Artificial stone integral bathtub and method for making same

A production method and technology of artificial stone, applied in the field of sanitary ware, can solve the problems of self-explosion and injury, easy cracking of the surface, complicated production process, etc., and achieve the effect of strong compression resistance, good heat preservation performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiment of the present invention provides an artificial stone integral bathtub and a manufacturing method thereof. The artificial stone integral bathtub made by the method has strong pressure resistance, good thermal insulation performance and convenient processing.

[0042] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

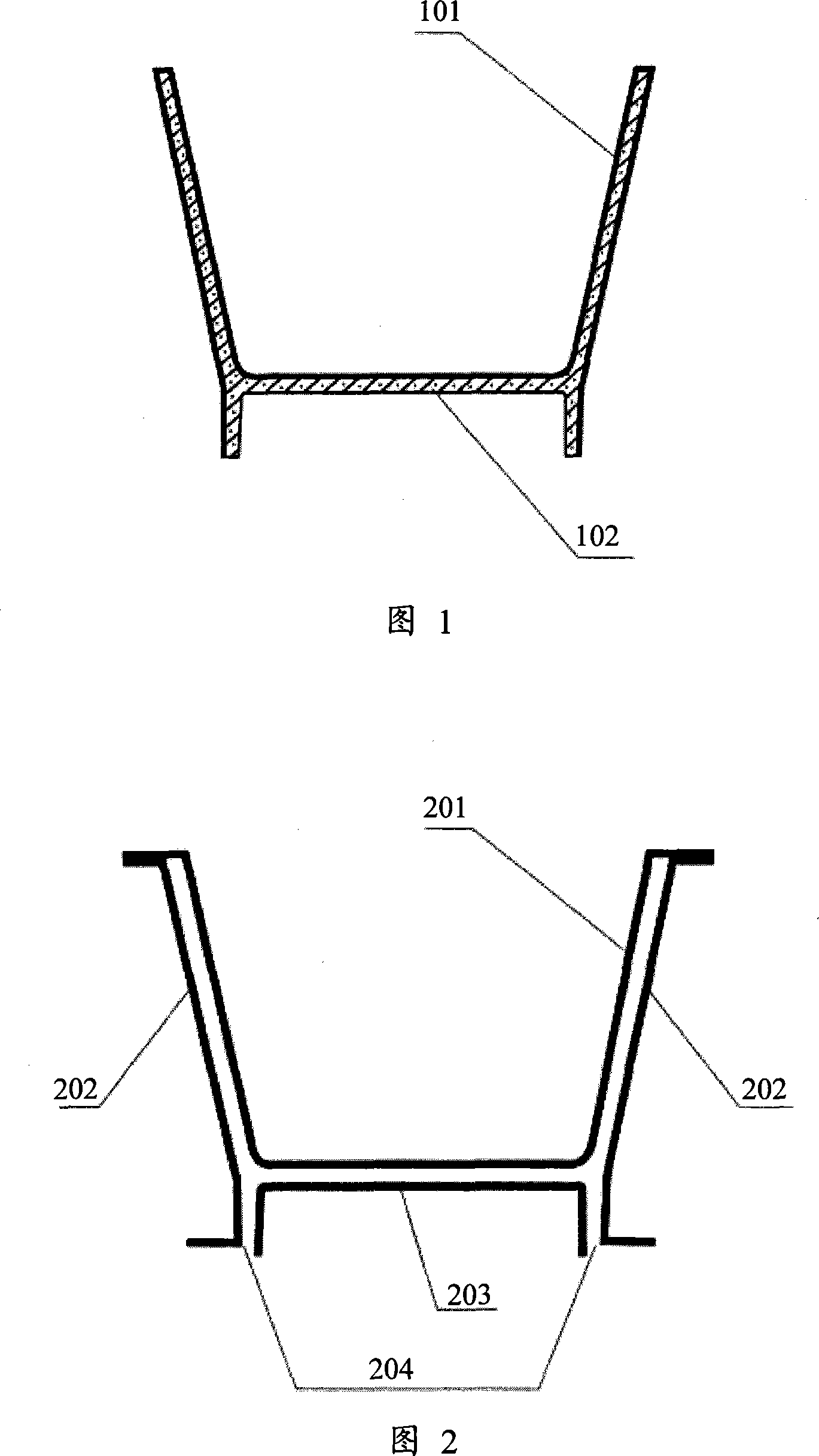

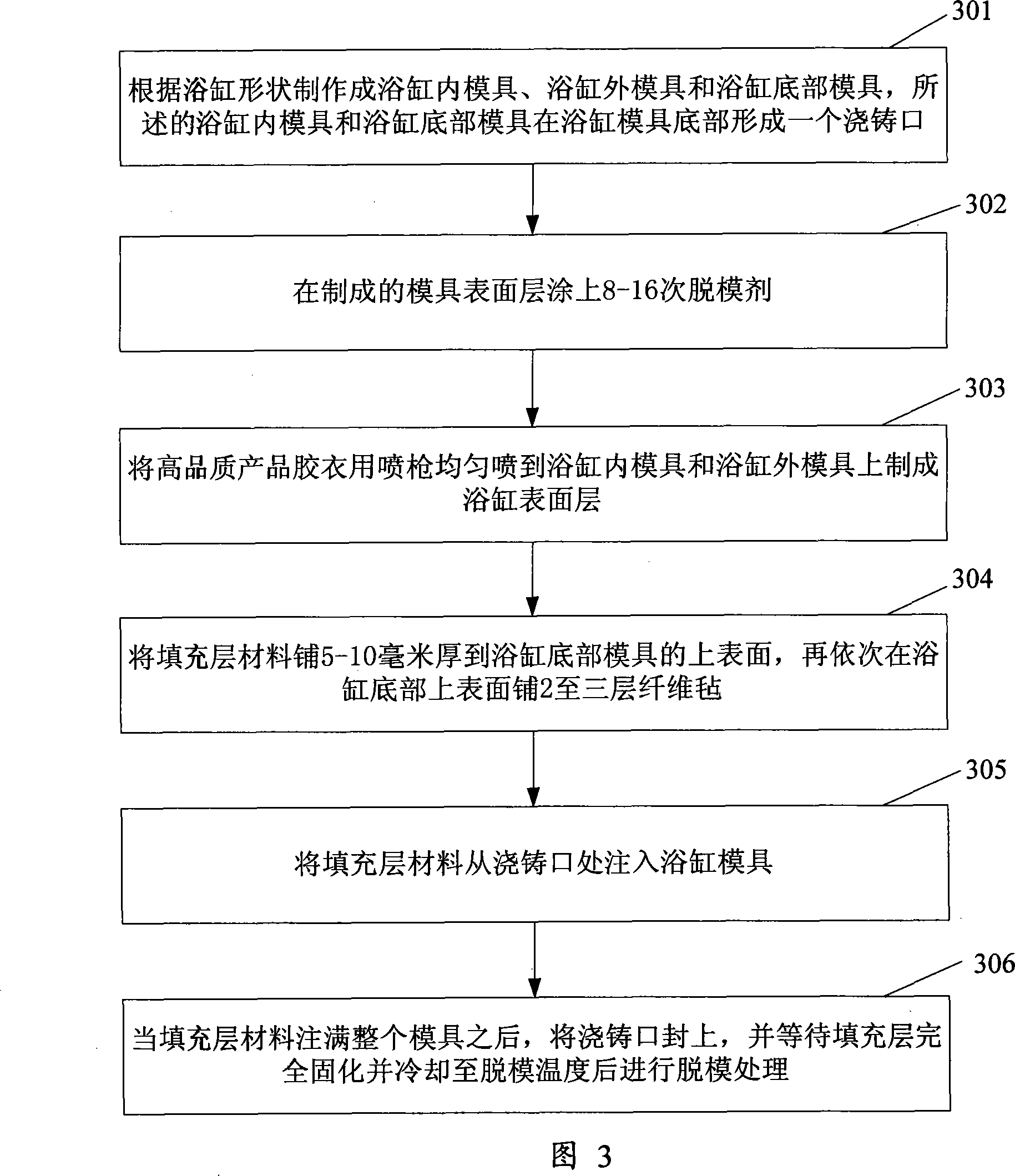

[0043] Please refer to Fig. 1 at first, Fig. 1 has shown the artificial stone integral bathtub structure schematic diagram in the embodiment of the present invention, and this bathtub comprises surface layer 101 and the filling layer 102 that is wrapped by surface layer 101, wherein:

[0044] The surface layer 101 is composed of high-quality product gel coat,

[0045] The filling layer 102 is composed of a mixture of resin, glass beads, light calcium carbonate and quartz sand or stone powder, wherein:

[0046] The resin accounts for about 40%-51% of the weight of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com