Water-in-sand coating and preparation method thereof

A technology of sand-in-water coating and quartz sand, which can be used in reflection/signal coatings, coatings, etc., to solve the problems of smaller color point, lower construction efficiency, and high viscosity of continuous phase of sand-in-water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0064] With reference to the raw materials and dosages shown in Table 1, the continuous phases of Examples 1-3 were prepared by the following preparation methods.

[0065] The preparation method of continuous phase is as follows:

[0066] Mix deionized water, defoamer FoamStar ST 2410AC, and S482, and disperse at medium and high speed for 20 minutes until there are no particles. Reduce the rotation speed, add 631 fungicide, ammonia water, ethylene glycol, alcohol ester-12, and 8087 emulsion in sequence, and stir at medium and low speeds for 5-8 minutes until uniform. Finally, slowly put in TT935, and stir at medium and high speed for 8-10 minutes to obtain the sand-in-water continuous phase.

[0067] Table 1

[0068]

[0069]

Embodiment 4-6

[0083] With reference to the raw materials and dosages shown in Table 4, the following preparation methods were used to prepare the dispersed phases of Examples 4-6.

[0084] The preparation method of dispersed phase is as follows:

[0085] Pre-prepared S482 aqueous solution with a mass fraction of 10%, that is, put the S482 powder into deionized water, disperse at high speed until there are no particles, and set aside.

[0086] Put defoamer FoamStar ST 2410AC, dispersant 731A, 631 fungicide, hydroxyethyl cellulose 250HBR and titanium dioxide SR-237 into deionized water, and disperse at high speed until there are no cellulose particles. Then add ammonia water, ethylene glycol, alcohol ester-12, and 1048-3 emulsion at a medium speed, and stir for 5min-8min until the mixture is uniform. Add TT615 thickener slowly, disperse at high speed for 5min-10min, then add the above 10% S482 protective glue solution, and disperse at high speed for 10min. Throw in hollow microspheres 461DE...

Embodiment 7

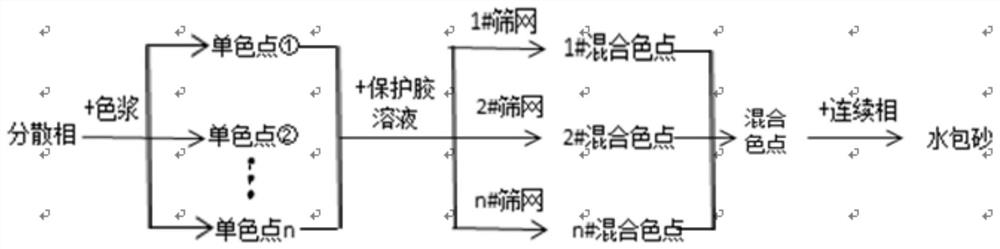

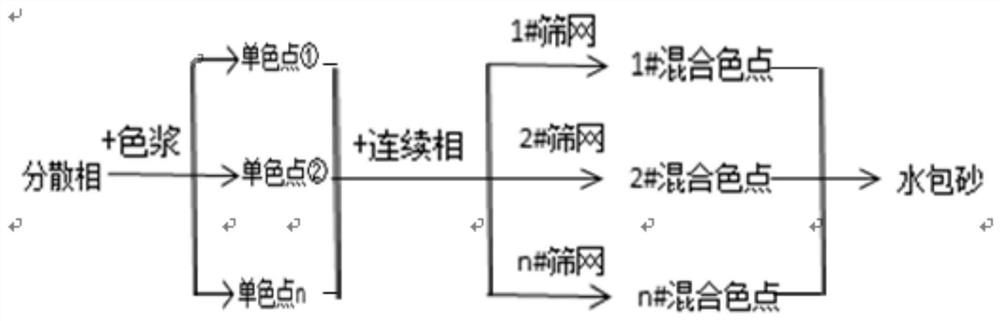

[0099] This embodiment provides a method for preparing sand-in-water coatings in a two-phase system, such as figure 2 As shown, the steps are as follows:

[0100] Toning: Add color paste to the dispersed phases of Examples 4-5 and Comparative Examples 5-8 respectively, adjust 2-5 color points each, and obtain 2-5 single-color points correspondingly in each embodiment and comparative example ,spare.

[0101] Granulation: Select the continuous phase of Example 1, respectively mix 2-5 monochromatic dots of each Example and Comparative Example with the continuous phase of Example 1 according to the weight ratio of 1:0.7, after pre-shearing through the screen Use colorful special granulation equipment (utility model patent number: 201520857183.9) for granulation;

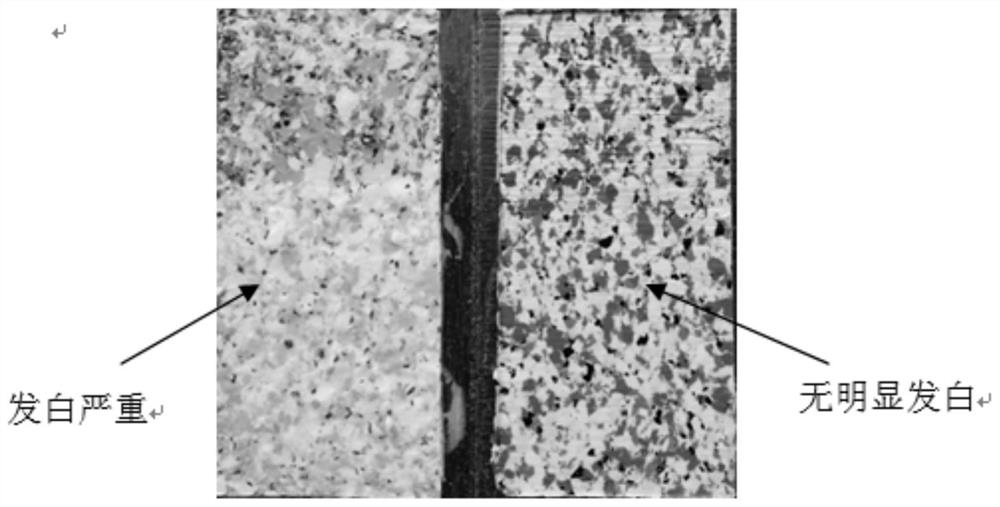

[0102] Mixing stage: Put the 2-5 color points corresponding to each embodiment and comparative example after granulation into colorful batch mixing equipment (utility model patent number: 201520850295.1) and mix evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com