Combined type bridge temporary support and construction method for rapidly building continuous beams by virtue of same

A temporary support and composite technology, which is applied in bridge construction, bridges, bridge parts, etc., can solve the problems of high use cost, sealing drop, and labor intensive, etc., and achieves strong compression resistance, convenient installation, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

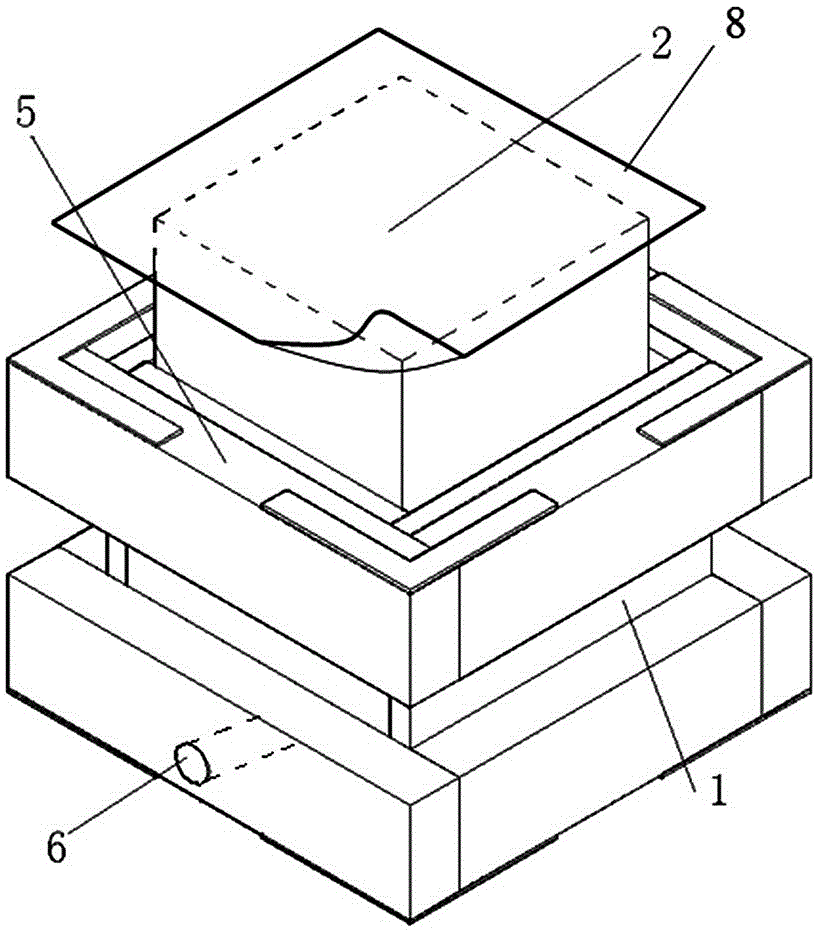

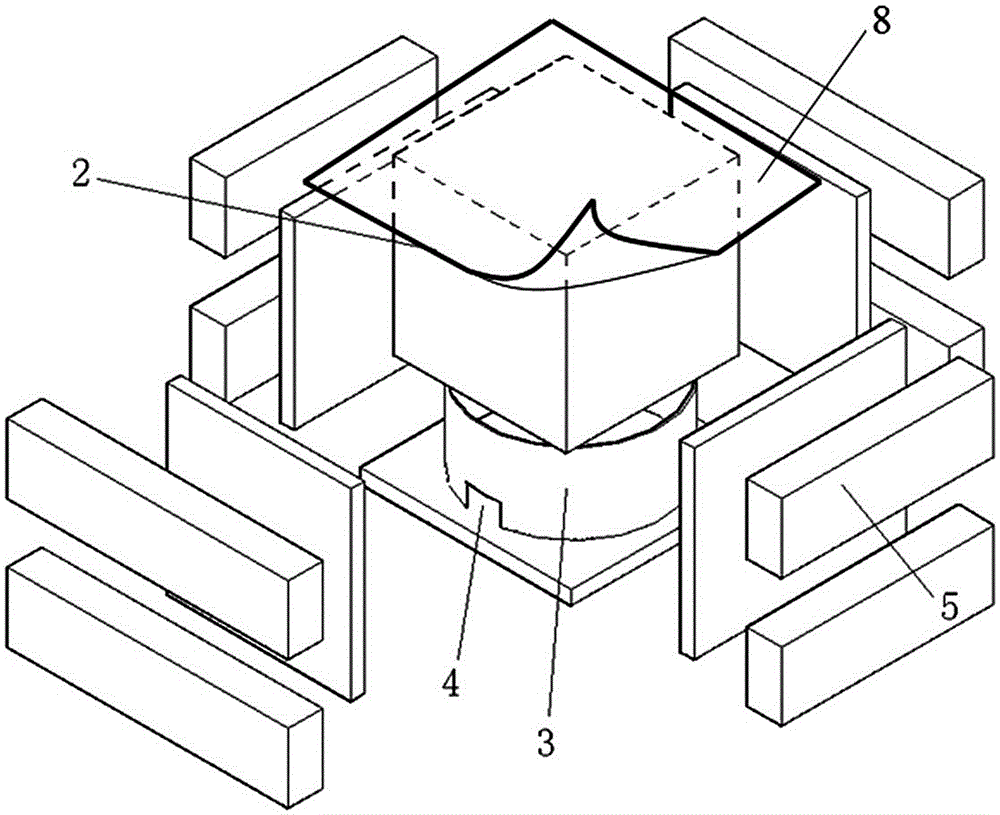

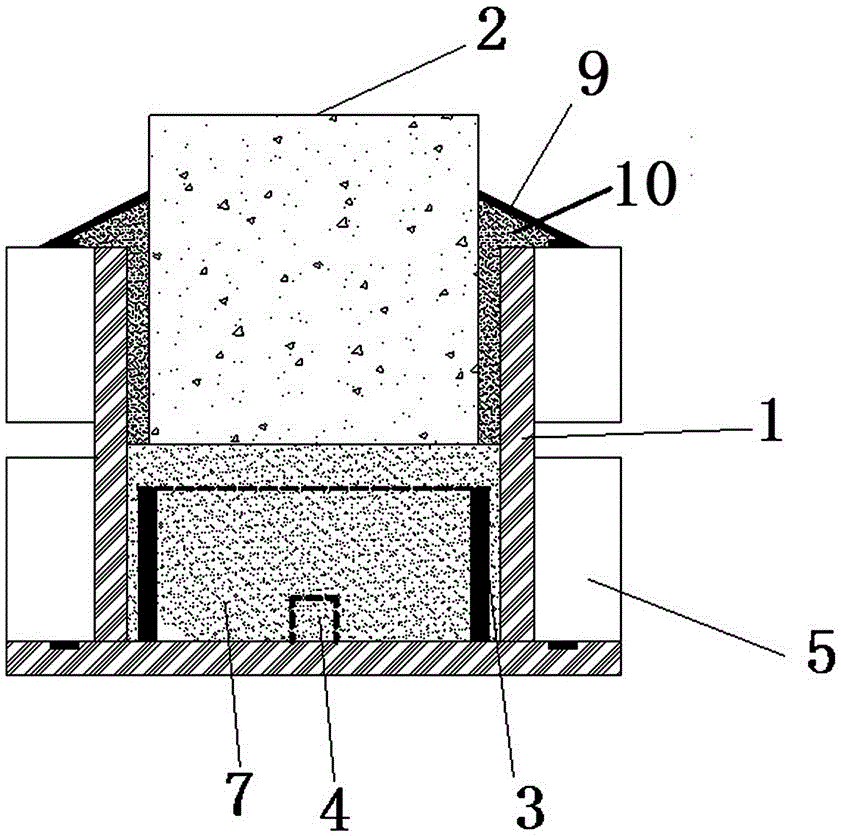

[0044] according to Figure 1-2 As shown, the composite bridge temporary bearing in the present invention comprises a wooden sand box 1 with an open top, filled in the wooden sand box 1 and has fluidity dry sand 7, placed in the wooden sand box 1 and The concrete support column 2 whose top protrudes from the opening of the top of the wooden sand box 1 also includes a steel pipe 3 vertically embedded in the dry sand 7, and a sand discharge hole 4 is reserved at the bottom of the steel pipe 3, which can be used as a preferred The steel pipe is seamless steel pipe 3. The top of concrete support column 2 is placed with rubber pad 8, can be used as preferably the thickness of rubber pad 8 is 2mm, and the size side length of rubber pad 8 is longer than the side length 3-4cm of concrete block.

[0045] Wherein, the wooden sand box 1 is made of phenolic resin multilayer board.

[0046] It is preferable that: the outer wall of the wooden sand box 1 is surrounded by a reinforcement bo...

Embodiment 2

[0049] A certain bridge in this embodiment adopts the technical standard of a first-class highway, with a total length of 306m, four holes and one connection, a total of three connections, the upper part adopts a 25m prestressed small box girder, which is simply supported first and then continuous, using the temporary support of the bridge in the first embodiment The construction method for erecting continuous beams on the seat includes the following steps:

[0050] 1. Material preparation

[0051]Select the existing leftover materials at the construction site, square wood, bamboo wood formwork, 5-8mm wall thickness 14-20cm steel pipe 3, high-grade concrete support column 2, dry and uniform fine quartz sand, wooden sand box 1 reinforcement, 2mm rubber pad 8 (The size of the rubber pad is 3-4cm longer than the concrete block), etc.

[0052] 2. Design of temporary bearings for composite bridges

[0053] The design of temporary bearings for composite bridges is carried out acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com