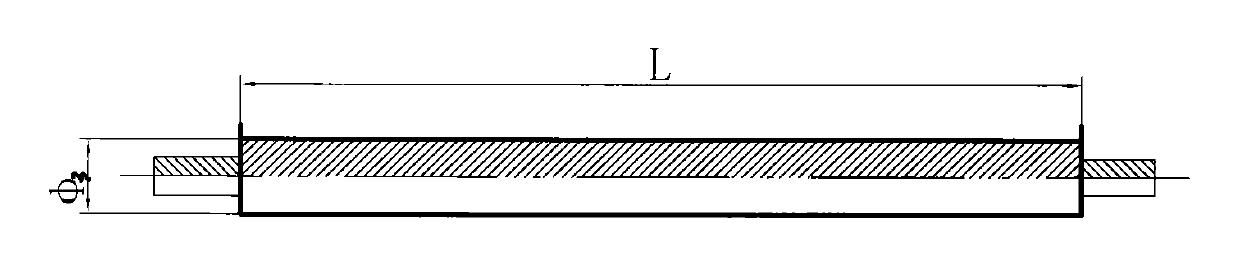

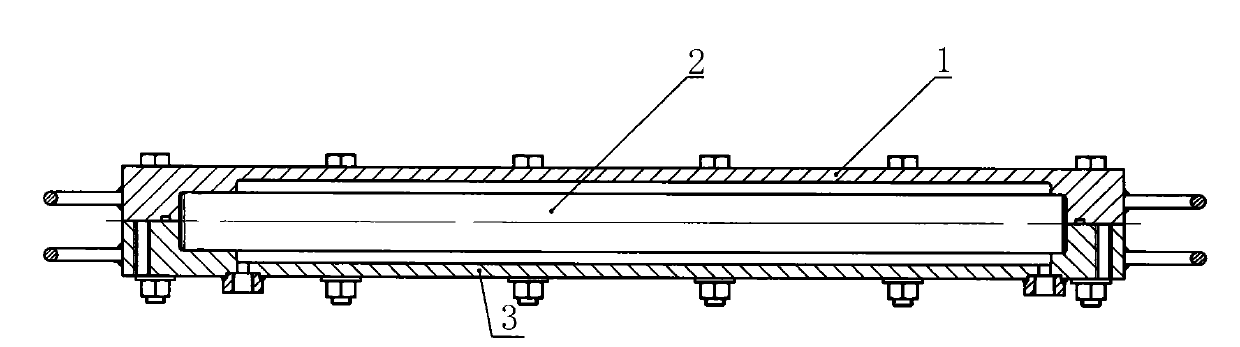

[0023] (1) On the surface of the male mold 2 of the RTM forming mold (such as figure 1 (shown in section L in the middle) spray a layer of 1904-045# vinyl resin with a thickness of 3.0mm, then put the male mold coated with vinyl resin into an oven to cure the vinyl resin, and the curing temperature is 70-80°C , curing time is 1~5h;

[0024] (2) The positive mold of the RTM forming mold solidified in step (1) is wound up according to the designed 18 layers with the dry prefabricated body not soaked in glue; the dry prefabricated body is reinforced material Kevlar-49 fiber and Mixed fabric of polyester fiber; the weaving process of the dry prefabricated body is: take Kevlar-49 fiber as the warp direction of the mixed fabric, and use polyester fiber as the weft direction of the mixed fabric to carry out plane ...

Embodiment 2

[0030] for 38mm, 46mm, 20mm, L is 354mm insulating support bar manufacturing (the schematic diagram of its structure is shown in image 3 shown)

[0031] (1) On the surface of the male mold 2 of the RTM forming mold (such as figure 1 (shown in section L in the middle) spray a layer of 1904-045# vinyl resin with a thickness of 3.0mm, then put the male mold coated with vinyl resin into an oven to cure the vinyl resin, and the curing temperature is 70-80°C , curing time is 1~5h;

[0032] (2) The positive mold of the RTM forming mold solidified in step (1) is wound up according to the designed 25 layers with the dry prefabricated body not soaked in glue; the dry prefabricated body is reinforced material F-12 fiber and Mixed fabric of polyester fiber; the weaving process of the dry prefabricated body is: use F-12 fiber as the warp direction of the mixed fabric, and use polyester fiber as the weft direction of the mixed fabric to carry out plane weaving;

[0033] (3) Assemb...

Embodiment 3

[0038] for 96mm, 100mm, Manufactured for an insulating support rod of 74mm and L of 2000mm (the schematic diagram of its structure is shown in image 3 shown)

[0039] (1) On the surface of the male mold 2 of the RTM forming mold (such as figure 1 (shown in section L in the middle) spray a layer of 1904-045# vinyl resin with a thickness of 3.0mm, then put the male mold coated with vinyl resin into an oven to cure the vinyl resin, and the curing temperature is 70-80°C , curing time is 1~5h;

[0040] (2) The positive mold of the RTM forming mold solidified in step (1) is wound up according to the designed 33 layers with the dry prefabricated body not soaked in glue; the dry prefabricated body is reinforced material Kevlar-49 fiber and Mixed fabric of polyester fiber; the weaving process of the dry prefabricated body is: take Kevlar-49 fiber as the warp direction of the mixed fabric, and use polyester fiber as the weft direction of the mixed fabric to carry out plane weavin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com