Railway liner plate for vibration reduction and noise reduction and preparation method of railway liner plate

A technology for railway and backing plates, which is applied in the field of shock-absorbing and noise-reducing railway backing plates and its preparation, which can solve problems affecting the shock-absorbing effect and service life of railway backing plates, material damage, etc., to achieve uniform force and improve impact resistance The effect of high performance and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Put 98g polystyrene particles and 2g expanded microspheres into the injection molding machine, the selected expanded microsphere density is 0.022g / cm 3 , The particle diameter is 120μm, and the screw temperature is set to 120℃, so that the material stays in the mold for 8 minutes.

[0057] Cut the product into the size of the standard railway backing plate in the current rail; take two pieces of products, and evenly coat the molten polyurethane hot melt adhesive on one side of them, and pass the polyurethane hot melt adhesive layer of the two pieces of products after vitrification The buffer layer is glued.

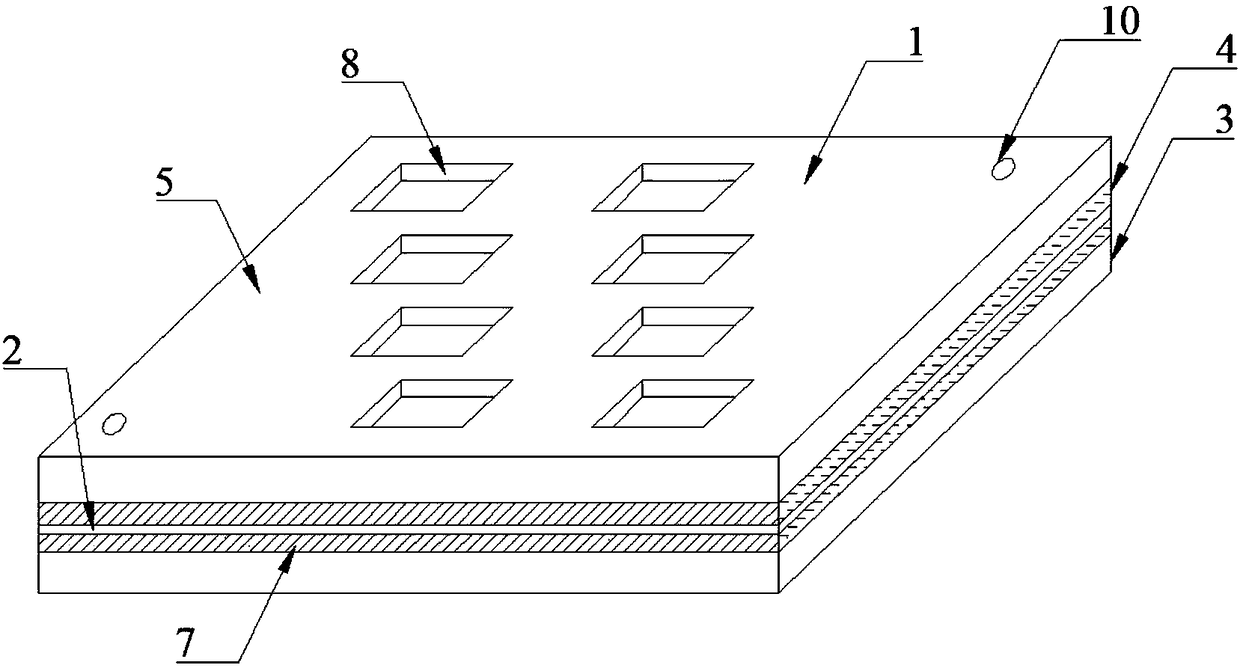

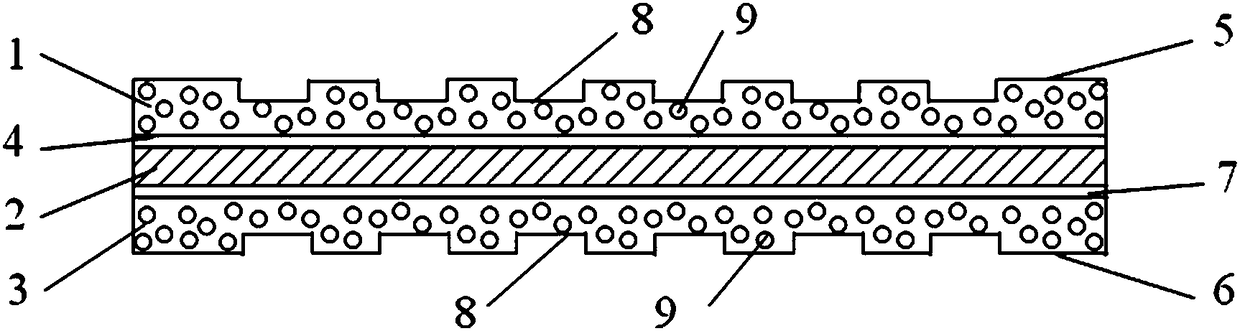

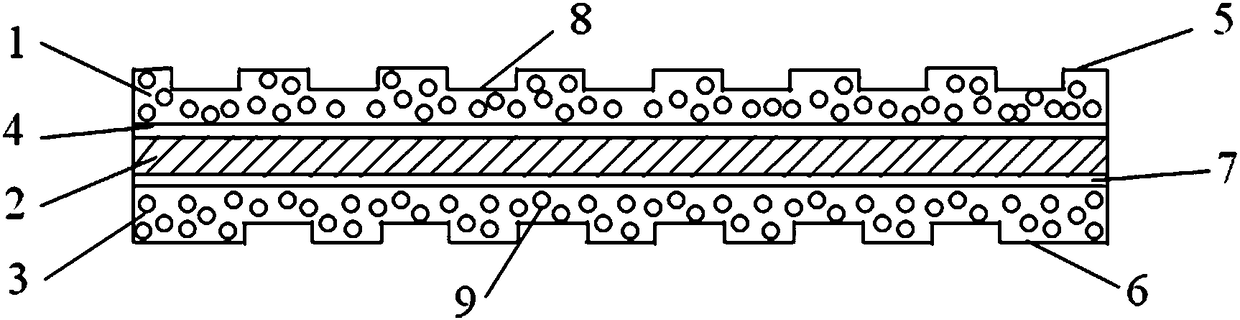

[0058] The structure of the railway pad in this embodiment is as figure 1 As shown, it is a multi-layer structure glued to each other, and from top to bottom are the upper surface layer 1, the first polyurethane hot melt adhesive layer 4, the buffer layer 2, the second polyurethane hot melt adhesive layer 3, and the lower layer 6 in order.

[0059] Among them, the thickne...

Embodiment 2

[0062] Put 99.5g of polycarbonate particles and 0.5g of expanded expanded microspheres into the injection molding machine. The density of the selected expanded microspheres is 0.028g / cm 3 , The particle diameter is 80μm, and the screw temperature is set to 150℃, so that the material stays in the mold for 10 minutes.

[0063] The shape and structure of the obtained railway backing plate are the same as the first embodiment.

Embodiment 3

[0065] Put 98g methyl methacrylate particles and 2g expanded expanded microspheres into the injection molding machine. The selected expanded microsphere density is 0.025g / cm 3 , The particle diameter is 100μm, the screw temperature is set to 130℃, so that the material stays in the mold for 9min.

[0066] The shape and structure of the obtained railway backing plate are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com