Halogen-free flame retardant gel coat resin and preparation method thereof

A flame retardant gel coat and resin technology, which is applied in the field of halogen-free flame retardant gel coat resin and its preparation, can solve the problem of large amount of phosphorus-based flame retardant, and achieve excellent flame retardant performance, high solid content and moderate viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

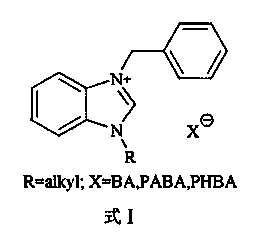

[0046] The weight ratio of each component in the halogen-free flame-retardant gel coat resin of this embodiment is as follows: 100 parts of liquid o-phthalic unsaturated polyester resin containing a polymerization inhibitor, 100 parts of aluminum hydroxide, 2 parts of ammonium polyphosphate, 1 part of triphenyl phosphate, 5 parts of barium sulfate, 0.05 part of 1-hexyl-3-benzylbenzimidazole p-aminobenzoate, 4 parts of fumed silica, 2 parts of BYK-A500, 2 parts of BYK- 300, 1 part of BYK-163, 15 parts of color paste.

[0047] Wherein the manufacture method of the liquid ortho-phthalic unsaturated polyester resin containing polymerization inhibitor is: first prepare unsaturated polyester, make the propylene glycol of 50:5:25:25 molar ratio, diethylene glycol, ortho The polycondensation reaction of phthalic acid and maleic anhydride produces o-phthalic unsaturated polyester, and the reaction end point is controlled as follows: the viscosity is U-V, the acid value is 25-33, so tha...

Embodiment 2)

[0050] The weight ratio of each component in the halogen-free flame-retardant gel coat resin of the present embodiment is as follows:

[0051] 120 parts of liquid m-phenylene type unsaturated polyester resin containing polymerization inhibitor, 150 parts of aluminum hydroxide, 2 parts of ammonium polyphosphate, 1 part of dimethyl phosphate, 2 parts of barium sulfate, 1-octyl-3-benzyl 1 part of benzimidazole p-aminobenzoate, 2 parts of fumed silica, 5 parts of BYK-401, 5 parts of BYK-515, 3 parts of BYK-110, 10 parts of color paste. Wherein the preparation method of the liquid m-benzene type unsaturated polyester resin containing a polymerization inhibitor is to add styrene and a polymerization inhibitor to it after obtaining the m-phenylene type unsaturated polyester, and obtain the resin containing a polymerization inhibitor after mixing evenly Liquid isophthalic unsaturated polyester resin. The polymerization inhibitor is hydroquinone.

[0052] The flammability level of th...

Embodiment 3)

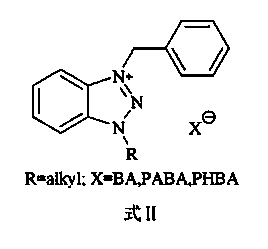

[0054] The weight ratio of each component in the halogen-free flame-retardant gel coat resin of this embodiment is as follows: 150 parts of liquid o-phthalate-neopentyl glycol type unsaturated polyester resin containing a polymerization inhibitor, 50 parts of magnesium hydroxide, poly 2 parts of ammonium phosphate, 1 part of triphenyl phosphate, 3 parts of silicon nitride, 0.1 part of 1-hexyl-3-benzylbenzotriazole p-aminobenzoate, 4 parts of fumed silica, 3 parts of BYK -300, 2 parts of BYK-500, 3 parts of BYK-163, 5 parts of color paste. The preparation method of the liquid o-phthalene-neopentyl glycol type unsaturated polyester resin is to add styrene and polymerization inhibitor to it after the o-phthalene-neopentyl glycol type unsaturated polyester is obtained, and obtain the matrix after mixing resin. The polymerization inhibitor is methyl hydroquinone.

[0055] The flammability level of the halogen-free flame-retardant gel coat resin of this embodiment reaches the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mw | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com