High-elastic weather-resistant waterproof sealing material for roof and preparation method of high-elastic weather-resistant waterproof sealing material

A waterproof sealing and weather-resistant technology, applied in the direction of chloroprene homopolymer coatings, coatings, etc., can solve the problem of elongation at break, UV resistance and long-term water resistance, and waterproof coatings cannot be effectively attached to it. , small elongation at break and other problems, to achieve the effect of easy maintenance and re-coating, improving interlayer adhesion, and improving the compactness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

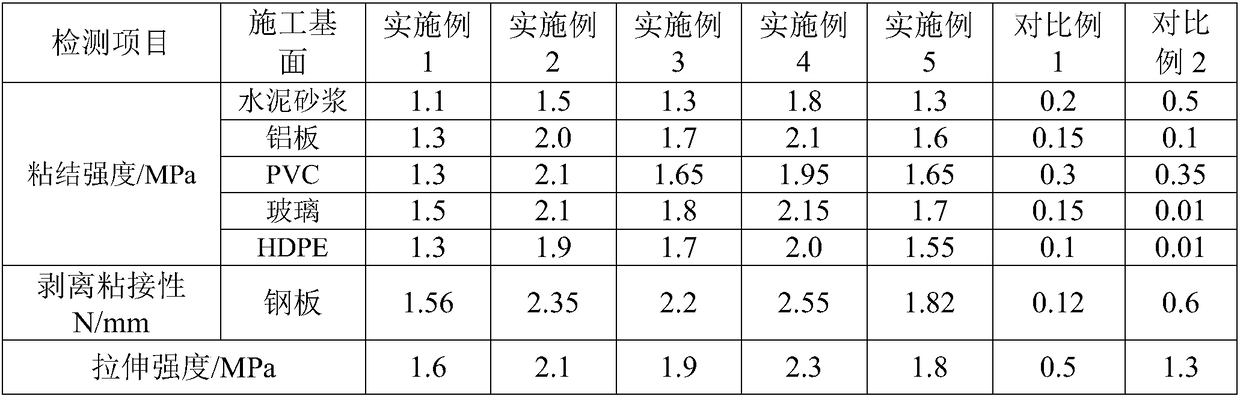

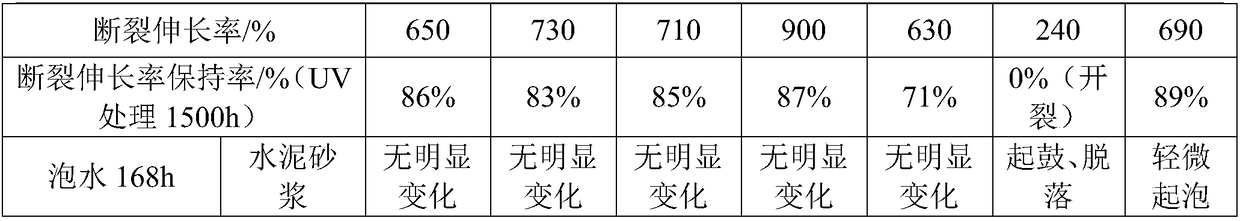

Examples

Embodiment 1

[0035] A high-elastic weather-resistant roof waterproof sealing material, the components of which are as follows:

[0036] Pure acrylic emulsion (Rohm and Haas EC-4811) 45%;

[0037] Neoprene latex (Xinterma Lipren-B) 5%;

[0038] Tackifier emulsion (Eastman's Tacolyn 4187) 1%;

[0039] Titanium dioxide (Dragon Python R-996) 10%;

[0040] Heavy calcium 30%;

[0041] Anti-ultraviolet additive (BASF Tinuvin326) 0.1%;

[0042] Dispersant (sodium hexametaphosphate) 0.5%;

[0043] Coupling agent (γ-(2,3-epoxypropoxy)propyltrimethoxysilane) 0.5%;

[0044] Thickener 0.1%;

[0045] Defoamer 1%;

[0046] Leveling agent 0.6%;

[0047] pH regulator (AMP95) 0.1%;

[0048] Clear water 6.1%.

[0049]The high-elastic weather-resistant and waterproof sealing material is prepared as follows:

[0050] (1) Put the measured pure acrylic emulsion into the dispersing kettle, control the rotation speed at 300-400rpm and stir for 5 minutes;

[0051] (2) After pre-mixing the measured dispe...

Embodiment 2

[0057] A high-elastic weather-resistant roof waterproof sealing material, the components of which are as follows:

[0058] Modified acrylic emulsion (Wanhua Lacper4055) 12%;

[0059] Modified acrylic emulsion (Rohm and Haas EC-1791) 18%;

[0060] Neoprene latex (Shanna SNL-551A) 20%;

[0061] Tackifier emulsion (Eastman's Tacolyn5085) 10%;

[0062] Titanium dioxide (DuPont R-706) 8%;

[0063] Calcined talc 17.4%;

[0064] Hollow glass microspheres 10%;

[0065] Anti-ultraviolet additive (BASF Tinuvin329) 0.2%;

[0066] Anti-ultraviolet additive (BASF Tinuvin770) 0.3%;

[0067] Dispersant (sodium tripolyphosphate) 0.3%;

[0068] Coupling agent (3-(2,3-epoxypropoxy)propyltriethoxysilane) 0.1%;

[0069] Thickener 0.1%;

[0070] Defoamer 1%;

[0071] Leveling agent 0.6%;

[0072] pH regulator (sodium carbonate) 1%;

[0073] Water 1%.

[0074] The preparation method of the high-elastic weather-resistant roof waterproof sealing material is basically the same as that of ...

Embodiment 3

[0076] A high-elastic weather-resistant roof waterproof sealing material, the composition of which is as follows:

[0077] Modified acrylic emulsion (Badfu RS2608) 8%;

[0078] Modified acrylic emulsion (Rohm and Haas EC-4811) 27%;

[0079] Neoprene latex (Shanna SNL-5042) 16%;

[0080] Tackifier emulsion (Eastman's Tacolyn5095) 5%;

[0081] Titanium dioxide (DuPont R-902+) 8%;

[0082] Talc 17%;

[0083] Hollow glass microspheres 8%;

[0084] Anti-ultraviolet additive (BASF Tinuvin770) 0.3%;

[0085] Dispersant (sodium tripolyphosphate) 0.3%;

[0086] Coupling agent (γ-(2,3-epoxypropoxy)propyltrimethoxysilane) 0.3%;

[0087] Thickener 0.5%;

[0088] Defoamer 0.6%;

[0089] Leveling agent 0.2%;

[0090] pH regulator (5% ammonia solution) 0.5%;

[0091] Clear water 8.3%.

[0092] The preparation method of the high-elastic weather-resistant roof waterproof sealing material is basically the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com