A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments

A low-temperature, high-humidity, real stone paint technology, applied in the field of exterior wall coatings, can solve the problems of poor water resistance, cracking of the paint film, easy whitening of the paint film, etc. The effect of improving adhesion and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

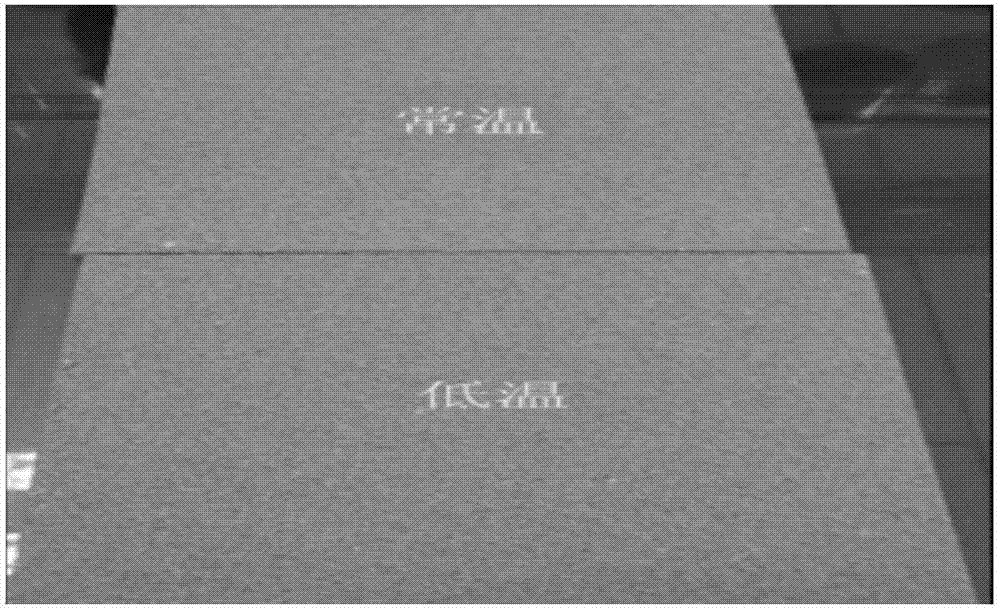

[0023] A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments. It mainly consists of 75kg colored sand, 13kg silicon-modified styrene-acrylic emulsion 8666, 0.7kg film-forming aid, 2.5kg silica sol, 0.11kg thickener and 8.69kg Composition of conventional additives (including diluents). Among them, the colored sand is composed of 40kg of 40-80 mesh coarse sand and 35kg of 80-120 mesh fine sand; the particle size of silicon-modified styrene-acrylic emulsion 8666 is 0.1-0.6μm, and the appearance is milky white with a slight blue phase; Membrane aid is compounded by 0.3kg of Texanol ester alcohol, 0.2kg of ethylene glycol monobutyl ether and 0.2kg of benzyl alcohol; thickener is made of 0.05kg of polyurethane thickener and 0.06kg of alkali thickener (such as hydrophobically modified acrylic copolymer, carboxylic acid acrylic copolymer, etc., the same below). During the construction of real stone paint, control the moistur...

Embodiment 2

[0025] A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments. It mainly consists of 80kg colored sand, 12kg silicon-modified styrene-acrylic emulsion 8666, 0.6kg film-forming aid, 2kg silica sol, 0.1kg thickener and 5.3kg Common additives (including diluents) composition. Among them, the colored sand is composed of 42.7kg of 40-80 mesh coarse sand and 37.3kg of 80-120 mesh fine sand; the particle size of silicon-modified styrene-acrylic emulsion 8666 is 0.1-0.6μm, and the appearance is milky white with a slight blue phase; The film aid is compounded by 0.257kg of Texanol ester alcohol, 0.1714kg of ethylene glycol monobutyl ether and 0.1714kg of benzyl alcohol; the thickener is compounded by 0.045kg of polyurethane thickener and 0.055kg. During the construction of real stone paint, control the moisture content of the base layer to less than 10%, and the pH value to less than 10, and use the hanging basket spraying meth...

Embodiment 3

[0027] A real stone paint for exterior walls suitable for construction in low-temperature and high-humidity environments. It mainly consists of 70kg colored sand, 15kg silicon-modified styrene-acrylic emulsion 8666, 0.8kg film-forming aids, 3kg silica sol, 0.15kg thickener and 11.05kg Common additives (including diluents) composition. Among them, the colored sand is composed of 37.33kg of 40-80 mesh coarse sand and 32.67kg of 80-120 mesh fine sand; the particle size of silicon-modified styrene-acrylic emulsion 8666 is 0.1-0.6μm, and the appearance is milky white with a slight blue phase; The film aid is compounded by 0.343kg of Texanol ester alcohol, 0.228kg of ethylene glycol monobutyl ether and 0.228kg of benzyl alcohol; the thickener is compounded by 0.0682kg of polyurethane thickener and 0.0818kg. During the construction of real stone paint, control the moisture content of the base layer to less than 10%, and the pH value to less than 10, and use the hanging basket sprayin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com