Aqueous microencapsulated fireproof paint for ultrathin steel structure

A technology of microencapsulation and fireproof coatings, applied in the field of coatings, can solve the problems of unsuitability for industrial production, low microencapsulation yield, poor compatibility of aluminum phosphate, etc., and achieves improved compatibility, high practicability, and adhesion. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

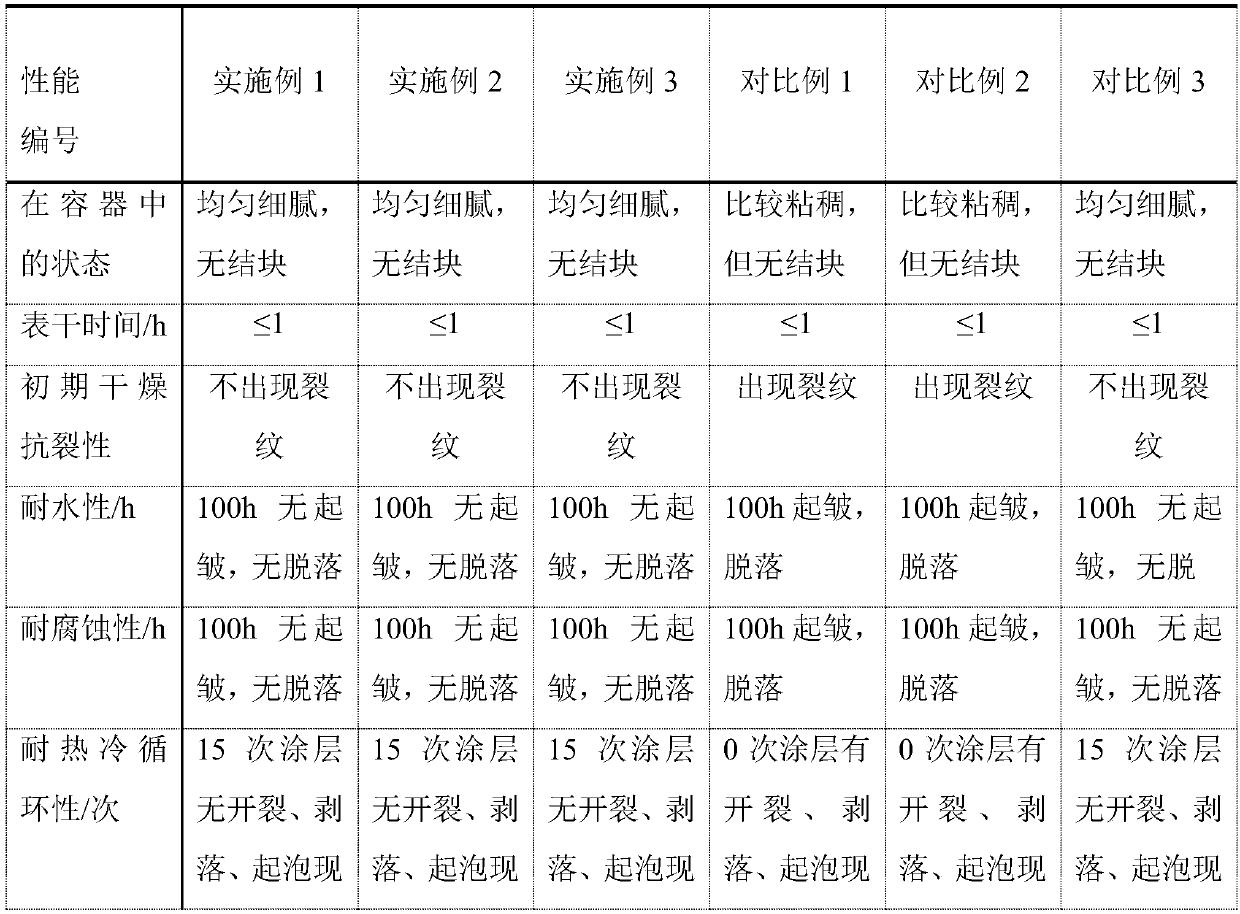

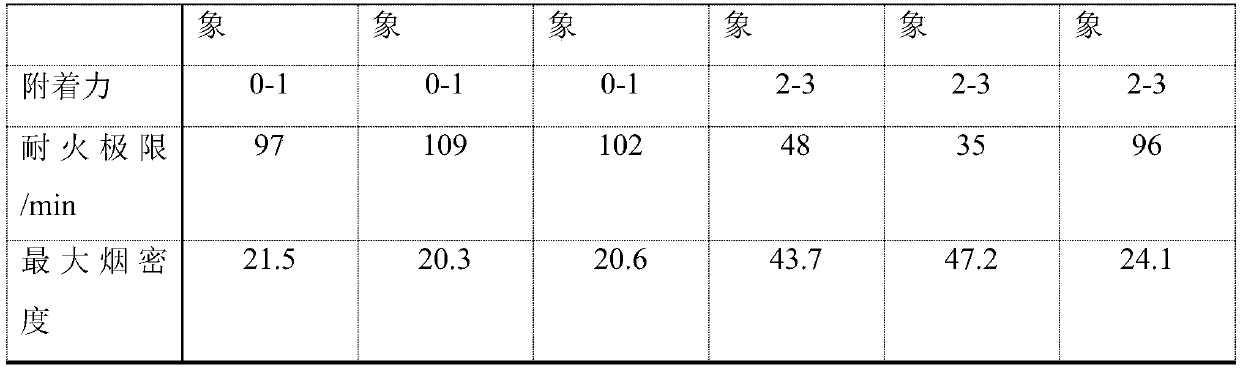

Embodiment 1

[0062] A water-based microencapsulated ultra-thin steel structure fireproof coating, the components and their mass percentages are: aluminum hypophosphite microcapsules 4%, ammonium polyphosphate microcapsules 35%, pentaerythritol 15%, melamine 12%, water-based benzene Acrylic core-shell emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%, its preparation method comprises the following steps:

[0063] 1) take the raw material by weighing the mass percentage of each of the above-mentioned components;

[0064] 2) Grind aluminum hypophosphite microcapsules, ammonium polyphosphate microcapsules, pentaerythritol, and melamine into powder, then add water to fully grind and mix evenly; then add hydroxyethyl cellulose, defoamer and dispersant, and continue to fully grind;

[0065] 3) Finally, water-based styrene-acrylic core-shell emulsion and n-octanol are added and thoroughly ground and mixed to obtain the water-based microencapsulate...

Embodiment 2

[0067] A water-based microencapsulated ultra-thin steel structure fireproof coating, the components and their mass percentages are: aluminum hypophosphite microcapsules 6%, ammonium polyphosphate microcapsules 33%, pentaerythritol 15%, melamine 12%, water-based benzene Acrylic core-shell emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%, and its preparation steps are the same as in Example 1.

Embodiment 3

[0069] A water-based microencapsulated ultra-thin steel structure fireproof coating, the components and their mass percentages are: aluminum hypophosphite microcapsules 8%, ammonium polyphosphate microcapsules 31%, pentaerythritol 15%, melamine 12%, water-based benzene Acrylic core-shell emulsion 20%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%, and its preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com