Patents

Literature

48results about How to "Strong ability to withstand pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

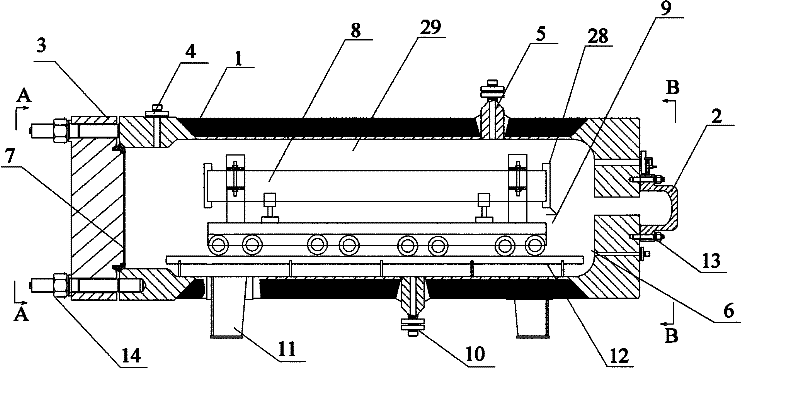

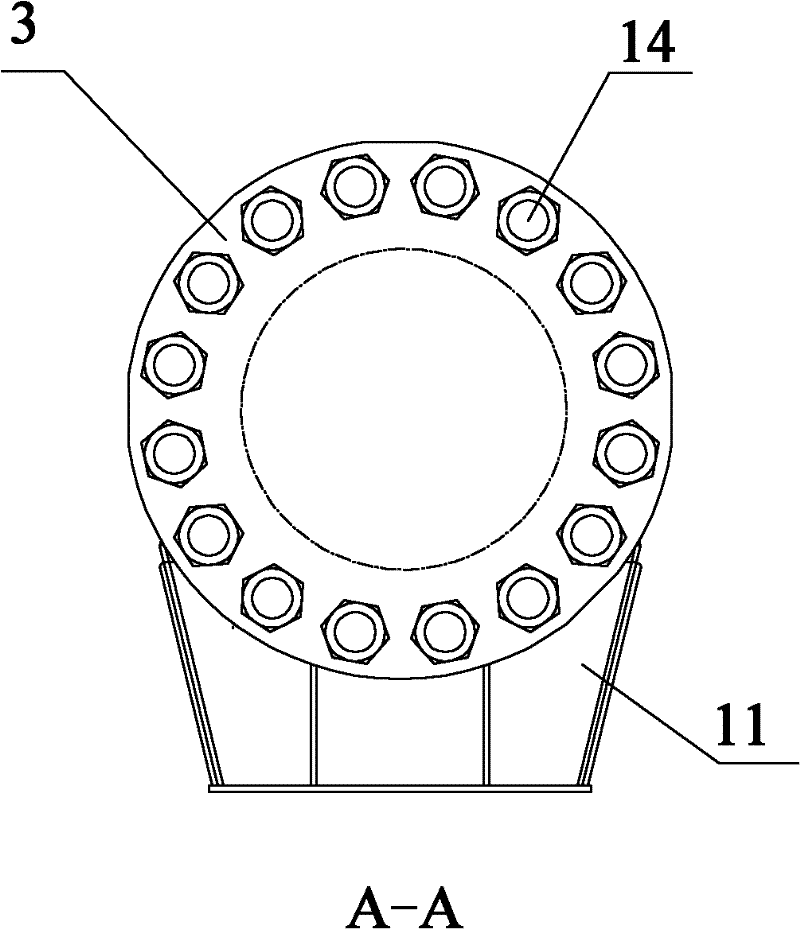

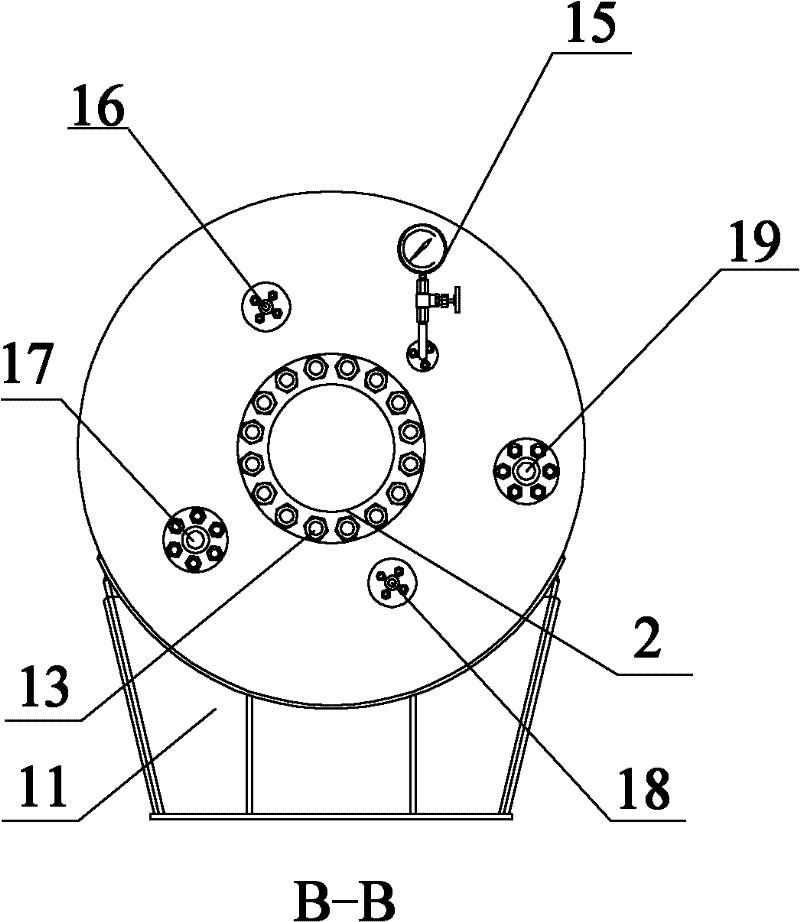

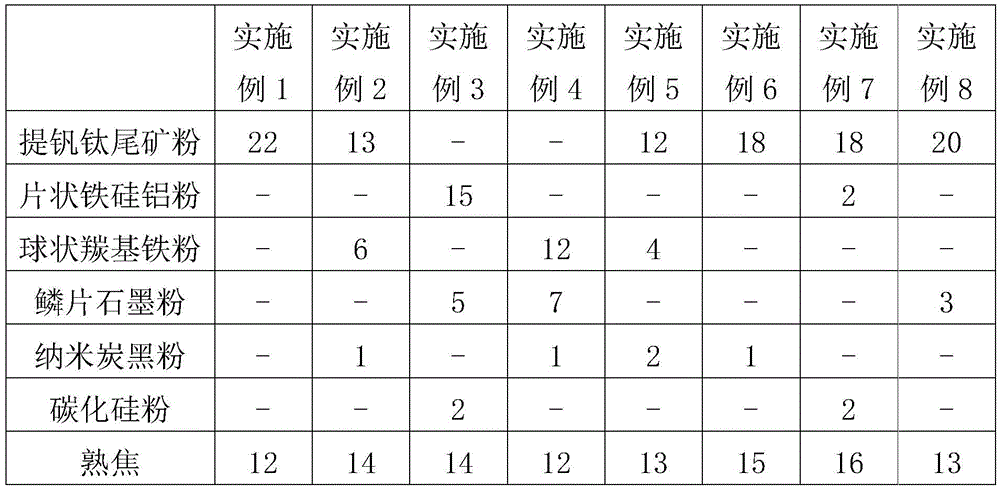

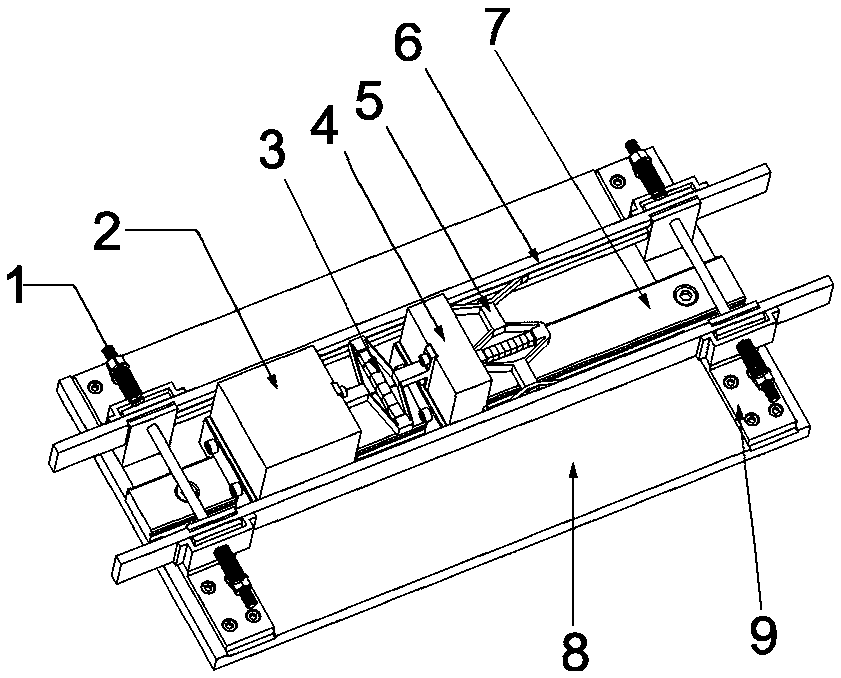

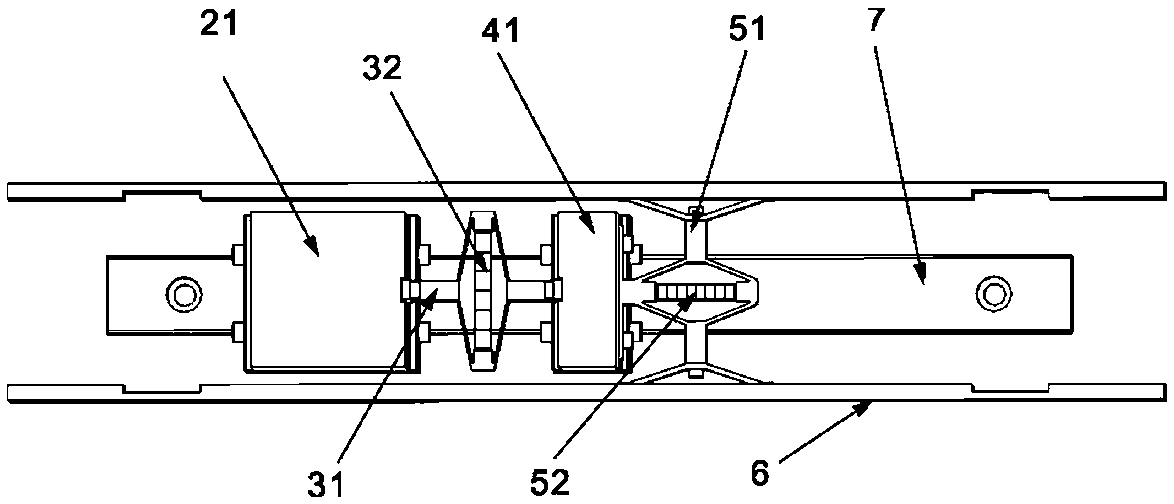

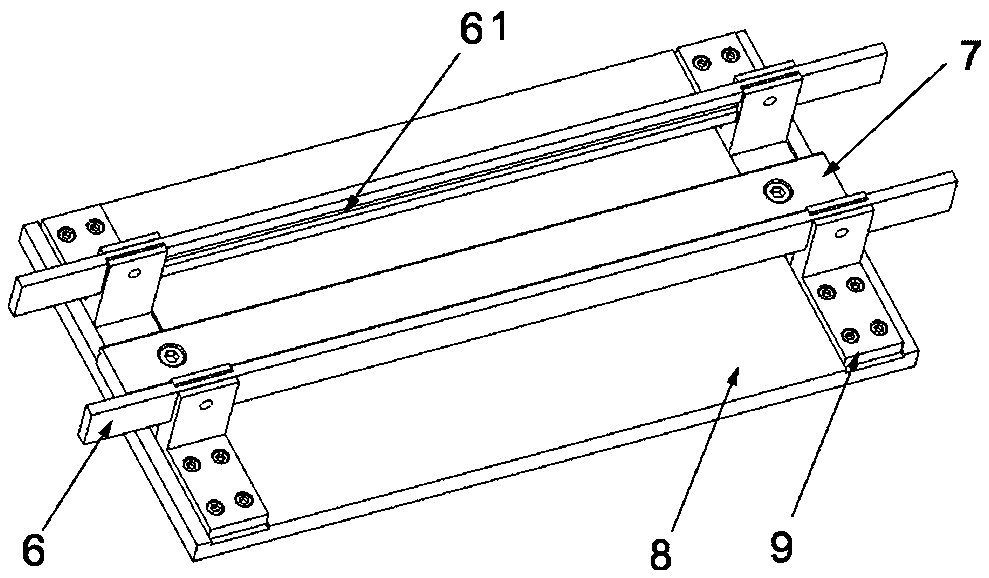

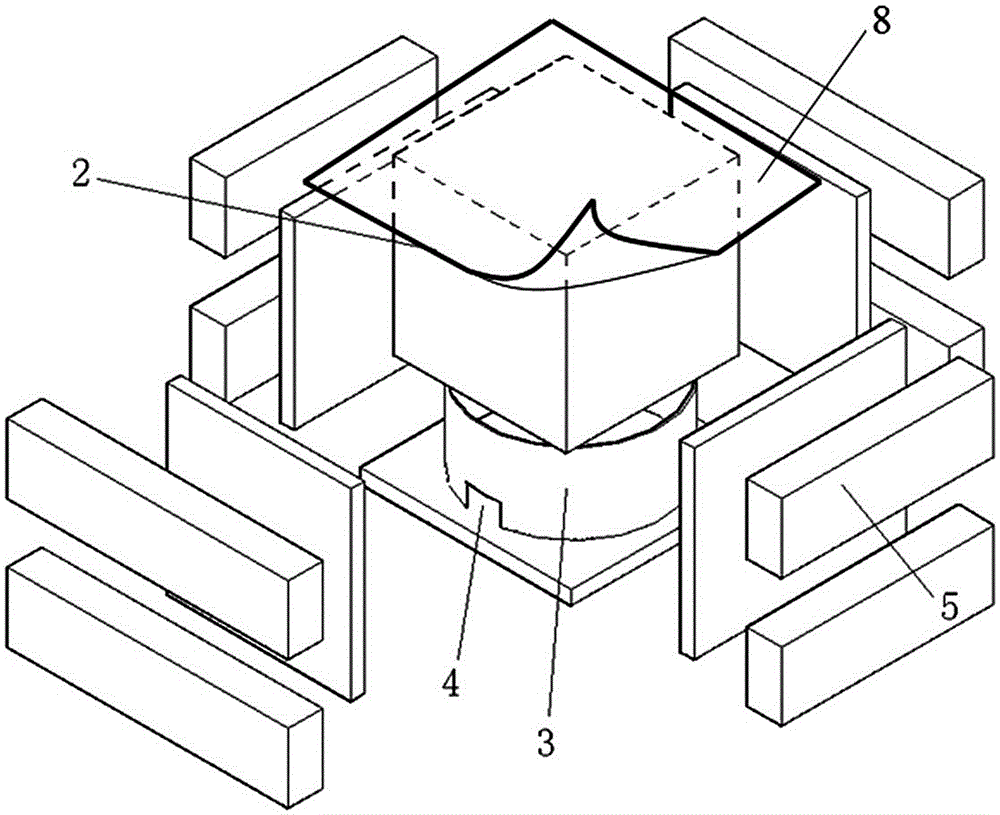

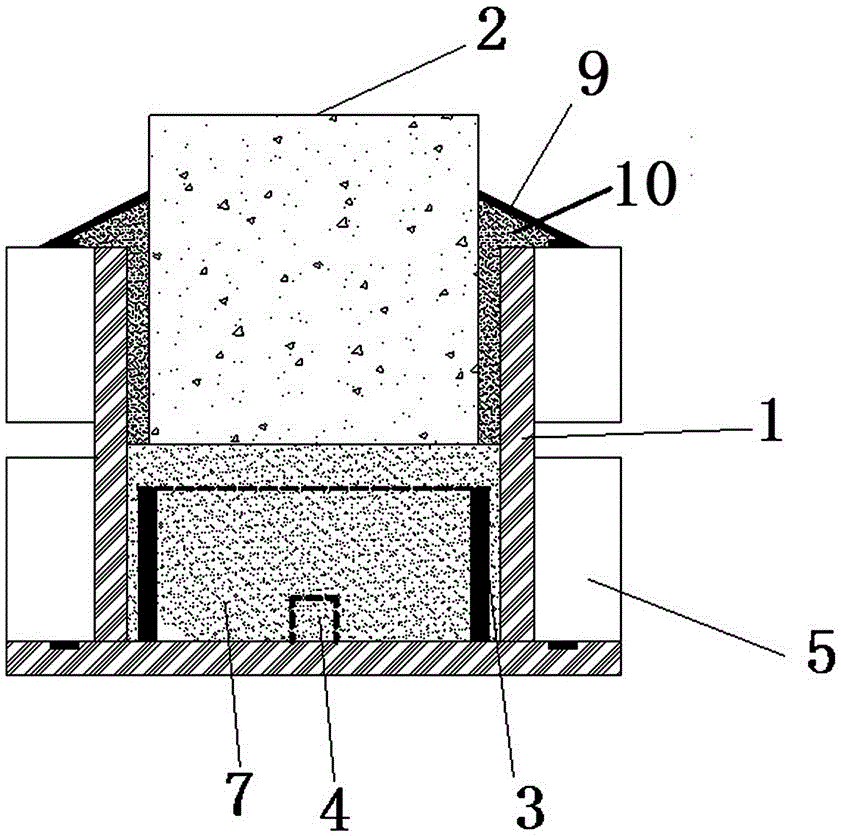

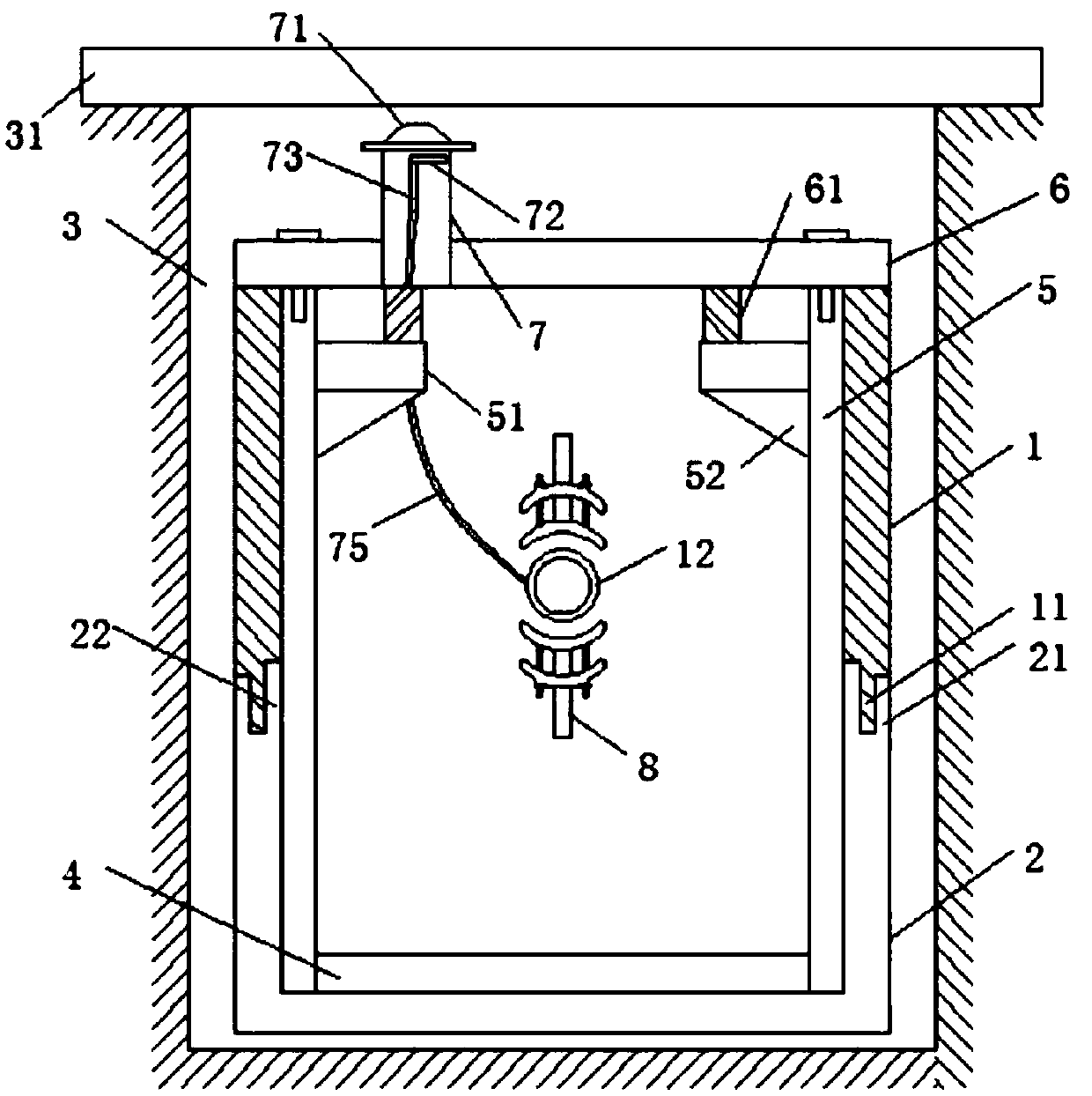

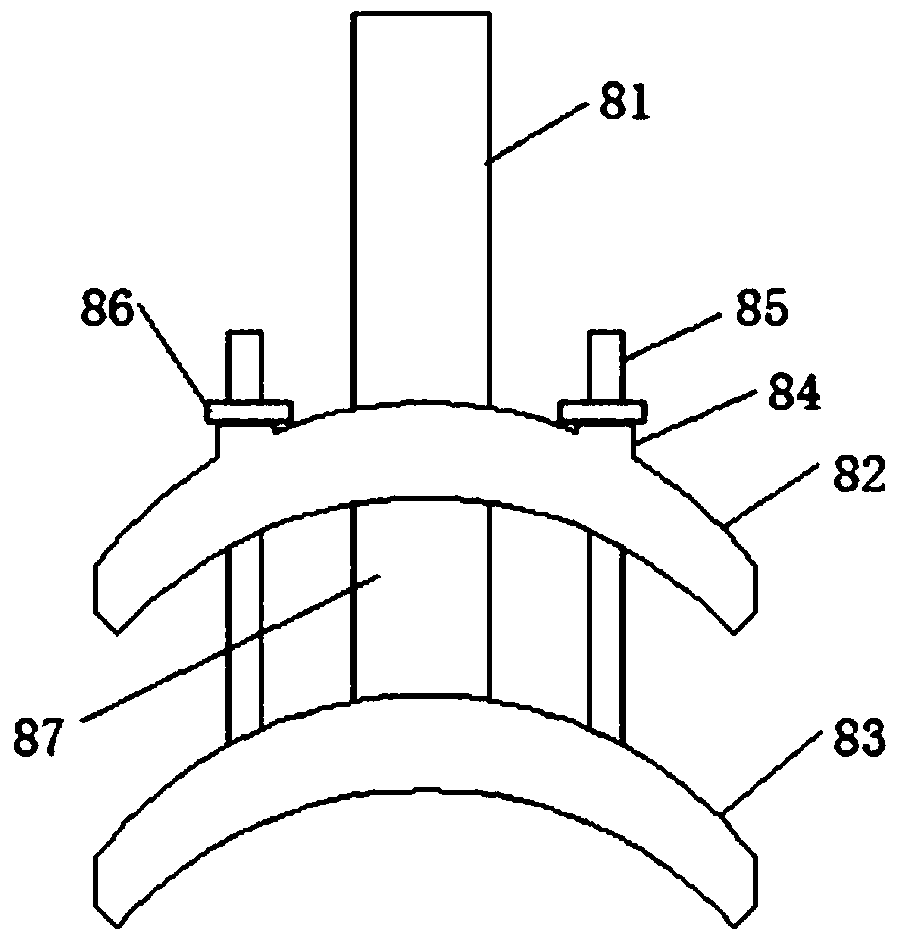

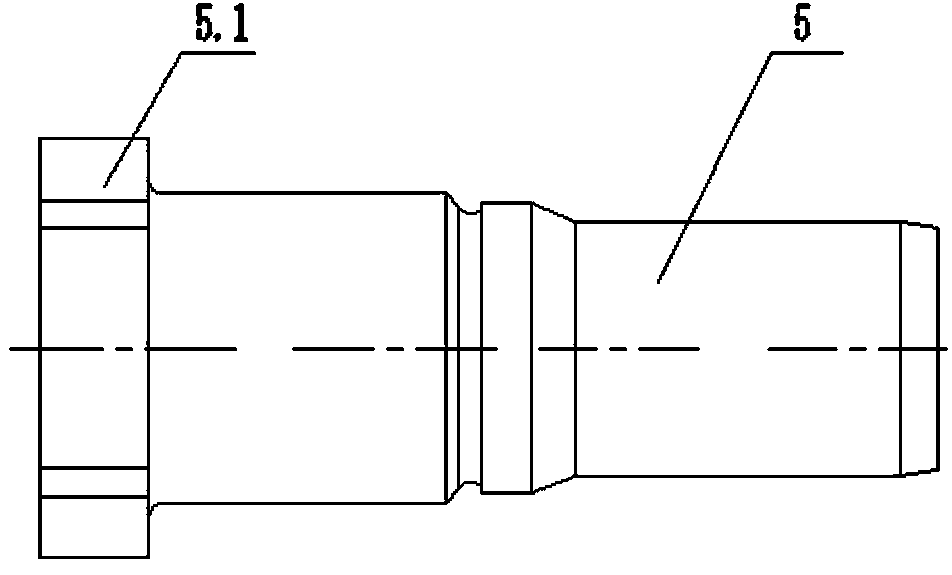

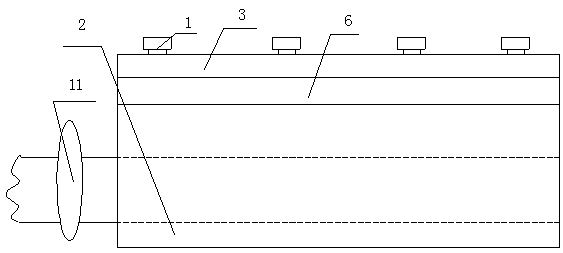

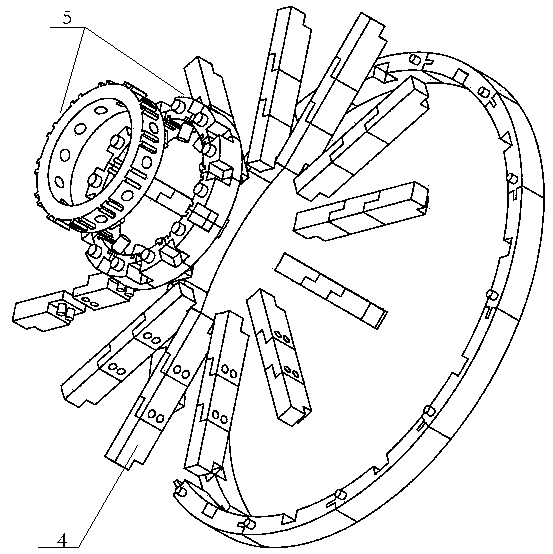

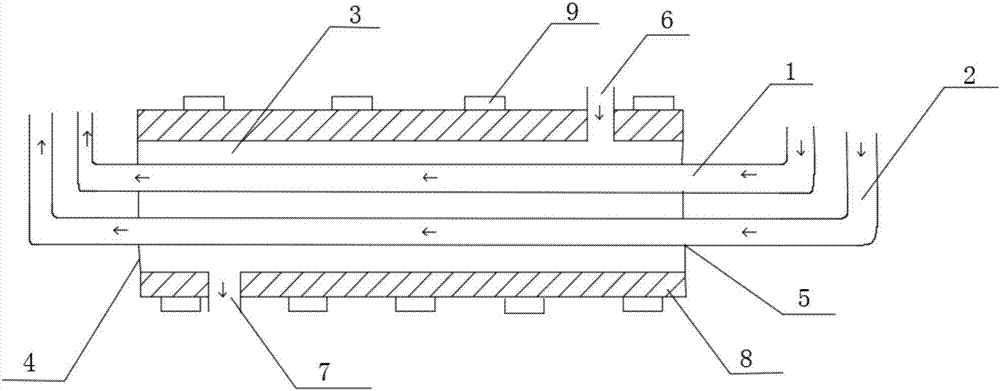

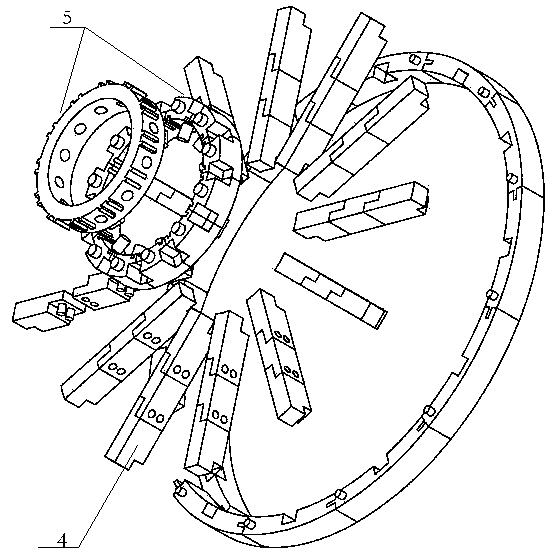

Separable type deepwater seabed pipeline bending test system

InactiveCN102175513AImprove test efficiencyStrong ability to withstand pressureStrength propertiesPetroleumInternal pressure

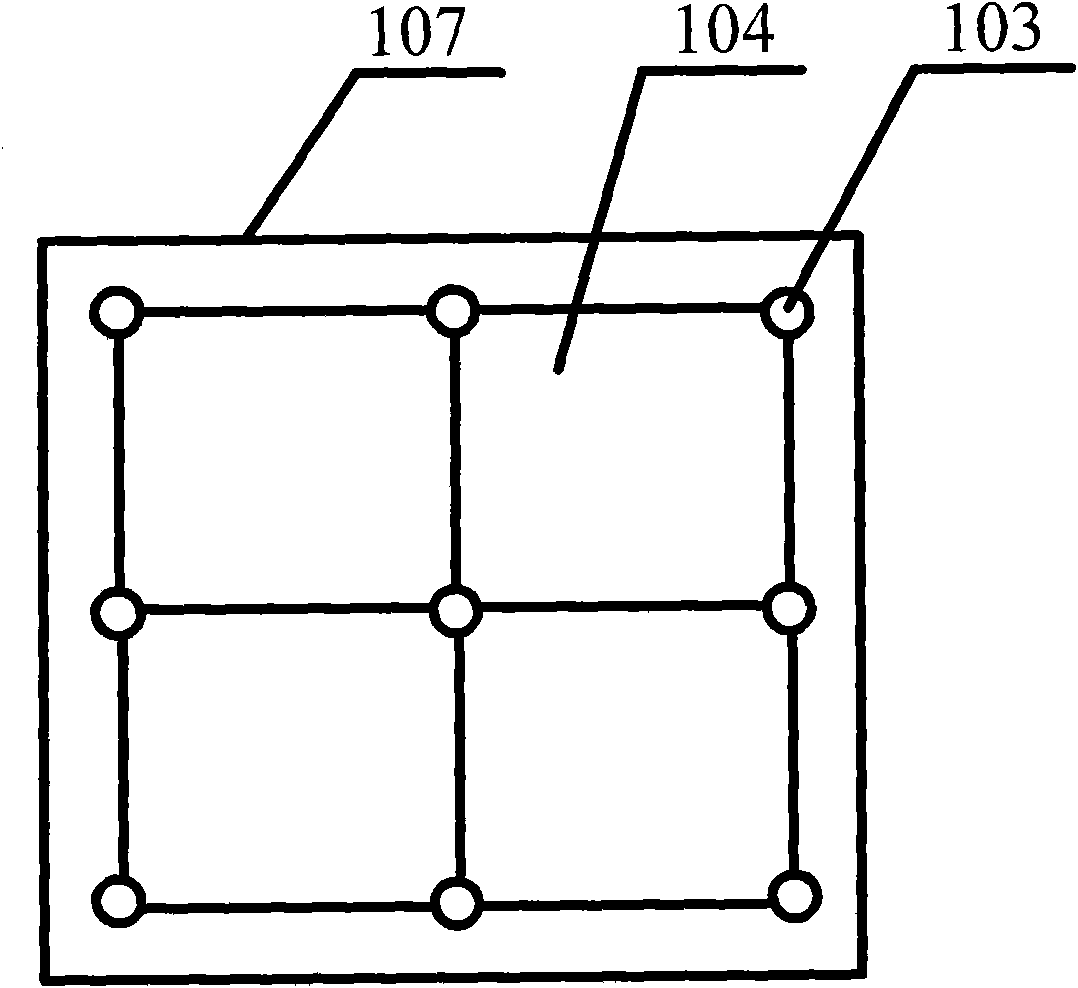

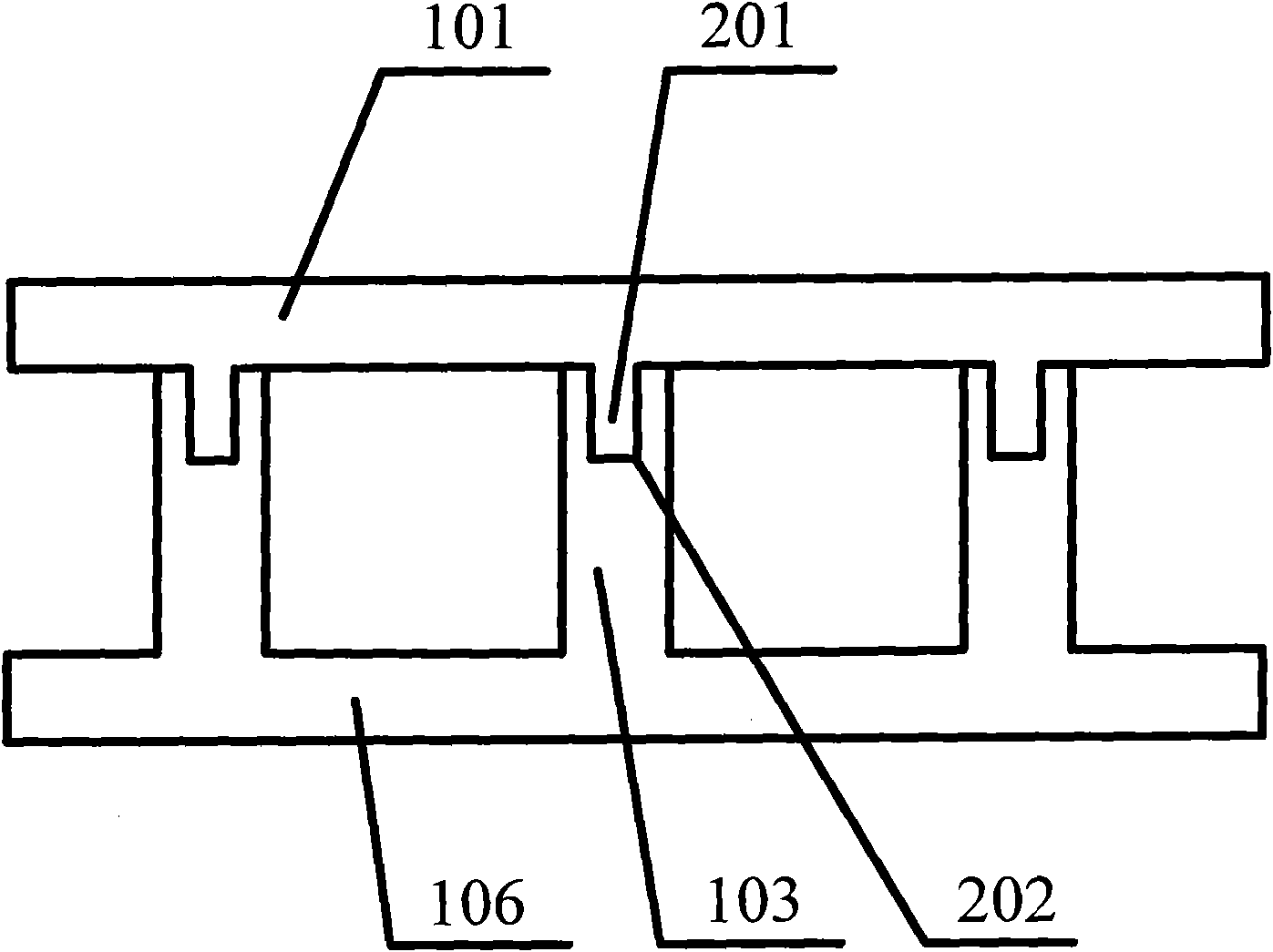

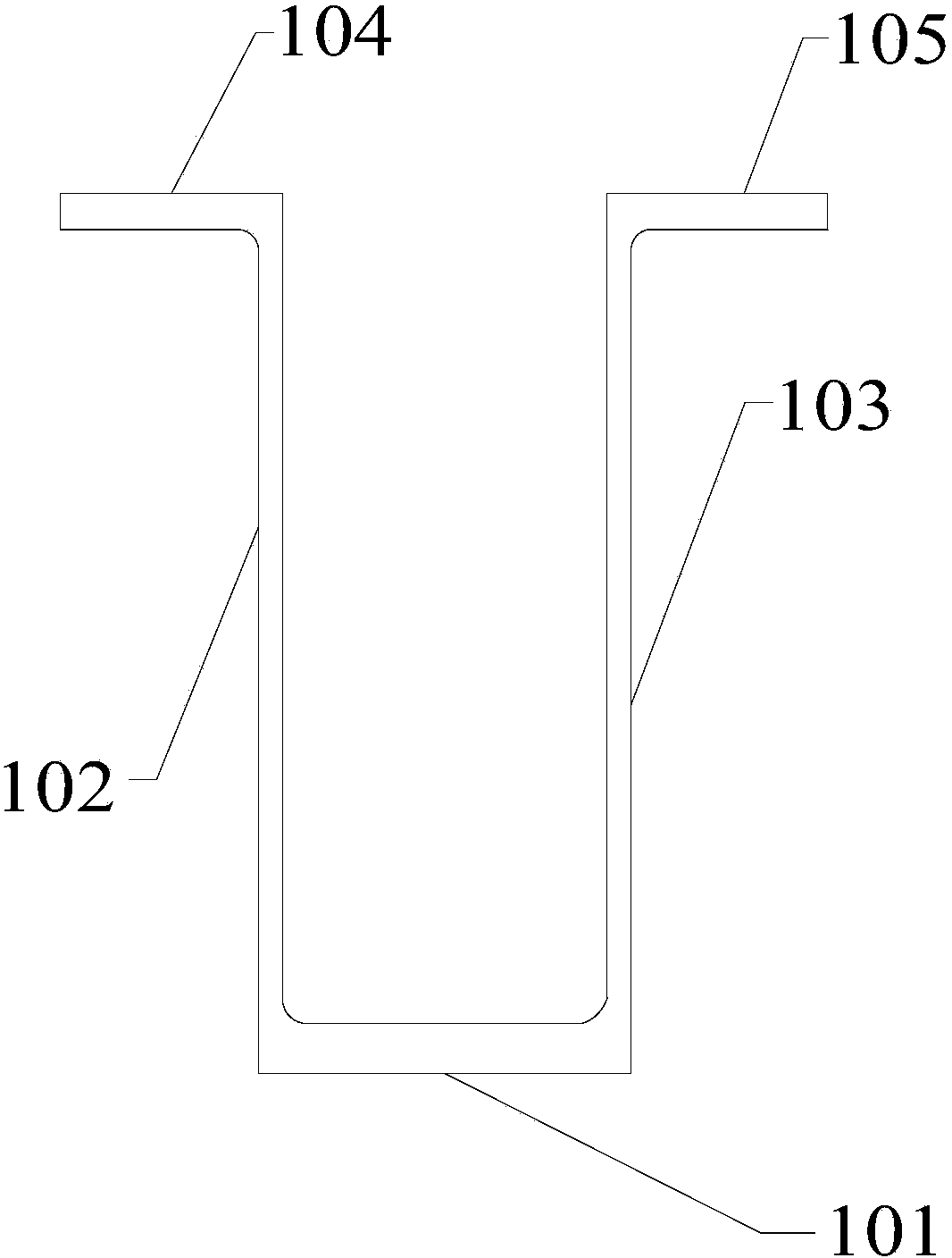

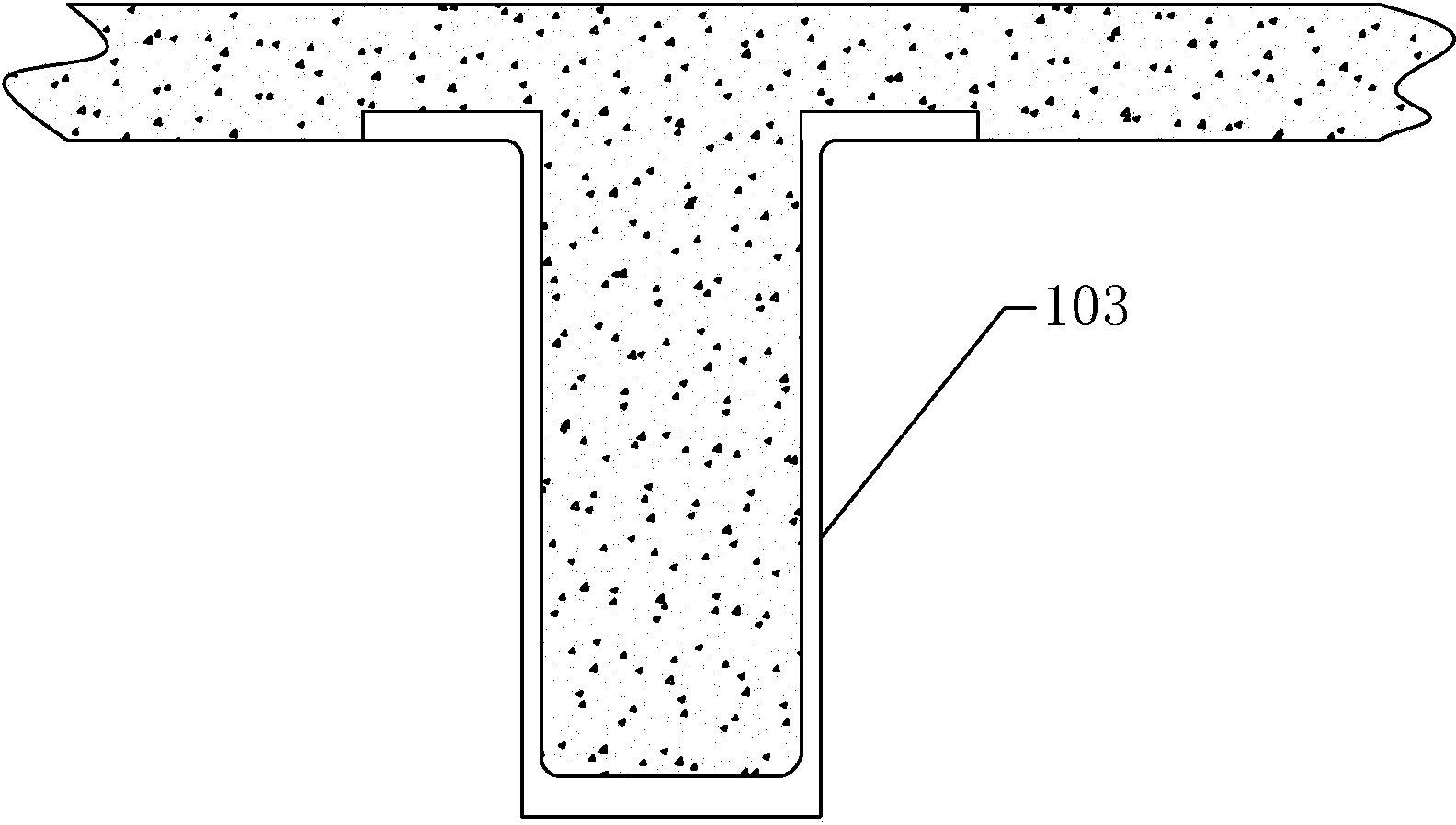

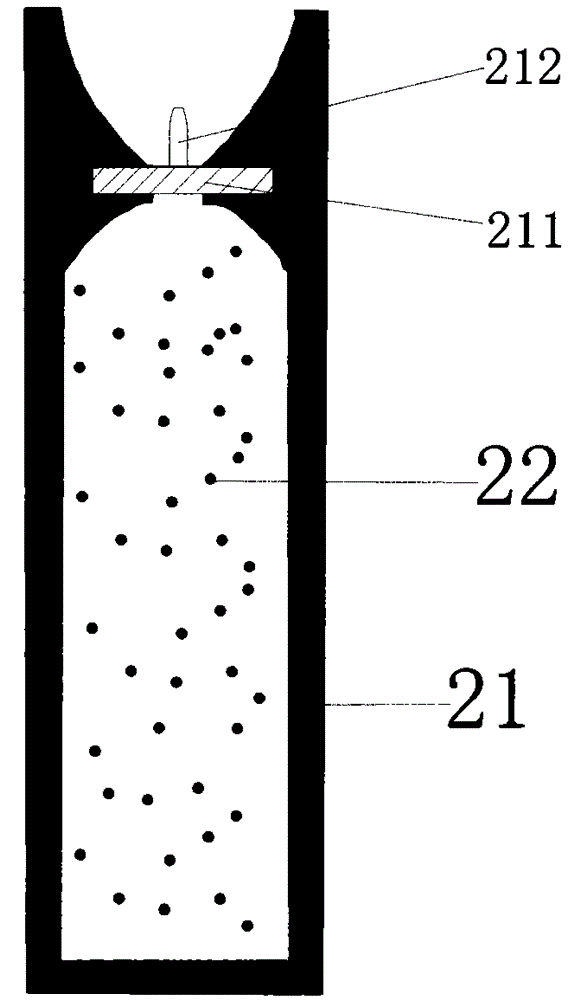

The invention belongs to the technical field of deep sea oil development, exploitation and transportation and relates to a separable type deepwater seabed pipeline bending test system which comprises a pressure chamber, a pipeline bending loading device, a hydraulic loading mechanism and a pipeline auxiliary device, wherein the pressure chamber comprises a main chamber body and front and tail end covers connected to two ends of the main chamber body; sealing rings are arranged inside the front and tail end covers; a guide rail is arranged on the upper surface of the bottom of the pressure chamber; the pipeline bending loading device which is composed of a bracket and a pulley is arranged on the guide rail; two end parts above the bracket are provided with a pair of U-shaped clamp slots with slotted plates; two pairs of detachable cover plates with slotted plates and bolts are arranged above the two U-shaped clamp slots; and a pair of hydraulic loading mechanisms are arranged at the inner side above the bracket. The system can be used for simultaneously loading an external static water pressure, a bending pressure and a test-piece inner pressure on a real proportional test-piece and can be used for simulating the actual flow condition of conveying different media at different temperatures by using the seabed pipeline in the actual engineering.

Owner:TIANJIN UNIV

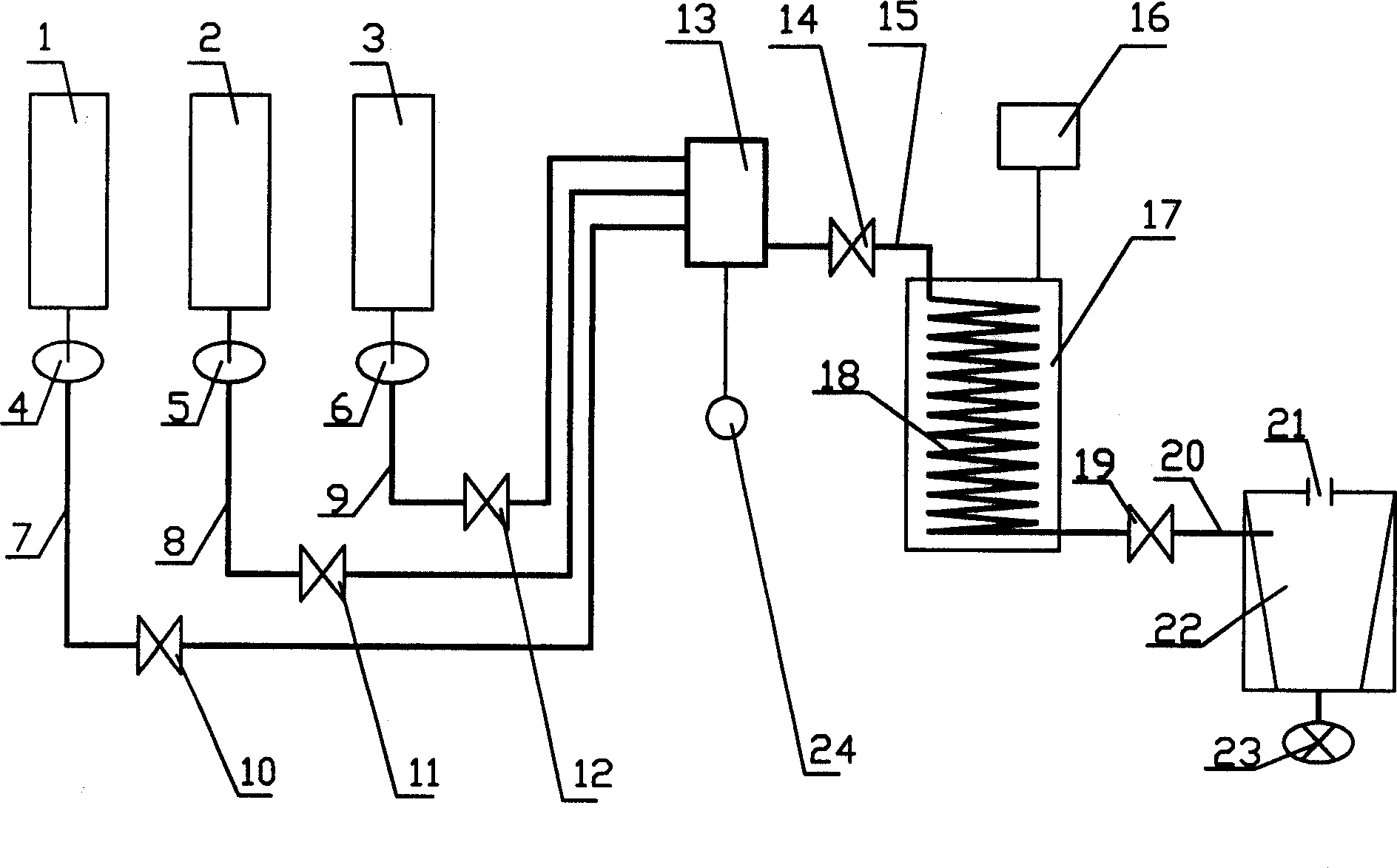

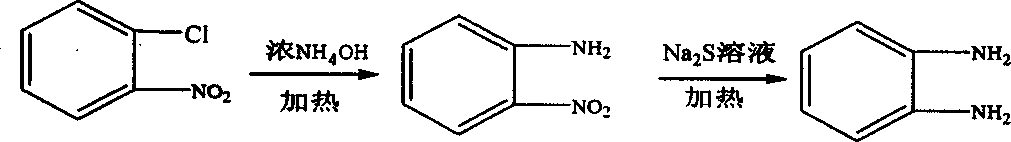

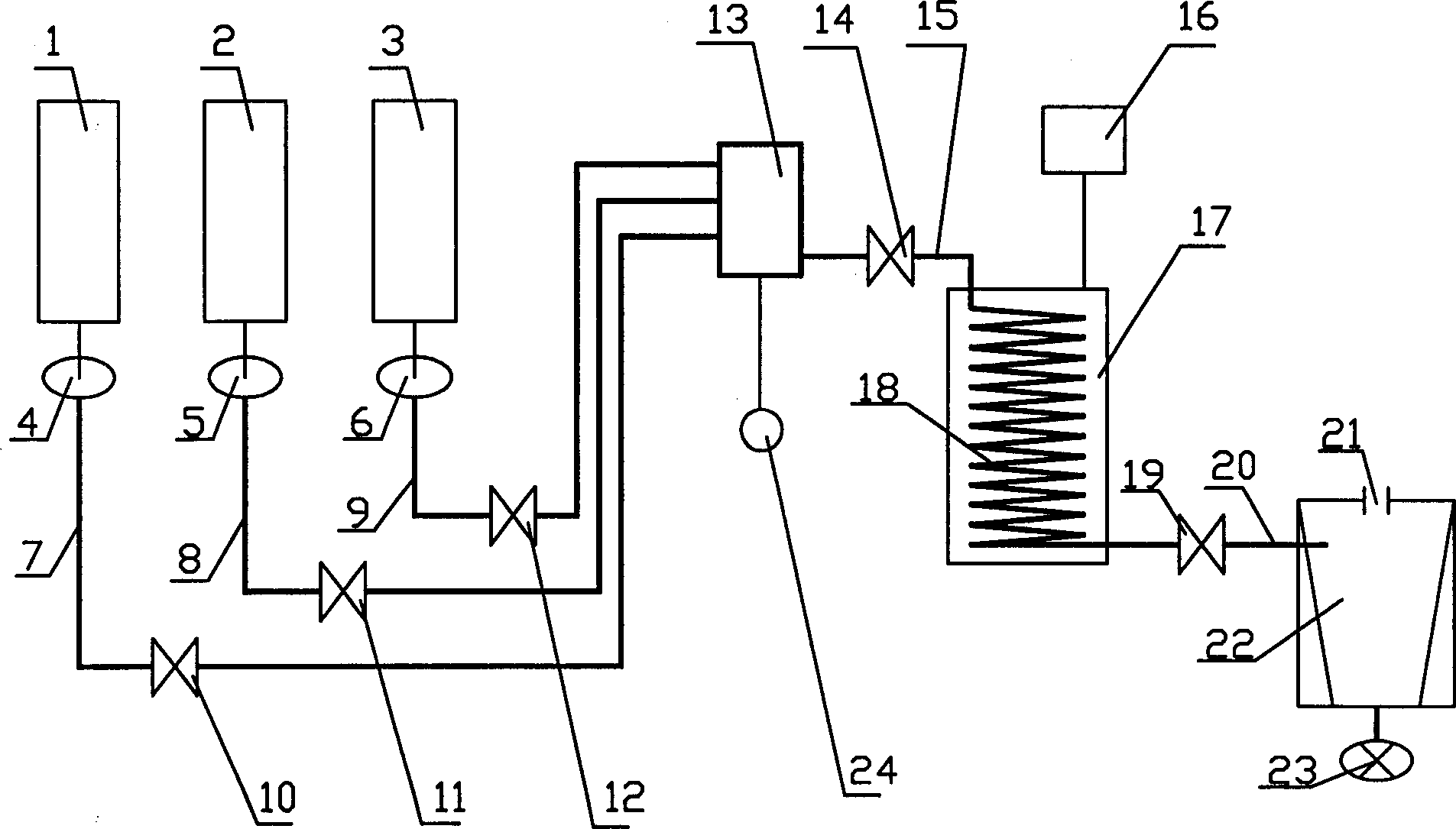

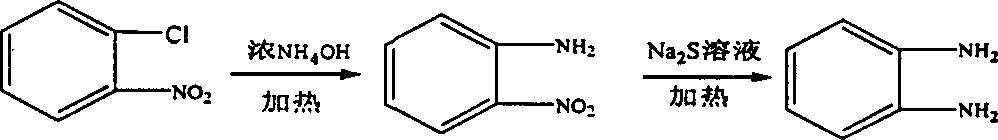

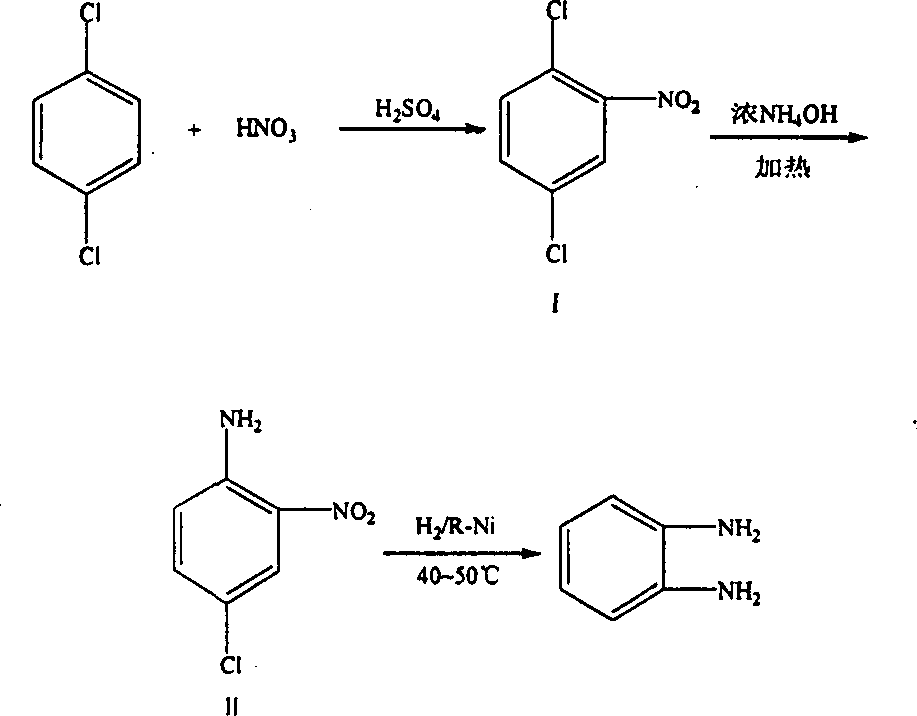

Process and apparatus for producing o-phenylenediamine

ActiveCN1594279AGood colorNo pollutionOrganic compound preparationAmino compound preparationPhase shiftedCopper

The invention provides a process for producing o-phenylendiamine comprising the steps of, charging ortho dichlorobenzene, ammonia into high temperature, high pressure container, proceeding ammonolysis reaction at the presence of catalyst, analyzing and separating the obtained reactant, charging ortho dichlorobenzene, liquid ammonia, copper catalyst, phase shift catalyst into pipe type reactor continuously for ammonolysis reaction. The invention also discloses a production apparatus for realizing the method.

Owner:江西扬帆新材料有限公司

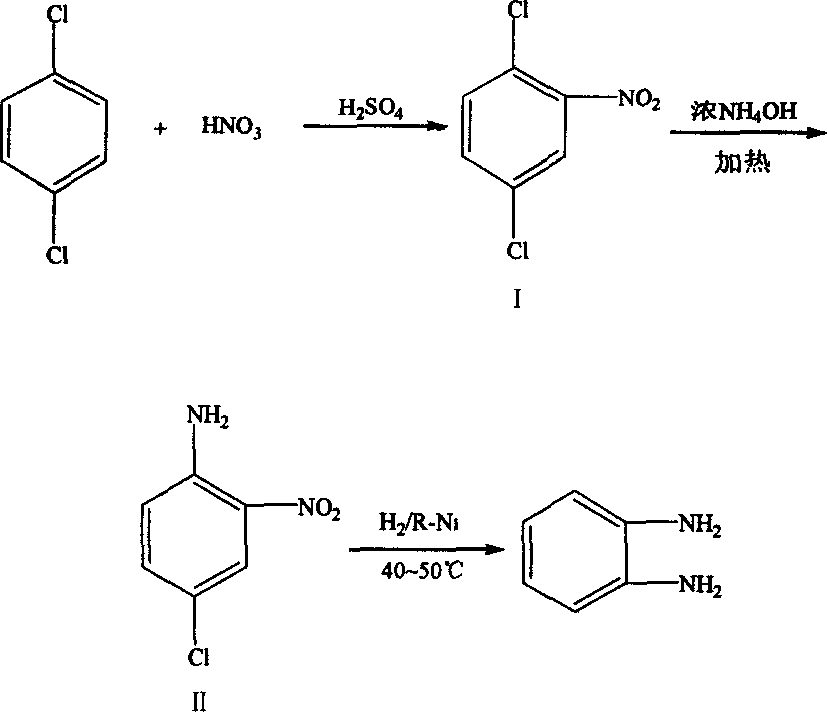

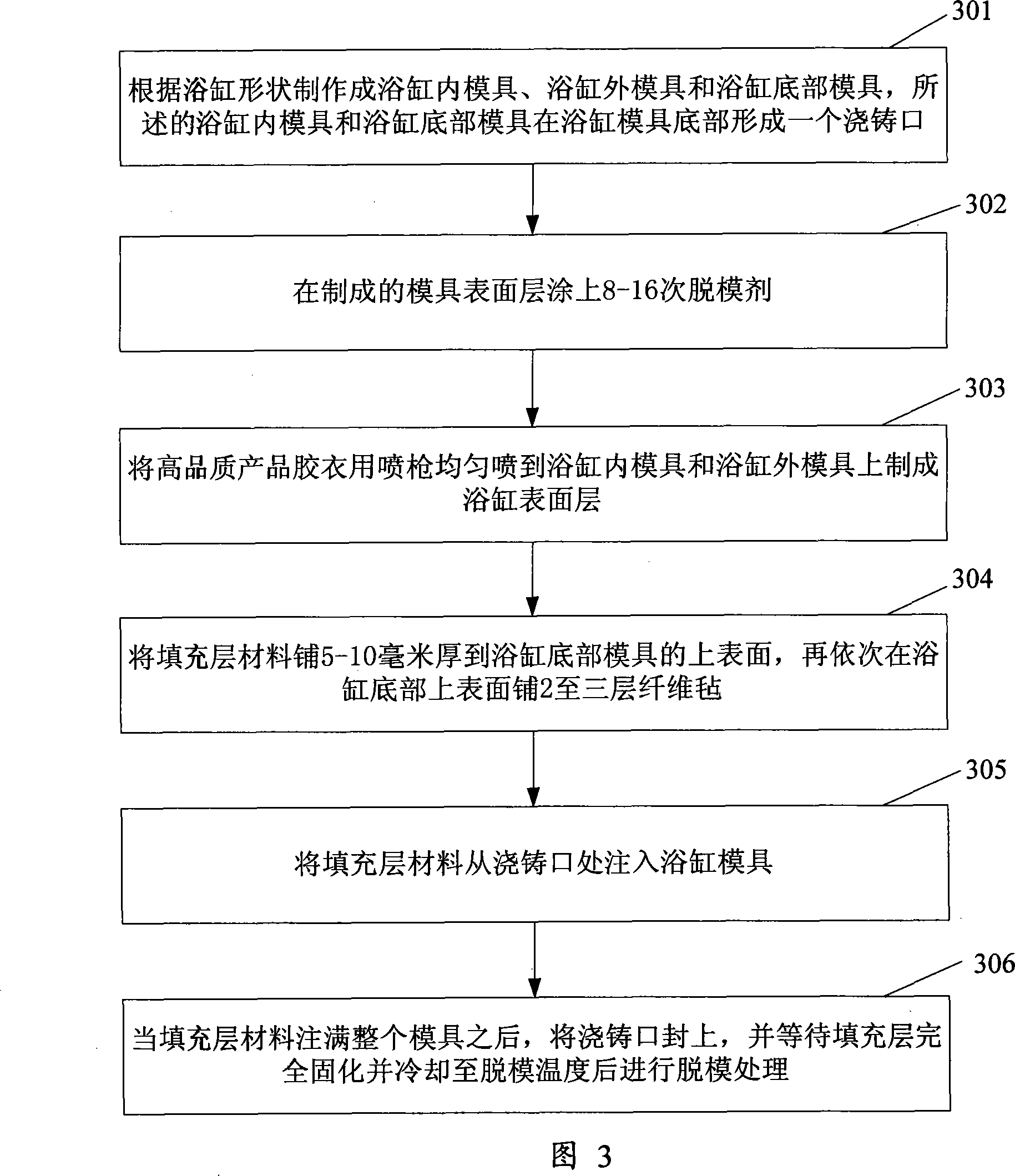

Artificial stone integral bathtub and method for making same

InactiveCN101181823AGood insulation performanceStrong ability to withstand pressureBathsDouchesFilling materialsBathtub

The invention discloses a manufacturing method of an artificial stone integrated bathtub, the method comprising the following steps: making a bathtub inner mold, a bathtub outer mold and a bathtub bottom mold according to the shape of the bathtub, and the bathtub inner mold and the bathtub bottom mold are located at the bottom of the bathtub mold Form a casting port; apply a release agent on the inner surface of the bathtub mold; spray the high-quality product gel coat evenly on the inner surface of the inner mold of the bathtub and the outer mold of the bathtub to form the surface layer of the bathtub; Spread the filling layer material on the upper surface of the mold at the bottom of the bathtub, and then spread the fiber felt on the filling layer material at the bottom of the bathtub in turn; inject the filling layer material into the bathtub mold from the casting port; when the filling layer material fills the entire mold, put The casting mouth is sealed, and the demoulding process is performed after the filling layer is completely solidified and cooled to the demoulding temperature. The invention also discloses an artificial stone integral bathtub, which has a simple manufacturing method and good thermal insulation performance of the bathtub.

Owner:罗桂华

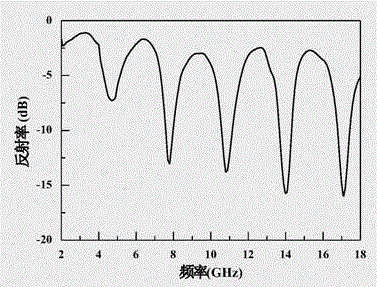

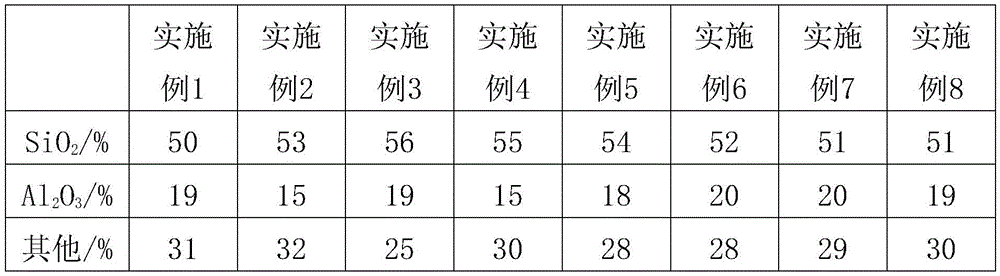

Ceramic tile with electromagnetic wave absorption function and preparation method of ceramic tile

InactiveCN105541290AStrong ability to withstand pressureBroad application prospectsClaywaresReflectivityCeramic tiles

The invention relates to a ceramic tile with an electromagnetic wave absorption function and a preparation method of the ceramic tile. The green body of the ceramic tile is prepared from the following raw materials in percentage by mass: 18 to 25 percent of electromagnetic wave absorber, 30 to 50 percent of clay, 10 to 20 percent of feldspar, 18 to 25 percent of quartz, and the sum of the amounts of the raw materials is 100 percent. The ceramic tile provided by the invention has good electromagnetic wave absorption function, the average reflectance in the range of 2 to 18 GHz of the ceramic tile to electromagnetic waves is less than -7.5dB, and the minimum reflectance reaches -16.0dB; the breaking strength is larger than or equal to 5000N, the rupture modulus is larger than 40 MPa; the ceramic tile has an architectural ornament function and the electromagnetic wave absorption function, and has wide application prospect.

Owner:中建材科创新技术研究院(山东)有限公司

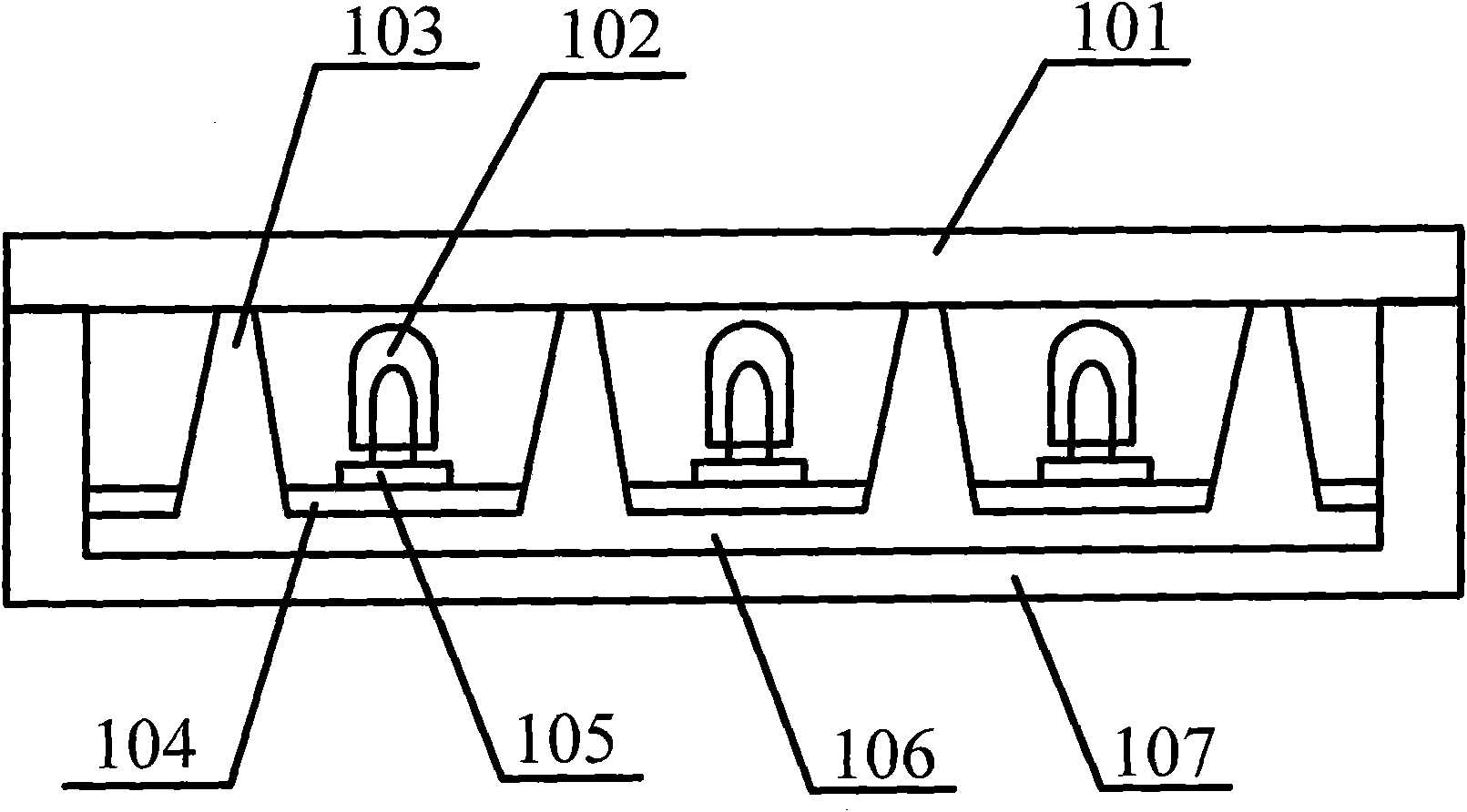

LED ground display device

InactiveCN101656031AStrong ability to withstand pressurePlay a supporting roleStatic indicating devicesIdentification meansControl signalDisplay device

The invention discloses an LED ground display device, comprising at least one LED ground display module which comprises a casing, a panel, a support plate and at least one mounting plate, wherein thecasing is fixedly connected with the panel and forms a box with edges thereof sealed; the support plate is fixed inside the casing and is provided with a projection facing upwards for supporting the panel; the mounting plate is provided with a power line, a master signal line, at least one slave signal line, a plurality of LED light-emitting units and a control module thereof including a failure detection submodule, a failure isolation submodule and a signal replacement submodule; the master signal line is detected to be corrective or not by the failure detection submodule, and a master control signal is isolated by the failure isolation submodule and is replaced with a slave control signal by the signal replacement submodule. The LED ground display device is strong in signal selectivity,high in stability and excellent in bearing pressure.

Owner:BEIJING JUSHU DIGITAL TECH DEV

Building waterproofing material

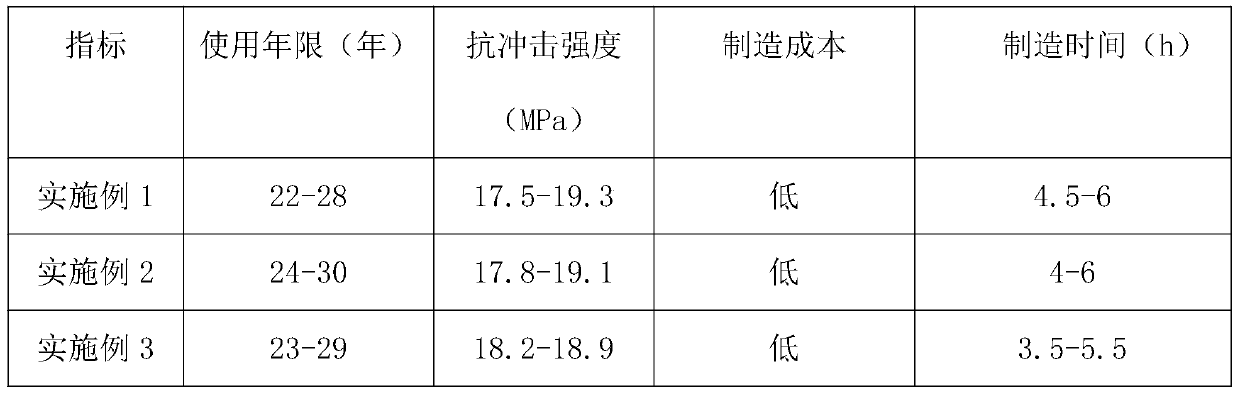

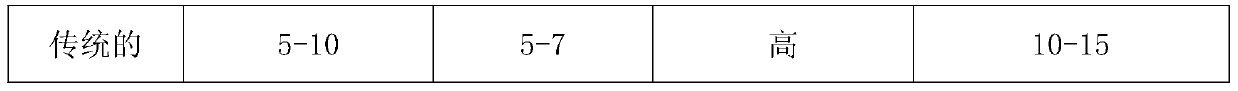

InactiveCN106009721AStrong ability to withstand pressureExtended service lifeBuilding insulationsRosinWaterproofing

The invention discloses a building waterproof material, which is made of the following raw materials in parts by weight: 35-40 parts of rubber asphalt, 10-15 parts of polyurethane, 3-8 parts of triethanolamine, and 3-6 parts of nano-magnesium oxide 0.1-0.3 parts of ultraviolet absorber, 5-12 parts of chlorinated polyethylene, 5-8 parts of toluene, 1-5 parts of epoxy resin, 0.6-1 part of rosin, 4-6 parts of calcium lignosulfonate, and 4-7 parts of sesame oil, 0.5-1 part of defoamer, 7-10 parts of asbestos powder, and 0-0.3 part of dispersant. The building waterproof material of the present invention integrates heat insulation performance and waterproof performance, has relatively strong compression resistance, long service life, excellent high temperature resistance, good extensibility, strong crack resistance, strong adhesion, and can form on the surface of objects. A waterproof layer can effectively avoid the oxidation of objects, and there is no overlapping seam to form an overall seal.

Owner:安庆越球建筑防水材料有限公司

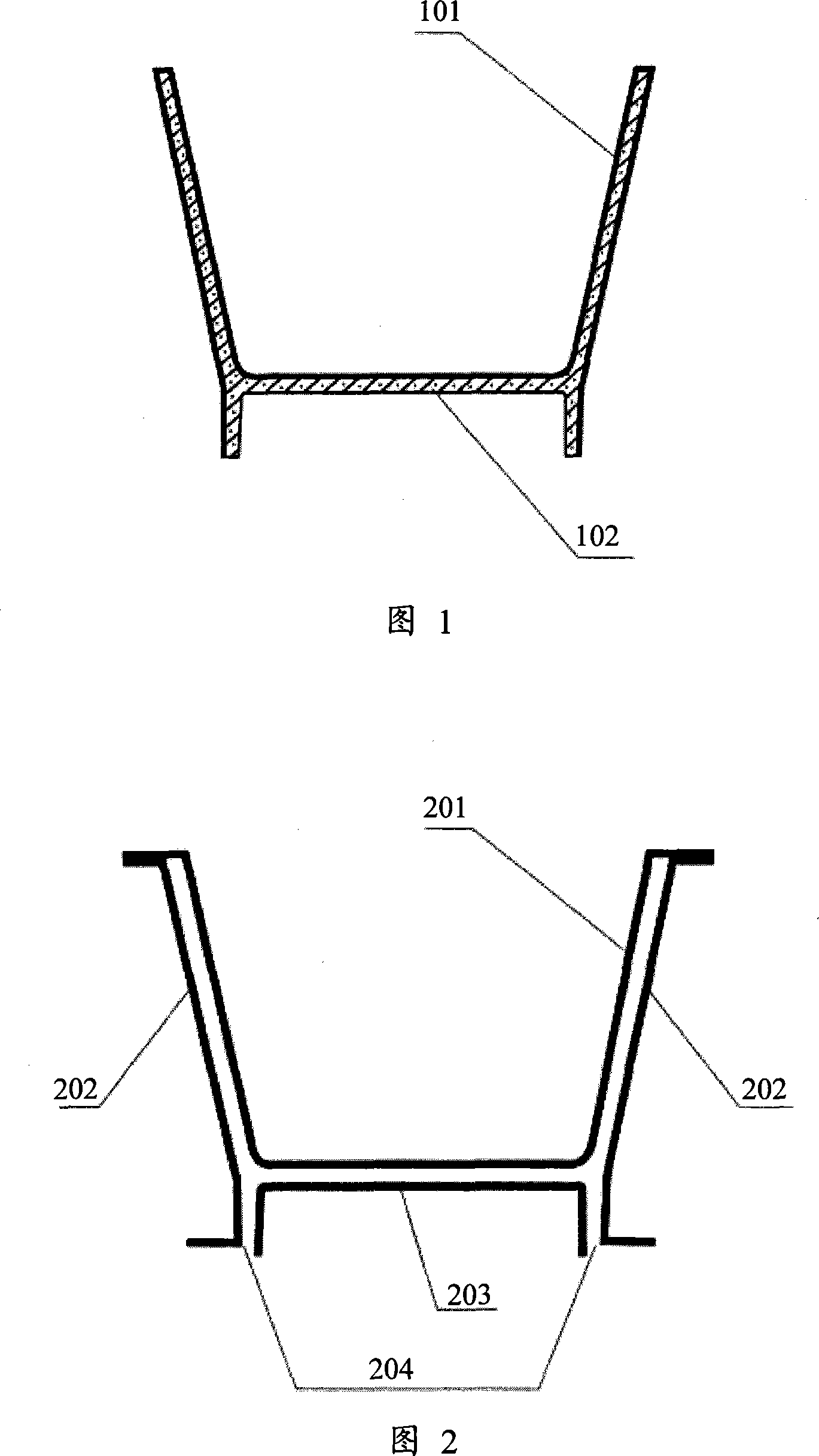

Inverted-n steel and production method thereof

InactiveCN103883867AStrong ability to withstand pressureStrong bending capacityElongated constructional elementsMetal rolling arrangementsWeld seamSteel plates

The invention relates to the field of steel machining, in particular to inverted-n steel and a production method thereof. The inverted-n steel comprises a bottom plate, wherein the two ends of the bottom plate extend in the same direction to form a first web and a second web respectively, the first web and the second web are vertical to the bottom plate, the end, away from the bottom plate, of the first web extends in the direction from the second web to the first web to form a first wing plate, the end, away from the bottom plate, of the second web extends in the direction from the first web to the second web to form a second wing plate, and both the first wing plate and the second wing plate are parallel with the bottom plate. The whole inverted-n steel is free of welding seams, and accordingly compared with inverted-n steel formed by welding five steel plates in the prior art, the inverted-n steel cannot deform and welding seams cannot break when the inverted-n steel bears large pressure, and better use performance is achieved.

Owner:胡杰

Railway liner plate for vibration reduction and noise reduction and preparation method of railway liner plate

InactiveCN108148220AStrong ability to withstand pressureGuaranteed mechanical strengthSynthetic resin layered productsMicrosphereRadiation resistance

The invention discloses a railway liner plate for vibration reduction and noise reduction, which relates to the field of railway vibration reduction parts. The railway liner plate for the vibration reduction and noise reduction comprises an upper surface layer and a lower surface layer which are made of 98 to 99.5 parts by weight of viscous resin and 0.5 to 2 parts of expansion microspheres, wherein the viscous resin comprises polyester, polyolefin and liquid rubber, and a shaping temperature of the expansion microspheres is higher than a melting temperature of the viscous resin. The railway liner plate for the vibration reduction and noise reduction has excellent elasticity, high vibration absorption capacity, good damping performance and excellent damping effect, and the absorbed energywhen in stress is large; and the railway liner plate also has the advantages of oil resistance, wear resistance, chemical corrosion resistance, radiation resistance and the like, and is small in compression deformation, high in mechanical strength, good in electric insulation performance and widely applicable to the high-speed railway tracks.

Owner:武汉鼎瑞新材料有限责任公司

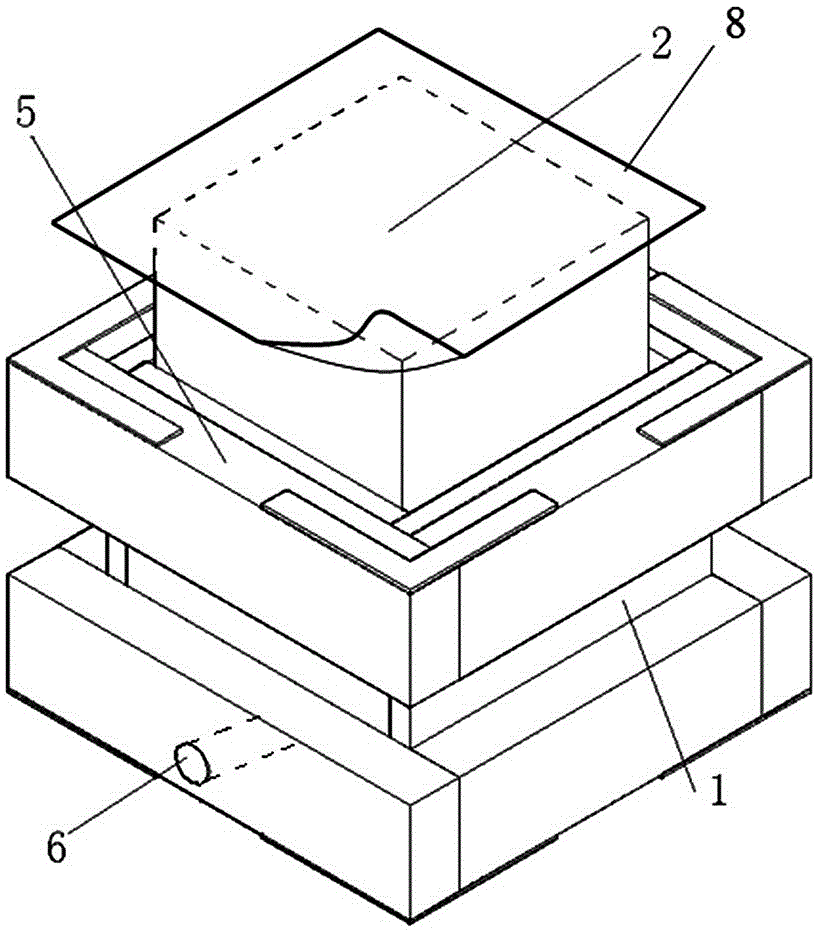

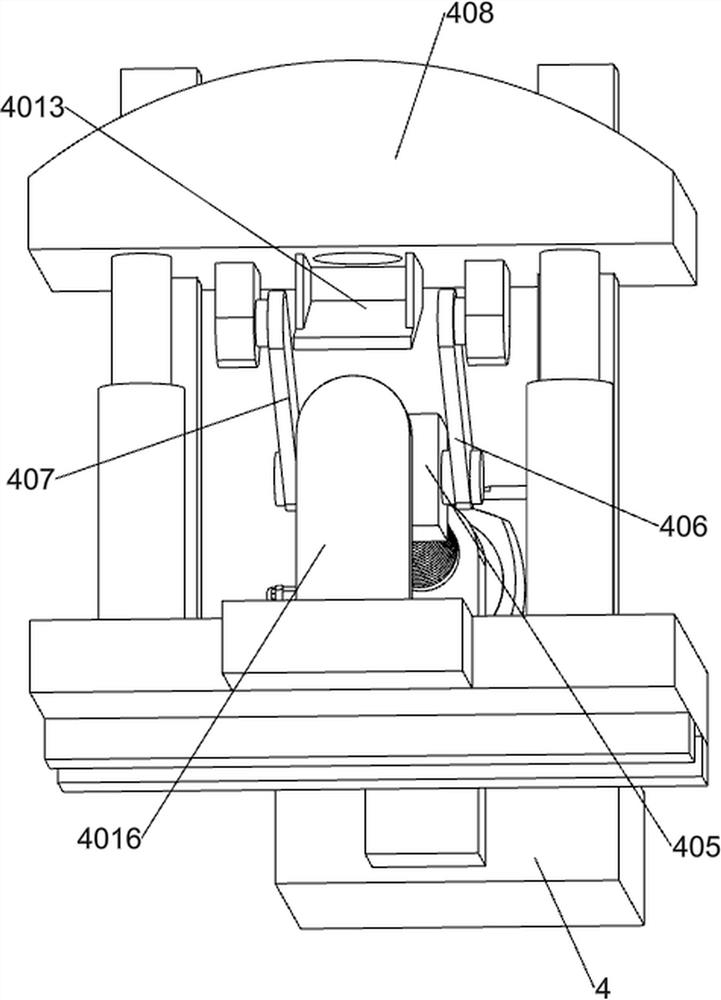

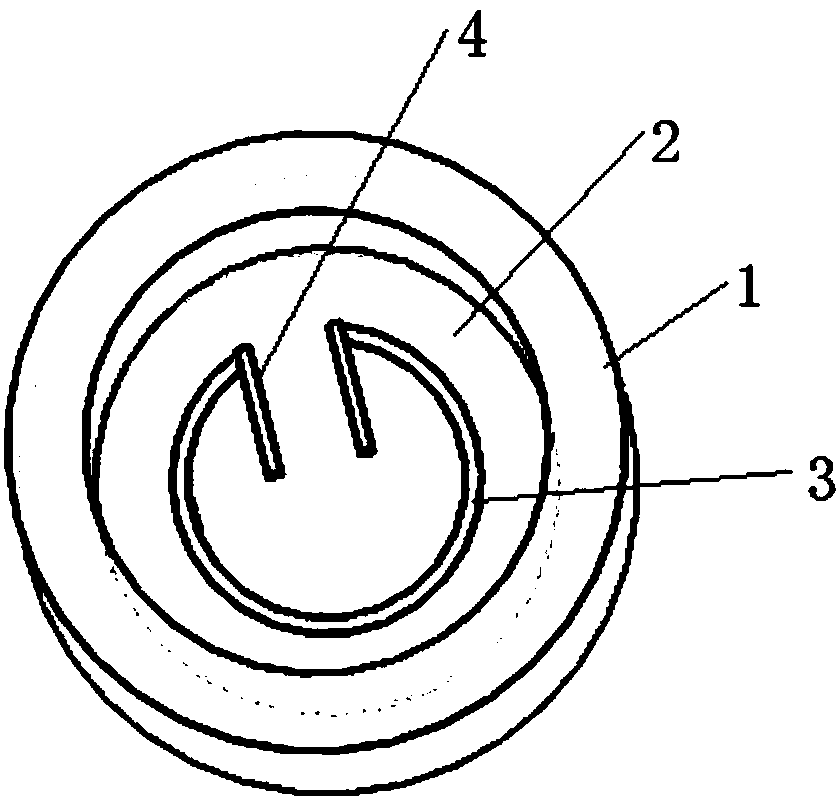

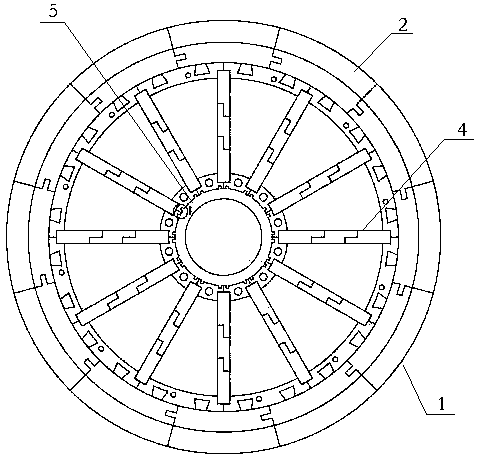

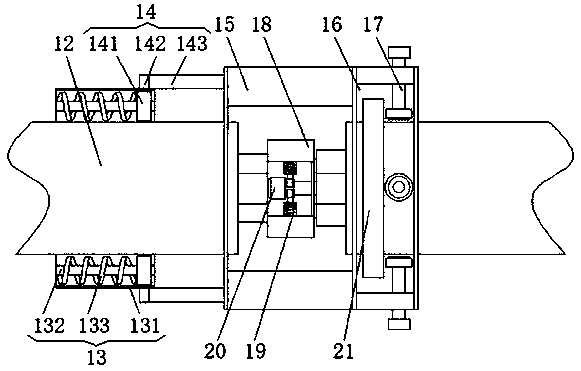

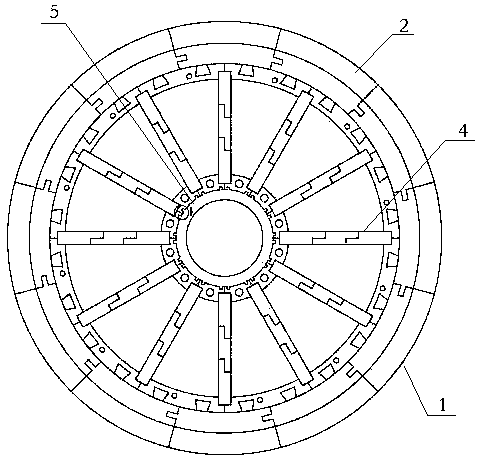

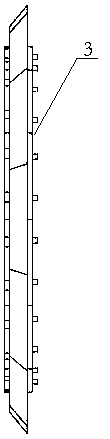

Clamping control inertial impact motor

ActiveCN111049422AStrong ability to withstand pressureSimple structurePiezoelectric/electrostriction/magnetostriction machinesLinear motionRhombic drive

The invention relates to a clamping control inertia impact motor, and belongs to the technical field of precision driving and positioning. The motor comprises a base, a pair of clamping guide rails, alinear slide rail, a weight balancing mechanism, a mass mechanism, a driving mechanism and a clamping mechanism; the two clamping guide rails are arranged on the base in parallel; the linear slide rail is arranged on the base and is located between the two clamp guide rails; the weight balancing block of the weight balancing mechanism and the mass block of the mass mechanism are arranged on the linear sliding rail in a sliding mode through sliding blocks respectively; the driving mechanism comprises a hollow rhombic driving piece and a driving piezoelectric stack; the clamping mechanism comprises a hollow rhombic clamping piece and a clamping piezoelectric stack; the driving mechanism controls the extension and contraction of a pair of driving feet by utilizing the inverse piezoelectric effect of the driving piezoelectric stack; the clamp mechanism controls the extension and contraction of the pair of clamping feet by utilizing the inverse piezoelectric effect of the clamping piezoelectric stack; the bidirectional linear motion of the piezoelectric motor is realized through the cooperative work of the driving mechanism and the clamping mechanism. Theoretically, the clamping mechanism does not generate sliding friction force, and therefore, energy loss is small.

Owner:HEFEI UNIV OF TECH

Epoxy resin adhesive used for repairing pipe

ActiveCN101058705AGood construction performanceStrong ability to withstand pressurePipe elementsEpoxy resin adhesivesChemistryEther

The invention discloses an epoxy resin adhesive to repair pipe, which consist of material A and material B with weight rate at 0. 2-0. 8, wherein the material A is composed of 1wt% liquid epoxy resin, 0. 05-0. 2wt% epoxypropane butyl ether, 0. 001-0. 02wt% isobutyl titanic acid, 0. 05-0. 2wt% organic alta-mud, 0. 02-0. 2wt% ferric powder, 0. 1-0. 5wt% aluminium powder, 0. 01-0. 1wt% titanium powder, 0. 02-0. 1wt% alumina, 0. 02-0. 1wt% carborundum; the material B contains 1wt% carbamoyl-amine, 0. 02-0. 1wt% acetic ether and 0. 02-0. 1wt% dimethylamino cresol methyl. The invention can reduce the repairing cost greatly, which simplifies the manufacturing technique without special equipment.

Owner:天津市巨星防腐检测工程有限公司

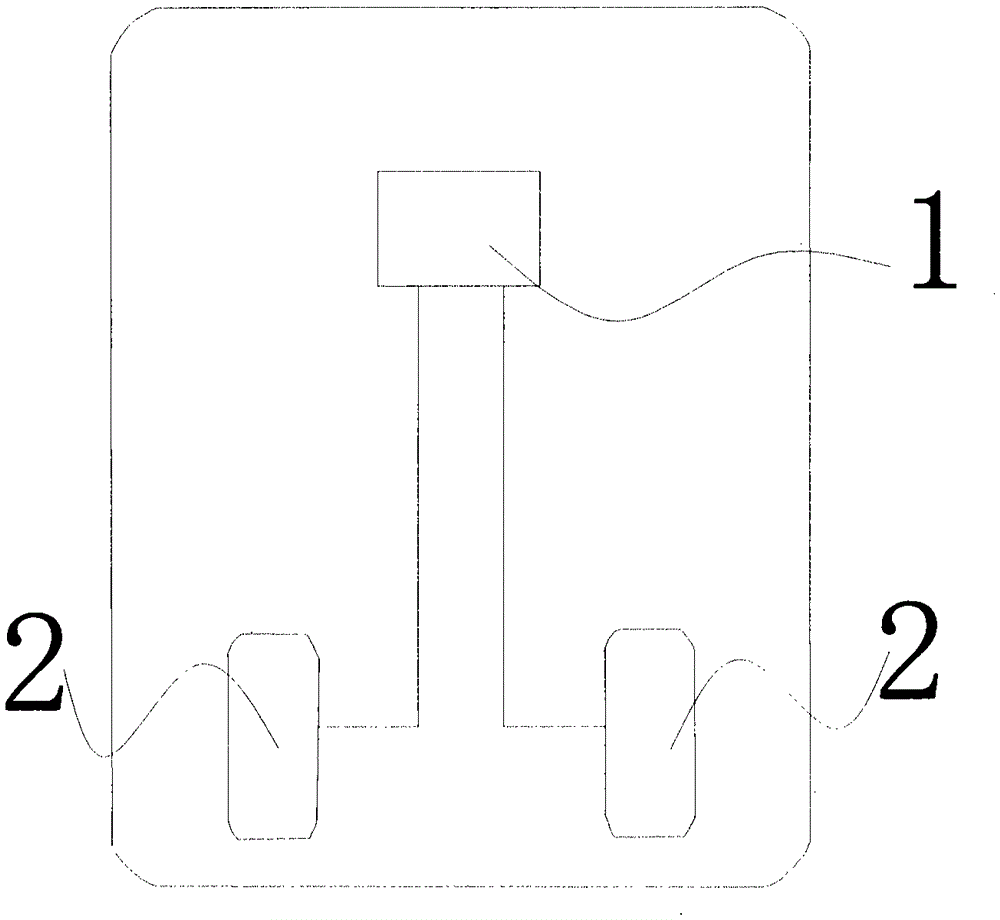

Combined type bridge temporary support and construction method for rapidly building continuous beams by virtue of same

ActiveCN105133487AStrong ability to withstand pressureSimple structureBridge structural detailsBridge erection/assemblyContinuous beamEnvironmental resistance

The invention discloses a combined type bridge temporary support and a construction method for rapidly building continuous beams by virtue of the same. According to the combined type bridge temporary support, by virtue of adequate utilization of mechanical properties of materials of steel, wood and concrete, the problems of poor compressive stability and durability, convenience in mounting and dismounting, low in bridge positioning accuracy and the like of various existing bridge temporary supports are solved. A top-open wood sand box serves as a dry sand container, and the lateral pressure of the sand box is negligible under loading; steel pipes and sand serve as a loaded entirety, i.e., the extremely good compressive property and stability of sand under a lateral constrain condition are adequately utilized; a concrete cube has good compressive property as well; the bridge temporary support produced by combining the dry sand container, the loaded entirety and the concrete cube has the advantages of safety, economical efficiency, environmental friendliness and stability. The bridge temporary support is low in production cost, high in mounting and dismounting speeds, safe and stable and can be repeatedly and circularly used; by virtue of a rapid positioning method of a T-shaped beam plate, bridges can be accurately mounted in one time, and the actual application effect of the bridge temporary support is good.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

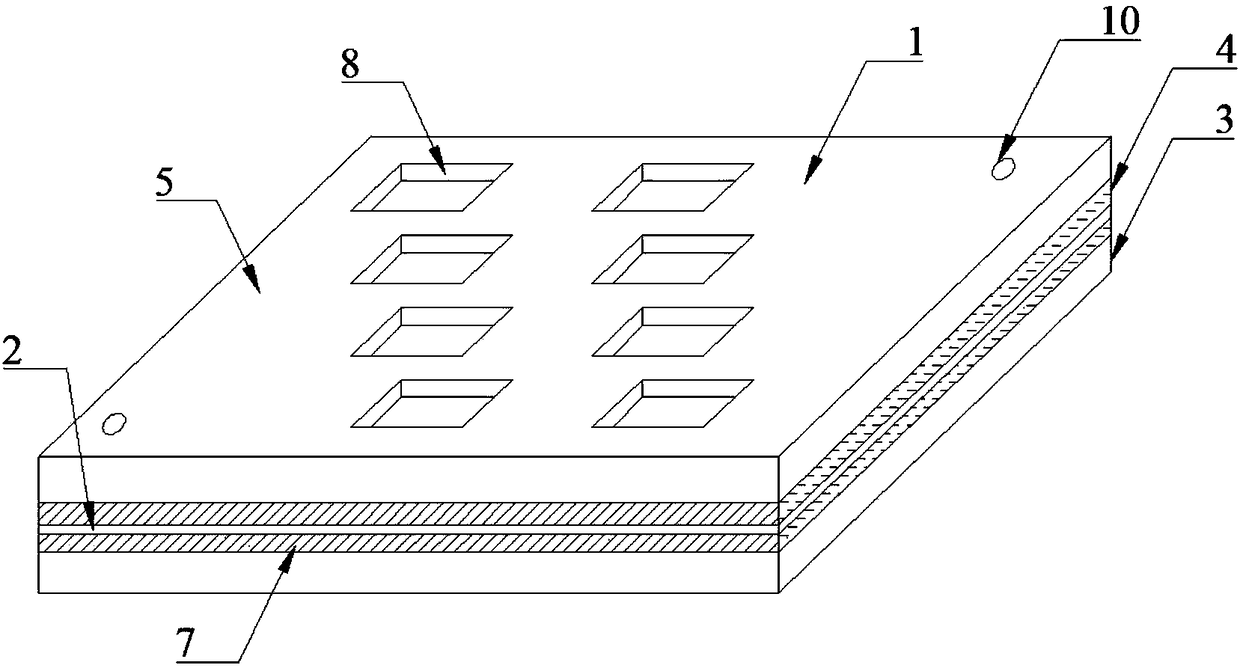

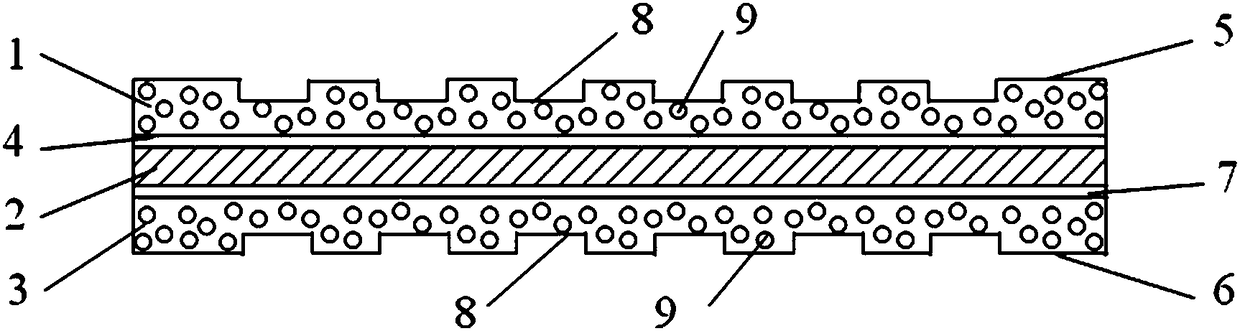

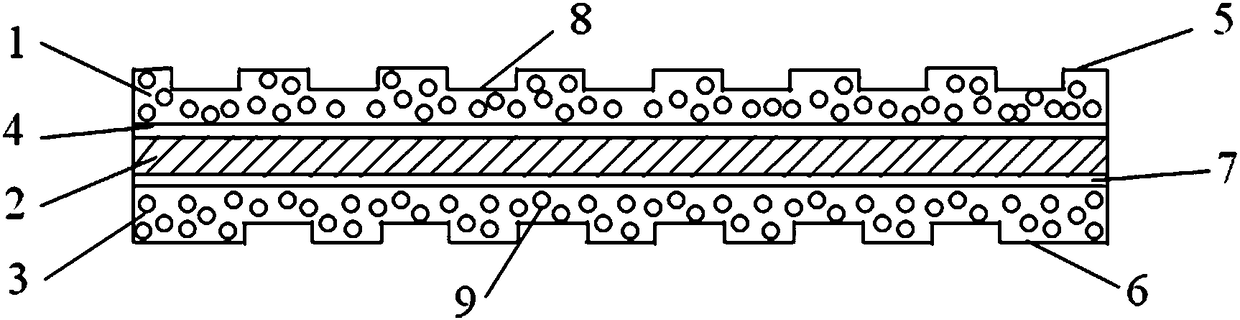

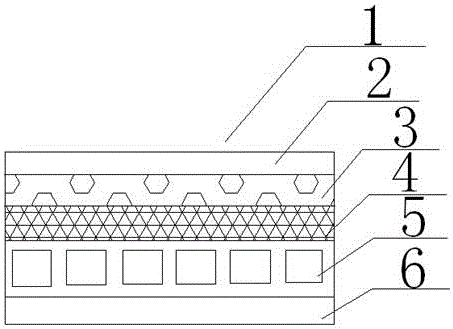

Sound insulation and flame retardance wood plastic plate

InactiveCN105937296AFlame retardantNoise-proofCovering/liningsFlooringPolymer sciencePolymer chemistry

The invention discloses a sound insulation and flame retardance wood plastic plate which comprises a plate body. The plate body comprises a fireproof coating layer, a sound insulation material layer, a high polymer material layer, a through hole layer and a base plate. The fireproof coating layer is arranged on the outmost layer of the plate body, the sound insulation material layer is arranged below the fireproof coating layer, the high polymer material layer is arranged below the sound insulation material layer, the through hole layer is arranged below the high polymer material layer, and the base plate is arranged below the through hole layer. The sound insulation and flame retardance wood plastic plate has the advantages of being strong in flame retardance, noise prevention and pressure bearing capacity, not prone to deformation, quite good in cooling function and the like.

Owner:ANHUI WANG YUE WPC

Plastic extrusion type physical low-foaming molding method

InactiveCN103434153AStrong ability to withstand pressureGood surface smoothnessFlat articlesCold airPolyresin

The invention provides a plastic extrusion type physical low-foaming molding method. The plastic extrusion type physical low-foaming molding method is characterized by comprising the following steps: taking expandable polyethylene as a main raw material and mixing the main raw material with an auxiliary material; then adding a mixture into an extruder hopper and uniformly fusing and plastifying resin by an extrusion screw rod; meanwhile, injecting a foaming agent into the fused rein under a condition of high pressure; uniformly mixing the foaming agent with the resin and cooling; extruding and foaming by using a die head; forcedly cooling the outer surface of a sheet material by a die head air ring; sizing by a sizing sleeve and cooling the inner surface of the sheet material by cold water; blowing cold air onto the outer surface of the sizing sleeve to cool the outer surface of the sheet material; planing the cooled sheet material by a cutter into finished sheet materials and winding. The plastic extrusion type physical low-foaming molding method has the beneficial effects that a produced foaming body is relatively strong in compressive capacity, has good size stability, surface flatness and vibration absorption performance, is low in cost, has the environment-friendly effect, is flat, and can be applied to the fields of various electric appliances, electronics, precise instruments, car decorations and indoor furniture.

Owner:SHANDONG TONGJIA MACHINERY

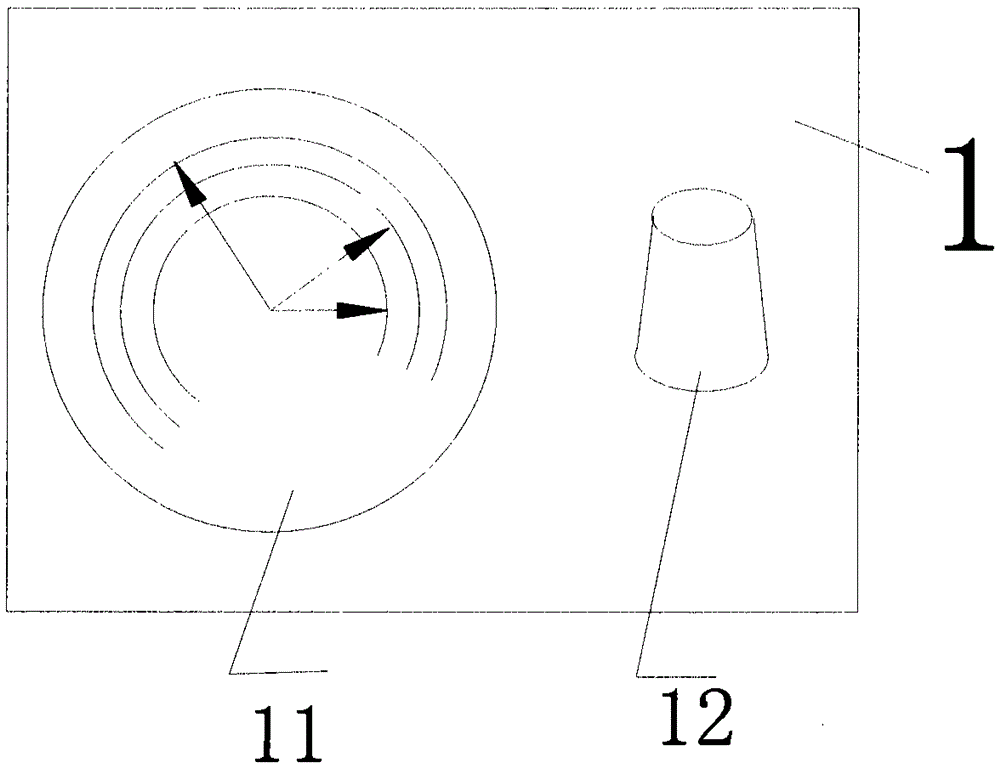

Vehicle acceleration device

The invention discloses a vehicle acceleration device. The vehicle acceleration device comprises a controller and boosters which are connected through wires. The vehicle acceleration device is characterized in that the controller comprises a dial plate and a valve control button. Each booster comprises a storage tank and stored materials inside a cavity of the storage tank, wherein a valve and a jet nozzle are arranged at a discharging outlet of the storage tank, and the jet nozzle is connected with the discharging outlet of the storage tank through the valve. The vehicle speed can be greatly increased by applying the vehicle acceleration device on a vehicle, especially a racing vehicle.

Owner:SHENZHEN YUZHENTONG TECH CO LTD

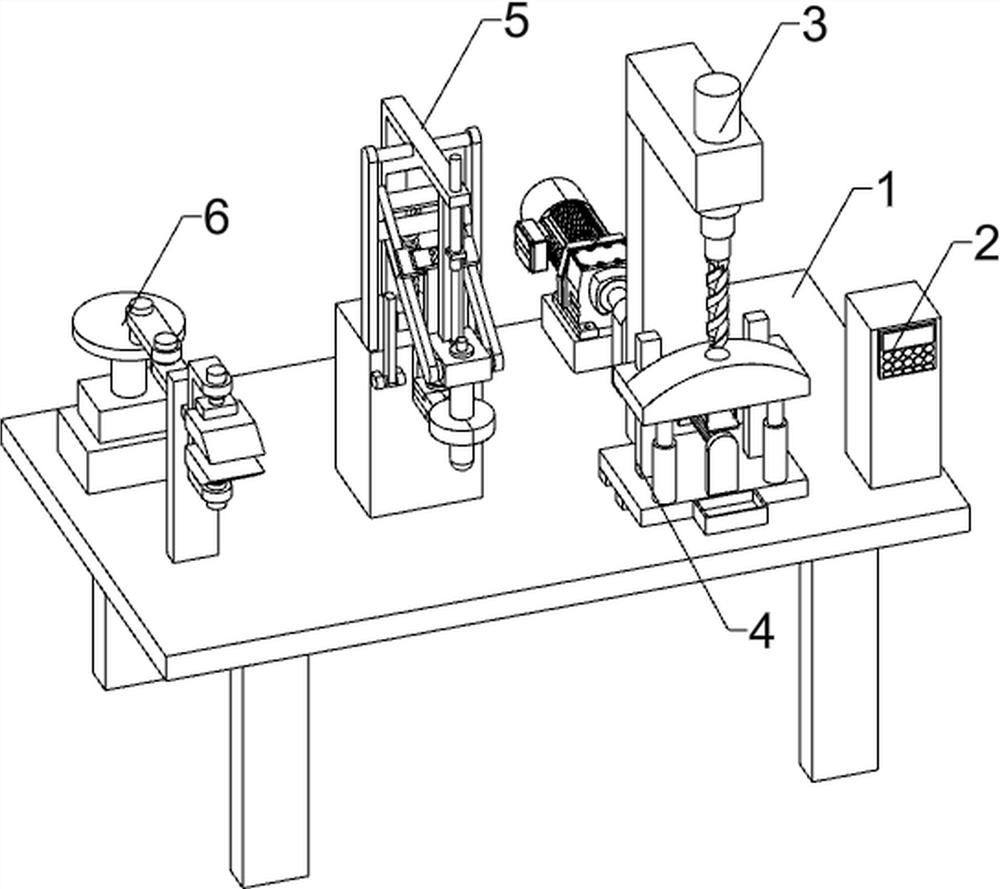

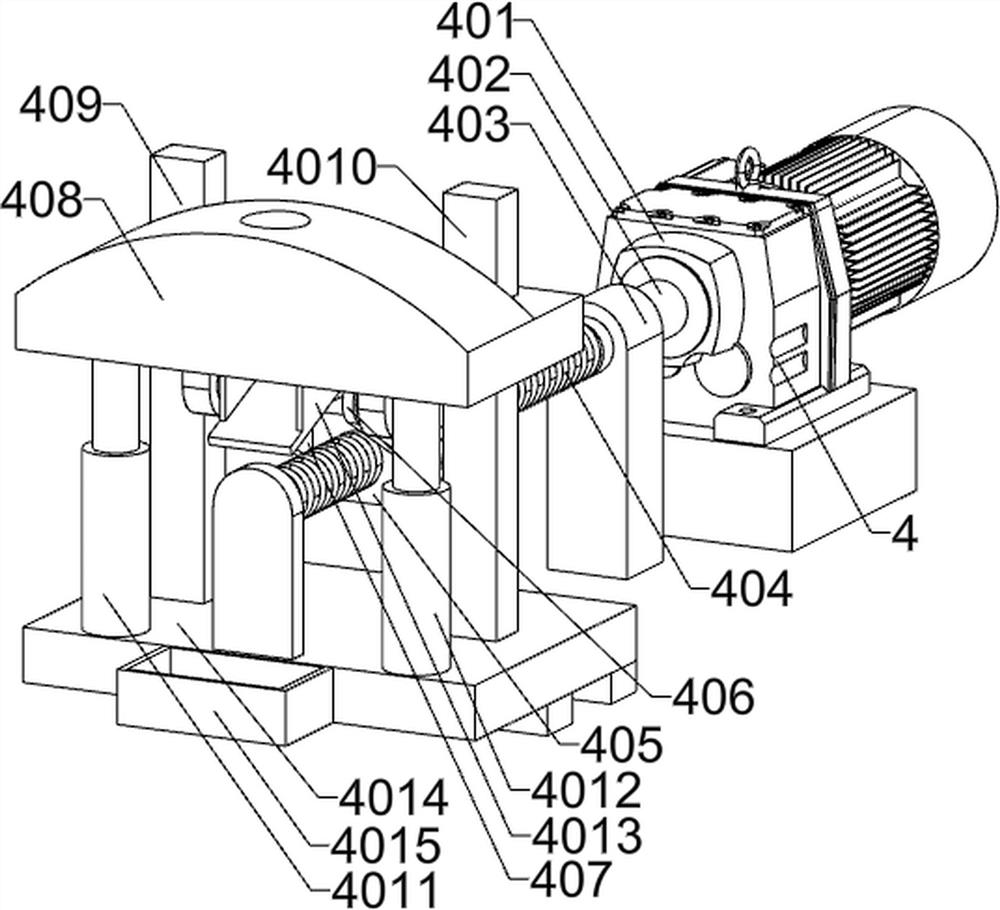

Automatic punching device for battery manufacturing

ActiveCN112976149AStrong ability to withstand pressureMaintain integrityCell component detailsMetal working apparatusPhysicsCell fabrication

The invention relates to the field of battery manufacturing, in particular to an automatic punching device for battery manufacturing. The technical problem of the invention is to provide the automatic punching device for battery manufacturing. According to the technical scheme, the automatic punching device for battery manufacturing comprises a working machine tool plate, an operation control screen, an electric telescopic electric drill, a punching system, a repairing system and a burr removing system; and the upper part of the working machine tool plate is connected with the operation control screen. In the drilling process, a plastic shell slightly arches from inside to outside, the situation that a drill hole and the nearby area sink inwards due to the inward drilling pressure of a drill bit is avoided, plastic residues on the edge of the drill hole are filled back into the drill hole after being hot-melted, the inner surface of the drill hole is a volcano-shaped curved surface with the diameter gradually enlarged instead of a cylindrical curved surface.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

Diamond film-based full-sea depth temperature sensor and preparation method thereof

PendingCN107631809AHigh mechanical strengthStrong ability to withstand pressureThermometer detailsTemperature measurement of flowing materialsSeawaterFilm material

A diamond film-based full-sea depth temperature sensor disclosed by the present invention comprises a tubular metal shell, a diamond substrate is arranged at the top end of the metal shell, and a temperature response element made of a boron doped diamond film material is arranged in the metal shell and on the diamond substrate. Electrode lead wires are arranged at the two ends of the temperature response element, the temperature response element and the electrode lead wires are covered with the ceramic or diamond-like carbon insulating layers, and a seal ring is arranged at the connection position of the metal shell and the diamond substrate. Meanwhile, the present invention also discloses a preparation method of the temperature sensor. The temperature sensor disclosed by the present invention is small in size, fast in response speed, high in resolution and stable in structure, and the measurement is not influenced by the external seawater pressure.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Communication optical cable well and construction method thereof

InactiveCN108678012AStrong ability to withstand pressureReduce construction difficultyArtificial islandsUnderwater structuresOptical fiber cableWater leakage

The invention discloses a communication optical cable well and a construction method thereof. The optical cable well comprises a lower semicircle cylinder, an upper semicircle cylinder and a well cover, wherein the upper semicircle cylinder and the lower semicircle cylinder are connected together, and the well cover is installed on the upper semicircle cylinder; a first reinforcing rib is installed at the bottom of the lower semicircle cylinder, and a second reinforcing rib is installed on the inner wall of a cylinder body formed by connecting the lower semicircle cylinder and the upper semicircle cylinder; and the upper semicircle cylinder is provided with a wire inlet and a wire outlet which are oppositely arranged, the inner wall of the upper semicircle cylinder is provided with clamping devices, and the two clamping devices are oppositely arranged; and the communication optical cable well is arranged in a pre-digging groove, and hollow rubber air bags are filled with a gap betweenthe pre-digging groove and the communication optical cable well. According to the method, the communication optical cable well is high in anti-pressure ability, and the situation that normal work is affected by occurring of water leakage due to the deformation of the pre-digging groove is avoided; and meanwhile, by dividing the well wall of the communication optical cable well into the upper semicircle cylinder and the lower semicircle cylinder, the construction difficulty is reduced, and the dismounting and the maintenance are convenient.

Owner:杨耙

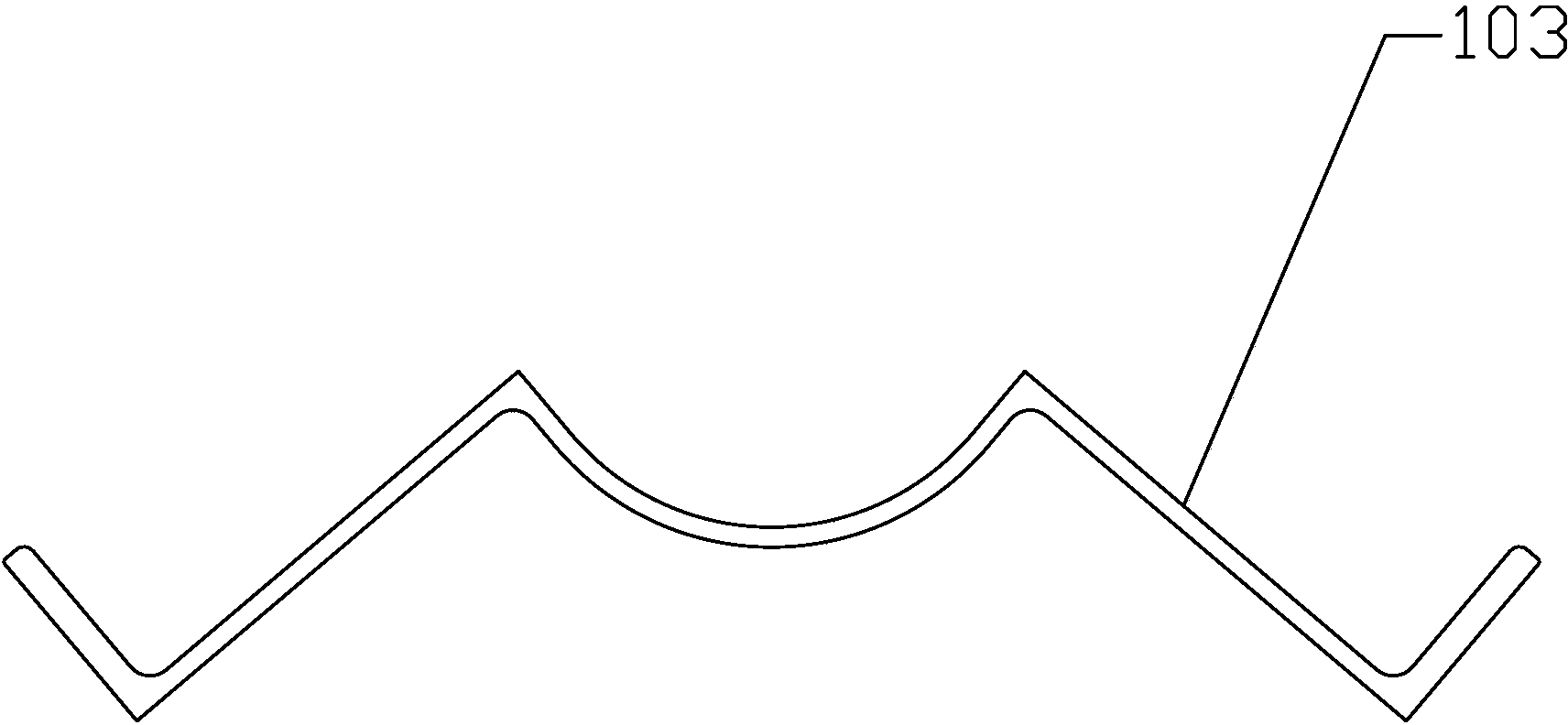

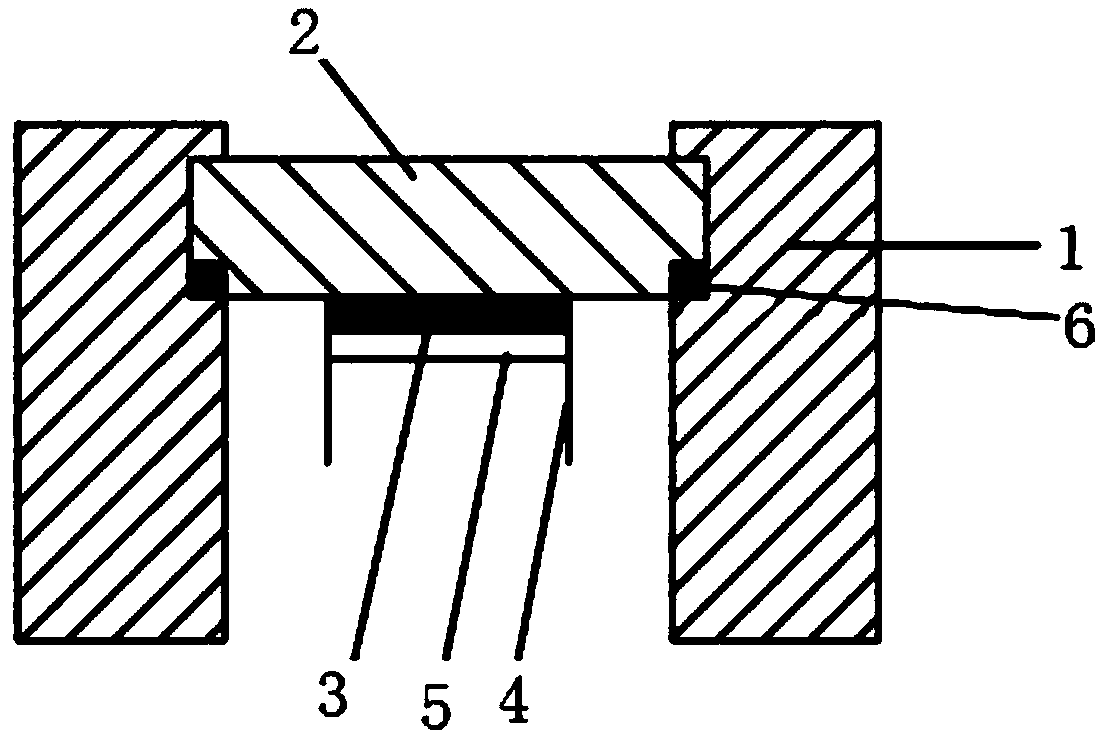

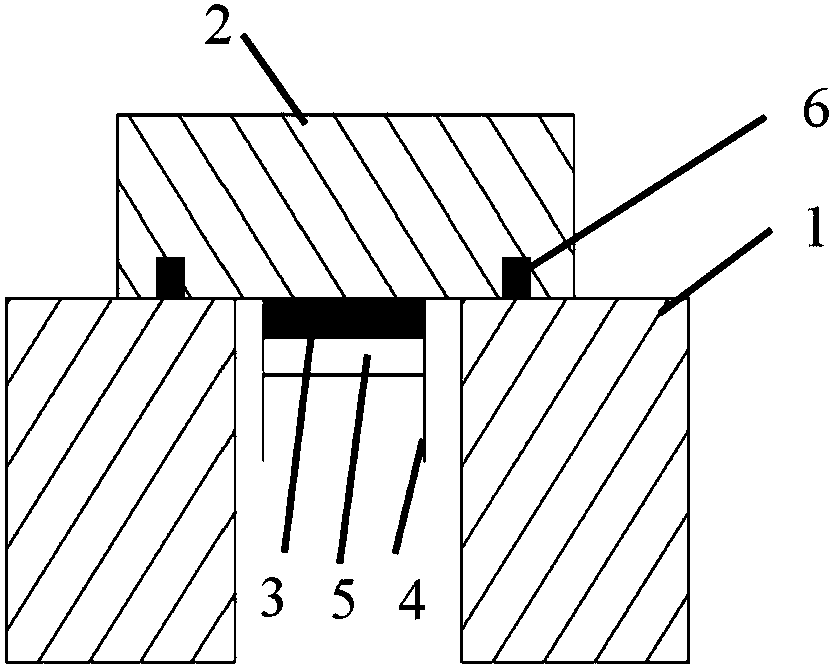

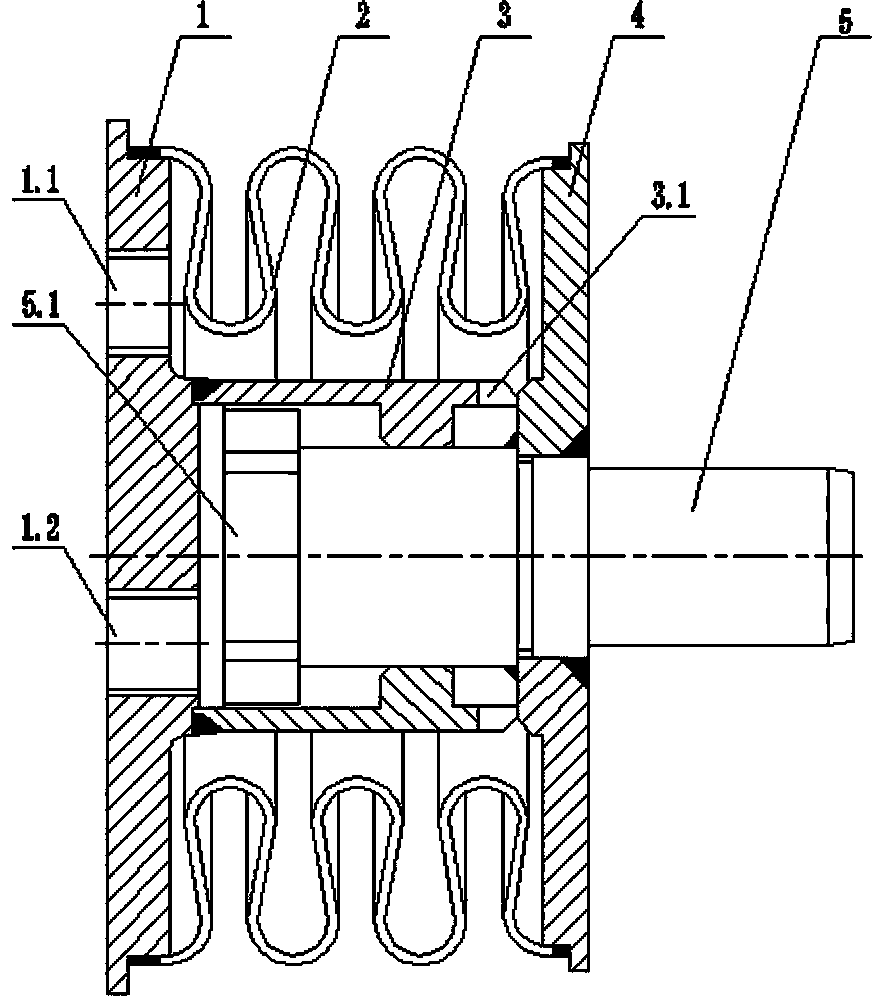

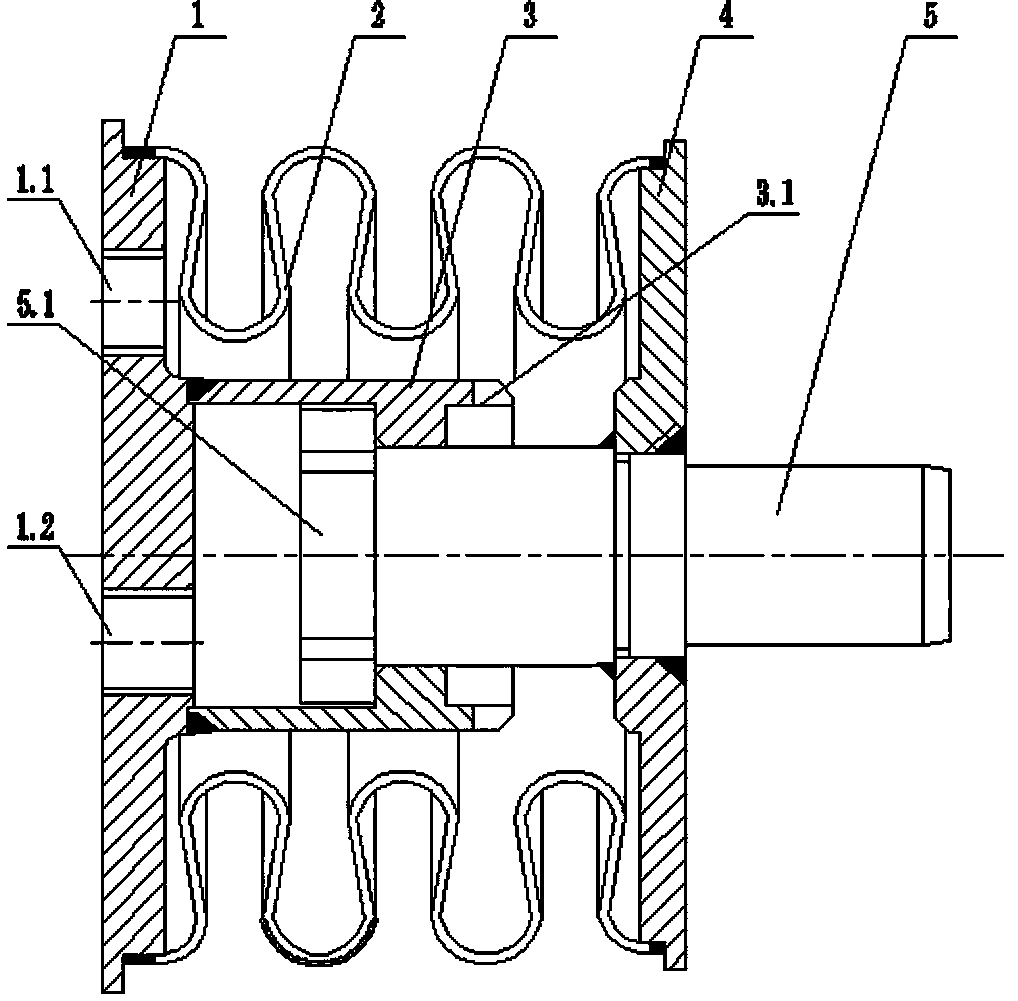

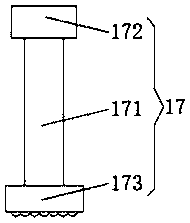

Guiding type corrugated limiter

InactiveCN103883826AUniform elastic deformationStrong ability to withstand pressurePipeline expansion-compensationThin walledEngineering

The invention discloses a guiding type corrugated limiter which is composed of a cover plate, corrugated tubes, a guiding sleeve, a base plate and a core shaft. The guiding sleeve is a thin wall shaft sleeve internally provided with a circular bead, a notch is formed in the opening portion of the right end of the guiding sleeve, the corrugated tubes are arranged outside the centered guiding sleeve, and the core shaft is arranged in the guiding sleeve in a clearance fit mode. The cover plate is respectively connected with the left end face of the guiding sleeve and the left end faces of the corrugated tubes in a sealed mode, and the base plate is installed on the core shaft in a sleeved mode, abuts against the right end face of the guiding sleeve, and is respectively connected with the right ends of the corrugated tubes and the core shaft in a sealed mode to form a linkage structure. The circular bead arranged in the guiding sleeve is of the structure that concave portions and convex portions are alternatively arranged on the same circumference, the shape of the cross section of the large end face of the core shaft is the same as the shape of the circular bead arranged in the guiding sleeve, and the core shaft is in clearance fit with the guiding sleeve to form an anti-torque structure for straight going of the core shaft. The waveform axial sections of the corrugated tubes in the guiding type corrugated limiter are in omega shapes, the tube walls of the corrugated tubes are smooth, thick, reasonable in stress and even in elastic deformation, limitation is accurate, and the corrugated tubes are particularly suitable for working under the high-temperature and high-pressure working conditions.

Owner:JIANGSU SHUGUANG PRESSURE VESSEL

Process and apparatus for producing o-phenylenediamine

ActiveCN1274665CGood colorNo pollutionOrganic compound preparationAmino compound preparationPhase shiftedCopper

The invention provides a process for producing o-phenylendiamine comprising the steps of, charging ortho dichlorobenzene, ammonia into high temperature, high pressure container, proceeding ammonolysis reaction at the presence of catalyst, analyzing and separating the obtained reactant, charging ortho dichlorobenzene, liquid ammonia, copper catalyst, phase shift catalyst into pipe type reactor continuously for ammonolysis reaction. The invention also discloses a production apparatus for realizing the method.

Owner:江西扬帆新材料有限公司

Antistatic PE pipe and manufacturing method thereof

InactiveCN109467776AStrong ability to withstand pressureGood weather resistanceWeather resistanceCarbon black

The invention discloses an antistatic PE pipe and a manufacturing method thereof. The antistatic PE pipe is prepared from the following raw materials in parts by mass: 80 to 100 parts of PE resin, 3 to 8 parts of dibasic lead sulfate, 3 to 5 parts of strontium stearate, 3 to 5 parts of lead stearate, 3 to 5 parts of a carbon fiber, 1 to 3 parts of carbon black, 1 to 3 parts of paraffin, 2 to 5 parts of zinc oxide, 1 to 3 parts of aluminum powder, 5 to 10 parts of a stabilizer, 5 to 10 parts of a curing agent, 5 to 10 parts of a reinforcing agent, 2 to 5 parts of a toughening agent, 1 to 5 parts of an antioxidant and 1 to 3 parts of a coupling agent. The manufacturing method comprises the following steps: mixing, extrusion molding, air cooling, quality inspection, packaging, and warehousing. The antistatic PE pipe has high pressure resistance, high weather resistance and high antistatic property and is suitable for conveying static sensitive flowable substances.

Owner:TAIZHOU UNIV

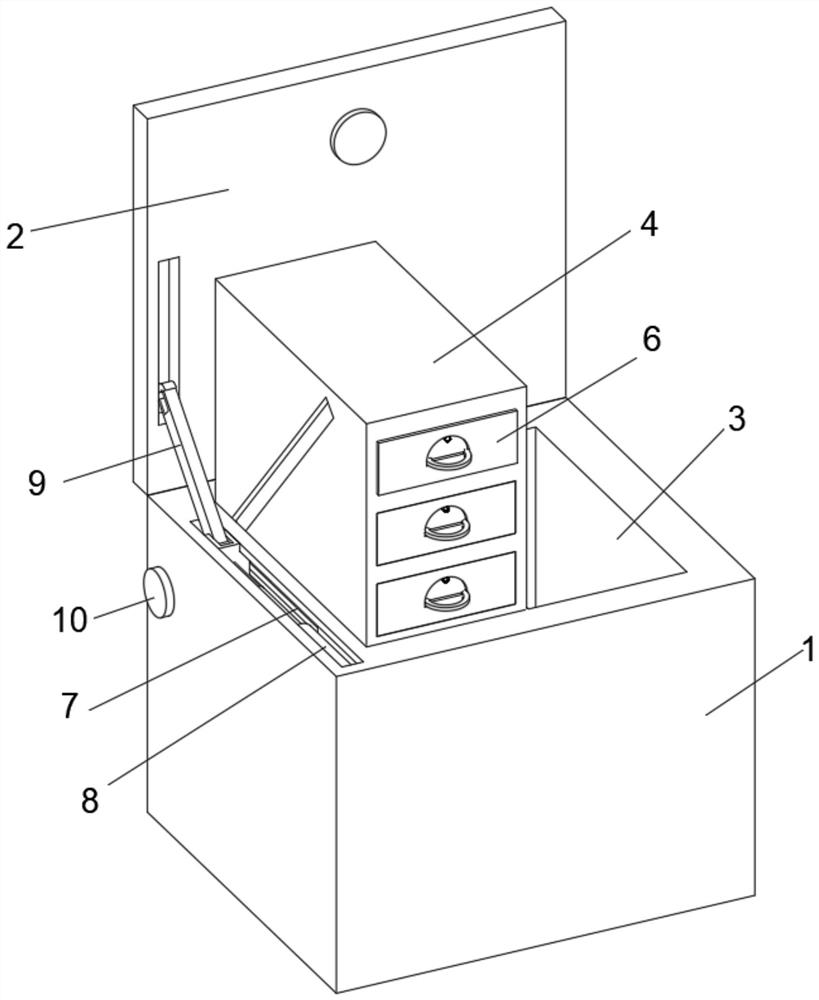

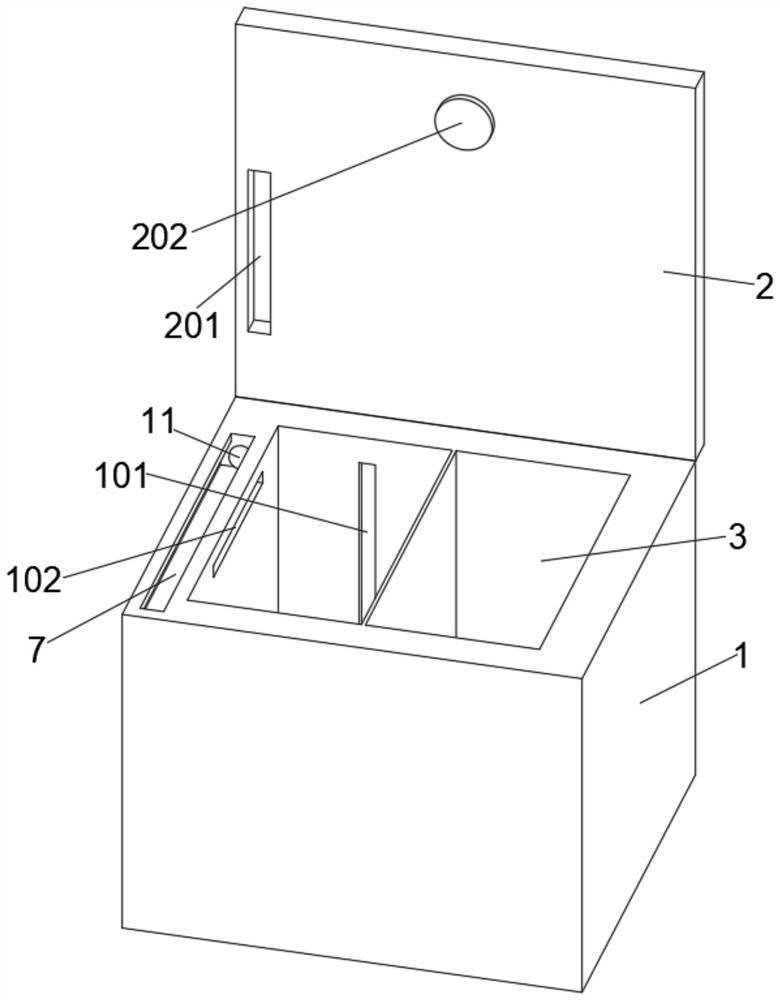

Remote medical equipment convenient for old people to take medicine based on Internet of Things

PendingCN112716807APrevent the problem of taking the wrong medicinePromote withdrawalPharmaceutical containersMedical packagingMedical equipmentThe Internet

The invention discloses remote medical equipment convenient for old people to take medicine based on the Internet of Things, and belongs to the technical field of remote medical equipment. Remote medical equipment convenient for old people to take medicine based on the Internet of Things comprises a medicine box, an electric push rod is fixedly arranged on the inner wall of the front side of a T-shaped groove, a transmission assembly is arranged in the T-shaped groove, a switch is installed on the rear wall of the T-shaped groove, and a loudspeaker is installed on the left wall of the medicine box. An electric push rod is used for driving a moving block to move, so that the moving block moves backwards, when the moving block moves, a connecting rod is driven to move, the hinged connecting rod drives a hinged cover plate to be opened, and when the moving block moves in place, the moving block makes contact with a rubber cover of a switch, and a loudspeaker makes a sound which is recorded in advance and reminds the old to take medicine. The old people can be reminded to take medicine through calling, and the old people can see that the medicine is taken up through the camera, so that family members outside can be relieved.

Owner:王斌

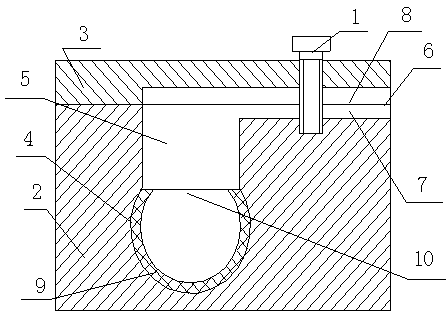

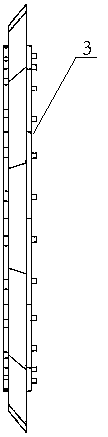

Gapless air curtain blow nozzle and air blowing method

InactiveCN103423832AStrong ability to withstand pressureExtended service lifeLighting and heating apparatusSpray nozzlesEngineeringMechanics

The invention relates to a gapless air curtain blow nozzle and an air blowing method. The air outlet hole of the existing air curtain blowing and flushing pipe is the circular hole, the spraying area for air blowing is very small and belongs to the dot spraying, and the harmful gas cannot be completely blocked from entering, so the air purity in the escape capsule and the refuge chamber cannot be ensured, and the safety of refugees cannot be ensured. The gapless air curtain blow nozzle consists of a base (2) and a press cover (3), wherein the base (2) and the press cover (3) are connected through a screw (1), the base is provided with an air inlet pipe groove (4), the air inlet pipe groove is connected with an air outlet groove (5), the air outlet groove is connected with a lower air spraying curtain port (7), the press cover is provided with an upper air spraying curtain port (8), the base is connected with the press cover, and the upper air spraying curtain port and the lower air spraying curtain port form an air spraying curtain port (6). The gapless air curtain blow nozzle is used for blocking the harmful air from entering the refugee chamber.

Owner:HEILONGJIANG YUXI MACHINERY MFG

High pressure-resistant and high temperature-resistant material and preparation process thereof

InactiveCN106883538AStrong ability to withstand pressureLow friction coefficientTitanium tetrachloridePolytetrafluoroethylene

The invention relates to a high pressure-resistant and high temperature-resistant material and a preparation process thereof. The high pressure-resistant and high temperature-resistant material comprises the following raw materials in parts by weight: 30-40 parts of polytetrafluoroethylene, 15-20 parts of sodium laurylsulfate, 25-30 parts of chlorinated polyethylene, 15-25 parts of polyurethane, 5-10 parts of titanium dioxide, 5-10 parts of titanium tetrachloride, 8-12 parts of stearic acid, 35-40 parts of acetylacetone peroxide, 15-25 parts of alkane and 30-50 parts of absolute ethyl alcohol. The high pressure-resistant and high temperature-resistant material is high in resistance to the pressure of -0.2MPa to 6.6MPa, resistant to high temperature and low temperature in the temperature range of -200 DEG C to 360 DEG C, small in friction coefficient, high in wear resistance, high in adaptability and excellent in corrosion resistance, oxidation resistance and flame retardance.

Owner:马鞍山纽盟知识产权管理服务有限公司

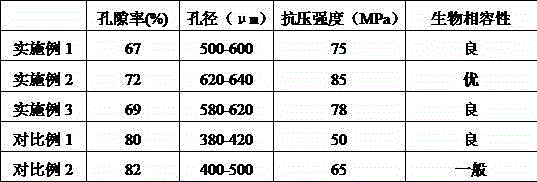

Medical titanium alloy and preparing method thereof

ActiveCN104962796AUniform pore size and porosityStrong ability to withstand pressureTitaniumTitanium alloy

The invention discloses medical titanium alloy and a preparing method thereof. The medical titanium alloy comprises, by mass, 12-18% of titanium, 28-42% of zirconium, 8-12% of copper, 0.5-1.4% of calcium, 12-26% of ceramic powder, 0.2-0.5% of nickel, 0.6-0.8% of tungsten, and 0.3-0.8% of platinum. The preparing method comprises the steps of weighing raw materials, adding titanium, copper, calcium, nickel, tungsten and platinum to a reaction still to be stirred, and conducting heating in the presence of inert gases at a constant speed to 3000-3500 DEG C to obtain a first mixture; adding ceramic powder to the first mixture, conducting stirring, and then conducting heating to 3800-4000 DEG C to obtain a second mixture; cooling the second mixture at the speed of 100-200 DEG C / min to 2200-2500 DEG C, and then conducting cooling at the speed of 400-500 DEG C / min to indoor temperature to obtain the medical titanium alloy. The titanium alloy has uniform bore diameter and high biocompatibility, is harmless to the human body, and is suitable for popularization.

Owner:南通金百吉五金制造有限公司

Petroleum pipeline plugging device

The invention provides a petroleum pipeline plugging device. The petroleum pipeline plugging device comprises a plugging part which is matched with a to-be-maintained pipeline in shape, wherein the bottom of one side, away from an opening part of the to-be-maintained pipeline, of the plugging part is sealed; flange shaped sealant is further arranged on the side surface of the plugging part; a groove is formed in the side surface of one side, close to the opening part of the to-be-maintained pipeline, of the sealant; and both the plugging part and the sealant are made of a material which can bedissolved into petroleum. The petroleum pipeline plugging device has the beneficial effects of high efficiency and high safety.

Owner:李得恩

Environment-friendly brick and preparation process thereof

The invention relates to the technical field of brick production, in particular, an environmentally-friendly brick. The environment-friendly brick is prepared from the following raw materials in partsby weight: 50 to 70 parts of waste glass powder, 50 to 70 parts of waste ceramic powder, 50 to 70 parts of waste coal slag powder, 40 to 50 parts of reservoir sludge, 30 to 35 parts of building gravel powder, 20 to 25 parts of clay, 6 to 10 parts of an accelerator, 6 to 10 parts of an adhesive and 8 to 12 parts of a degradation agent. The waste glass powder, waste ceramic powder, waste coal slagpowder, reservoir sludge and building gravel powder are used as main raw materials, building wastes and cleaning dirt are effectively recycled, environmental pollution is reduced, and the prepared environment-friendly brick is high in compression resistance, rapid in moulding and good in toughness by adding the clay, the accelerator and the adhesive. The degradation agent is added, through the combined action of photo-degradation and biodegradation, when the environment-friendly brick is discarded, the environment-friendly brick can be directly decomposed, no pollution is generated, the defects of a traditional environment-friendly brick are overcome, the quality of the environment-friendly brick is improved, the cost of the environment-friendly brick is effectively reduced, and the requirements of current development are met.

Owner:湖南耀盛新型建材有限公司

Filter material surrounded corrugated pipe for saline-alkali soil and preparation method thereof

InactiveCN110437561AStrong ability to withstand pressureGood low temperature toughnessAlkali soilGlycerol

The invention discloses a filter material surrounded corrugated pipe for saline-alkali soil, which is prepared from the following components in parts by weight: 65-70 parts of polyvinyl chloride resin, 0.1-0.5 part of acrylate, 0.5-1.2 parts of silane coupling agent KH-550, 1-2 parts of nano zinc oxide, 0.5-1.5 parts of barium stearate, 1-2 parts of calcium aluminum borosilicate, 0.8-1.5 parts ofsodium acetate, 2-3 parts of glycerol triacetate, 0.2-0.6 part of butylene glycol laurate, 1-3 parts of neopentyl glycol diheptanoate, and 0.5-1.5 parts of ethyl hexyl triazinone. The filter materialsurrounded corrugated pipe for saline-alkali soil provided in the invention is high in compression strength, good in low-temperature toughness, not prone to aging, and also high in saline-alkali tolerance.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Multistage layered high-intensity tunnel cable

ActiveCN108899124AStrong ability to withstand pressureImprove securityInsulated cablesPower cablesGeotechnical engineeringHigh intensity

The invention relates to the technical field of a cable, and discloses a multistage layered high-intensity tunnel cable. The multistage layered high-intensity tunnel cable comprises an insulation rod,wherein a cable core is arranged at the outer part of the insulation rod; a cable insulation protection layer is movably sheathed at the outer side of the cable core; a cable inner protection layer is fixedly sheathed at the outer part of the cable core; an insulation filling layer is filled between the cable inner protection layer and the cable insulation protection layer; a rubber protection layer is fixedly sheathed at the outer part of the cable inner protection layer; a cable shielding layer is arranged at the outer part of the rubber protection layer. The multistage layered high-intensity tunnel cable has the advantages that through the matched use of the insulation rod, the cable core, the cable insulation protection layer, the cable inner protection layer and the insulation filling layer, when being twisted, the cable can rotationally slide in the cable inner protection layer, so that the conditions that when the cable is twisted in the use and installing process, the moving cannot be performed, so that the cable damage is caused, and the service life of the cable is influenced are avoided.

Owner:新疆百商电线电缆有限公司

Directly buried heating pipeline system with corrosion-resistant heat-insulation function

InactiveCN107300091AGood insulation effectStrong ability to withstand pressureThermal insulationCorrosion preventionCorrosion resistantEngineering

The invention discloses a directly buried heating pipeline system with a corrosion-resistant heat-insulation function. The directly buried heating pipeline system with the corrosion-resistant heat-insulation function comprises a first heating pipeline, a second heating pipeline and heat-insulation shell pipeline, wherein the first heating pipeline and the second heating pipeline are arranged in the heat-insulation shell pipeline; sealing plates are respectively arranged at two ends of the heat-insulation shell pipeline; two small holes are formed in each sealing plate; the diameters of the two small holes of each sealing plate are the same as the diameter of the first heating pipeline and the diameter of the second heating pipeline; the first heating pipeline and the second heating pipeline can pass through each sealing plate through the two corresponding small holes separately; the heat-insulation shell pipeline further comprises an air inlet hole and an air outlet hole; the air inlet hole is formed in the upper end of the heat-insulation shell pipeline; the air outlet hole is formed in the lower end of the heat-insulation shell pipeline; the first heating pipeline and the second heating pipeline are arranged in the heat-insulation shell pipeline; and the heat-insulation shell pipeline is filled with hot air by the air inlet hole and the air outlet hole. The problem that the heating pipelines in the traditional directly buried pipeline system are in direct contact with soil to cause poor heating effect of the heating pipeline is solved.

Owner:MIANYANG FEIYUAN TECH CO LTD

Oil pipeline plugging device

Owner:李得恩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com