Gapless air curtain blow nozzle and air blowing method

A technology of air curtains and air intake pipes, applied in heating methods, space heating and ventilation, shielding with air flow, etc., can solve the problem of inability to ensure the purity of air in rescue cabins and refuge chambers, and the inability to completely prevent harmful gases from entering , Can not guarantee the safety of refugees and other issues, to achieve the effect of good spraying effect, sufficient gas, and large gas outlet area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

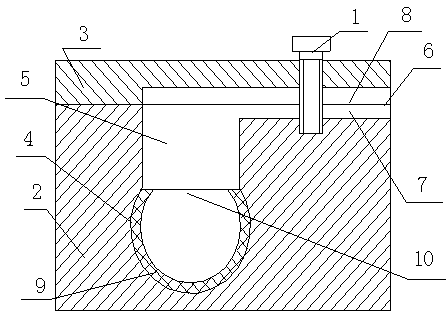

[0024] An infinite air curtain blowing nozzle, which consists of: a base 2 and a gland 3 connected by screws 1, the base is provided with an air inlet pipe groove 4, the air inlet pipe groove is connected to an air outlet groove 5, and the air outlet groove is connected to The lower air jet curtain opening 7, the gland has an upper air jet curtain opening 8, the base is connected to the gland so that the upper air jet curtain opening and the lower air jet curtain opening form an air jet curtain opening 6.

[0025] It is mainly used for the gas mist purging of the door of the refuge chamber when the compressed air is sprayed through the 0.03-0.05mm jet curtain opening to make the door form a dense, continuous and uninterrupted air curtain, which can effectively block the intrusion of harmful gases in all directions and play a role To isolate and shield the role of strong purge positive pressure control.

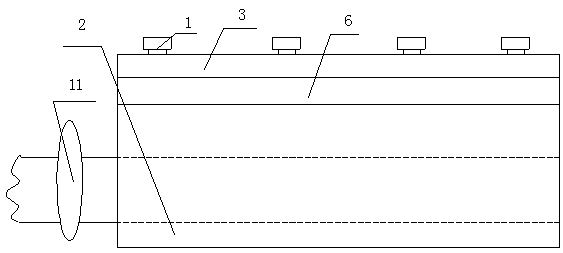

[0026] This product is installed on the top and both sides of the e...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 , attached figure 2 As shown, in the described seamless air curtain blowing nozzle, an air inlet pipe 9 is installed in the air inlet pipe groove, and an air outlet hole 10 is opened at the upper end of the air inlet pipe, and the air outlet hole is located below the air outlet groove, and the air inlet pipe The air pipe is connected to the pneumatic valve 11.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that, as attached figure 1 , attached figure 2 As shown, for the seamless air curtain blowing nozzle, the height of the air jet curtain opening is 0.03-0.05mm, and the air supply pressure of the air jet curtain opening is 0.4-0.6Mpa.

[0031] The height of the air jet curtain mouth is 0.03-0.05mm, and the air supply pressure is 0.4-0.6Mpa. Under this height and air supply pressure, the airflow ejected is relatively strong, which can completely cut off the harmful gas entering the rescue cabin and refuge chamber, making the rescue cabin And the refuge chamber has become a real life-saving space, ensuring the safety of the asylum seekers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com