Patents

Literature

57results about How to "Good water and weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plastic lens and method production thereof

InactiveUS20050041298A1Efficiently formedImprove scratch resistanceCoatingsMountingsChemical compoundImpact resistance

The present invention includes a plastic lens having a plastic lens base material, a primer layer formed on the plastic lens base material, and a hard coat layer formed on the primer layer, the hard coat layer being formed from a hard coat composition having (A) an inorganic fine particle having a particle diameter of 1 to 100 millimicrons, (B) an organic silicon compound expressed in terms of a specified Formula (1), (C) a multi-functional epoxy compound, and (D) a curing catalyst. Such a plastic lens is excellent in shock impact resistance by including the primer layer and also shows improvements in scratch resistance, water resistance, and permanence properties while keeping the coloring properties of the hard coat layer of a colorable type.

Owner:SEIKO EPSON CORP

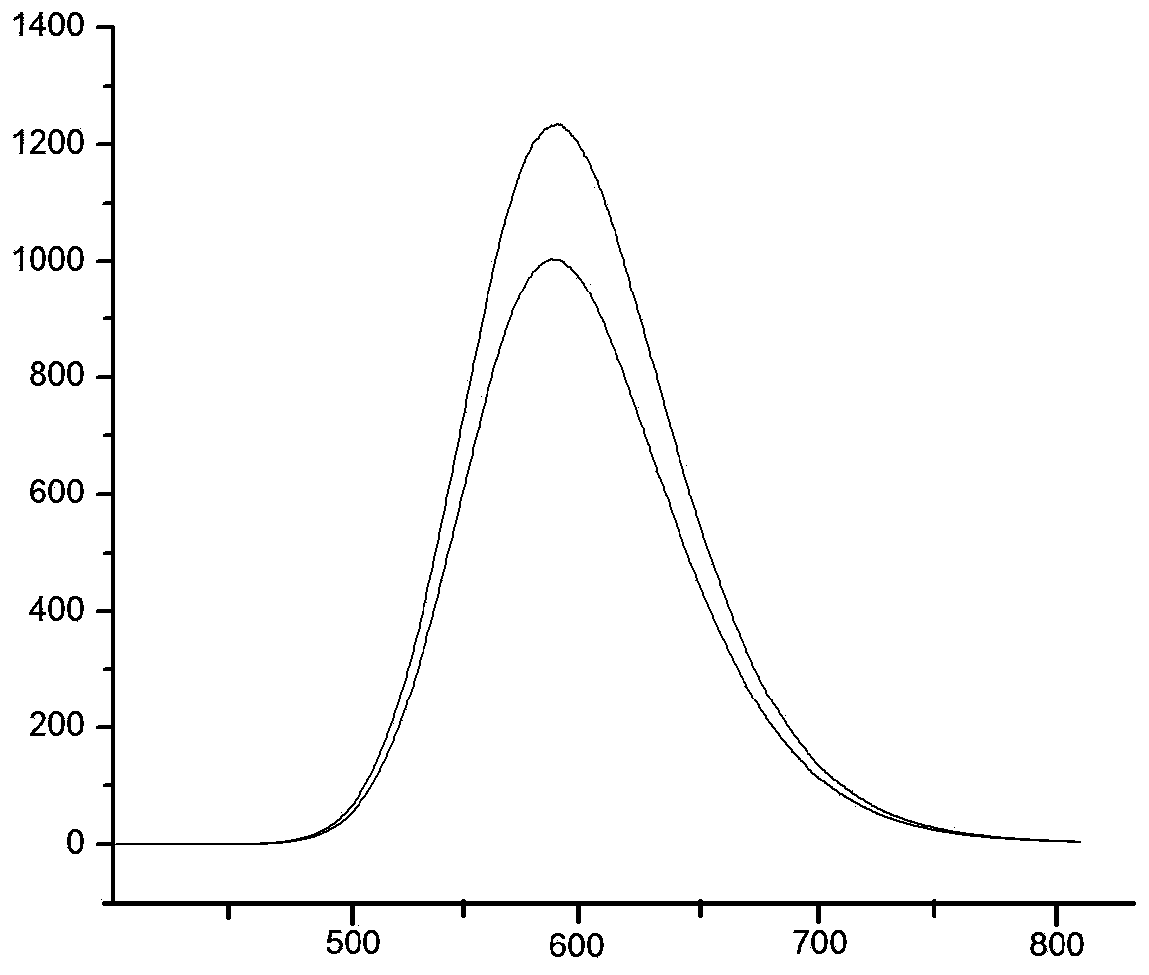

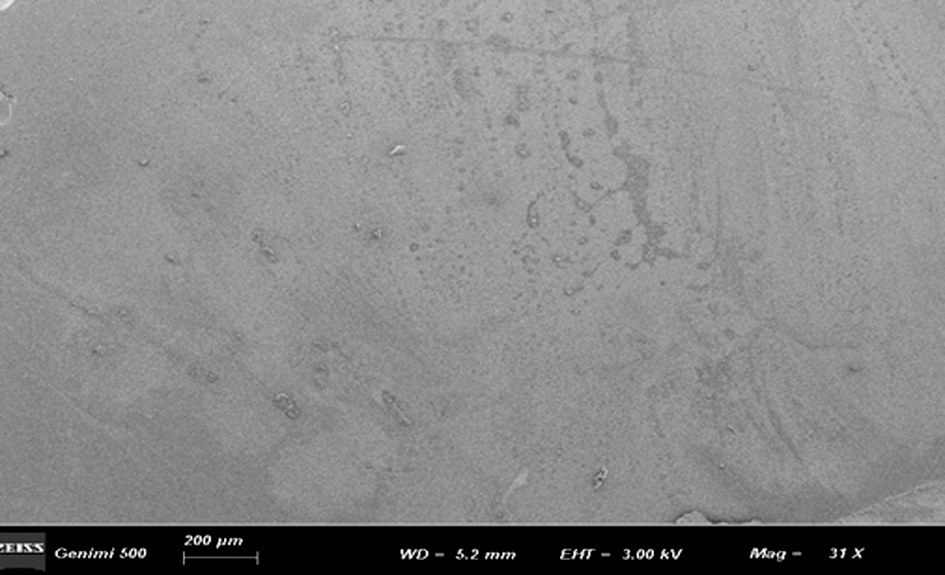

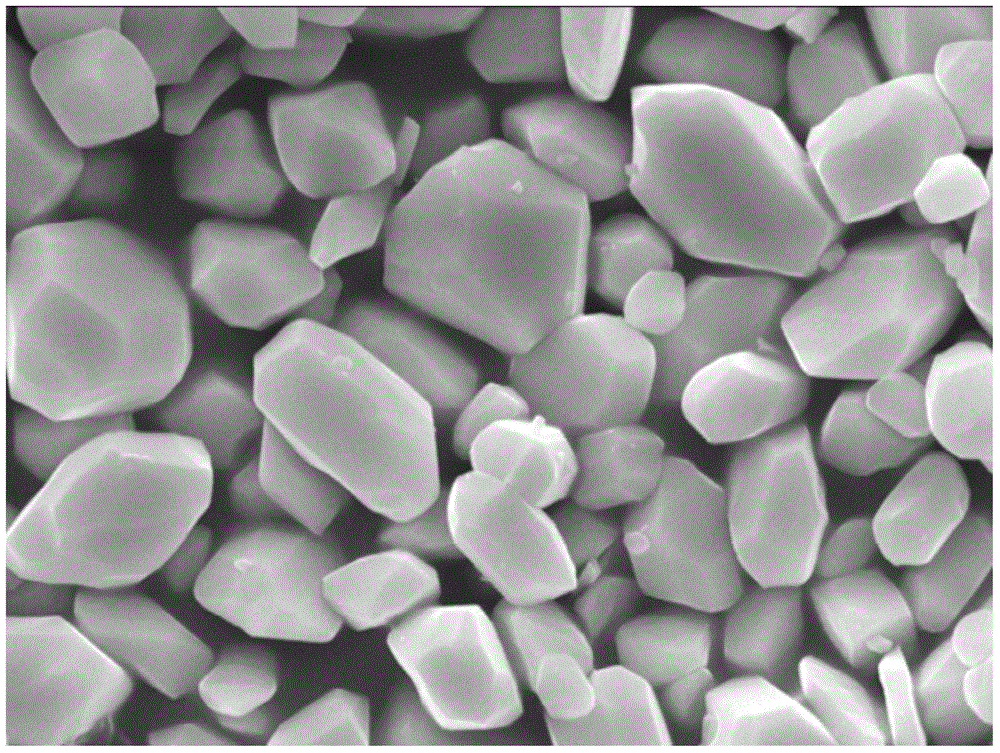

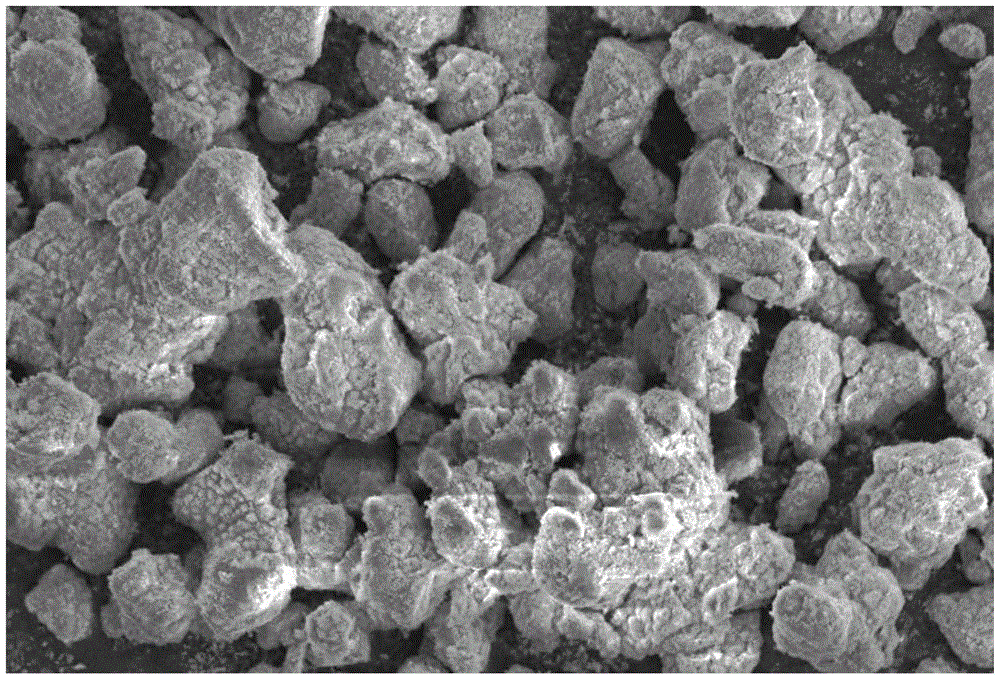

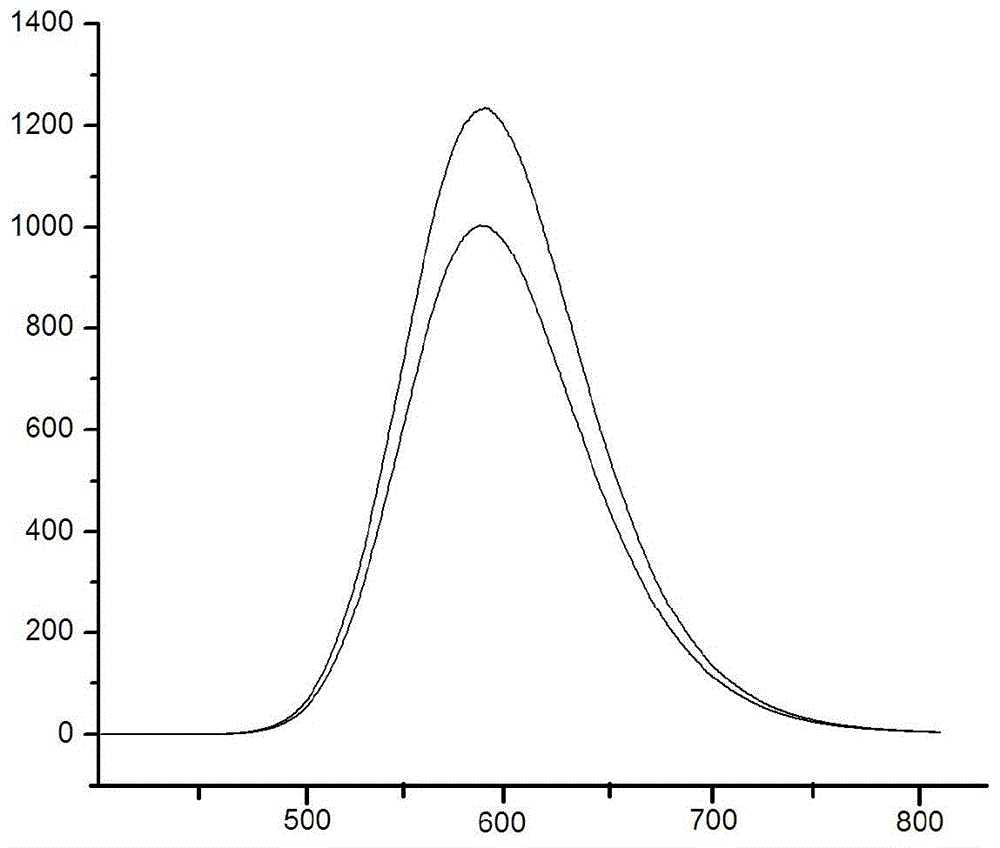

Coated silicate fluorescent powder and film-coating method thereof

ActiveCN103725282APrecise thickness controlImprove stabilityLuminescent compositionsFluidized bedMetallurgy

The invention discloses coated silicate fluorescent powder. According to the invention, an inner core adopts silicate fluorescent powder and coated with an inner shell layer and an outer shell layer, the inner shell layer adopts SiO2, and the outer shell layer adopts Al2O3. The invention further provides a film-coating method of the silicate fluorescent powder. The method comprises the following steps: (1) mixing fluorescent powder and SiO2 according to the mass ratio of (10-20):1, dry grinding and sieving; (2) placing the sieved powder in a fluidized bed reactor, and feeding N2 to enable the powder to suspend in the fluidized bed reactor; (3) mixing trimethylaluminum with N2, and feeding the mixture in the reactor, wherein the mass of the trimethylaluminum is 0.3-2% of that of the fluorescent powder; (4) feeding O2 containing O3 at 170-200 DEG C, and reacting for 1-2 h. According to the invention, the method is simple, the controllability is high, and the thickness of a film can be accurately controlled; the luminance of fluorescent powder can be improved through SiO2 coating , and the strength and the adhesive force of the film can be improved through Al2O3 coating, so that the water-tolerant and weather-resisting properties of fluorescent powder can be effectively improved, the luminescence property of fluorescent powder is optimized, and the service life of fluorescent powder is prolonged.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

Modified stannic oxide sol, stannic oxide-zirconium oxide composite sol, coating composition and optical element

ActiveUS20060025518A1Bonding properties)Reduce defectsMaterial nanotechnologyTin compoundsOligomerColloidal particle

It is to provide a sol useful as a component of a hard coating agent to be applied on the surface of a plastic lens or useful for other applications, and its production process. A sol containing modified metal oxide particles which comprise, as nuclei, colloidal particles (A) being stannic oxide particles or composite particles comprising stannic oxide particles and zirconium oxide particles, containing these oxides in a weight ratio of ZrO2:SnO2 of from 0:1 to 0.50:1 and having particle sizes of from 4 to 50 nm, and as a coating covering the surface of the nuclei, alkylamine-containing Sb2O5 colloidal particles, an oligomer thereof or a mixture thereof (B1), or composite colloidal particles comprising diantimony pentaoxide and silica, an oligomer thereof or a mixture thereof (B2), in a weight ratio of (B) / (A) of from 0.01 to 0.50 based on the weights of the metal oxides, and have particle sizes of from 4.5 to 60 nm. A coating composition containing a silicon-containing substance and the above particles. An optical element covered with the coating composition.

Owner:NISSAN CHEM IND LTD

EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and preparation method thereof

ActiveCN101928529AHigh affinityWide operating temperature rangeMonocarboxylic acid ester polymer adhesivesPolyureas/polyurethane adhesivesPolymer scienceDi n butyl phthalate

The invention discloses an EVA (Ethylene-Vinyl Acetate) composite emulsion type low temperature-resistant and environmentally-friendly all-purpose adhesive and a preparation method thereof, belonging to the field of water-based adhesives. The invention adopts the technical scheme that an EVA emulsion is modified by utilizing a rosin tackifying resin emulsion and a polyurethane emulsion together to prepare the EVA emulsion all-purpose adhesive. The all-purpose adhesive comprises the following components in parts by weight: 65-80 parts of EVA emulsion, 5-15 parts of rosin tackifying resin emulsion, 5-15 parts of polyurethane emulsion and the balance of auxiliary agent, wherein the auxiliary agent comprises an antifreeze agent, a plasticizer, a mildew-proof agent, a wetting agent and a pH regulator. When making, the preparation method comprises the following steps of: adding the EVA emulsion to a dispersion kettle with a stirrer, and uniformly stirring; adding the polyurethane emulsion, and stirring and mixing for 1.0-1.5h; then adding the rosin tackifying resin emulsion, the plasticizer of dibutyl phthalate, the antifreeze agent of glycol, the mildew-proof agent of Kathon and the wetting agent, and stirring and uniformly mixing; adding the pH regulator, such as ammonia water or triethylamine to regulate pH value to be 4.5-5.5, and filtering and discharging. The obtained all-purpose adhesive has indexes which reach or exceed common white latexes, convenient use and wide applicability, and can be widely used for architectural decoration, furniture making, cases, and the like and used at normal temperature but also at the low temperature from 5 DEG C to 5 DEG C below zero.

Owner:东莞市山力高分子材料科研有限公司

Unsaturated polyester resin for machine-made or hand-pasted plane skylight and preparation method thereof

InactiveCN102181017AGood water and weather resistanceGood water and aging resistanceGelcoatUnsaturated polyester

The invention relates to the technical field of preparation of high polymer materials, in particular to unsaturated polyester resin for a machine-made or hand-pasted plane skylight and a preparation method thereof. The preparation method comprises the following steps of: undergoing an esterification reaction on organic polylol, saturated or unsaturated polyatomic acid or acid anhydride and a monofunctional compound in the presence of catalyst; and dissolving a polymer prepared by condensing in inhibitor-containing cinnamene to obtain the unsaturated polyester resin. The invention has the advantages that the unsaturated polyester resin is prepared from lower-cost raw materials and has low preparation cost; and lower viscosity and good glass fiber wetting property are achieved while the strength is ensured. The resin and the compound of the resin can be widely applied to products, such as automobile parts, gel coatings, artificial stones and the like with higher requirements on weather resistance, in particular to weather-resistant plates.

Owner:CHANGZHOU HUAKE POLYMERS

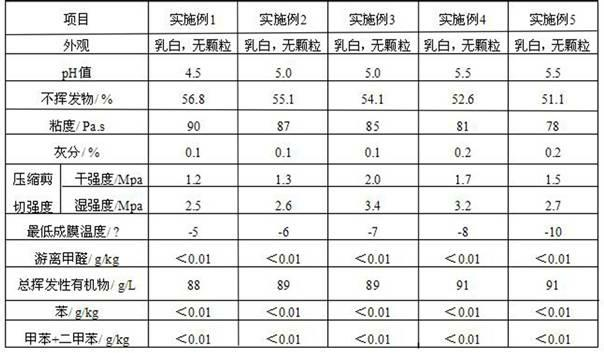

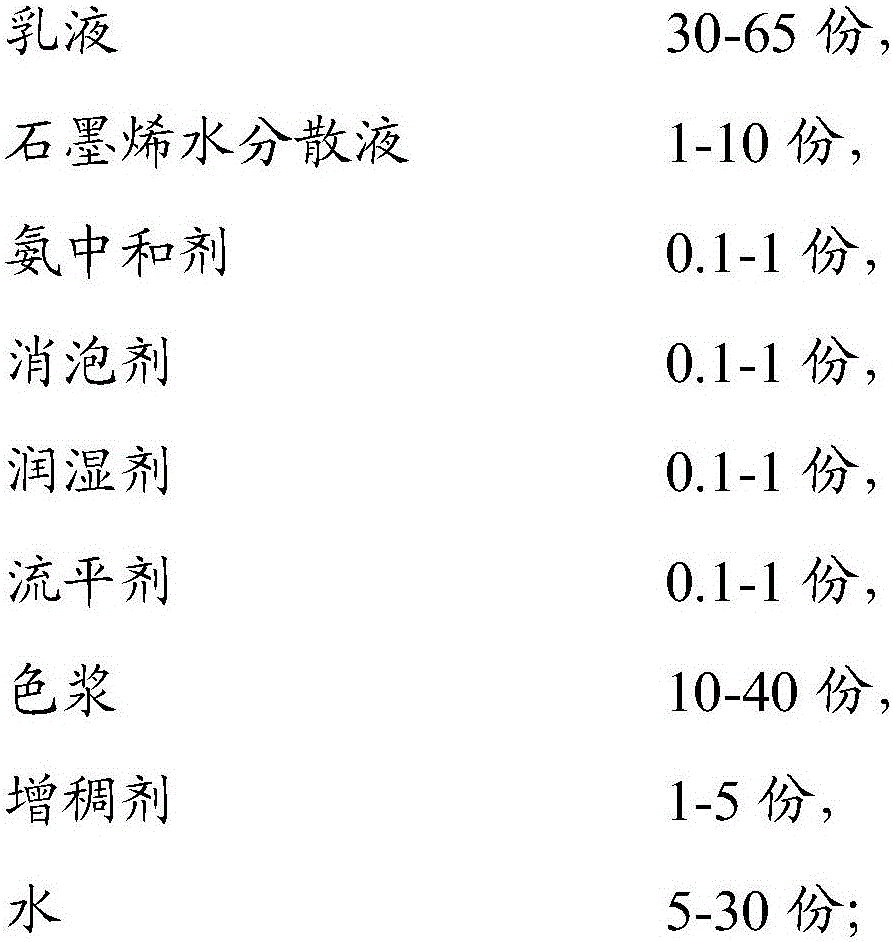

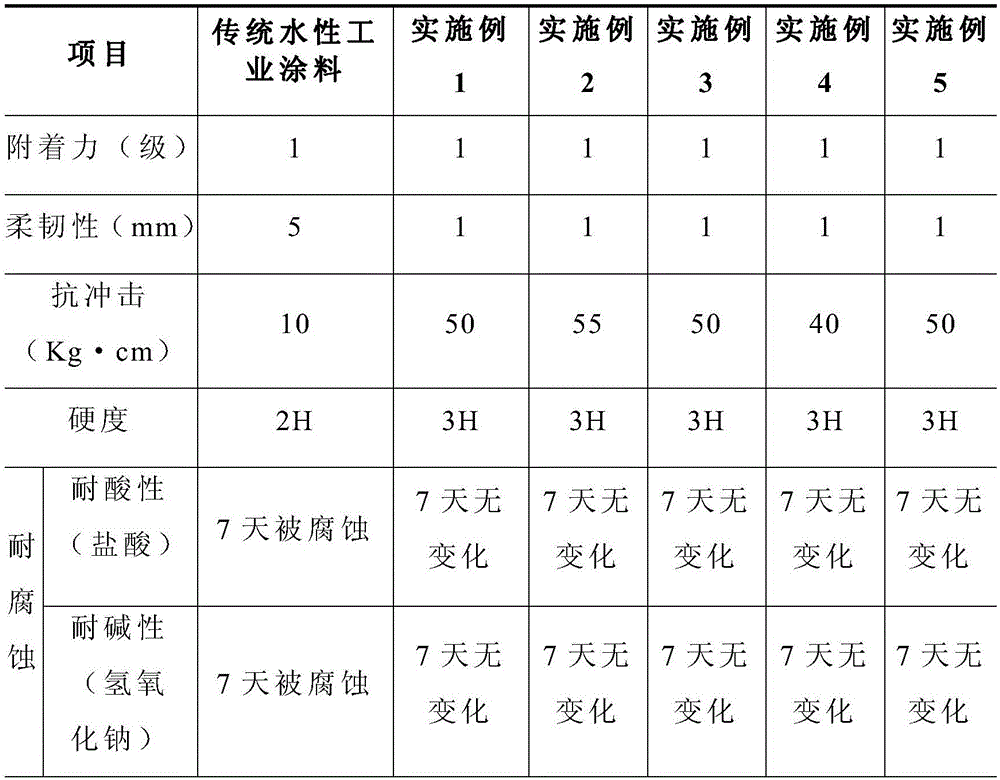

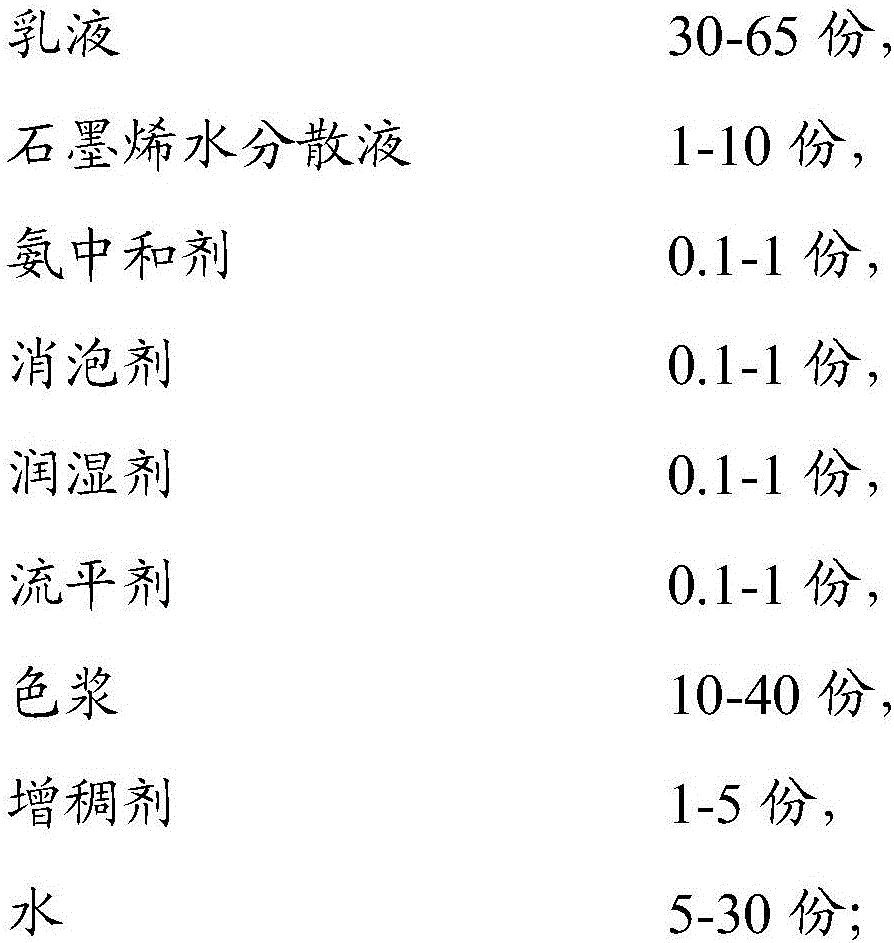

Graphene waterborne industrial coating and preparation method thereof

InactiveCN105670474AImprove water and weather resistanceImprove wear resistance, heat resistance and aging resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsDefoamerEmulsion

The invention relates to the field of chemical engineering, in particular to a graphene waterborne industrial coating and a preparation method thereof.The graphene waterborne industrial coating comprises emulsion, graphene water dispersion liquid, an ammonia neutralization agent, an antifoaming agent, a wetting agent, a flatting agent, colour paste, a thickening agent and water.The preparation method includes the steps that the emulsion and the graphene water dispersion liquid are added into a mixing kettle to be stirred till all materials are mixed to be uniform, and the mixture is obtained; the antifoaming agent, the wetting agent, the flatting agent and the colour paste are added in sequence, the mixture is stirred continuously till the mixture is mixed to be uniform, the water, the ammonia neutralization agent and the thickening agent are added slowly and stirred to be uniform, and a finished product of the graphene waterborne industrial coating is obtained.Through high stability and high strength capacity of the grapheme, abrasive resistance and hardness of the whole system are improved; meanwhile, the grapheme has excellent electrical conductivity, and electrochemical corrosion can be effectively relieved; a protection membrane can be formed due to the structural characteristics of the grapheme, and the abrasive resistance of the waterborne industrial coating is further improved.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

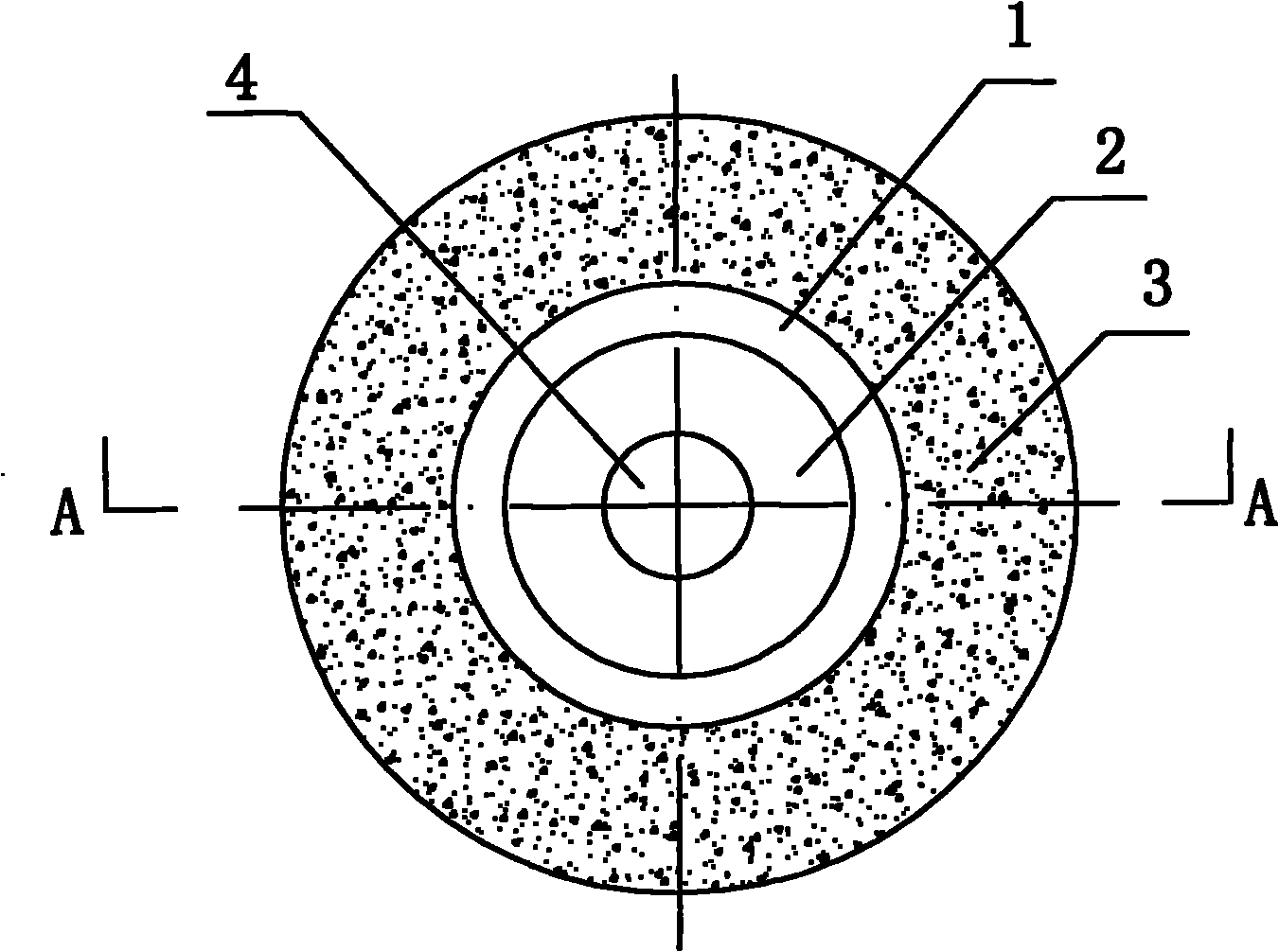

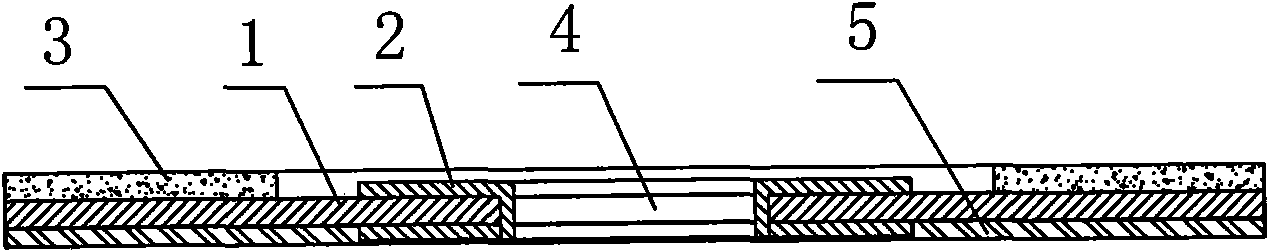

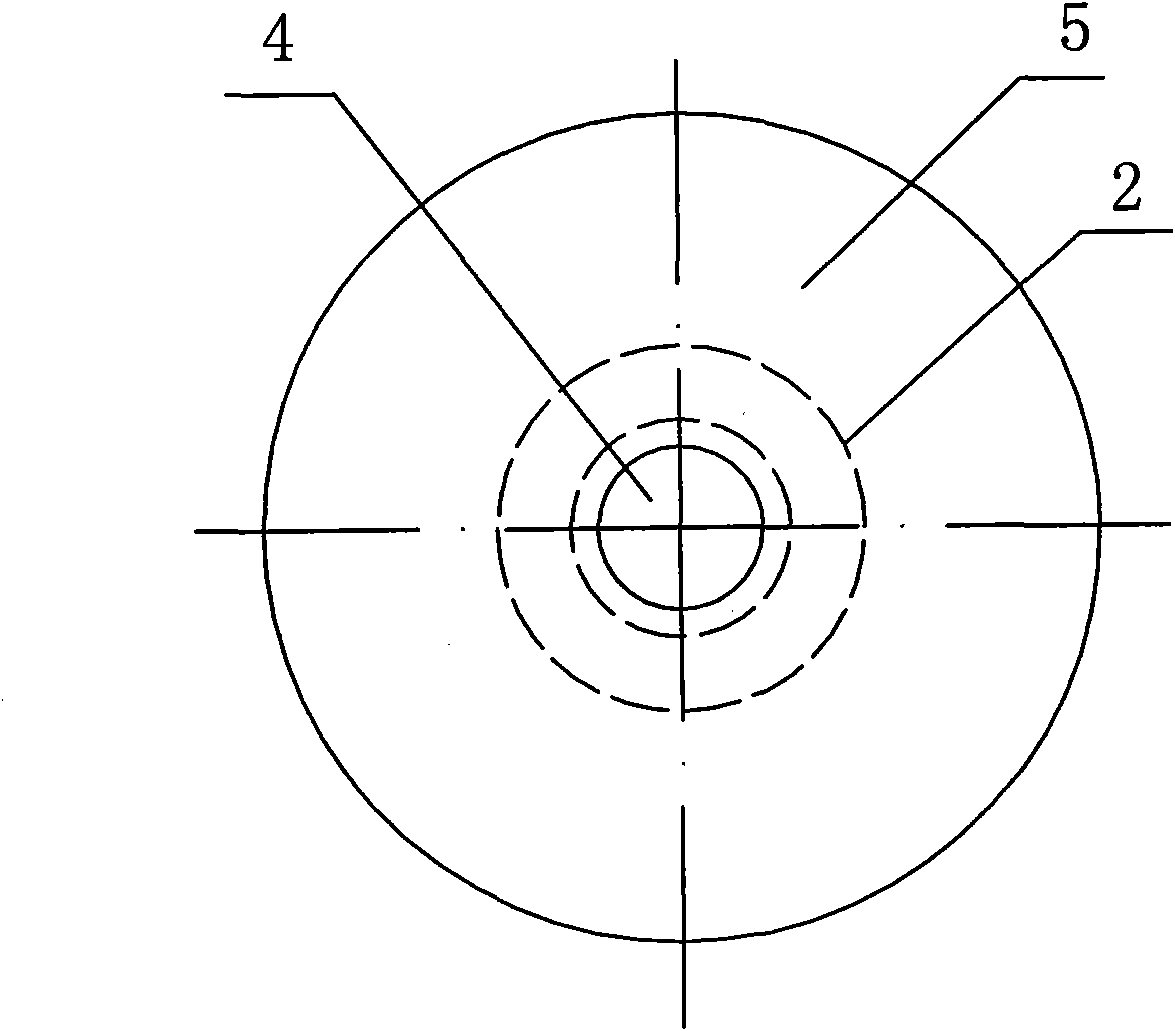

Powerful grinding sand disk

The invention relates to a grinding tool. The powerful grinding sand disk is characterized by comprising a substrate, a reinforcing ring and a grinding work layer; the middle of the substrate is provided with a through hole; the reinforcing ring is fixed on the through hole of the substrate; the front side of the substrate is provided with the annular grinding work layer; the reinforcing ring is positioned on the inner side of the grinding work layer; and the material of the substrate comprises glass fibre or polyester cotton. The powerful grinding sand disk has the characteristics of high strength, good water resistance and weather fastness, low production cost and strong grinding force and is simple to manufacture.

Owner:HUBEI YULI ABRASIVE BELTS GRP

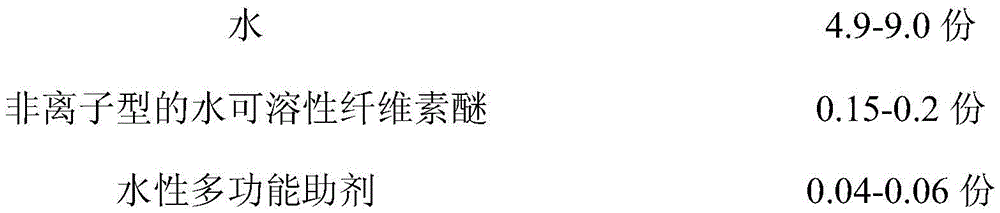

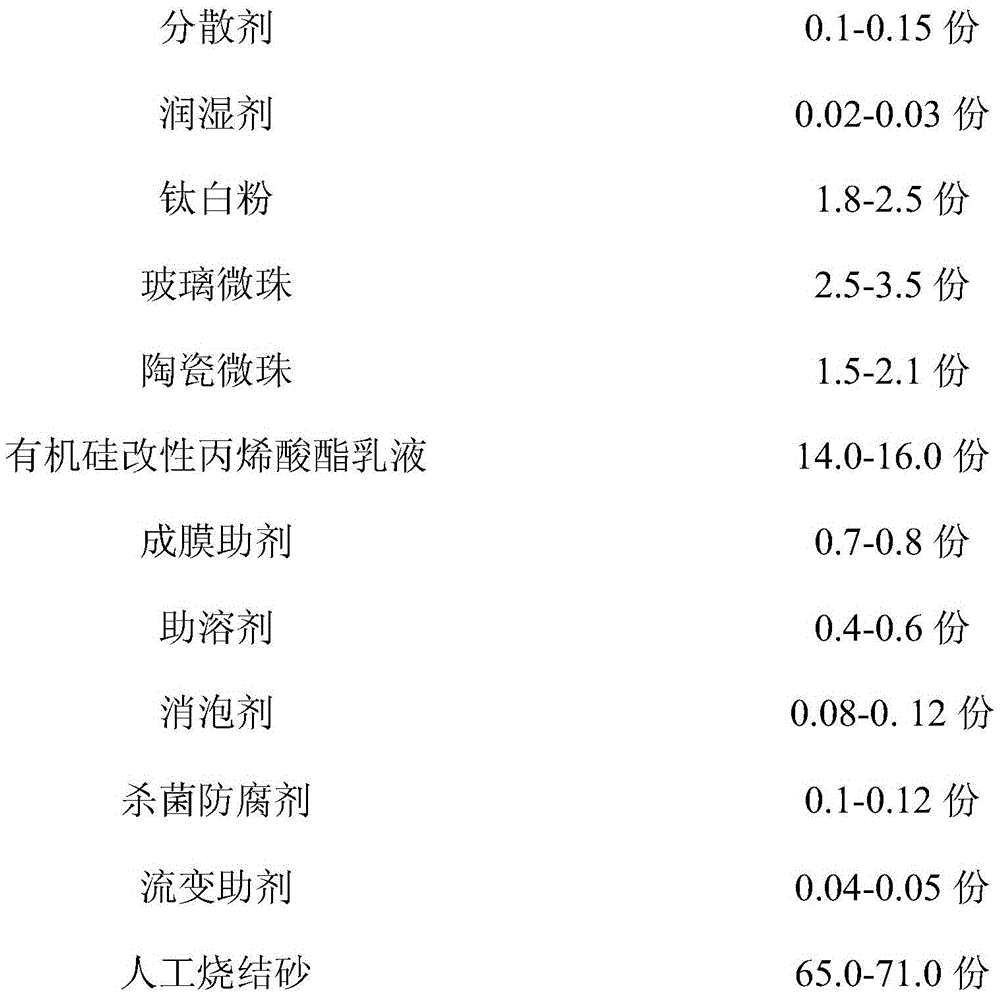

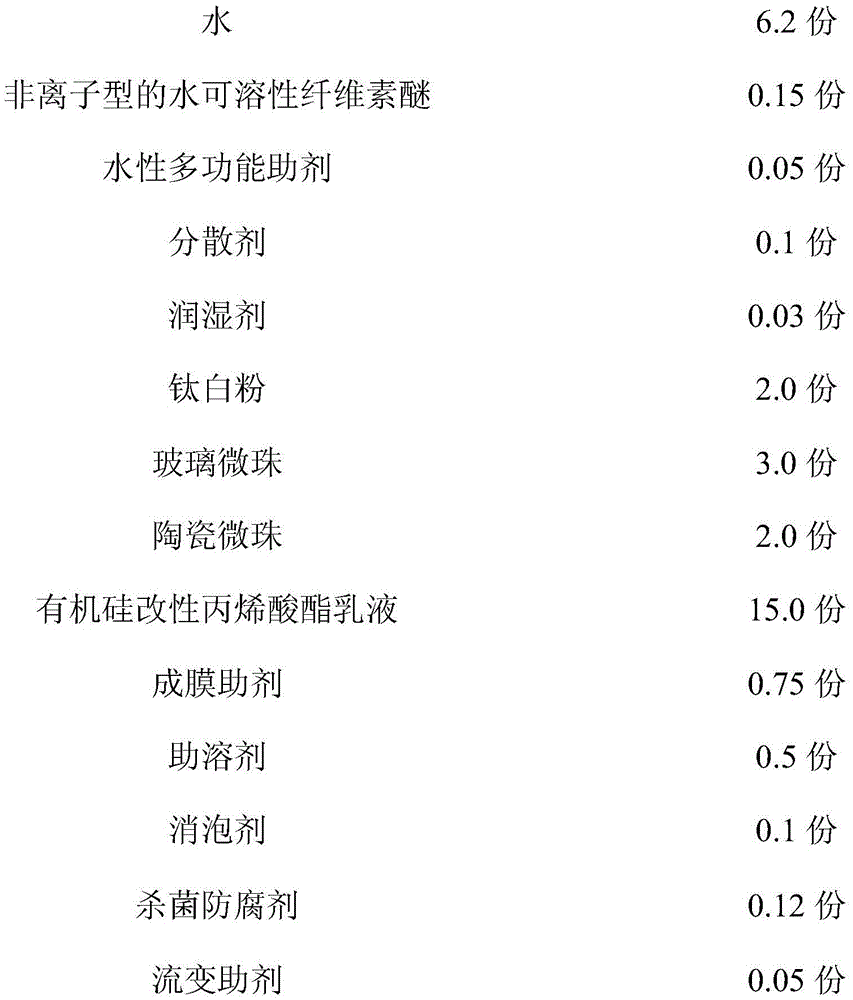

Thermal insulation reflective stone-like coating and preparation method thereof

The present invention relates to a thermal insulation reflective stone-like coating, which is made from the following components by weight: water, non-ionic water-soluble cellulose ethers, a water-based multi-functional additive, a dispersant, a wetting agent, titanium dioxide powder, glass beads, ceramic beads, a organosilicon-modified acrylate emulsion, a coalescent, a cosolvent, a defoamer, an antiseptic, a rheological additive and artificial sintering sand. The invention overcomes the disadvantage of safety hidden trouble caused by large dead load of the coating in the matching operation of insulation system and a stone-like coating of the prior art. The thermal insulation reflective stone-like coating has the advantages of simple operation, light weight, and good heat reflection properties and film properties.

Owner:SKSHU PAINT

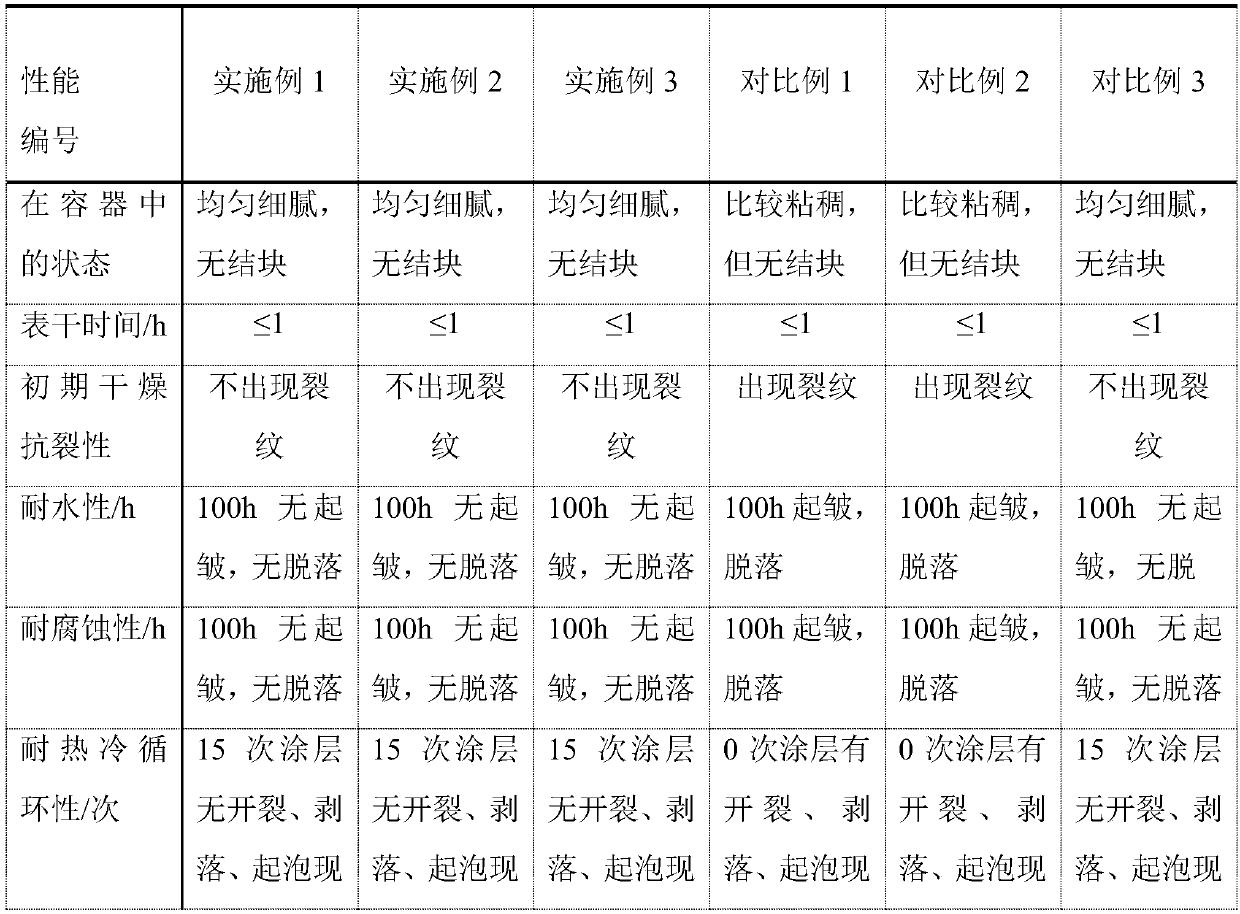

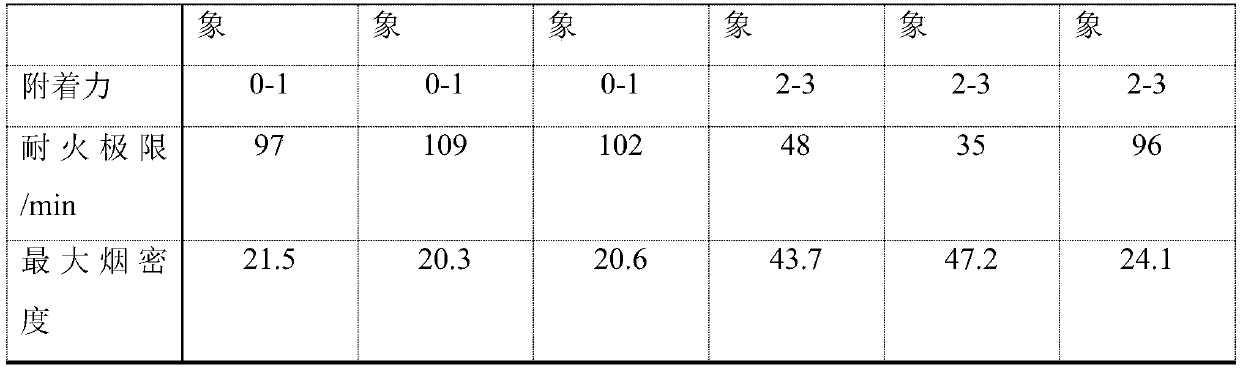

Aqueous microencapsulated fireproof paint for ultrathin steel structure

ActiveCN108676427ASolve the problem of easy cracking of paintGood compatibilityFireproof paintsMicroballoon preparationPhosphoric acidMelamine formaldehyde resin

The invention discloses an aqueous microencapsulated fireproof paint for an ultrathin steel structure. The fireproof paint is prepared from an aluminum hypophosphite microcapsule, an ammonium polyphosphate microcapsule, pentaerythritol, melamine, hydroxyethyl cellulose, an antifoaming agent, a dispersant, aqueous styrene-acrylic emulsion with a core-shell structure, and water. The aluminum hypophosphite microcapsule is wrapped by modified urea melamine formaldehyde resin, the problems that aluminum hypophosphite is easily decomposed and the coating can be cracked easily are solved; the thermalstability of aluminum hypophosphite is improved, the water absorbing performance is reduced; the efficient synergetic effect between the ammonium polyphosphate microcapsule and the aluminum hypophosphite microcapsule is utilized to greatly improve the fireproof performance of the fireproof paint; the fuming amount of the fireproof paint is largely reduced, the problem that ammonium polyphosphateis easily hydrolyzed, migrated, and precipitated in a damp environment is solved; and the provided fireproof paint has the advantages of efficient fireproof performance, good smoke inhibiting performance, excellent film forming property, excellent waterproof performance, good weatherability, environmental friendliness, and simple preparation, and is suitable for popularization and application.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

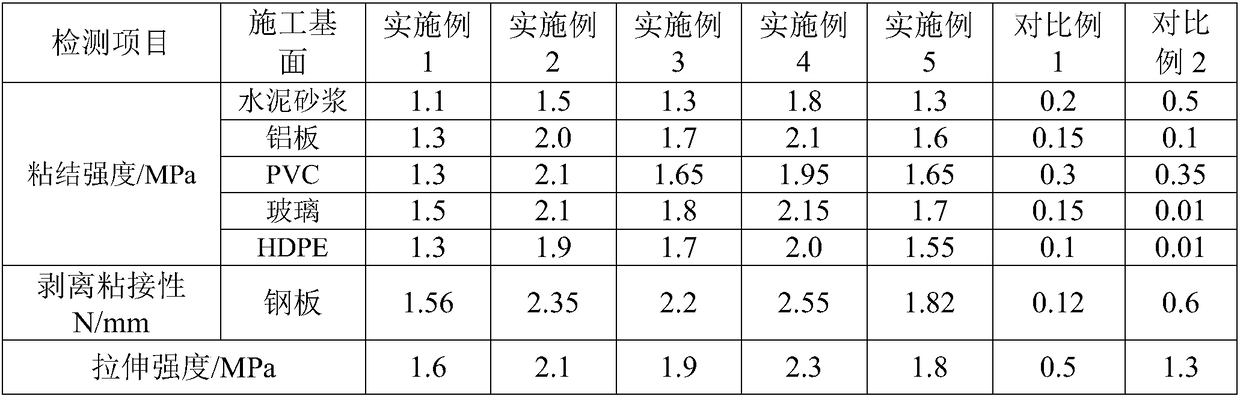

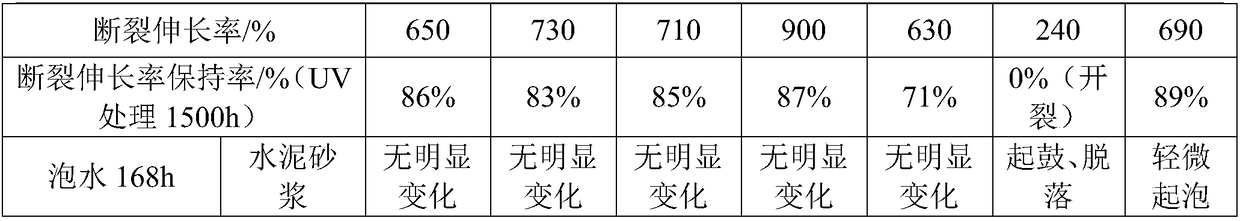

High-elastic weather-resistant waterproof sealing material for roof and preparation method of high-elastic weather-resistant waterproof sealing material

ActiveCN108395794AImprove compactnessRaise room temperatureChloropene polymer coatingsEmulsionWeather resistance

The invention discloses a high-elastic weather-resistant waterproof sealing material for a roof and a preparation method of the high-elastic weather-resistant waterproof sealing material. The high-elastic weather-resistant waterproof sealing material is prepared from the following components: 20-45% of pure acrylic emulsion, 5-20% of neoprene latex, 1-10% of tackifier emulsion, 15-40% of pigment and filler, 1-20% of water and 2-5% of other additives. The high-elastic weather-resistant waterproof sealing material does not need to cover a protection layer, the water resistance and the weather resistance are high, the strength is high, and the elongation at break is high; the sealing material is bonded with most substrates of an existing roof system well, and the surface of the sealing material is covered with a traditional waterproof anticorrosive paint, so that effective adhering is realized, the sealing material is easy to maintain and coat again; and the sealing material can be used as an exposed roof waterproof paint as well as a caulking compound, a node sealing compound and a rolled material edge sealing compound.

Owner:南通科顺建筑新材料有限公司

Epoxy adhesive with high strength and high elasticity

InactiveCN102086362AIncrease elasticityImprove thixotropyEpoxy resin adhesivesHigh intensityToughness

The purpose of the invention is to provide an epoxy adhesive with high toughness, good elasticity, and good cementability. The high strength and high elasticity epoxy adhesive is suitable for steel-to-steel bonding and steel-to-metal bonding. The adhesive in the invention employs an epoxy resin with more than two epoxy groups in one molecule, and available epoxy resins include bisphenol A epoxy resin, bisphenol F epoxy resin, novolac epoxy, glycidyl ester type epoxy resin, glycidol amine type epoxy resin etc.

Owner:柴中南

Production method of fireproof and flame-retardant type medium-density fiber wood floor

InactiveCN109366680AAlleviate the contradiction between supply and demandImprove fire and flame retardant performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMedium density

The invention discloses a production method of a fireproof and flame-retardant type medium-density fiber wood floor. The production method comprises the steps of (1) pretreatment of raw materials; (2)screening; (3) stewing softening operation; (4) grinding operation; (5) glue application and drying; (6) pre-pressing operation; (7) hot-pressing operation; (8) sawing and sanding; (9) glue coating and veneering hot-pressing operation; and (10) preservation and grooving, so that the finished product is obtained. According to the production method, the eucalyptus bark, branches and waste leftovermaterials which remain after board manufacturing is accomplished are used as main raw materials, then other miscellaneous trees are added, the waste is turned into the wealth, and therefore the sufficient and effective utilization of timber resources can be achieved; and due to the fact that modified paraffin and flame-retardant urea-formaldehyde resin adhesives are added, the fireproof and flame-retardant performance of the wood floor can be greatly improved, and the produced medium-density fiber wood floor is excellent in fireproof and flame-retardant performance, good in water resistance and low in formaldehyde content, and is a safe, environmentally friendly and durable wood floor.

Owner:广西横州丽冠环保材料有限公司

Ink absorbent

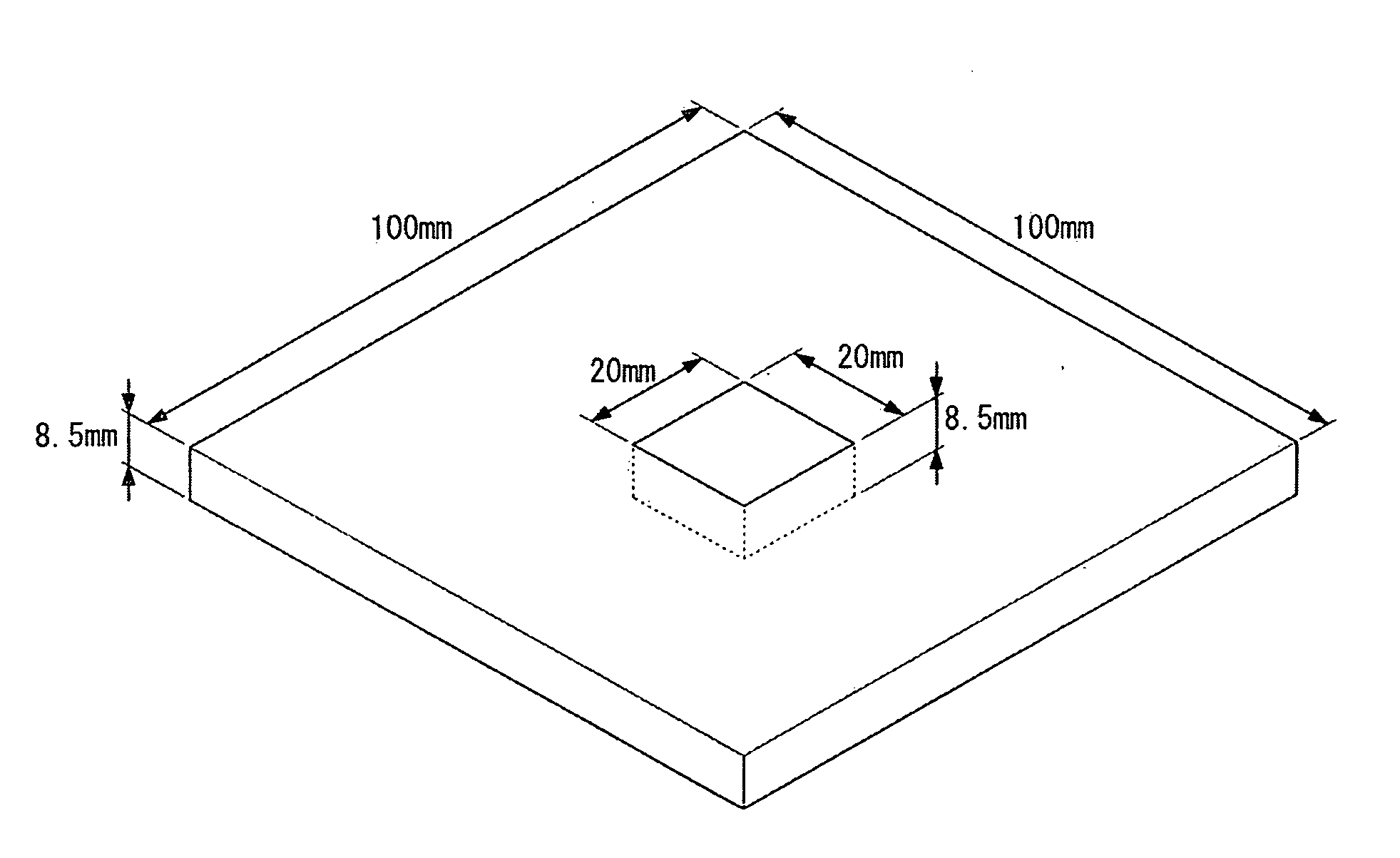

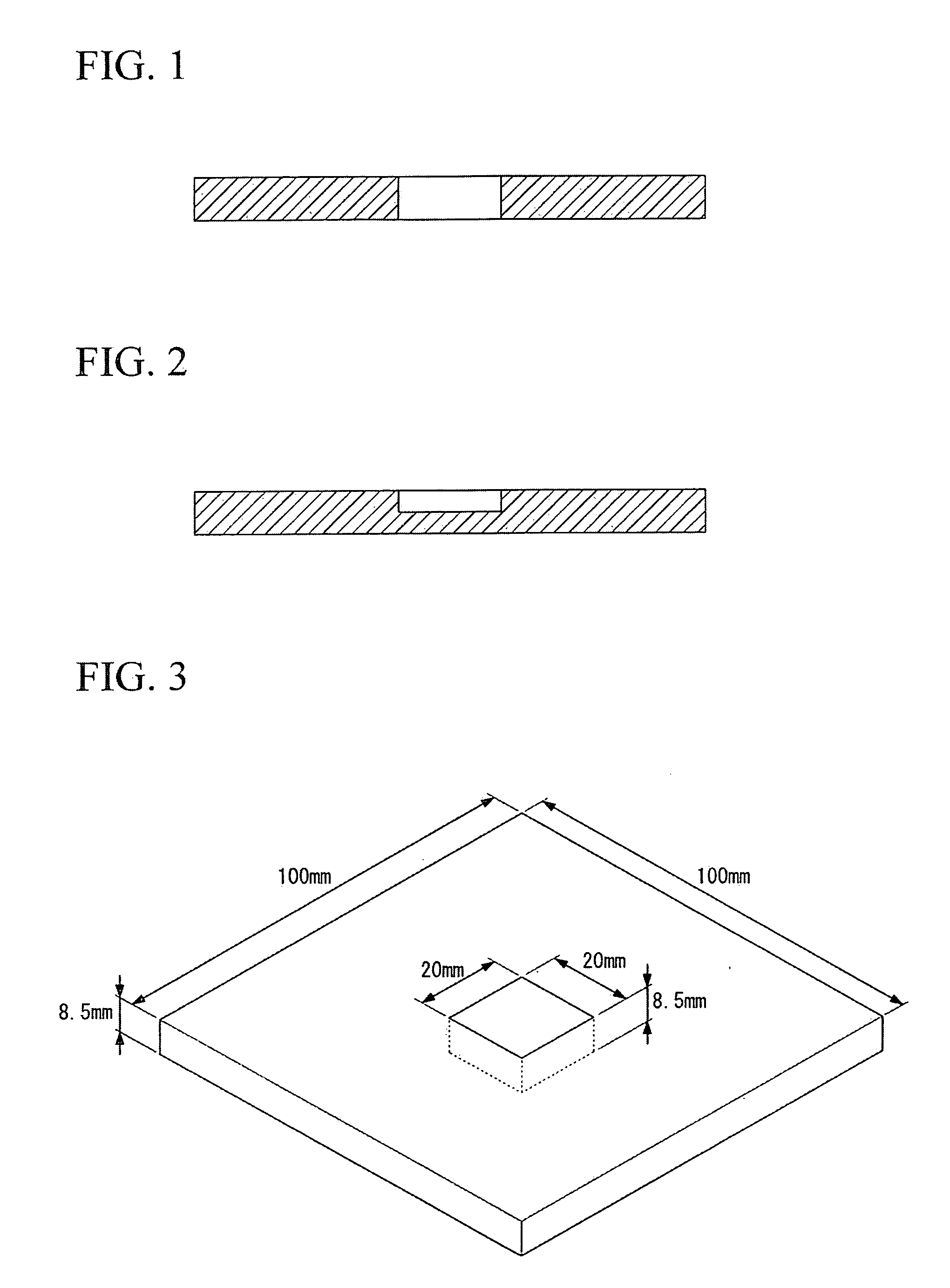

InactiveUS20080318025A1Ink viscosity is highHigh viscosityDuplicating/marking methodsSynthetic resin layered productsNonwoven fabricChemistry

An ink absorbent including a base sheet comprising a dry nonwoven fabric having the density of 0.05 to 0.5 g / cm3 and a porous member fitted to the base sheet, wherein the density of the porous member is lower than one of the base sheet, is provided.

Owner:OJI KINOCLOTH +1

Modified stannic oxide sol, stannic oxide-zirconium oxide composite sol, coating composition and optical element

ActiveUS7563827B2Reduce defectsGood water and weather resistanceMaterial nanotechnologyTin compoundsOligomerAntimonate

Owner:NISSAN CHEM IND LTD

Geopolymer-based water-based inorganic coating and preparation method thereof

The invention discloses a geopolymer technology-based water-based inorganic coating and a preparation method thereof, and the coating mainly comprises the following components: 50-60 parts of geopolymer metakaolin, 40-50 parts of powdery water glass, 1-5 parts of mica powder, 1-5 parts of titanium dioxide, 1-5 parts of a modifier, 10-20 parts of a silicone acrylic emulsion and 50-60 parts of deionized water. The coating is prepared by a simple powder mixing and stirring process. The geopolymer has high-temperature stability, high binding force and durability, low permeability and high chemicalcorrosion resistance, so that the prepared coating has good water resistance, fire resistance, crack resistance and scrub resistance, the market requirements are met, the production process is environmentally friendly, the raw materials are cheap and easy to obtain, the process is simple, and the energy consumption is low. The future development requirements of the coating industry are met, and the sustainable development concept is met.

Owner:HEFEI UNIV OF TECH +1

Water-based adhesive

The invention discloses a water-based adhesive. The water-based adhesive is prepared from the following raw materials in parts by weight: 75-80 parts of styrene, 55-60 parts of ethyl acetate, 30-35 parts of silicon acrylic emulsion, 29-32 parts of asbestos powder, 18-21 parts of antiaging agent, and 75-80 parts of water. The water-based adhesive has strong bonding strength and tensile strength as well as good water resistance and weather resistance performances.

Owner:WEIHAI YONGLIJIAN DECOR CO LTD

Production method of weather-proof, low-aldehyde and medium-density fiber office table special board

InactiveCN109203172AConducive to alleviating the contradiction between supply and demandLow water resistanceFlat articlesDomestic articlesWeather resistanceSizing

The invention discloses a production method of a weather-proof, low-aldehyde and medium-density fiber office table special board. The method comprises the following steps: (1) pretreating raw materials, (2) screening, (3) cooking and softening, (4) grinding, (5) sizing and drying, (6) pre-pressing, (7) hot pressing, (8) sawing and sanding, (9) veneering hot pressing, and (10) edge cutting. In thisway, a finished product is obtained. According to the invention, eucalyptus barks, branches and waste leftover materials left in the manufacturing process are taken as main raw materials. Meanwhile,other miscellaneous wood is added, so that the full and effective utilization of wood resources can be realized. The modified paraffin and the weather-proof urea-formaldehyde resin adhesive are added,and the production process is strictly controlled. As a result, the waterproof and weather-proof performance is greatly improved and the board is low in formaldehyde content. The prepared medium-density fiber wardrobe special board is environment-friendly, low in formaldehyde content and excellent in weather resistance. Therefore, the board is a safe, environment-friendly and low-formaldehyde-content office table special board.

Owner:广西横州丽冠环保材料有限公司

Waterborne paint and preparation method thereof

InactiveCN107964301AHigh hardnessImprove adhesionFireproof paintsAntifouling/underwater paintsAcrylic resinAntioxidant

The invention relates to a waterborne paint and a preparation method thereof. The waterborne paint is characterized by comprising the following raw materials by weight: 35-50 parts of organosilicon modified acrylic resin, 10-15 parts of methylated melamino-formaldehyde resin, 4-8 parts of methanol, 4-8 parts of dipropylene glycol butyl ether, 1-3 parts of filler and pigment, 0.1-1 part of a wetting agent, 0.1-1 part of an efficient defoamer, 0.1-1 part of a leveling agent, 0.1-0.5 part of a drier, 0.1-0.5 part of an antioxidant, and 40-60 parts of deionized water. The waterborne paint providedby the invention can achieve high hardness, good adhesion and wear resistance after spraying, also has excellent flexibility, water resistance and weather resistance, moisture and heat resistance andsalt spray resistance, also the preparation process is simple, and is suitable for large-scale production.

Owner:张聪聪

Production method of dedicated fireproof flame-retardant medium-density fiber cabinet board

InactiveCN109366667AIncrease surface areaImprove adsorption capacityWood working apparatusFlat articlesEnvironmental resistanceFiber

The invention discloses a production method of a dedicated fireproof flame-retardant medium-density fiber cabinet board. The production method comprises the following steps: (1) raw material pretreatment; (2) sieving; (3) softening through stewing; (4) grinding; (5) gluing and drying; (6) prepressing; (7) hot-pressing; (8) sawing and sanding; (9) veneering hot-pressing; and (10) edge cutting, thereby obtaining the finished product. Eucalyptus bark, branches, and waste leftover materials left in plate manufacturing are used as main raw materials, and other weedtrees are added, so that waste isturned into wealth, and timber resources are sufficiently and effectively utilized; modified paraffin and a flame retardant urea resin adhesive are added, so that the fire resistance and the flame retardation performance are greatly improved, and the manufactured dedicated medium-density fiber cabinet board is high in fire resistance and the flame retardation performance, high in water resistance,and low in formaldehyde content, and is a safe and environmental-friendly dedicated cabinet board.

Owner:广西横州丽冠环保材料有限公司

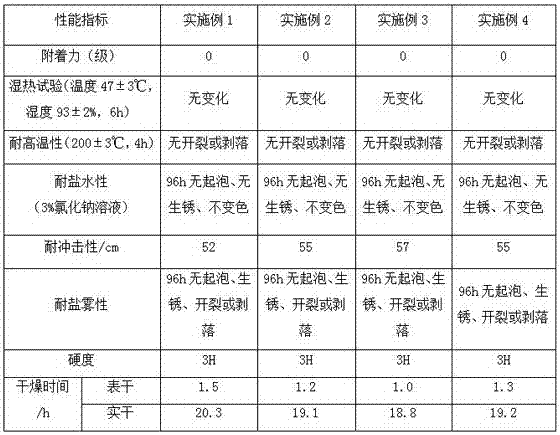

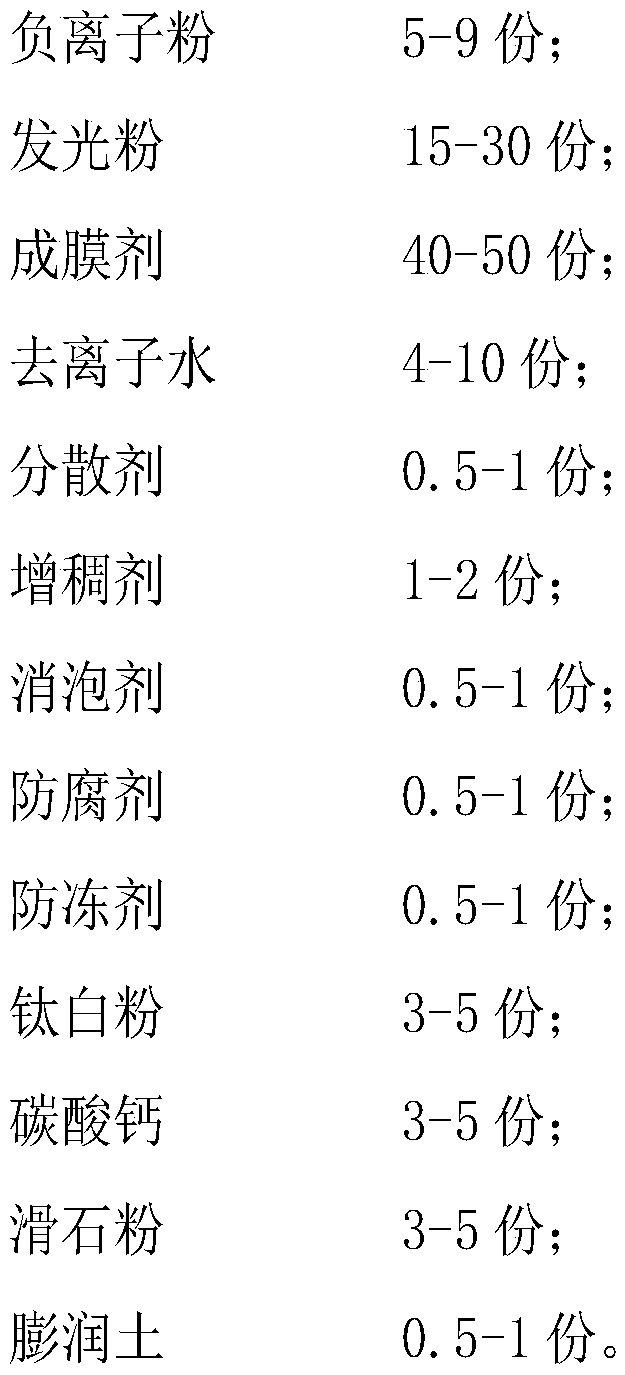

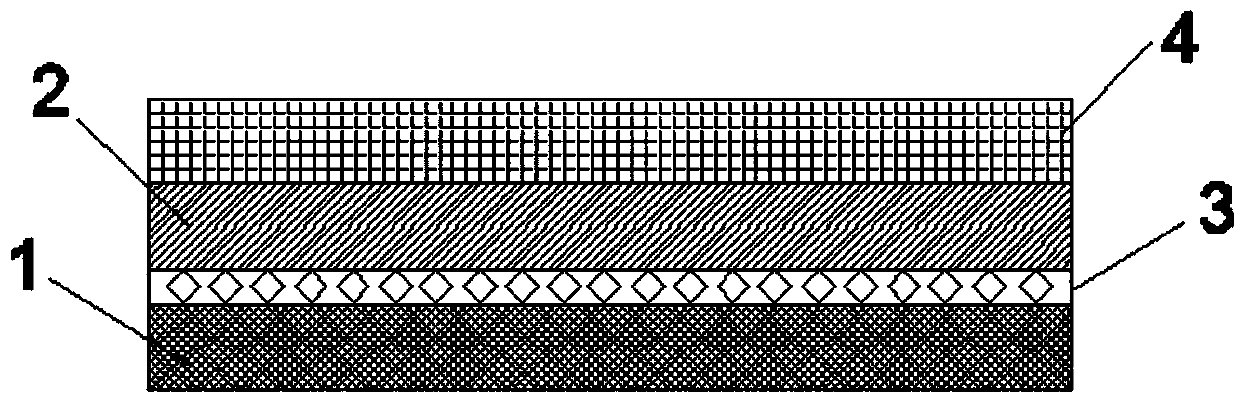

Energy-storage luminous negative-ion water-based interior wall coating and preparation method thereof

The invention relates to the technical field of coatings, in particular to an energy-storage luminous negative-ion water-based interior wall coating. The coating comprises the following components: negative ion powder, luminous powder, a film forming agent, deionized water, a dispersing agent, a thickening agent, a defoaming agent, a preservative, an antifreezing agent, titanium dioxide, calcium carbonate, talcum powder and bentonite. The preparation method comprises the following steps: firstly, adding the film forming agent, deionized water and the dispersing agent into a stirring kettle, and carrying out stirring; then, adding the thickening agent, and carrying out stirring; when the thickening agent is completely dissolved, sequentially adding the negative ion powder, the luminescent powder, titanium dioxide, calcium carbonate, talcum powder and bentonite, and carrying out stirring at a high speed; and finally, adding the defoaming agent, the preservative and the antifreezing agent, carrying out stirring at a high speed, and then carrying out stirring at a low speed to complete preparation of the coating. According to the energy-storage luminous negative-ion water-based interior wall coating and the preparation method thereof, the coating has the functions of energy storage luminescence and negative ion release, and can achieve composite effects of illumination, energy conservation and air purification.

Owner:嘉兴凤翼特种材料科技有限公司

Method for producing fireproof flame-retarding medium-density fiber plate special for office table

InactiveCN109397463AAlleviate the contradiction between supply and demandLow costWood veneer joiningDomestic articlesScrapSizing

The invention discloses a method for producing a fireproof flame-retarding medium-density fiber plate special for an office table. The method comprises the steps of (1) raw material treatment, (2) screening, (3) steaming and softening, (4) grinding, (5) sizing and drying, (6) pre-pressing, (7) hot pressing, (8) sawing and sanding, (9) facing hot pressing and (10) edge cutting. According to the method, eucalyptus bark, branches and scraps left after plate manufacturing are adopted as main raw materials, other miscellaneous trees are added, waste is turned into wealth, and full and effective utilization of timber resources can be achieved. Modified paraffin and an inflaming retarding urea-formaldehyde resin adhesive are added, so that the fireproof flame retarding performance is greatly improved; and the manufactured medium-density fiber plate special for the office table is good in fireproof and flame retarding performance, good in water resistance, low in formaldehyde content, safe andenvironment-friendly.

Owner:广西横州丽冠环保材料有限公司

Anti-static flame-retardant composite fabric and preparation method thereof

ActiveCN109572092AImprove breathabilityBreathable and comfortableSynthetic resin layered productsCoatingsFiberAdhesive

The invention discloses anti-static flame-retardant composite fabric and a preparation method thereof. The anti-static flame-retardant composite fabric comprises a first fabric layer, a second fabriclayer, an electric conducting layer and a flame-retardant layer. The second fabric layer is positioned above the first fabric layer. The first fabric layer and the second fabric layer adopt comfortable ventilating fabric. The electric conducting layer is between the first fabric layer and the second fabric layer. The flame-retardant layer is positioned on an outermost layer of the fabric, and theouter surface of the second fabric layer is coated by the flame-retardant layer. The preparation method is capable of, through blending natural silks and ice silks, forming the first fabric layer andthe second fabric layer, wherein the fabric is soft in texture and has good air permeability; through alternately spinning graphite fibers and acetate fibers, forming a fiber net, and forming the electric conducting layer to connect the first fabric layer and the second fabric layer, wherein the air permeability of the fabric is guaranteed, and the fabric has excellent electrical conductivity; andthrough an adhesive, coating on the second fabric layer by flame-retardant paint so as to form the flame-retardant layer, thereby forming the anti-static, flame-retardant, ventilating and comfortablefabric.

Owner:安徽劲派新材料科技有限公司

Production method of weather-proof low-formaldehyde medium-density fiber wardrobe special board

InactiveCN109318333AImprove waterproof performanceHigh strengthDomestic articlesFlat articlesFiberWeather resistance

The invention discloses a production method of a weather-proof low-formaldehyde medium-density fiber wardrobe special board. The preparation method comprises the following steps of (1) pretreating rawmaterials, (2) screening, (3) cooking and softening, (4) grinding, (5) applying adhesives and drying, (6) pre-pressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing, and (10) edge cutting to obtain a finished product. According to the production method, eucalyptus barks and branches and waste leftover materials left in the board manufacturing process are taken as the main raw materials, other miscellaneous wood is added, waste is changed into things of value, so that full and effective utilization of the wood resources can be realized; modified paraffin and the weather-proof urea-formaldehyde resin adhesives are added, the production process is strictly controlled, so that the waterproof and weather-proof performance is greatly improved, the formaldehyde content is low, the medium-density fiber wardrobe special board is prepared, the prepared medium-density fiber wardrobe special board has the advantages of being environmentally friendly, low in formaldehyde and good in weather resistance, and is a safe, environment-friendly and low-formaldehyde wardrobe special board.

Owner:广西横州丽冠环保材料有限公司

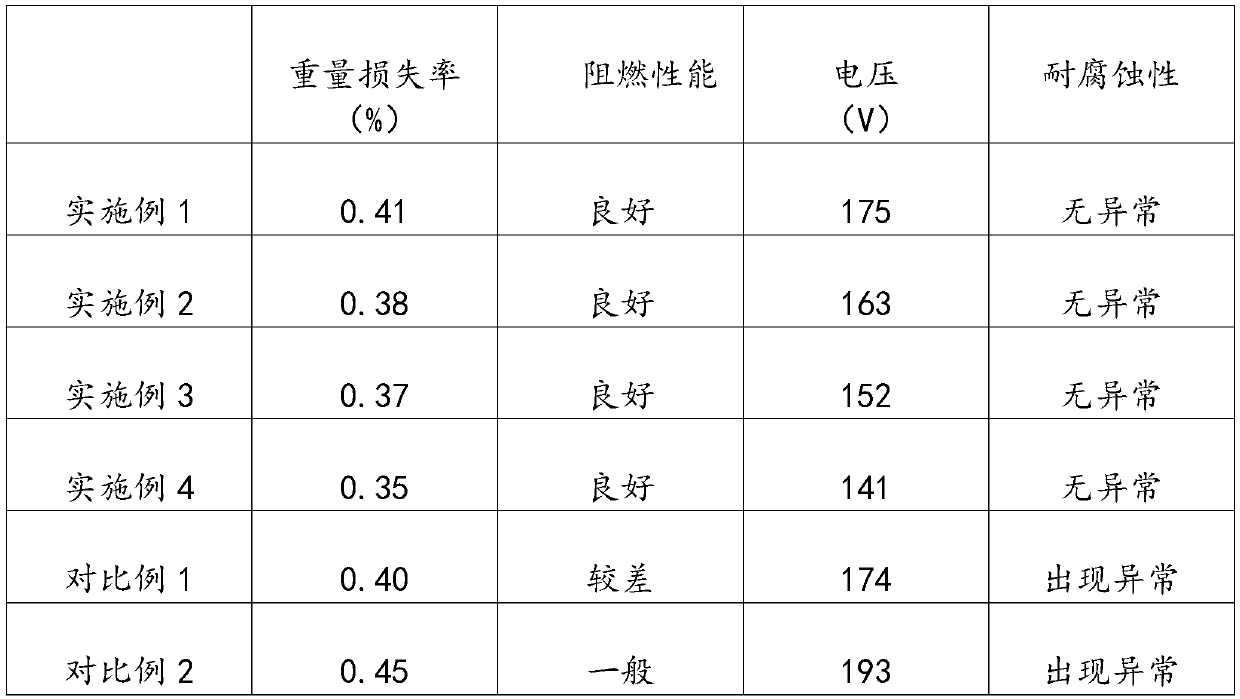

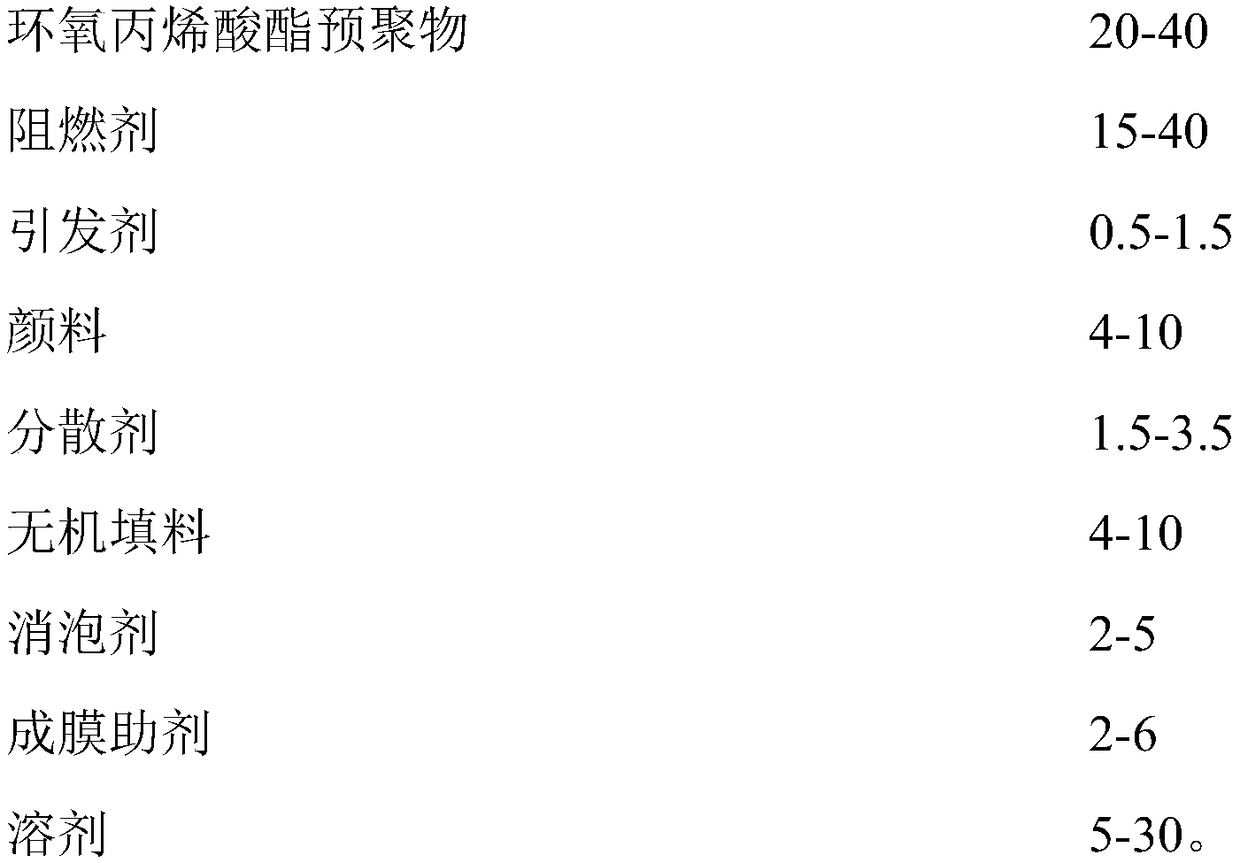

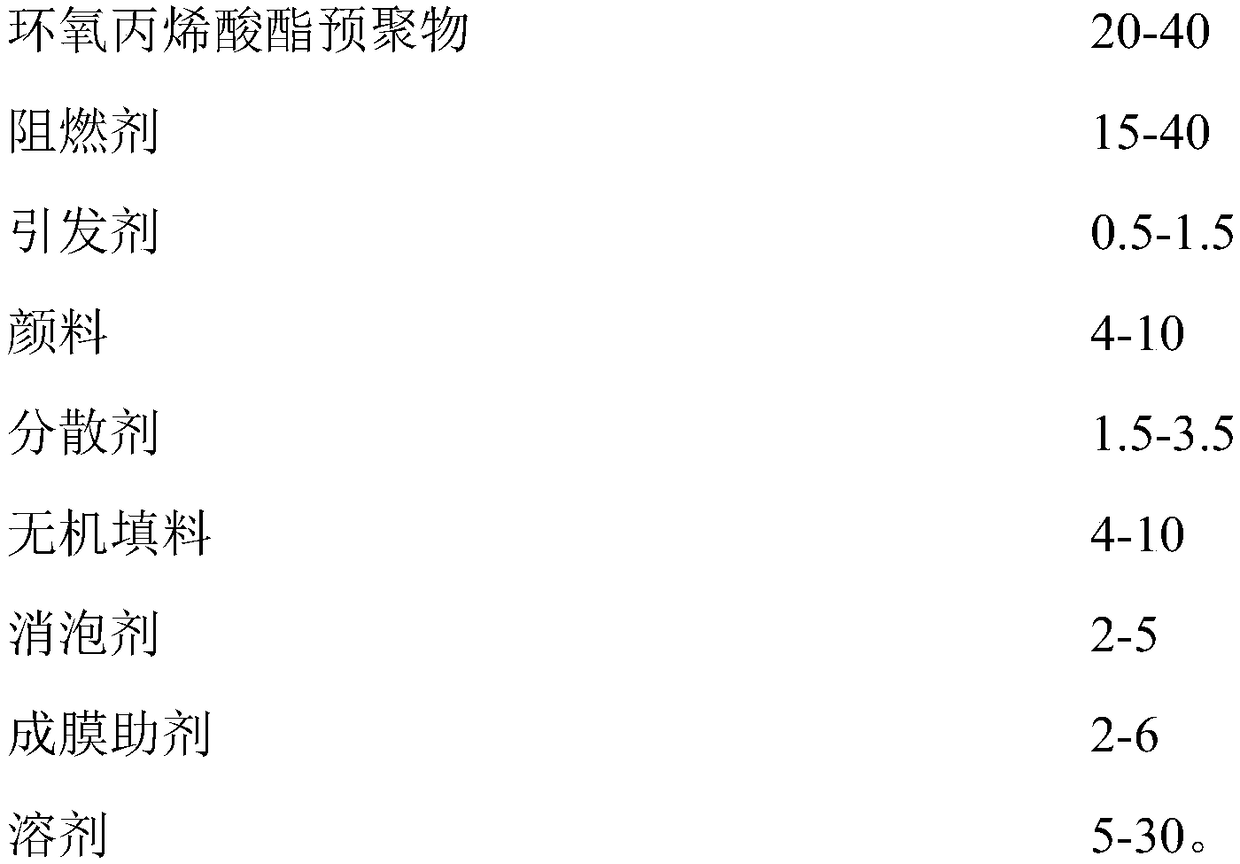

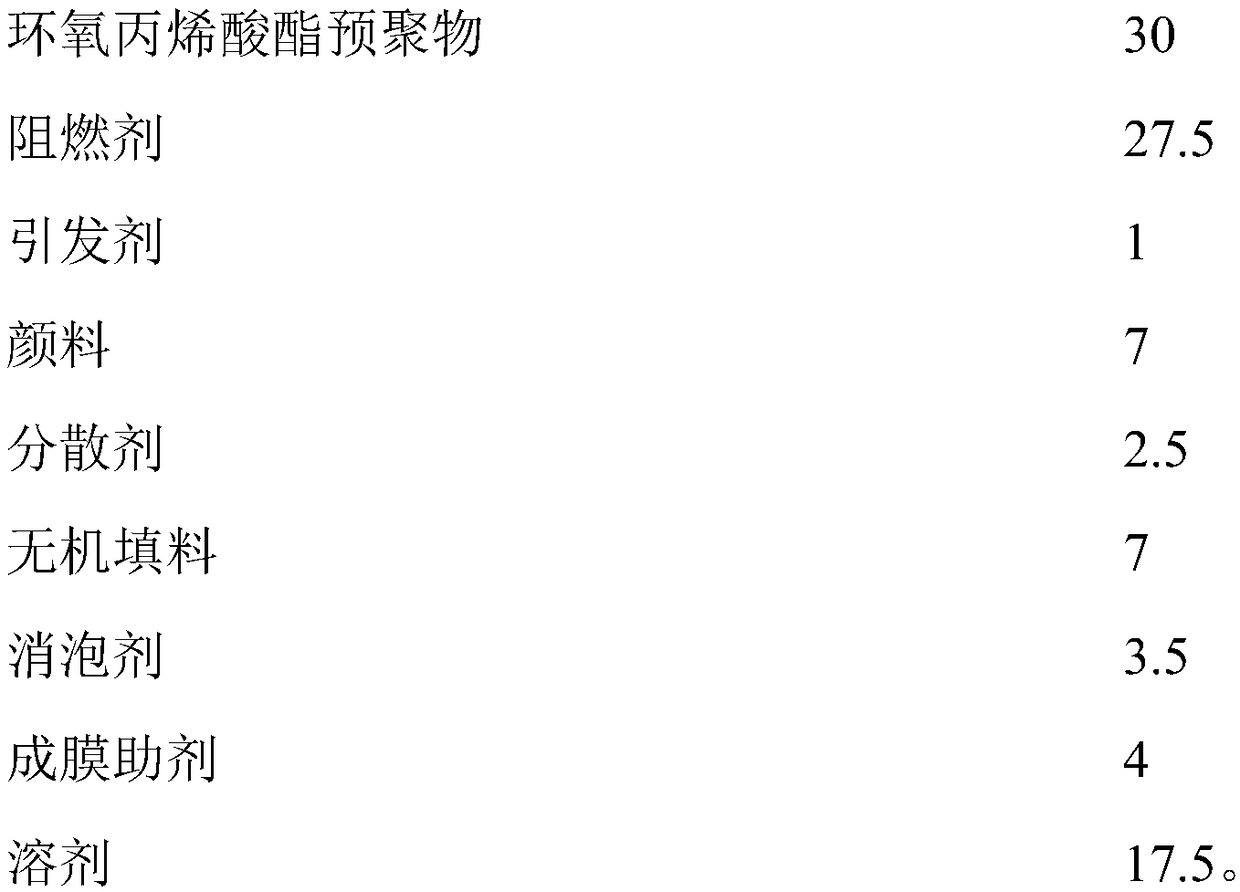

Epoxy acrylic resin flame-retarding coating and preparation method thereof

The invention discloses an epoxy acrylic resin flame-retarding coating and a preparation method thereof, wherein the coating includes, by weight, 20-40 parts of an epoxy acrylate prepolymer, 15-40 parts of a flame retardant, 0.5-1.5 parts of an initiator, 4-10 parts of a pigment, 1.5-3.5 parts of a dispersant, 4-10 parts of inorganic filler, 2-5 parts of a defoamer, 2-6 parts of a film-forming additive, and 5-30 parts of a solvent. By adding the reactive flame retardant that can form completely compatible entirety with the epoxy acrylate prepolymer, the flame-retarding coating not only has excellent and durable flame-retarding effect, but also has excellent physical and mechanical performance, water resistance and anti-chemical corrosion effect and high adhesion strength.

Owner:广东鑫皇冠新材料有限公司

Coated silicate fluorescent powder and film-coating method thereof

ActiveCN103725282BPrecise thickness controlImprove stabilityLuminescent compositionsFluidized bedMetallurgy

The invention discloses coated silicate fluorescent powder. According to the invention, an inner core adopts silicate fluorescent powder and coated with an inner shell layer and an outer shell layer, the inner shell layer adopts SiO2, and the outer shell layer adopts Al2O3. The invention further provides a film-coating method of the silicate fluorescent powder. The method comprises the following steps: (1) mixing fluorescent powder and SiO2 according to the mass ratio of (10-20):1, dry grinding and sieving; (2) placing the sieved powder in a fluidized bed reactor, and feeding N2 to enable the powder to suspend in the fluidized bed reactor; (3) mixing trimethylaluminum with N2, and feeding the mixture in the reactor, wherein the mass of the trimethylaluminum is 0.3-2% of that of the fluorescent powder; (4) feeding O2 containing O3 at 170-200 DEG C, and reacting for 1-2 h. According to the invention, the method is simple, the controllability is high, and the thickness of a film can be accurately controlled; the luminance of fluorescent powder can be improved through SiO2 coating , and the strength and the adhesive force of the film can be improved through Al2O3 coating, so that the water-tolerant and weather-resisting properties of fluorescent powder can be effectively improved, the luminescence property of fluorescent powder is optimized, and the service life of fluorescent powder is prolonged.

Owner:QIDONG CHUANGLYU GREENING ENG CO LTD

Aqueous dispersion

The invention provides an aqueous dispersion which includes i) an aqueous dispersion (I) resulting from dispersion of a block copolymer (I) composed of at least one polymer block (A) containing olefin monomer units and at least one polymer block (B) containing 2 to 100 mole percent of units derived from at least one vinyl monomer having a carboxyl or carboxylic anhydride group and 98 to 0 (zero) mole percent of units derived from another vinyl monomer or monomers copolymerizable with the carboxyl group- or carboxylic anhydride group-containing vinyl monomer, in an aqueous solution of not less than 0.05 equivalent, relative to the carboxyl or carboxylic anhydride group, of a basic substance, and ii) a polyurethane (II), iii) vinyl polymer (III) or iv) tackifier (IV) incorporated in the aqueous dispersion (I). The aqueous dispersion of the invention has excellent adhesiveness to various substrates and stability, and gives a coating layer having excellent weather resistance, water resistance and resistance to solvent attack. The aqueous dispersion of the invention is particularly useful as a coating composition and / or a primer.

Owner:KURARAY CO LTD

High-elasticity epoxy resin adhesive

InactiveCN104194702AHigh elongation at breakEasy to useNon-macromolecular adhesive additivesEpoxy resin adhesivesPolysulfide rubberResin adhesive

The invention provides a high-elasticity epoxy resin adhesive which comprises 80-100 parts of epoxy resin containing more than two epoxy groups, 50-100 parts of epoxy-terminated polysulfide rubber, 8-10 parts of curing agent, 5-8 parts of accelerator, 0.3-0.5 part of anti-settling agent, 1-1.5 parts of coupling agent, 6-8 parts of thixotropic agent, 20-40 parts of nano calcium carbonate and 20-40 parts of pigment. The high-elasticity epoxy resin adhesive has the characteristics of favorable bonding property, high elongation at break (greater than 50%) and the like.

Owner:王寿高

A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments

ActiveCN106007634BImprove water whitening resistanceGood water whitening resistanceLacquerBENZYL ALCOHOL/WATER

The invention relates to an external wall natural stone paint suitable for construction in a low-temperature high-humidity environment. The invention is characterized in that the paint is mainly composed of the following components in percentage by mass: 70-80% of colored sand, 12-15% of silicon-modified styrene-acrylic emulsion 8666, 0.6-0.8% of film forming aid, 2.0-3.0% of silica sol, 0.1-0.15% of thickener and the balance of conventional aid, totaling 100%. The film forming aid is mainly compounded from Texanol ester alcohol, ethylene glycol monobutyl ether and benzyl alcohol. The thickener is compounded from a polyurethane thickener and an alkali thickener. The natural stone paint can achieve the constructability of the normal temperature environment in the low-temperature high-humidity environment.

Owner:湖南德泰建筑工程有限公司

Production method of weather-proof low-formaldehyde medium-density fiber plate special for cabinet

InactiveCN109366639AAlleviate the contradiction between supply and demandLow water resistanceWood veneer joiningDomestic articlesFiberMaterials science

The invention discloses a production method of a weather-proof low-formaldehyde medium-density fiber plate special for a cabinet. The production method comprises the steps of (1) raw material pretreatment; (2) screening; (3) stewing softening; (4) grinding; (5) gluing and drying; (6) prepressing; (7) hot pressing; (8) sawing and sanding; (9) hot pressing for veneer; and (10) edge sealing and acquisition of a finished product. According to the production method, eucalyptus bark and branches and waste leftover materials of plate manufacturing are adopted as main raw materials, other wood is added, waste is made profitable, and full and effective utilization for wood resources can be achieved; and modified paraffin and an weather-proof urea resin adhesive are added, the production process isstrictly controlled, water-proof and weather-proof properties are greatly improved, the formaldehyde content is low, and the manufactured medium-density fiber plate special for the cabinet has the advantages of being environmentally-friendly in use, low in formaldehyde content and excellent in weather-proof property, and is safe, environmentally-friendly and low-formaldehyde.

Owner:广西横州丽冠环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com