Inverted-n steel and production method thereof

A production method and technology of steel beams, which are used in slender elements, building elements, metal rolling, etc., can solve the problems of poor performance, deformation, and fracture of steel beams, and achieve strong flexural bearing capacity. , The effect of easy control and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

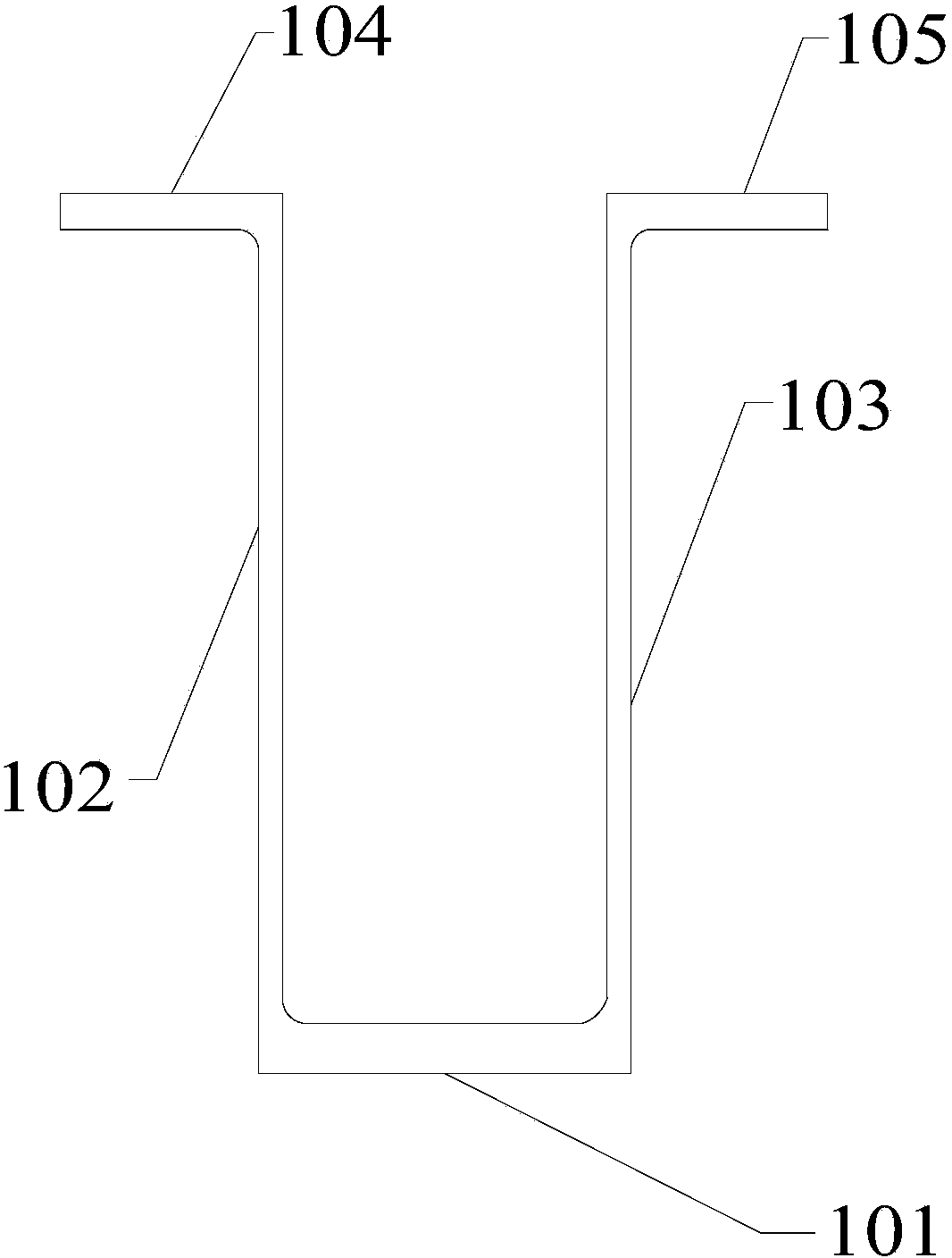

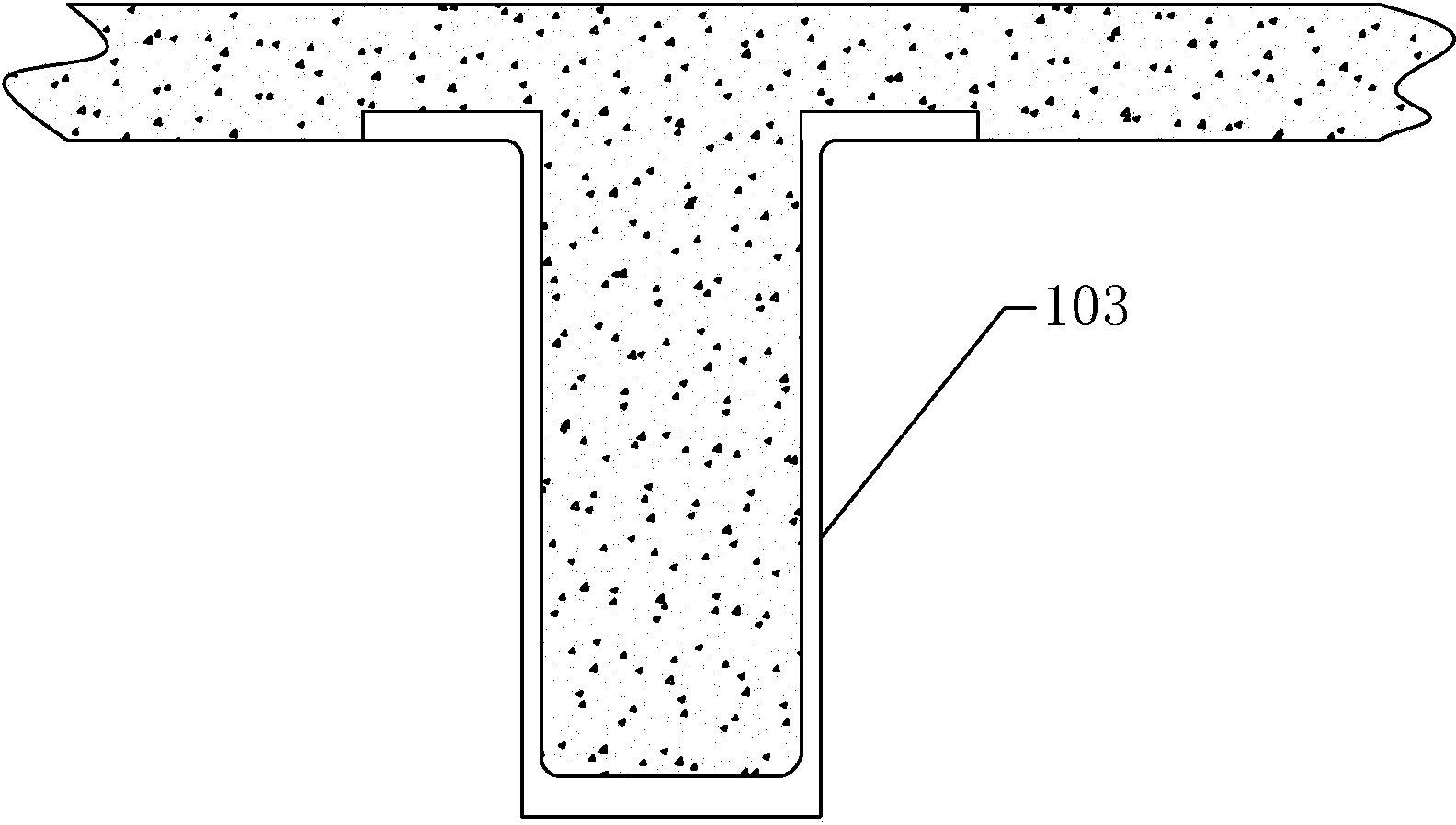

[0033] Please refer to figure 1 , the present embodiment provides a type of steel, including a bottom plate 101; the two ends of the bottom plate 101 extend in the same direction to a first web 102 and a second web 103, and the first web 102 and the second web 103 The second web 103 is perpendicular to the bottom plate 101; the end of the first web 102 away from the bottom plate 101 extends along the direction from the second web 103 to the first web 102 The first wing plate 104; the end of the second web plate 103 away from the bottom plate 101 extends a second wing plate 105 along the direction from the first web plate 102 to the second web plate 103; Both the first wing plate 104 and the second wing plate 105 are parallel to the bottom plate 101 .

[0034] The glyph steel provided by the present invention includes two webs, two wing plates and a bottom plate 101 . Two webs extending in the same direction are respectively extended from both ends of the bottom plate 101 , a...

Embodiment 2

[0038] In this embodiment, in order to make the several-shaped steel in use (such as applied to a reinforced concrete box girder), the force on the first web 102 and the second web 103 is uniform, preferably, the The first web 102 and the second web 103 are arranged symmetrically along the bottom plate 101 .

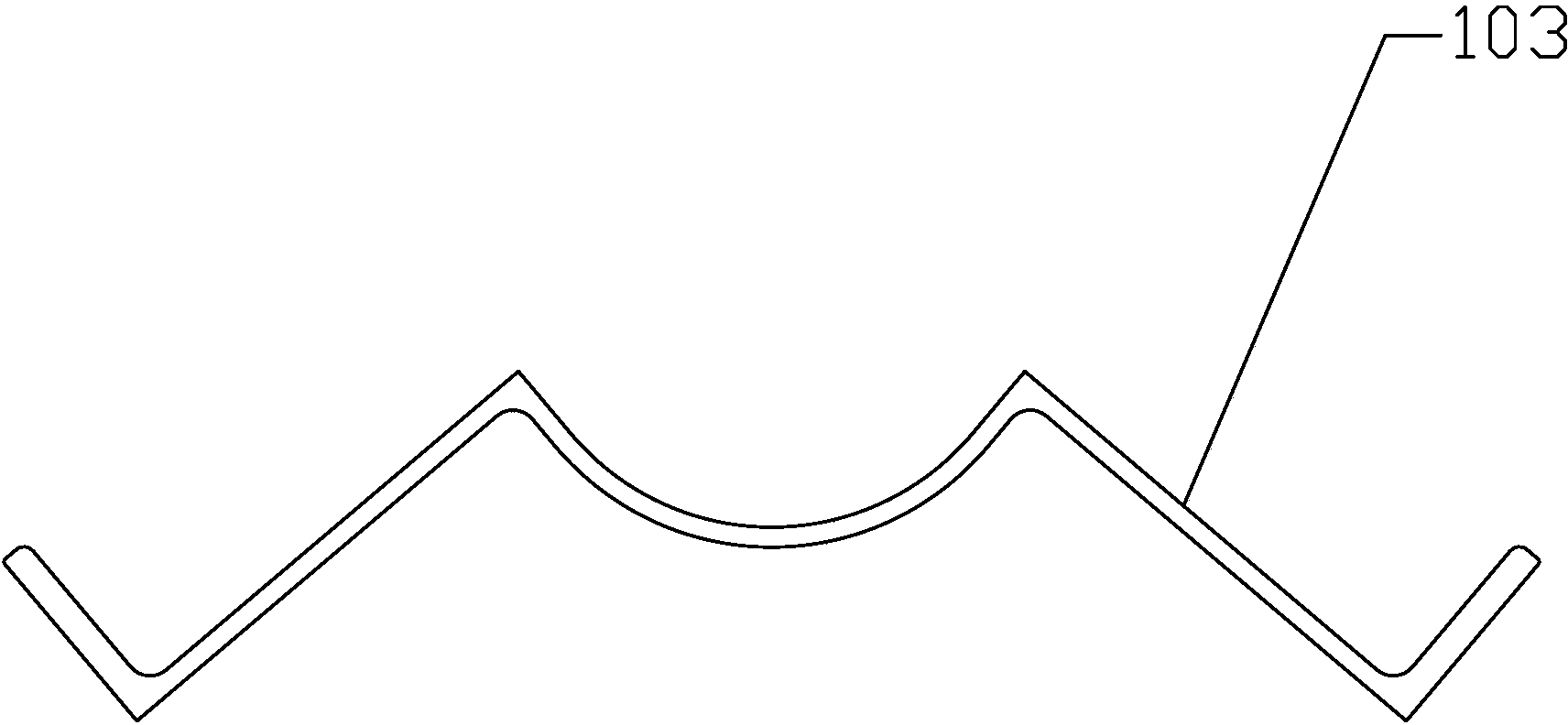

[0039] In addition, in this embodiment, when using a few-shaped steel, generally speaking, the first wing plate 104 and the second wing plate 105 mainly play the role of load-bearing, while the role of the bottom plate 101 is in the two positions of support and positioning. The two webs between the wing plate and the bottom plate 101 then play the role of support and force transmission. Therefore, in order to increase the load and support performance of the entire azimuth steel, preferably, the bottom plate 101, the first web 102, The second web 103, the first web 104, and the second web 105 are all rectangular; the first web 102 and the second web 103 have the same shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com