Methods and tool for maintenance of hard surfaces, and a method for manufacturing such a tool

a technology for hard surfaces and manufacturing methods, applied in the direction of manufacturing tools, carpet cleaners, cleaning machines, etc., can solve the problems of not being suitable for daily maintenance purposes, method described, and ep-b-0 562 919 is thus too complicated for being used on a daily basis, and achieves the effect of convenient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

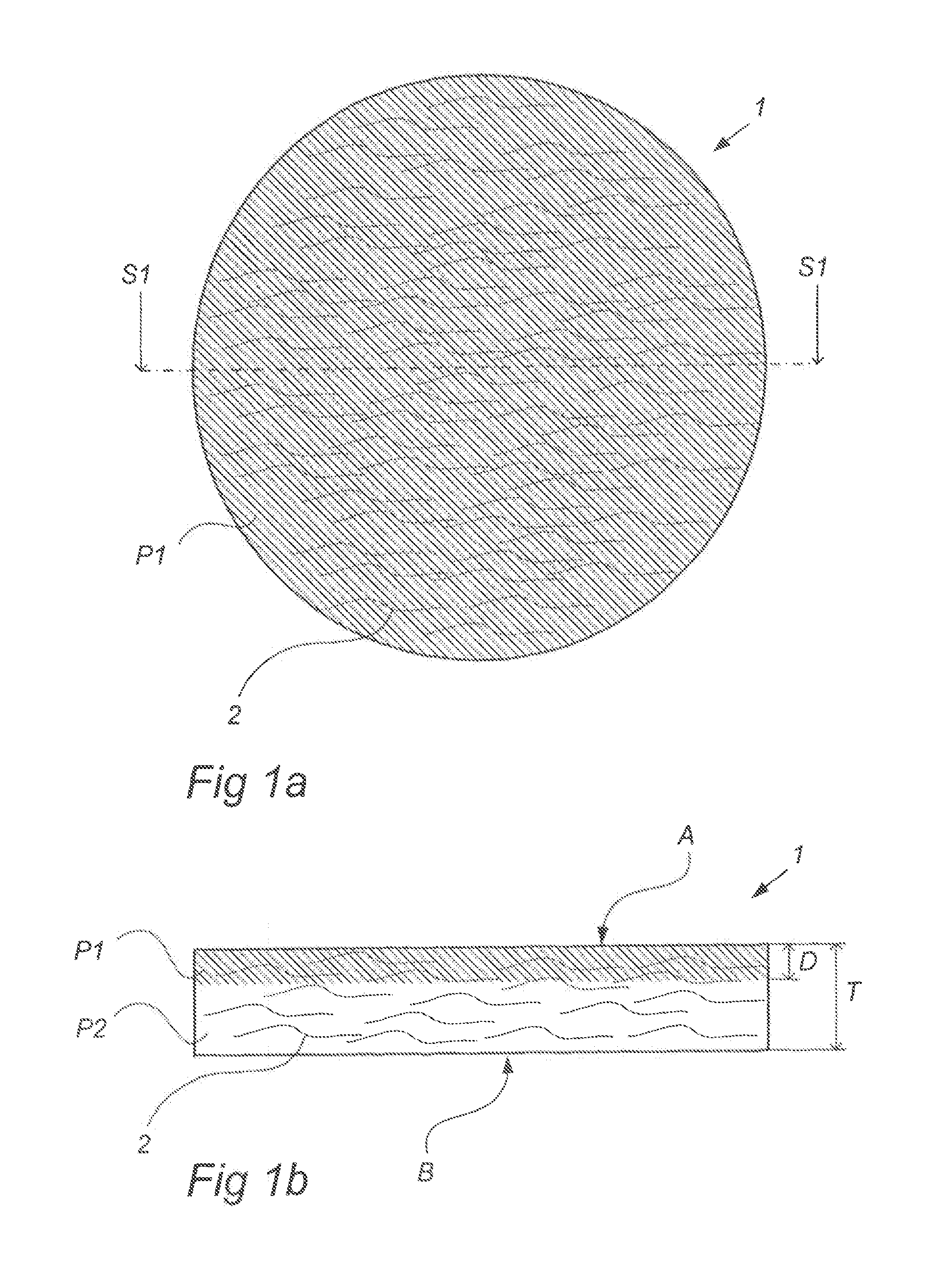

[0102]As is clear from the above, the pad according to the present disclosure comprises an open, lofty, three dimensional non-woven web, including a plurality of fibers, which are adhered to each other at their points of mutual contact by means of a primary binder, and in which abrasive particles are mixed with a secondary binder and applied only to a first surface of the pad, such that the pad is only partially impregnated by the binder / particle mixture. Alternatively, or additionally, the fibers may be melt-bonded to each other.

second embodiment

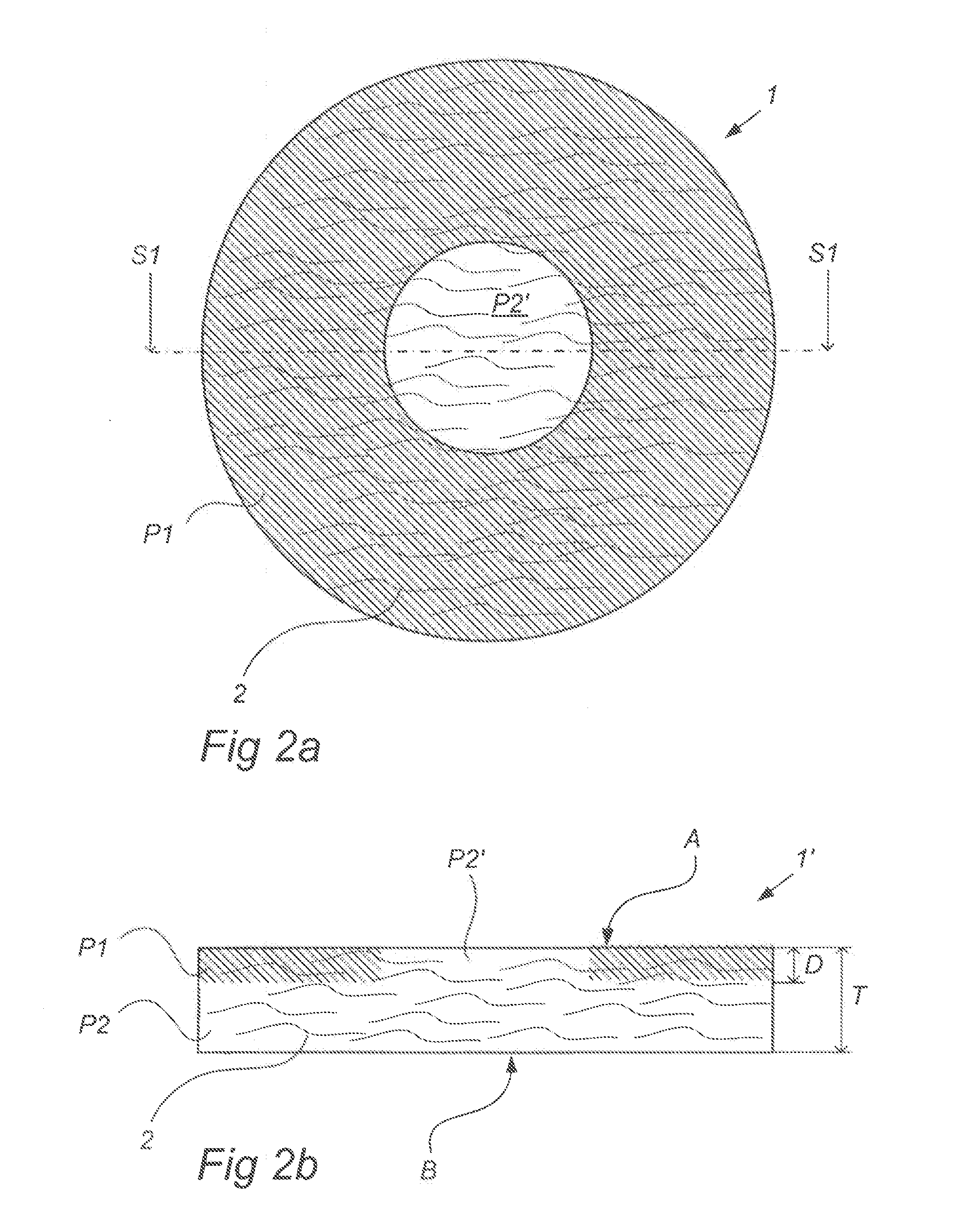

[0103]In the pad, binder / particle mixture is only applied to parts of said first surface. This can be achieved by masking those parts of the surface to which the binder / particle mixture should not be applied.

third embodiment

[0104]In a third embodiment, the pad is entirely impregnated with the binder / particle mixture, e.g. by using such squeeze rollers as are described in EP-B-0 562 919. In a variant of this embodiment, a relatively thin impregnated woven or non-woven pad is attached to a thicker carrier pad in order to provide the flexibility. According to variants of this embodiment, a substantially two-dimensional woven or non-woven web is attached to a thicker carrier pad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com