Medical titanium alloy and preparing method thereof

A titanium alloy and mixture technology, which is applied in the field of medical titanium alloy and its preparation, can solve the problems of human injury and human discomfort, and achieve the effects of strong compression resistance, good biocompatibility, and uniform pore size and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

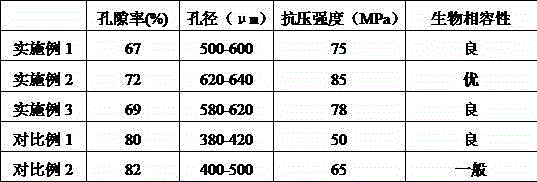

Examples

Embodiment 1

[0019] A medical titanium alloy, comprising the following components by mass percentage: 12% titanium, 28% zirconium, 8% copper, 0.5% calcium, 12% 800-mesh ceramic powder, 0.2% nickel, 0.6% tungsten, and 0.3% platinum .

[0020] The preparation method of the above-mentioned medical titanium alloy comprises the following steps:

[0021] Step 1: Weigh the raw materials, put titanium, copper, calcium, nickel, tungsten and platinum into the reactor and stir at 150rpm, and then under inert gas at 200°C / min. Heating at a constant rate to 3000°C to obtain the first mixture;

[0022] Step 2, adding ceramic powder to the first mixture, stirring at 2500rpm for 5min, then raising the temperature to 3800°C to obtain the second mixture;

[0023] In step 3, the temperature of the second mixture is lowered to 2200° C. at a rate of 100° C. / min, and then lowered to room temperature at 400° C. / min to obtain a medical titanium alloy.

Embodiment 2

[0025] A medical titanium alloy, comprising the following components by mass percentage: 14-16% titanium, 35-40% zirconium, 9-11% copper, 0.8-1.2% calcium, 20-24% 800 mesh ceramic powder, nickel 0.3-0.4%, tungsten 0.6-0.8%, platinum 0.4-0.6%.

[0026] The preparation method of the above-mentioned medical titanium alloy comprises the following steps:

[0027] Step 1, weighing the raw materials, putting titanium, copper, calcium, nickel, tungsten and platinum into the reactor and stirring at 175rpm, and then raising the temperature to 3200°C at a constant speed of 250°C / min under an inert gas to obtain the first mixture;

[0028] Step 2, adding ceramic powder to the first mixture, stirring at 2800rpm for 8min, then raising the temperature to 3900°C to obtain the second mixture;

[0029] In step 3, the temperature of the second mixture is lowered to 2300° C. at a rate of 150° C. / min, and then lowered to room temperature at a rate of 450° C. / min to obtain a medical titanium alloy...

Embodiment 3

[0031] A medical titanium alloy, comprising the following components by mass percentage: 18% titanium, 42% zirconium, 12% copper, 1.4% calcium, 26% 800-mesh ceramic powder, 0.5% nickel, 0.8% tungsten, and 0.8% platinum .

[0032] The preparation method of the above-mentioned medical titanium alloy comprises the following steps:

[0033] Step 1, weighing the raw materials, putting titanium, copper, calcium, nickel, tungsten and platinum into the reactor and stirring at 180rpm, and then raising the temperature to 3500°C at a constant speed of 300°C / min under an inert gas to obtain the first mixture;

[0034] Step 2, adding ceramic powder to the first mixture, stirring at 3000rpm for 10min, then raising the temperature to 4000°C to obtain the second mixture;

[0035] In step 3, the temperature of the second mixture is lowered to 2500° C. at a rate of 200° C. / min, and then lowered to room temperature at a rate of 500° C. / min to obtain a medical titanium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com