Unsaturated polyester gel coat resin capable of being subjected to UV-LED photocuring and paint preparation method thereof

A technology of gel coat resin and polyester coating, which is applied in the field of unsaturated polyester coating and its preparation, can solve the problems of poor acid and alkali resistance, large shrinkage rate, and easy orange peel of unsaturated polyester, so as to increase the turnover Link density, reduce volume shrinkage, improve the effect of coating rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

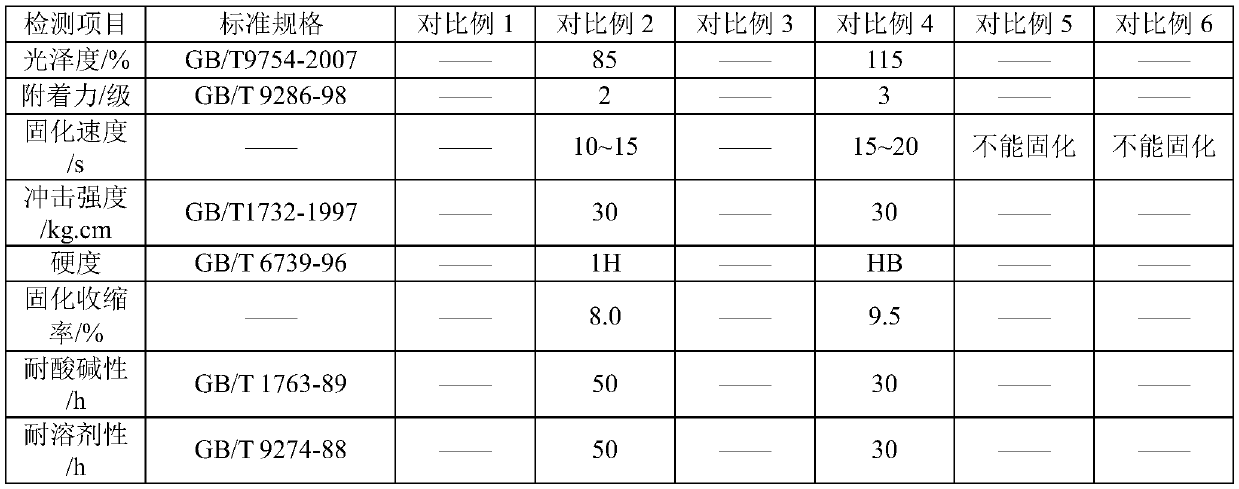

Examples

Embodiment 1

[0038]Add 5.0g of triphenyl phosphite, 2.0g of sodium hypophosphite, 424.0g of diethylene glycol, 27.2g of pentaerythritol, and 355.6g of phthalic anhydride in sequence, and then add the electric stirring, water separator, thermometer, In the reaction vessel heated by the electric heating mantle, after heating to 100-110°C, start to stir slowly for half an hour, then raise the temperature to 160°C, react for 2 hours, cool down to 100°C and add 156.9g of maleic anhydride, the molar ratio of phthalic anhydride to maleic anhydride 3:2, react at constant temperature for 1 hour, raise the temperature to 195±2°C and react until the acid value is below 40mgKOH / g, add 0.5g hydroquinone, cool down to 95±1°C, slowly drop in 98.1g and mix in 0.6g Triphenyl phosphite, glycidyl methacrylate of 1.2g N,N'-dimethyl benzylamine is capped, and after the drop-in is completed, the temperature is slowly raised to 104±0.5°C, and the reaction is when the acid value is below 10mgKOH / g When the temper...

Embodiment 2

[0041] Put 5.0g of triphenyl phosphite, 2.0g of sodium hypophosphite, 381.6g of diethylene glycol, 36.8g of glycerol, and 370.0g of phthalic anhydride into the equipment equipped with electric stirring and water separator in sequence. , thermometer, electric heating mantle heating reaction vessel, after heating to 100-110°C, start to stir slowly for half an hour, then raise the temperature to 160°C, react for 2 hours, cool down to 100°C, add 98.0g maleic anhydride, phthalic anhydride and maleic anhydride The molar ratio is 2.5:1, react at constant temperature for 1 hour, raise the temperature to 195±2°C and react until the acid value is below 30mgKOH / g, add hydroquinone, cool down to 95±1°C, slowly drop in 74.3g and mix with 0.34 g triphenyl phosphite, 0.6g N, N-dimethyl phenylamine glycidyl methacrylate for end-capping, slowly heat up to 104±0.5°C after the drop-in is completed, and react until the acid value is below 10mgKOH / g When the temperature drops below 85°C, add 286.0...

Embodiment 3

[0044] Add 5.0g of triphenyl phosphite, 2.0g of sodium hypophosphite, 296.8g of diethylene glycol, 27.2g of pentaerythritol, and 370g of phthalic anhydride, and add them in sequence with electric stirring, water separator, thermometer, In the reaction vessel heated by the electric heating mantle, after heating to 100-110°C, start to stir slowly for half an hour, then raise the temperature to 160°C, react for 2 hours, cool down to 100°C and add 98g of maleic anhydride, the molar ratio of phthalic anhydride to maleic anhydride is 1:1, constant temperature reaction for 1 hour, heat up to 195±2°C and react until the acid value is below 90mgKOH / g, add hydroquinone, cool down to 95±1°C, slowly drop in 223.4g and mix with 0.6g triphosphite Phenyl ester, 1.2g N,N'-dimethyl benyl amine glycidyl methacrylate for end-capping, after the drop-in is completed, the temperature is slowly raised to 104±0.5°C, and when the acid value is below 10mgKOH / g, the temperature is lowered to When the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com