A kind of high-performance colorful paint and preparation method thereof

A multi-color paint, high-performance technology, applied in the direction of multi-color effect paint, coating, etc., can solve the problems of reducing the cross-linking reaction speed, color bleeding, delamination, etc. Bleeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of above-mentioned high-performance colorful paint, comprises the steps:

[0049] (1) Prepare the protective colloid solution of C component

[0050] The following raw materials are used according to mass percentage: each raw material is 70-99% of deionized water and 1-30% of protective colloid;

[0051] Add the protective colloid into deionized water at a speed of 100-200rmp, increase the speed to 1500rmp, until the protective colloid is completely dissolved, and set aside;

[0052] (2) Preparation of colored particles of component A

[0053] The following raw materials are used according to mass percentage: each raw material is 30-40% of deionized water, 5-30% of protective colloid, 0.1-5% of thickener A, 0.1-2% of wetting agent, and 0.3-1.5% of dispersant , pigment 0-10%, filler 2-10%, defoamer 0.1-1%, pH regulator 0.1-1%, elastic pure acrylic emulsion 20-40%, surface organically modified cellulose ether 0.1-5% ;

[0054] Add water, wetting...

Embodiment 1

[0063] The present embodiment provides a kind of high-performance colorful paint, the preparation method of this high-performance colorful paint is as follows:

[0064] Each component is made up of following raw material by mass percentage in the present embodiment:

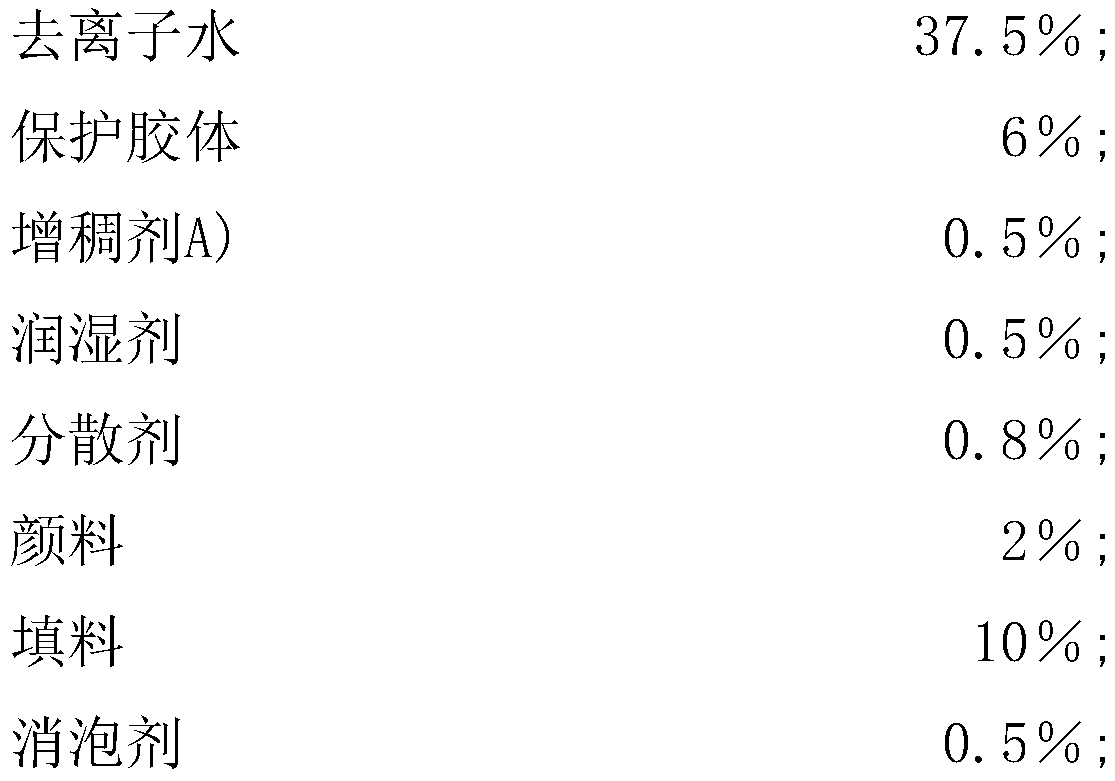

[0065] A component mass percentage

[0066]

[0067]

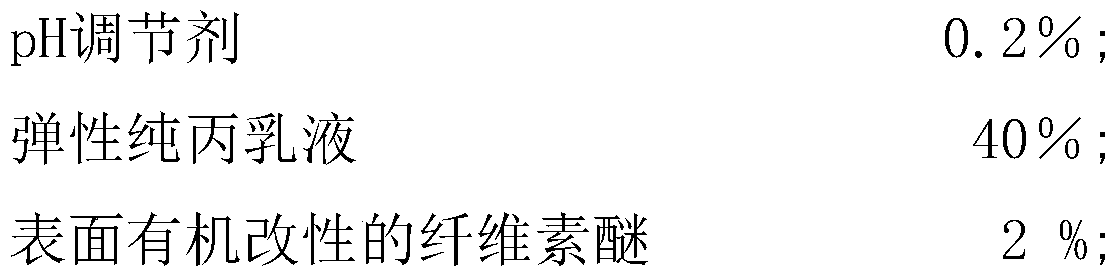

[0068] B component mass percentage

[0069]

[0070] C component mass percentage

[0071] Deionized water 90%;

[0072] Protective glue 10%;

[0073] The preparation steps are as follows:

[0074] (1) Preparation of colored particles of component C

[0075] Use the following raw materials by mass percentage: 10g of protective glue, 90g of deionized water;

[0076] Add 50g of protective gel and 450g of deionized water into the dispersion tank, and stir for 30 minutes at a speed of 1200-1500rmp to obtain a clear liquid for later use;

[0077] (1) Preparation of colored particles of component A

[0078] The following raw materials are used in ma...

Embodiment 2

[0086] The present embodiment provides a kind of high-performance colorful paint, the preparation method of this high-performance colorful paint is as follows:

[0087] Each component is made up of following raw material by mass percentage in the present embodiment:

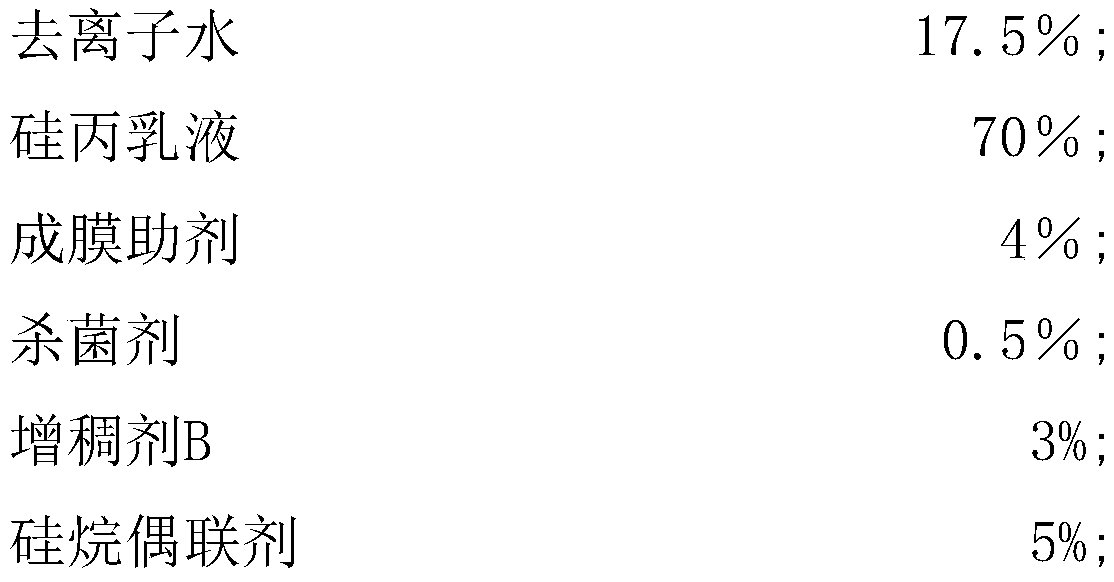

[0088] A component mass percentage

[0089]

[0090] B component mass percentage

[0091]

[0092] C component mass percentage

[0093] Deionized water 85%;

[0094] Protective glue 15%;

[0095] The preparation steps are as follows:

[0096] (1) Preparation of colored particles of component C

[0097] Use the following raw materials by mass percentage: 15g of protective glue, 85g of deionized water;

[0098] Add 75g of protective gel and 425g of deionized water into the dispersion tank, and stir for 30 minutes at a speed of 1200-1500rmp to obtain a clear liquid for later use;

[0099] (1) Preparation of colored particles of component A

[0100] The following raw materials are used in mass percentag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com