Sound insulation and flame retardance wood plastic plate

A sound insulation material and board technology, applied in the field of wood-plastic boards, can solve the problems of increased noise pollution, poor sound insulation effect, poor flame retardant effect, etc., and achieve the effect of strong pressure bearing capacity, good heat dissipation function and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

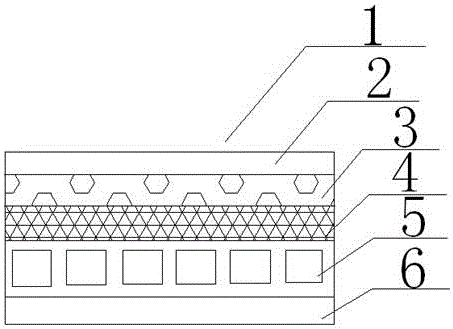

[0014] Such as figure 1 As shown, a new type of sound-insulating and flame-retardant wood-plastic panel includes a panel body 1, and the panel body 1 includes a fire-resistant coating layer 2, a sound-insulating material layer 3, a polymer material layer 4, a through-hole layer 5 and a backing plate 6 , the outermost layer of the plate body 1 is provided with a fireproof coating layer 2; the soundproof material layer 3 is provided under the fireproof coating layer 2; the polymer material layer 4 is provided under the soundproof material layer 3; the polymer material layer 4 is provided under A through-hole layer 5 is provided; a backing plate 6 is arranged under the through-hole layer 5 .

[0015] The fire-resistant coating layer is made of high-strength film-forming material, which has good flame retardancy and can ensure that the interior of the board body is not damaged. Even in the event of an open flame, this material will not produce toxic and harmful substances that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com