Separable type deepwater seabed pipeline bending test system

A subsea pipeline and buckling test technology, which is applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of limited test length and small effective research area of pipeline specimens, and achieves easy procurement and customization, easy implementation, and high safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

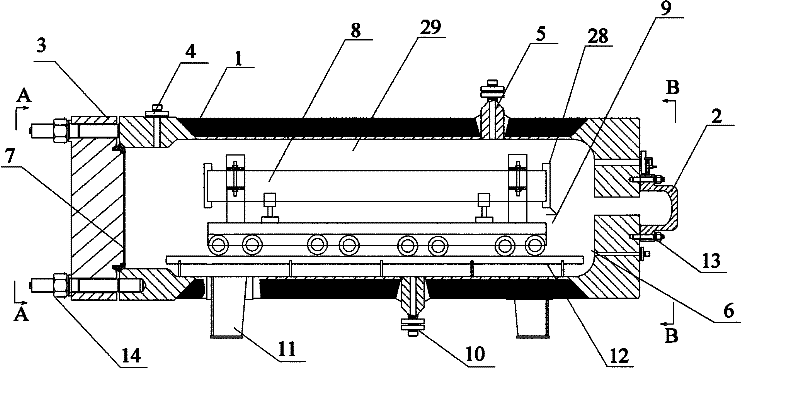

[0045] The separable deep-sea pipeline buckling test device of the present invention includes two parts: a pressure chamber and a pipeline bending and internal pressure loading device which can be separated into independent systems.

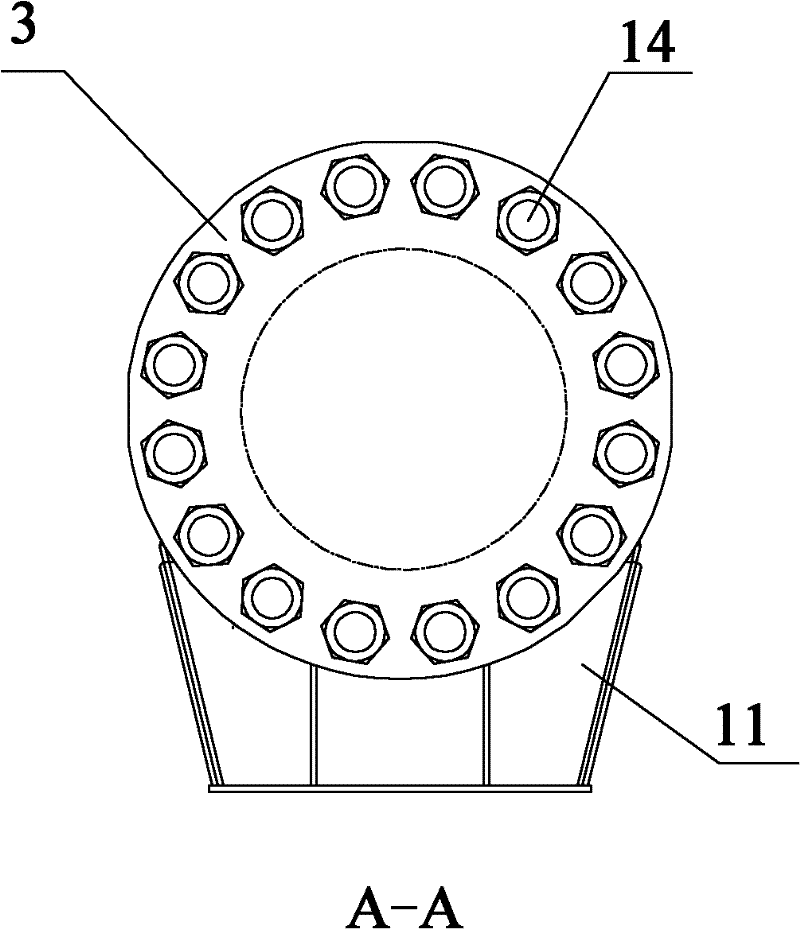

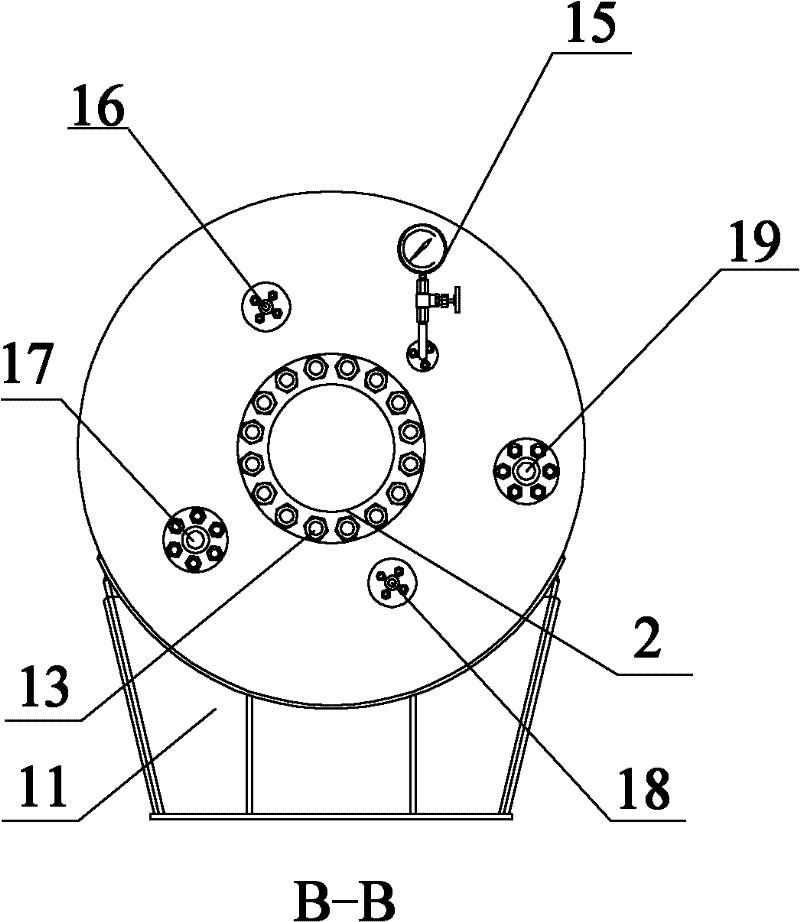

[0046] 1. The pressure chamber can simulate the deep-sea high-pressure environment, with water as the internal pressure medium. The pressure chamber includes the front cover of the pressure chamber, the tail end cover, the main body of the pressure chamber, the pressurization and pressure relief port, and the opening of the test line. The front end cover of the pressure chamber is connected and sealed with the main cabin by large bolts, and the rear end cover is connected to the rear of the cabin by 16 smaller bolts. Both the front and rear end caps are waterproof and sealed with aluminum sealing rings that are tightly hooped inside the end caps. The test data of the pipe fittings in the cabin is transmitted to the data acquisition and processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com