Waterborne paint and preparation method thereof

A water-based coating and modification technology, applied in the field of coatings, can solve the problems of low physical indicators such as hardness and wear resistance, poor alcohol and alkali resistance, general comprehensive performance, etc., and achieve good solvency, adhesion and wear resistance Good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

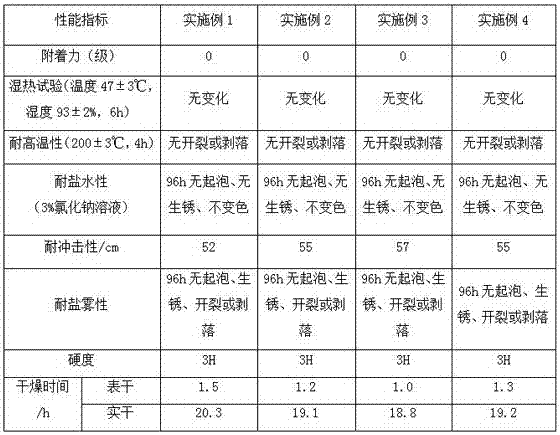

Examples

Embodiment 1

[0027] The raw materials and preparation method of water-based paint are as follows:

[0028] 35 parts of silicone modified acrylic resin, 10 parts of methyl etherified melamine formaldehyde resin, 4 parts of methanol, 4 parts of dipropylene glycol butyl ether, 1 part of pigment and filler, 0.1 part of wetting agent (perfluoroalkyl sulfonate), high-efficiency 0.1 part of defoamer, 0.1 part of leveling agent (alkyl modified organosiloxane and polyether polyester modified organosiloxane), 0.1 part of drier, 0.1 part of antioxidant, 40 parts of deionized water .

[0029] Preparation:

[0030] (1) Put silicone-modified acrylic resin, methyl etherified melamine formaldehyde resin, methanol and dipropylene glycol butyl ether into the dispersion container according to the formula, stir while feeding, control the speed at 800 rpm, and stir for 10-20 minutes , to obtain a uniform mixed solution system;

[0031] (2) Then add pigments and fillers, wetting agent, high-efficiency defoam...

Embodiment 2

[0033] The raw materials and preparation method of water-based paint are as follows:

[0034] 40 parts of silicone modified acrylic resin, 12 parts of methyl etherified melamine formaldehyde resin, 5 parts of methanol, 5 parts of dipropylene glycol butyl ether, 2 parts of pigment and filler, 0.5 part of wetting agent (alkyl aryl polyether), high-efficiency disinfectant 0.5 parts of foaming agent, 0.5 parts of leveling agent (polydimethylsiloxane), 0.2 parts of drier, 0.2 parts of antioxidant, 50 parts of deionized water.

[0035] The above water-based paint preparation method is the same as in Example 1.

Embodiment 3

[0037] The raw materials and preparation method of water-based paint are as follows:

[0038] 45 parts of silicone modified acrylic resin, 14 parts of methyl etherified melamine formaldehyde resin, 6 parts of methanol, 6 parts of dipropylene glycol butyl ether, 2.5 parts of pigment and filler, 0.8 part of wetting agent (sodium octyl succinate sulfonate), high-efficiency disinfectant 0.8 parts of foaming agent, 0.8 parts of leveling agent (alkyl modified organosiloxane), 0.3 parts of drier, 0.3 parts of antioxidant, 55 parts of deionized water.

[0039] The above water-based paint preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com