Patents

Literature

103results about How to "Reduce the amount of mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

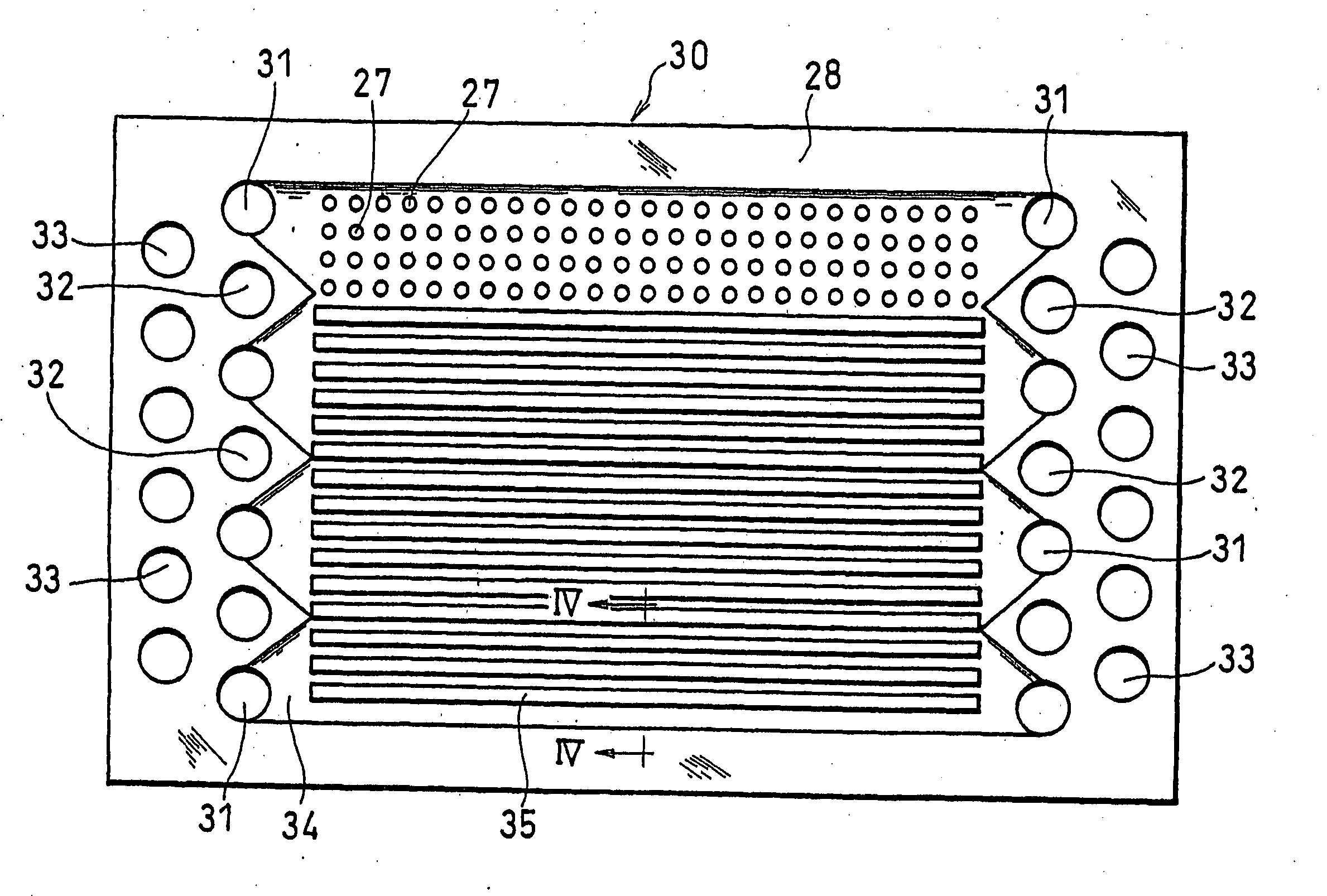

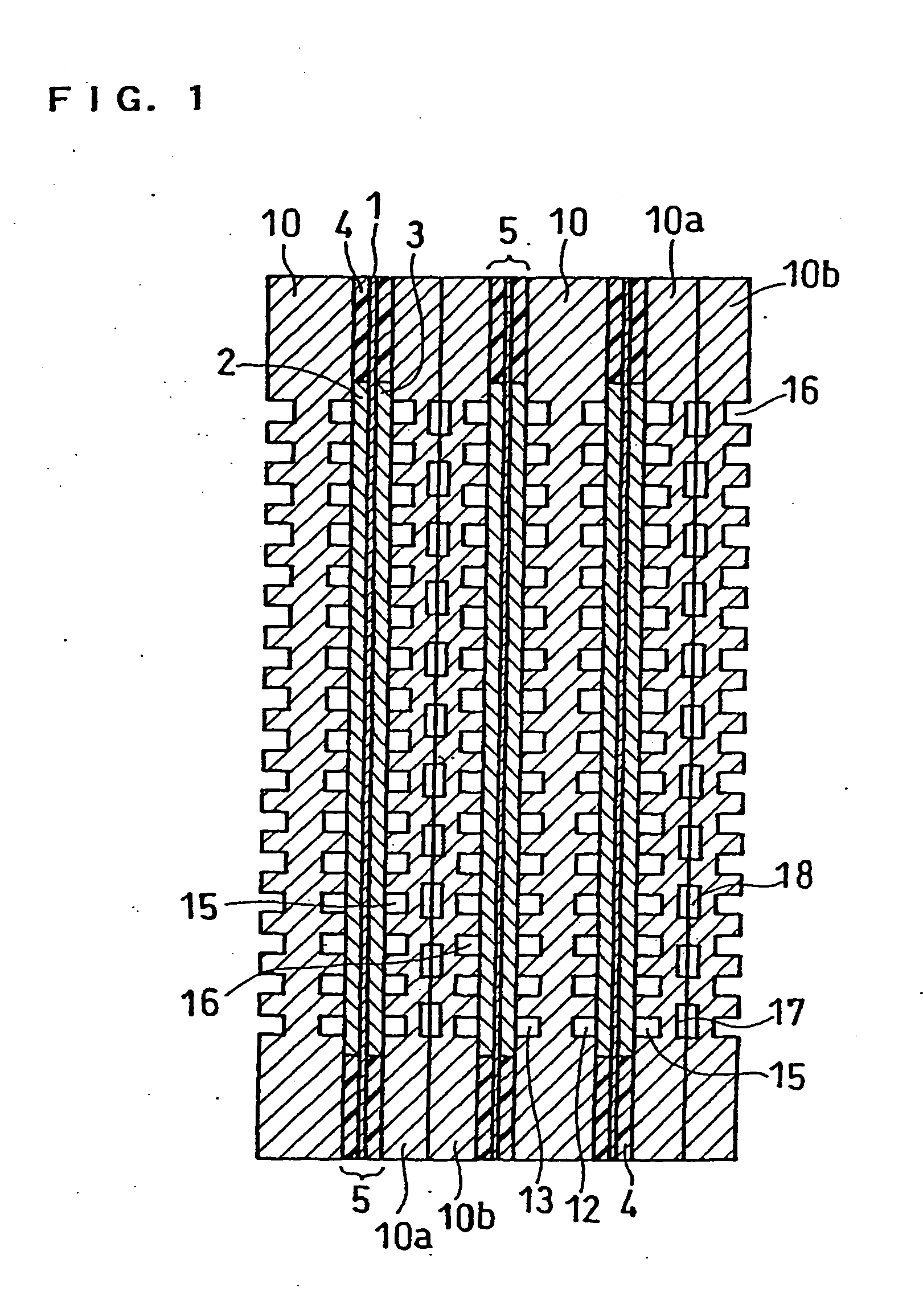

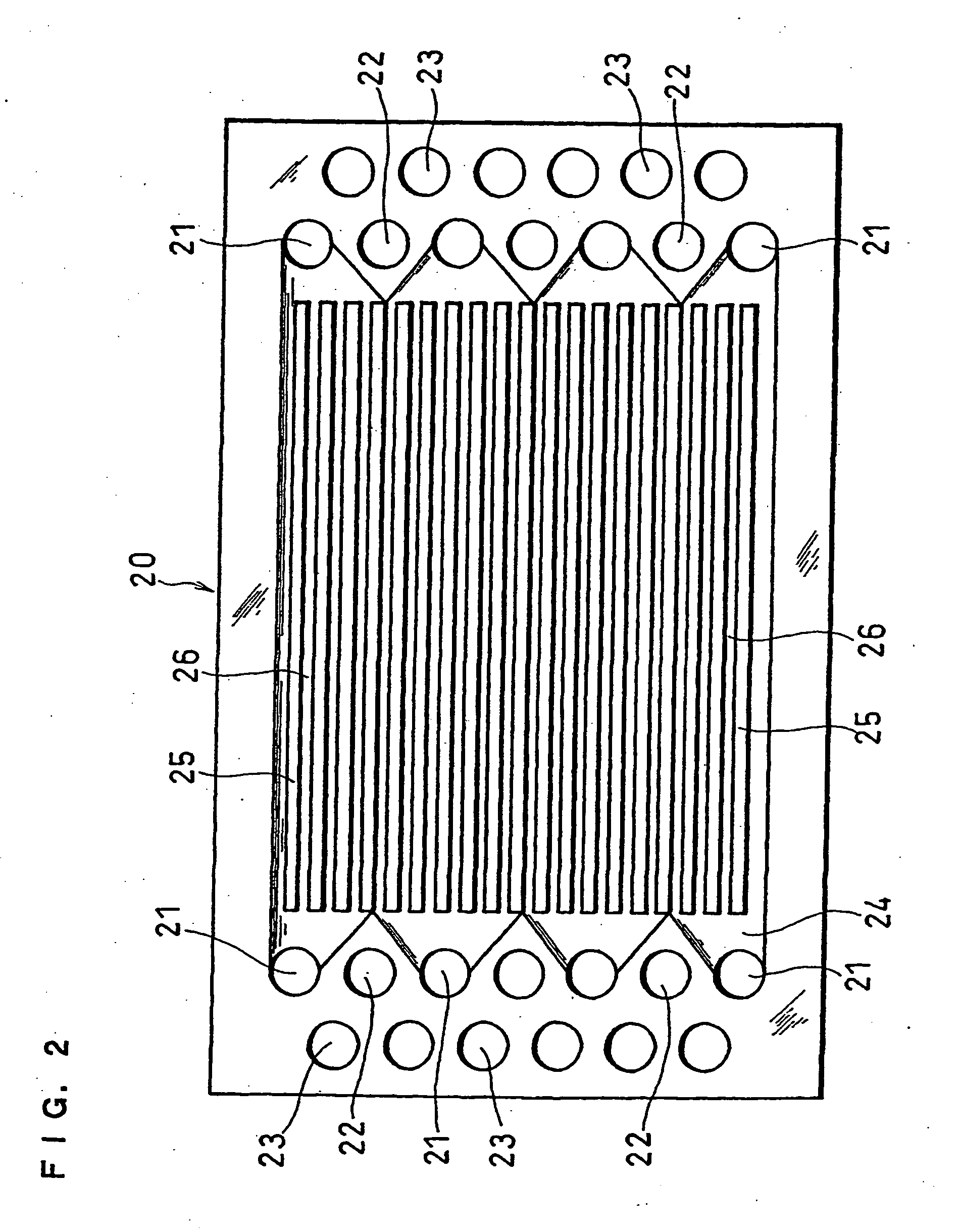

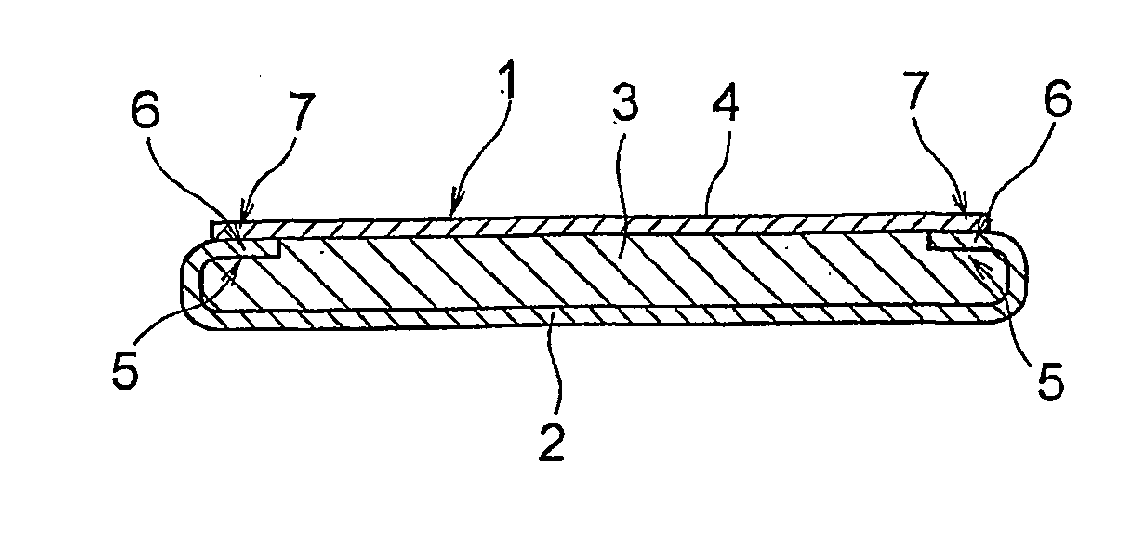

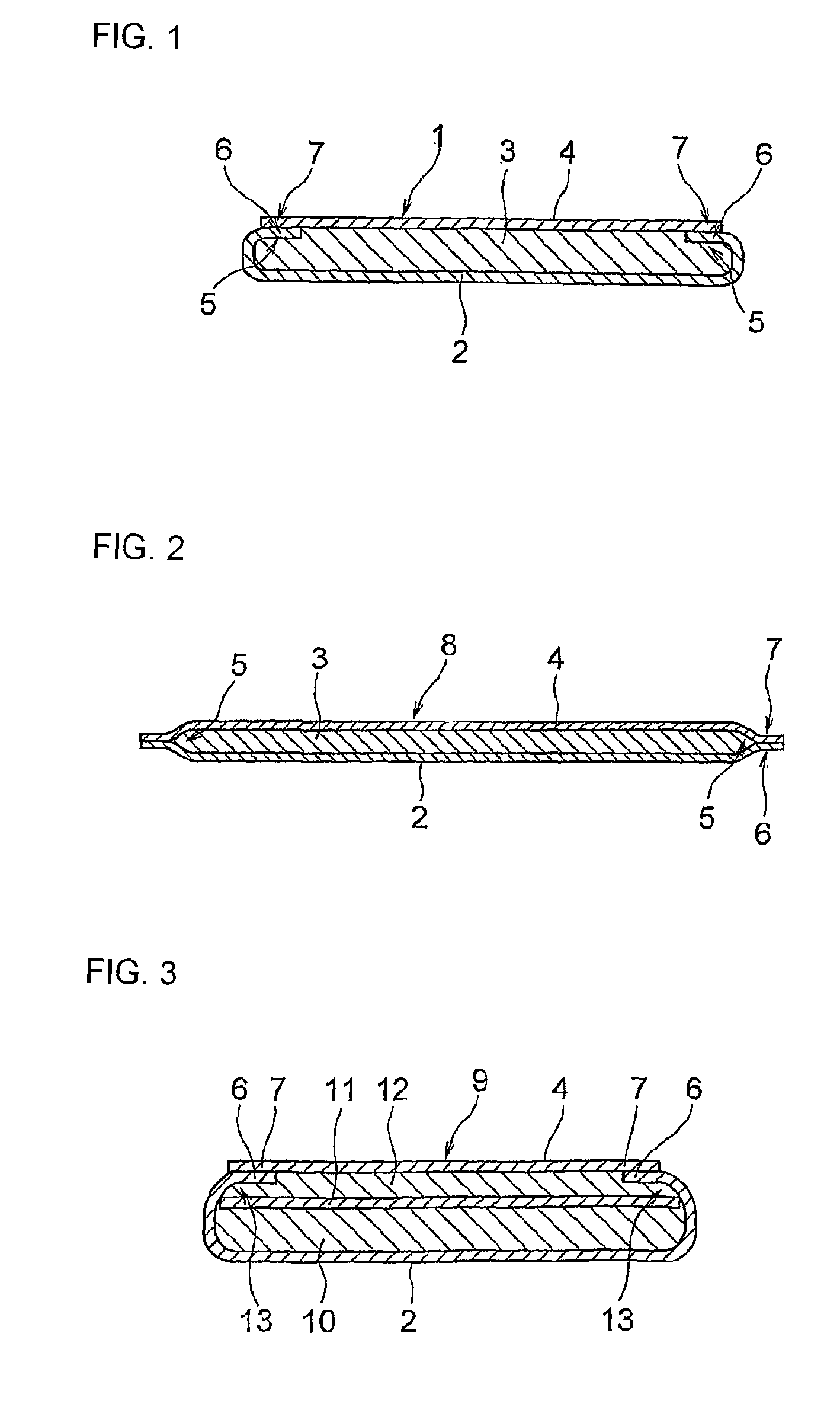

Polymer electrolyte fuel cell and method of manufacturing the same

InactiveUS20040197633A1Improves product water-removal efficiencyEvenly distributedFuel cell heat exchangeFinal product manufacturePolymer electrolytesFuel cells

The present invention relates to a polymer electrolyte fuel cell comprising: an electrolyte membrane-electrode assembly including an anode, a cathode and a polymer electrolyte membrane interposed therebetween; an anode-side conductive separator plate having a gas flow channel for supplying a fuel gas to the anode; and a cathode-side conductive separator plate having a gas flow channel for supplying an oxidant gas to the cathode. A conductive separator plate made of carbon has poor wettability with water. This has posed the disadvantage that variations in performance are induced by nonuniform gas distribution among cells due to the accumulation of product water or humidifying water in the gas flow channel on the surface of the separator plate. The present invention employs a conductive separator plate comprising a conductive carbon having a hydrophilic functional group, at least in a portion of the gas flow channels, thereby preventing water from accumulating in the gas flow channels.

Owner:PANASONIC CORP

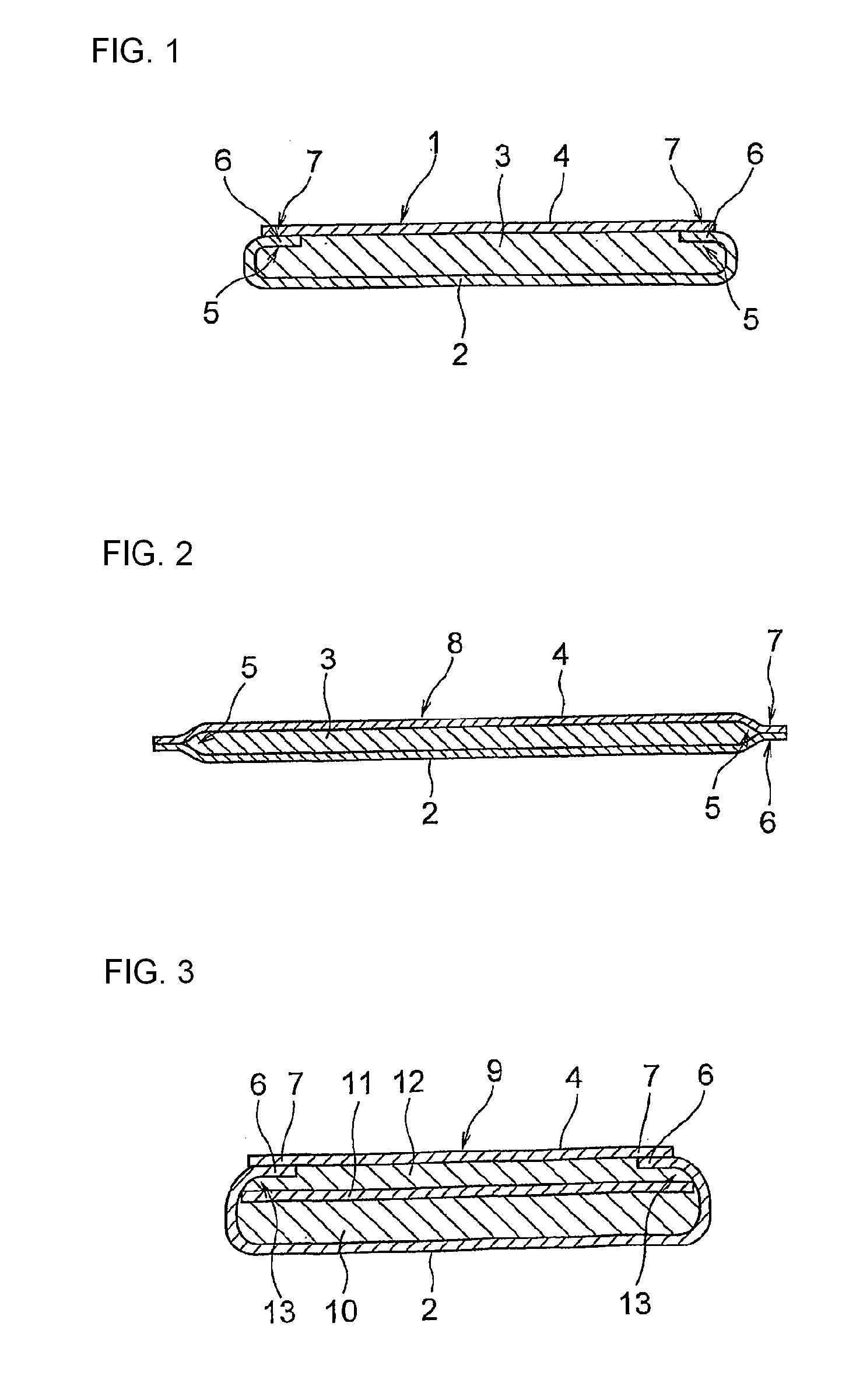

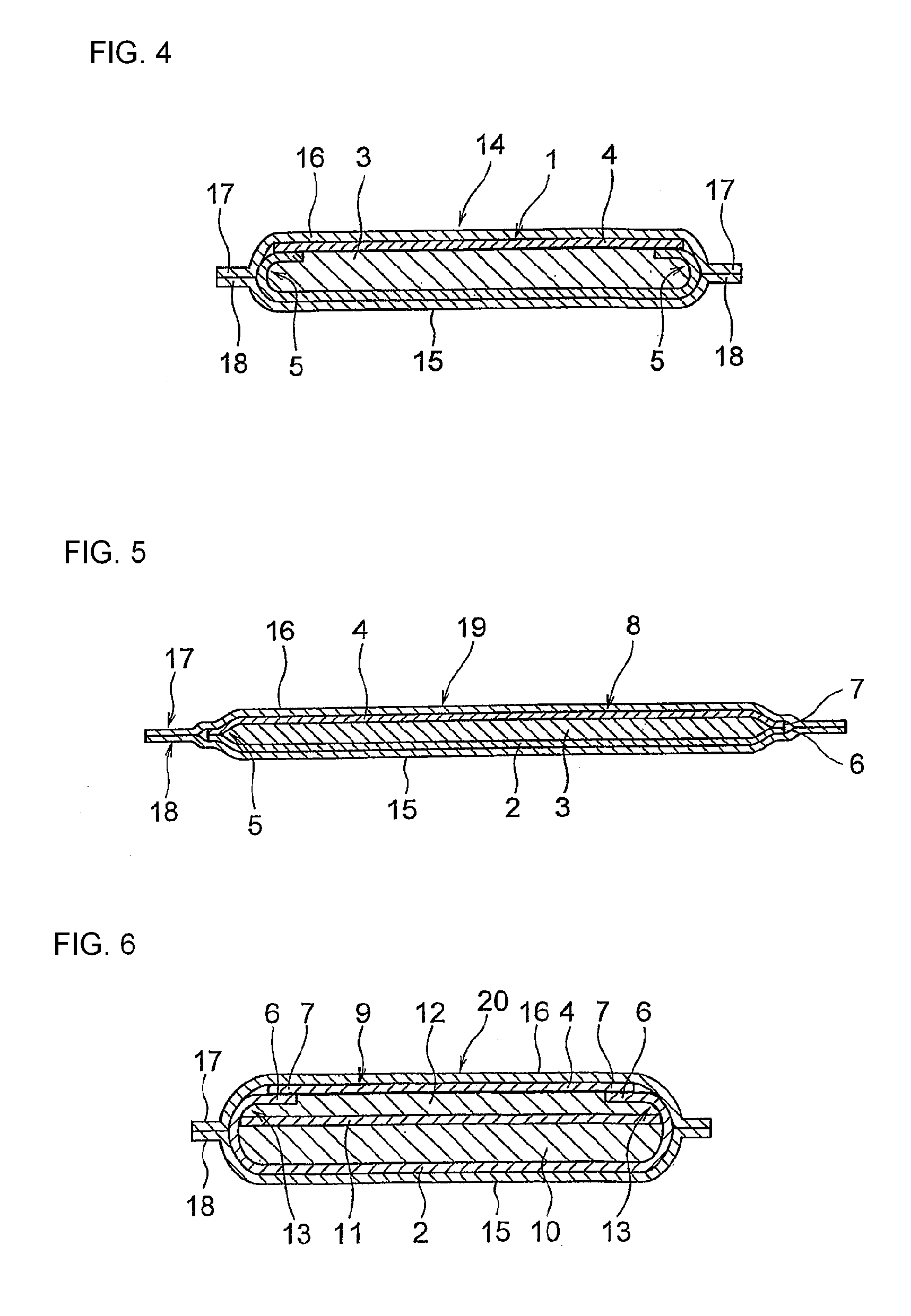

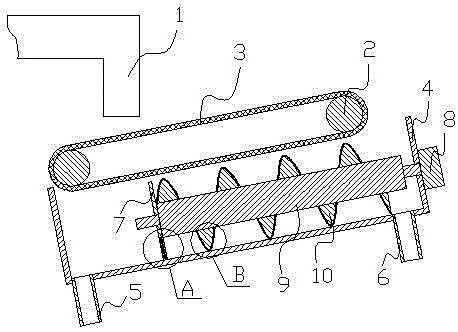

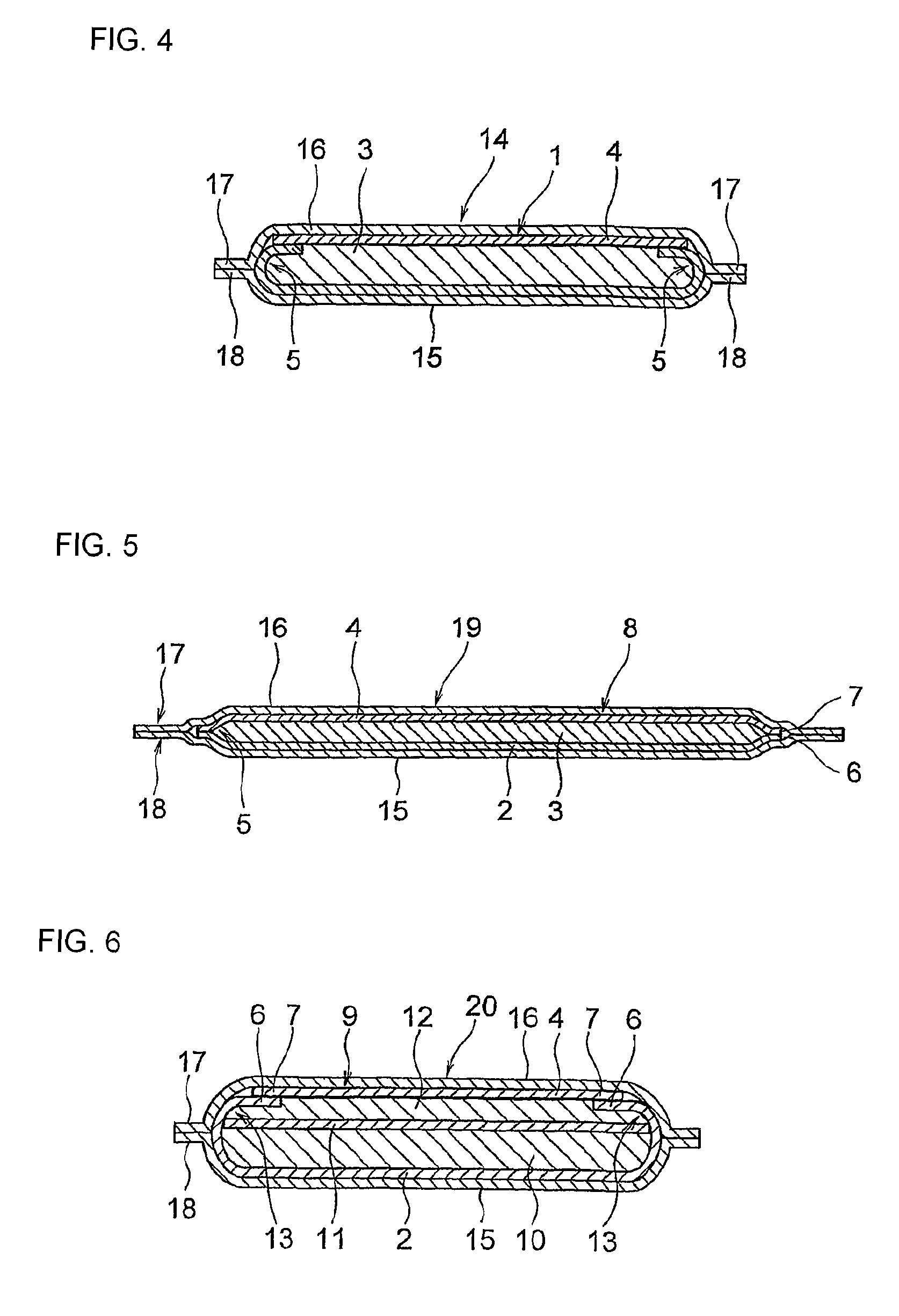

Absorber, sanitary articles using the absorber, and production method thereof

InactiveUS20100249737A1Reduce the amount of mixingSlight non-uniformityLaminationLamination apparatusFiberMaterials science

It is an object to provide an absorber wherein crushed tea leaves having a particle size of 0.05 to 4.6 mm are dispersed and held within a pulp fiber material having a fiber length of 0.1 to 7 mm, the absorber is superior in water-absorbing, drying, and odor-eliminating performances, exhibits a good visual quality, and can maintain sanitary conditions for a longer time, and sanitary articles using the absorber.An upper water-absorbing paper layer portion to form an upper surface, a lower water-absorbing paper layer portion to form a lower surface, and a water-absorbing mixture layer portion provided between the upper water-absorbing paper layer portion and the lower water-absorbing paper layer portion are overlapped in layers and integrated to form the absorber; the water-absorbing mixture layer portion is formed by including a crushed pulp fiber material beaten to have a fiber length of 0.1 to 7 mm, crushed tea leaves having a particle size of 0.05 to 4.6 mm, and a water-absorbing resin in an amount less than the crushed pulp fiber material; the absorber and sanitary articles using the absorber can provide sanitary articles with excellent sanitary affairs and superior odor-eliminating performance due to mixing the crushed tea leaves and also without degrading water-absorbing property.

Owner:DAIKI CO LTD

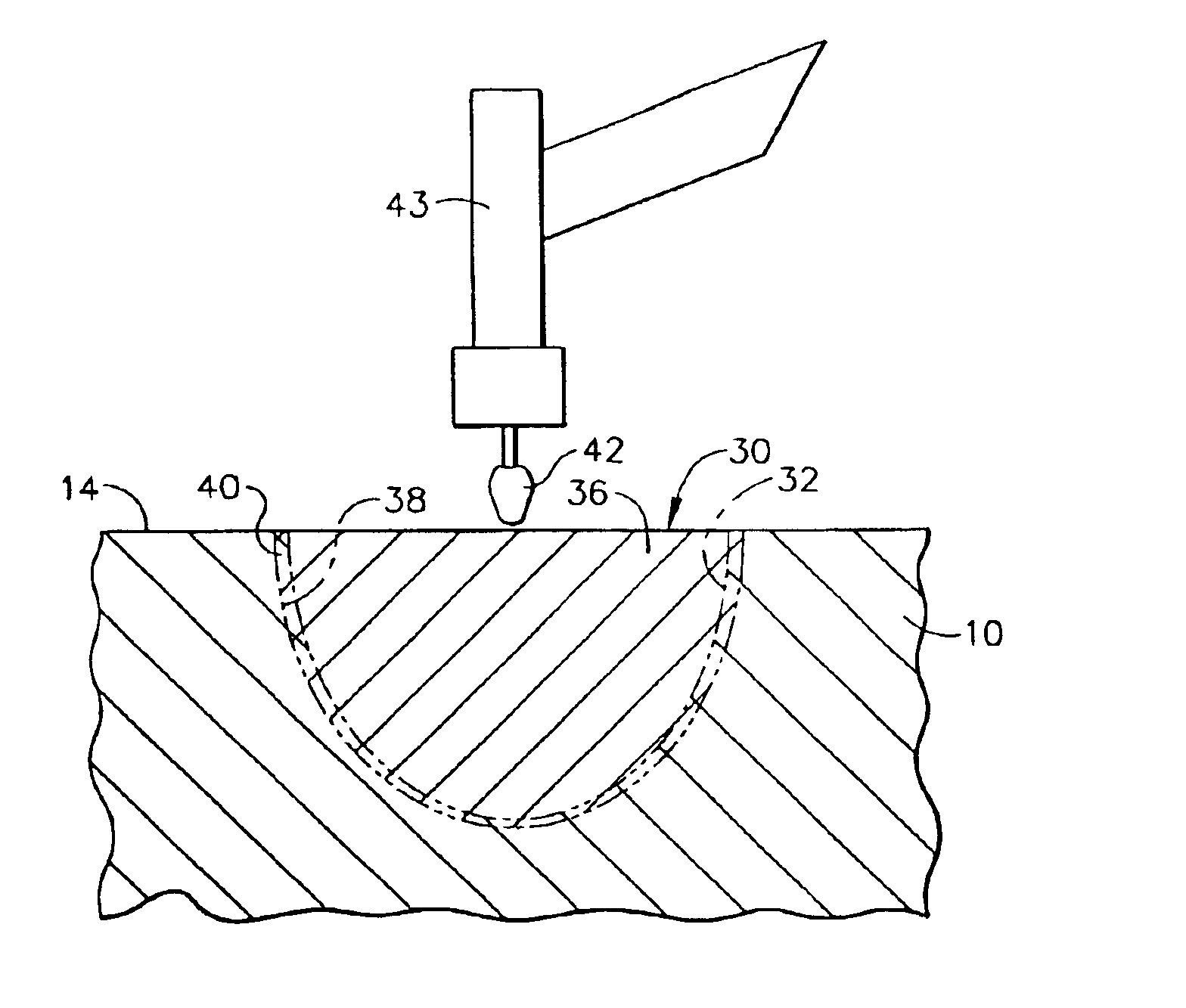

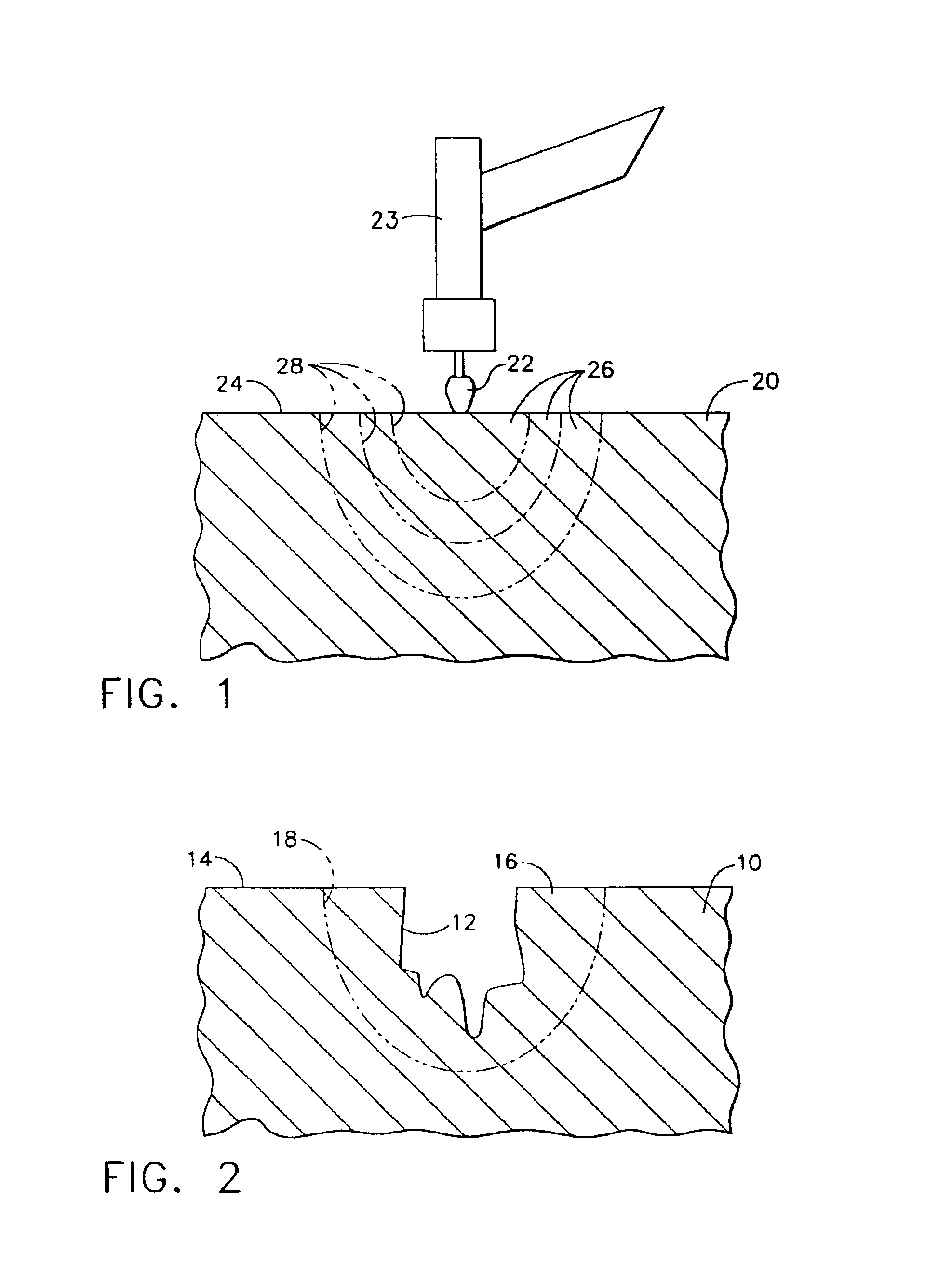

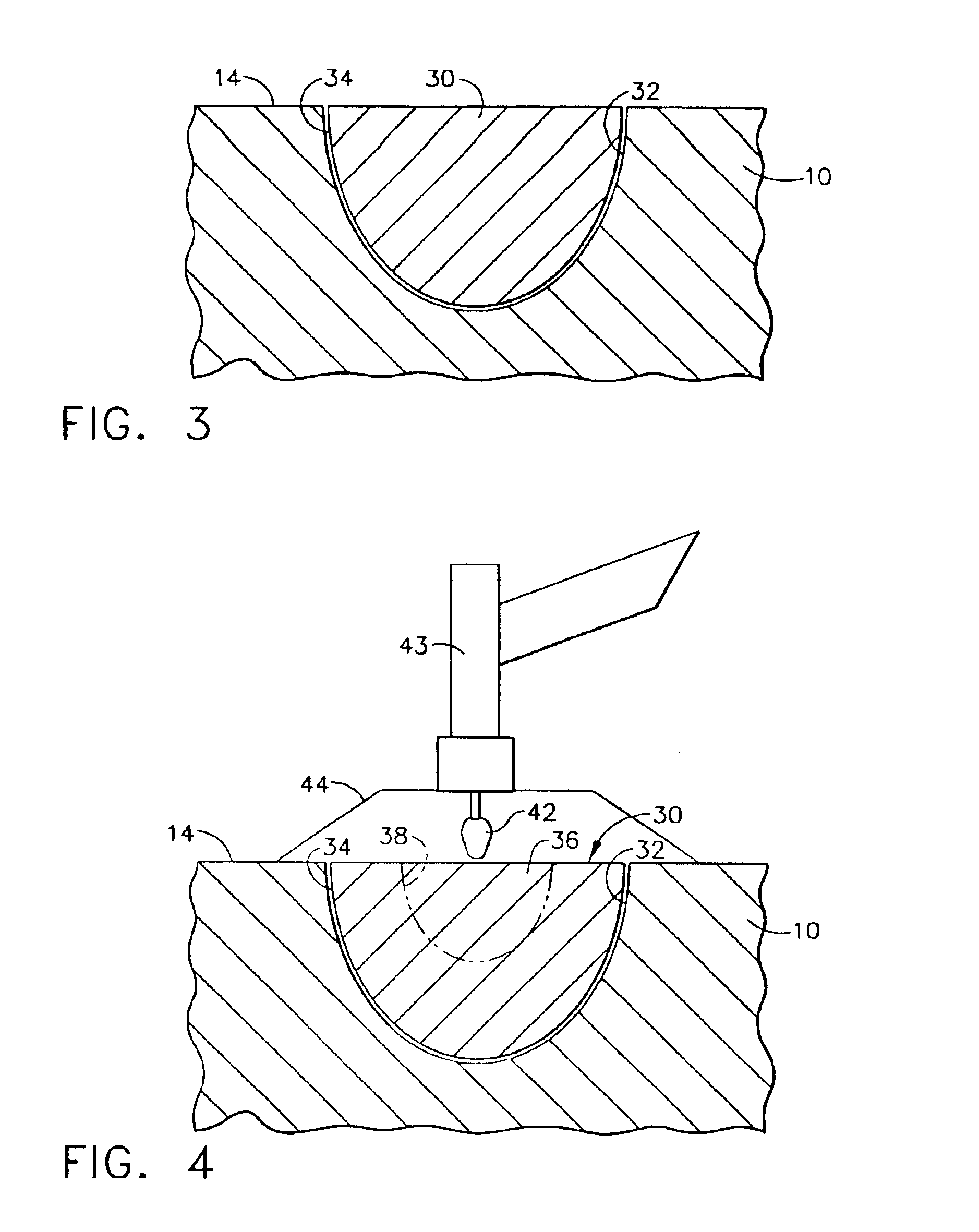

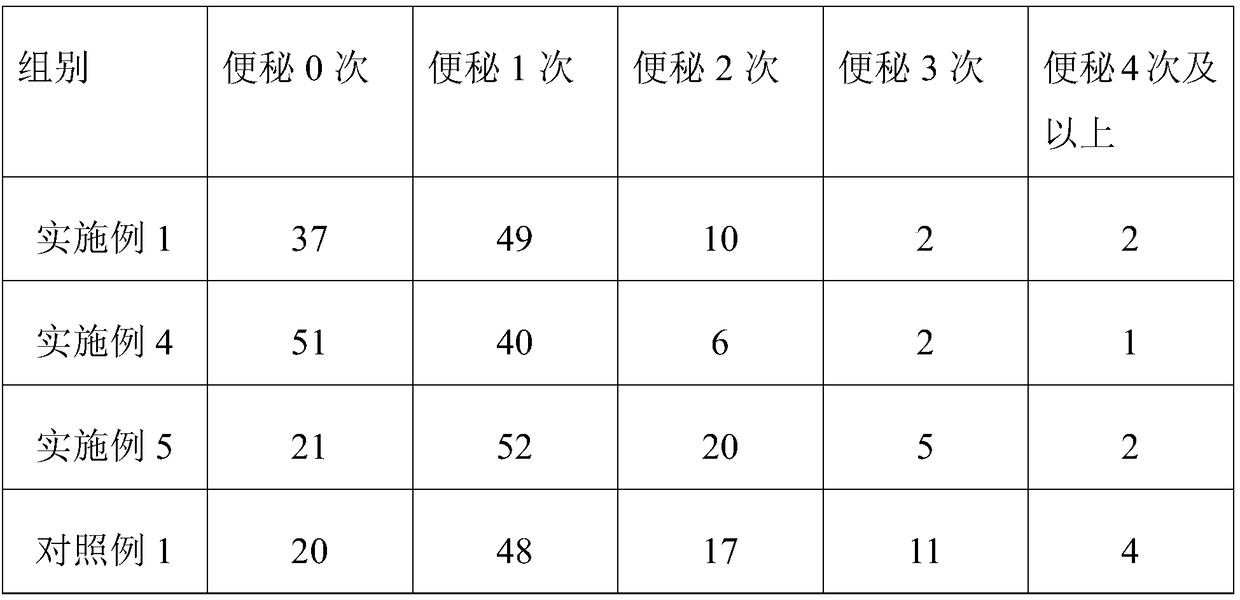

Method of weld repairing a component and component repaired thereby

InactiveUS6884964B2Reduced risk of crackingMinimize mixingArc welding apparatusElectron beam welding apparatusMetal alloy

The method of repairing a metal alloy component, and the resulting repaired component. The method involves machining the component surface to remove a defect, and then placing in the resulting surface cavity a filler insert whose size and shape are predetermined so that the welding operation can be carried out to completely melt the insert while minimizing the melting of the component immediately surrounding the insert. As such, minimum mixing occurs between the materials of the insert and the component, thereby reducing the risk of cracking following the welding operation.

Owner:GENERAL ELECTRIC CO

Double-component silane-terminated sealing adhesive and preparation method thereof

InactiveCN102304340AFlexible ratio rangeFlexible dosageOther chemical processesPolyureas/polyurethane adhesivesEndcappingPolymer science

The invention discloses a double-component silane-terminated seal adhesive which comprises a component A and a component B, wherein the component A is prepared from silane-terminated prepolymer, plasticizer, thixotropic agent, ultraviolet absorbent, ultraviolet stabilizer, moisture remover, accelerator, curing agent, colorant, bulking filler and reinforcing filler; the component B is prepared from silane-terminated prepolymer, plasticizer, cocatalyst, surfactant and water absorbent; and the component A and the component B are mixed in a weight ratio of 5:1-49:1. In the invention, the proportioning range of the double-component system is more flexible, and the consumption of the component B is flexible and low, so that the properties of the double-component system are closer to and even superior to those of the single component A in the curing process after reducing the A\B mixture.

Owner:TONSAN ADHESIVES INC

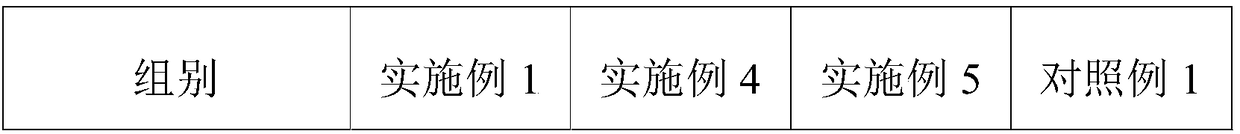

Probiotic solid beverage and preparation method thereof

InactiveCN108991327AReduce lossesPromote value-addedLactobacillusBifidobacteriumLactobacillus salivariusLactobacillus rhamnosus

The invention relates to probiotic solid beverage and a preparation method thereof. The probiotic solid beverage comprises the following raw materials in parts by weight: 24 to 70 parts of maltodextrin, 20 to 60 parts of inulin and 1 to 5 parts of probiotics, wherein the probiotics comprises lactobacillus salivarius, lactobacillus acidophilus, bacillus coagulans, lactobacillus rhamnosus, bifidobacterium bifidum, lactobacillus plantarum and bifidobacterium longum. The probiotic solid beverage provided by the invention has high living bacterium quantity and can reduce loss of the probiotics whenthe probiotics pass through the gastrointestinal tract and increase the survival rate; in addition, the probiotic solid beverage can promote intestinal colonization of the probiotics; moreover, through mutual promotion of the actions of various bacteria, the probiotic solid beverage can adjust intestines and stomach well, promote intestinal tract movement, relieve constipation and diarrhea, reduce serum cholesterol, reduce lactose intolerance, accumulate proteolytic enzyme, adjust nutrient absorption and adjust the immunologic function.

Owner:北京奥维森基因健康科技有限公司

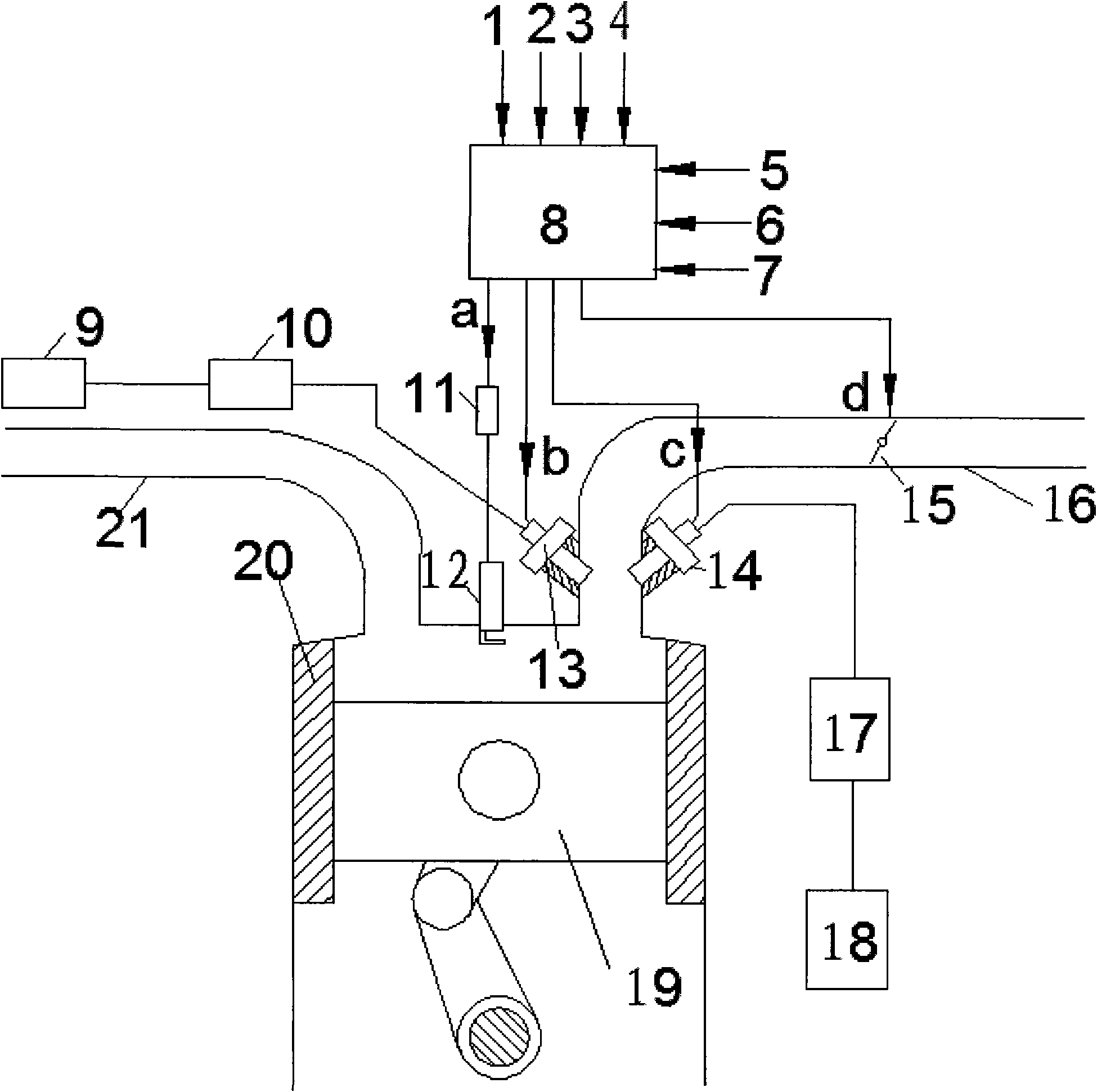

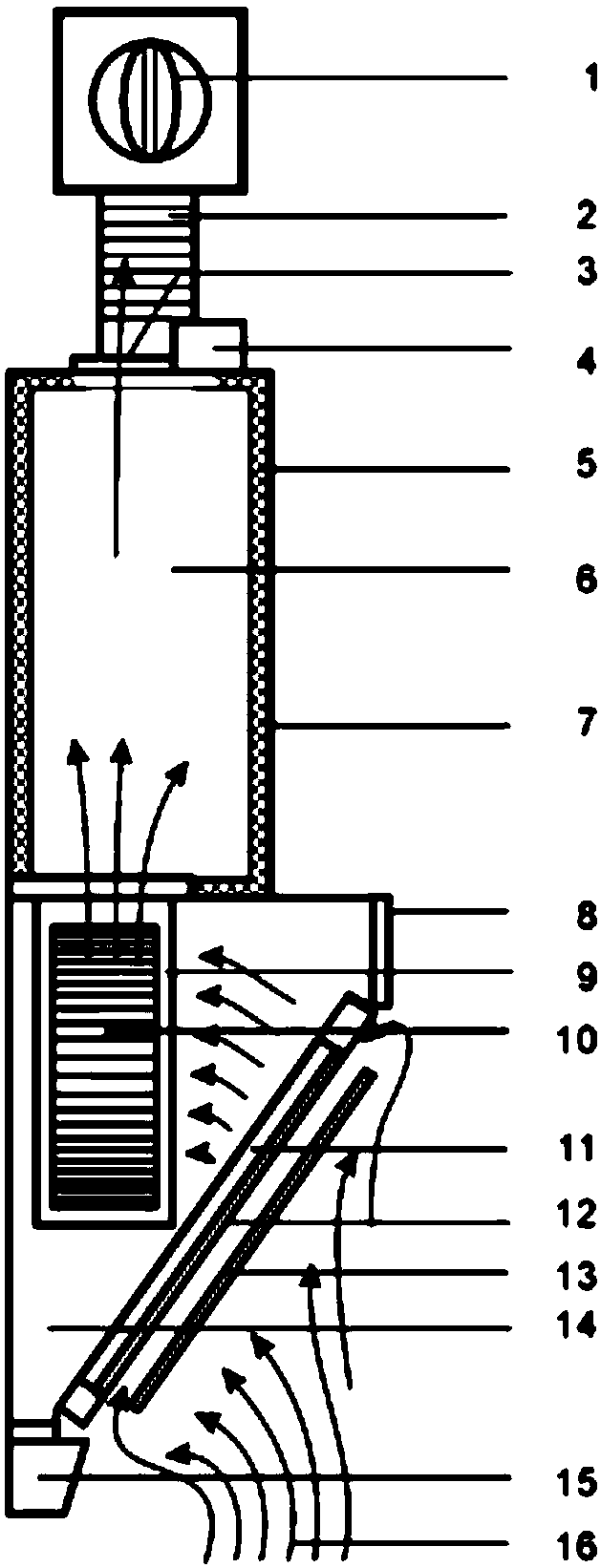

Internal combustion engine with fuels being mixed and ignited on the spot and control method thereof

ActiveCN101649785AMeet octane requirementsLive mix implementationElectrical controlMachines/enginesMixed fuelElectronic control unit

The invention provides an internal combustion engine with fuels being mixed and ignited on the spot and a control method thereof, in particular preparation, feeding and combustion control of fuels ofa combustion engine. A set of high-cetane and high-octane fuel feed and control system is additionally arranged in the internal combustion engine, and the system comprises a mixed fuel electronic control unit (8), a high-octane fuel box (9), a high-octane fuel pressure regulator (10), a high-octane fuel nozzle (13), a high-cetane fuel nozzle (14), a high-cetane fuel pressure regulator (17) and a high-cetane fuel box (18); and by controlling the high-octane flue nozzle, the high-cetane fuel nozzle and an ignition module, the spot mixing, the mixing ratio control, the excess air coefficient control and the ignition control of high-octane fuel and high-cetane fuel are achieved. The invention avoids accidental fire of the traditional single-fuel spark-ignition internal combustion engine in a cold starting process, improves the idling performance and the intermediate-speed and high-speed performance of the internal combustion engine effectively, and achieves the aims of energy saving and emission reduction of all working conditions of the internal combustion engine.

Owner:BEIJING UNIV OF TECH

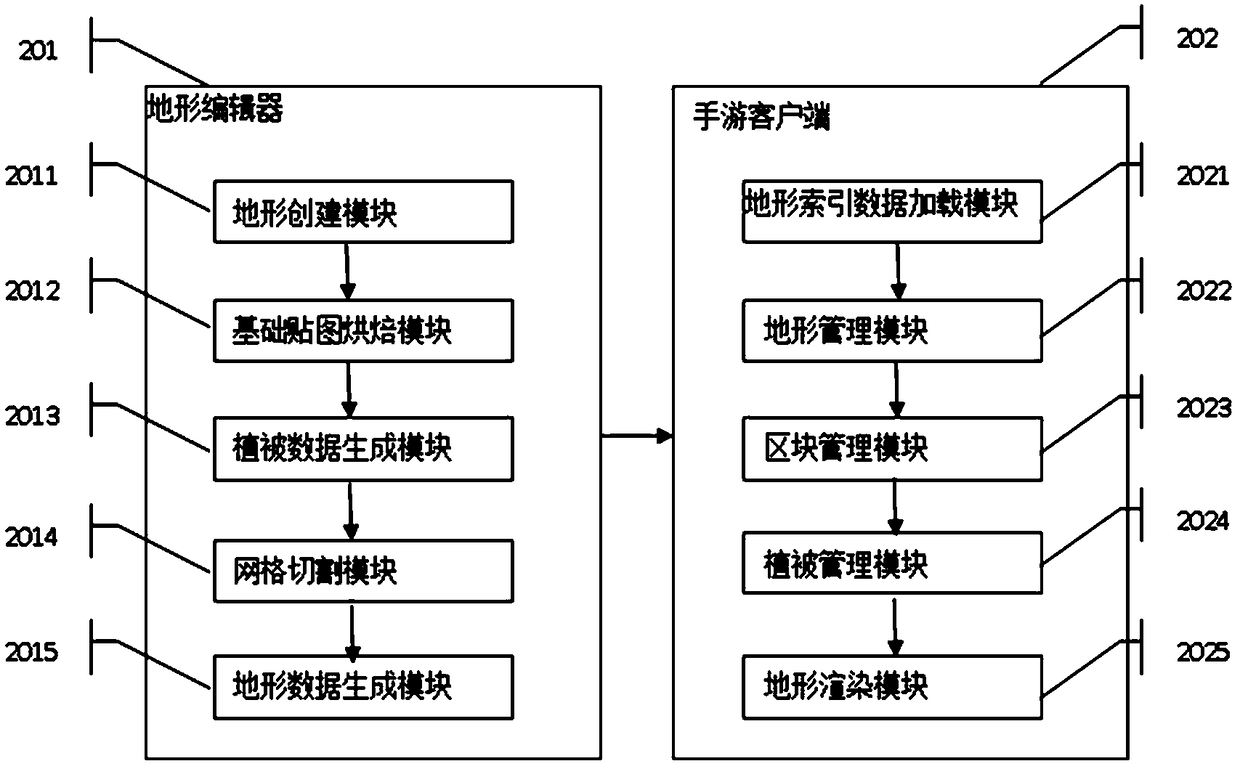

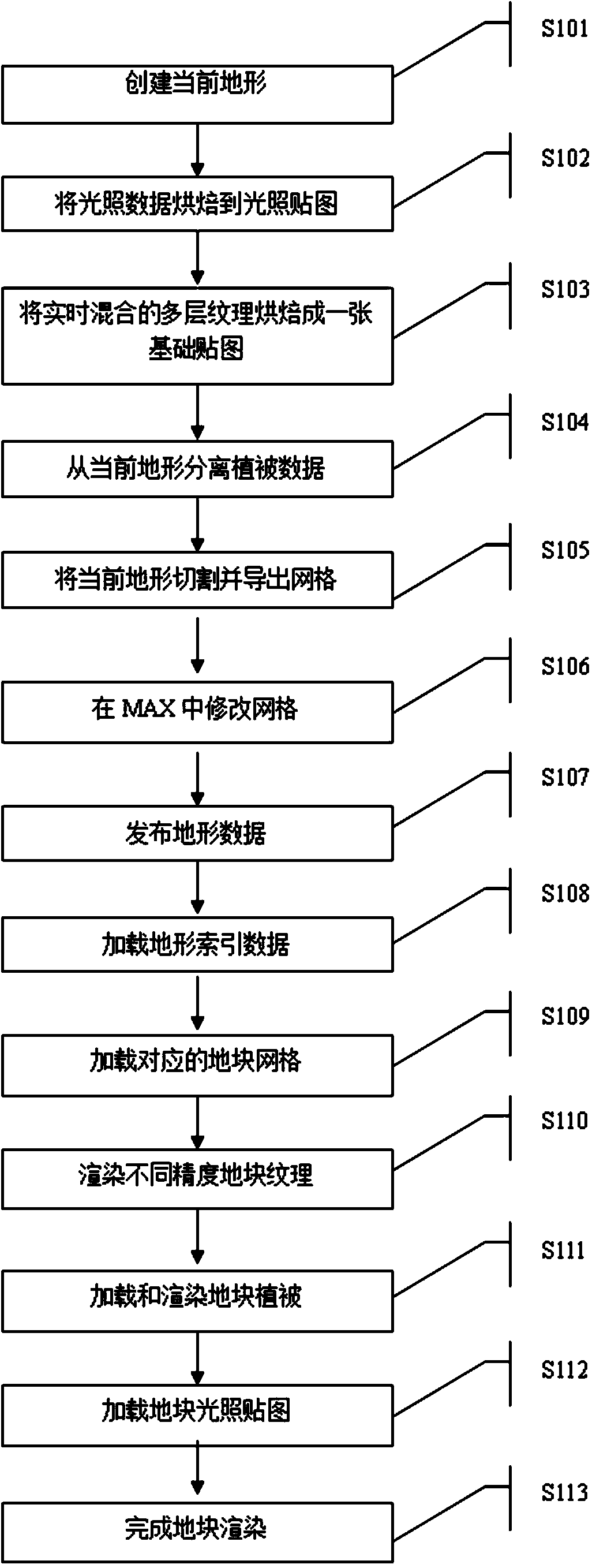

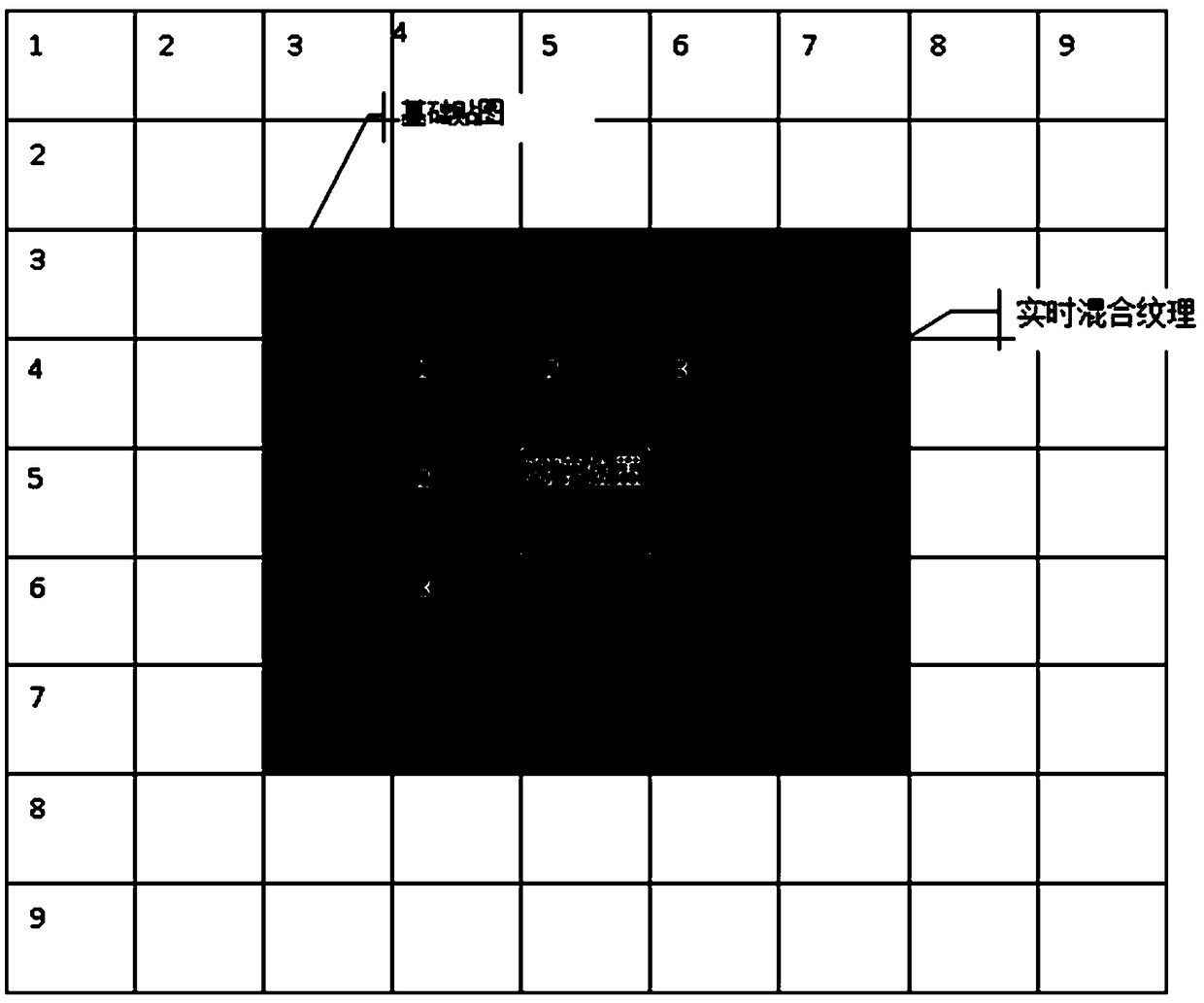

Method and system for making and rendering large-scale terrain

ActiveCN108109204AReduce texture blend timesImprove rendering efficiency3D modellingTerrainClient-side

A system for making and rendering a large-scale terrain is disclosed, which includes a terrain editor and a game client. The terrain editor is used to create a current terrain and process and serialize generated terrain data into data required when a game is running. The game client instantiates a terrain management object, gives the basic rendering texture, and renders the terrain during the running of the game. The terrain data include terrain height data, surface texture data and vegetation data. The invention also provides a system method for making and rendering a large-scale terrain, which can produce different shapes of the ground surface, effectively reduce the number of texture mixing, improve the rendering efficiency, effectively reduce the number of grids within the field of view, and reduce the rendering pressure and memory consumption.

Owner:SNAIL GAMES

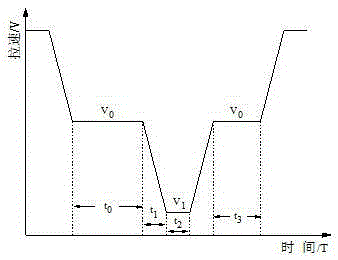

Control method for continuous casting of different steel grade

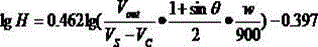

The invention relates to a control method for continuous casting of the different steel grade. The method comprises the following steps: firstly, according to the shape and structural parameters of a tundish flow control device, the mixed casting tonnage M is determined, and the value is the molten steel amount correspondingly when the height of the liquid level of the molten steel in a tundish is the height of a retaining dam; according to following formulas, the remaining steel amount of the previous steel grade is determined as Mo (shown in the specification), and when casting of a molten steel large ladle of a previous furnace is finished, speed begins to be slowly reduced; the mixed casting initial tonnage of the tundish is M1, the pull speed is reduced to the lowest pull speed V0 during normal production of the steel grade, and the retaining time is t0; thirdly, according to the casting cross section, the large ladle cast-on tonnage is selected, when the remaining weight of the tundish is M2, the pull speed is reduced to V1 from V0, and large ladle cast-on operation is carried out; fourthly, after large ladle cast-on operation, the amount of molten steel of the tundish is kept M, the pull speed is kept V1, after t2, the pull speed rises to V0, the reference formula of t2 is shown in the specification, the pull speed rises to V0, meanwhile, the molten steel amount of the tundish is kept M, after the retaining time t3 is equal to 5 min to 8 min, the opening degree of a sliding plate of the large ladle is gradually increased, the tonnage of the tundish rises to the normal casting tonnage, and the pull speed rises to the normal production target value.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Cubic boron nitride, catalyst for synthesizing cubic boron nitride, and process for producing cubic boron nitride

ActiveCN1744943AHigh strengthReduce or suppress deterioration componentsNitrogen compoundsOther chemical processesProduction rateAdditive ingredient

Cubic boron nitride (CBN) is produced with a CBN synthesis catalyst which comprises a CBN synthesis catalyst ingredient and an organic substance with which the surface of the catalyst ingredient has been coated. The amount of the organic substance is preferably 0.01 to 50 parts by weight per 100 parts by weight of the CBN synthesis catalyst ingredient. The organic substance preferably is stearic acid and / or lauric acid. By the use of such CBN synthesis catalyst, CBN which has a sharp shape with a well developed (111) plane and which is reduced in catalyst ingredient inclusion therein can be produced at a high conversion (in high yield) through simple steps and operations with satisfactory productivity.

Owner:SHOWA DENKO KK

Method for preparing biological oil through vacuum pyrolysis of biomasses

InactiveCN101613617AImprove heat transfer efficiencyReduce consumptionBiofuelsLiquid hydrocarbon mixture productionHysteresisWater vapor

The invention relates to a method for preparing biological oil through vacuum pyrolysis of biomasses, which comprises the following technological processes: (1) vacuum pyrolysis: adding raw materials after pretreatment into a reaction kettle, and heating a peripheral pipe type furnace to raise the temperature for pyrolysis, wherein a heat conducting device is arranged in the reaction kettle; (2) condensation: introducing volatile components (mainly comprising water vapor) at a low temperature into a drying tower, and guiding the volatile components at a high temperature into a coil condenser for condensation, wherein the online sampling can be achieved in the process of the pyrolysis; and (3) absorption: absorbing the water vapor in incondensable gas by the drying tower and absorbing nitride and sulfide by a bubbling absorption bottle so as to effectively reduce the pollution caused by vacuum pump oil. The method partially solves the problem of temperature rise hysteresis caused by the low heat transfer efficiency of the biomasses in the process of the temperature rise and the problem of low condensation efficiency and the online sampling, and simultaneously the method preliminarily reduces the water content in the biological oil.

Owner:SOUTHEAST UNIV

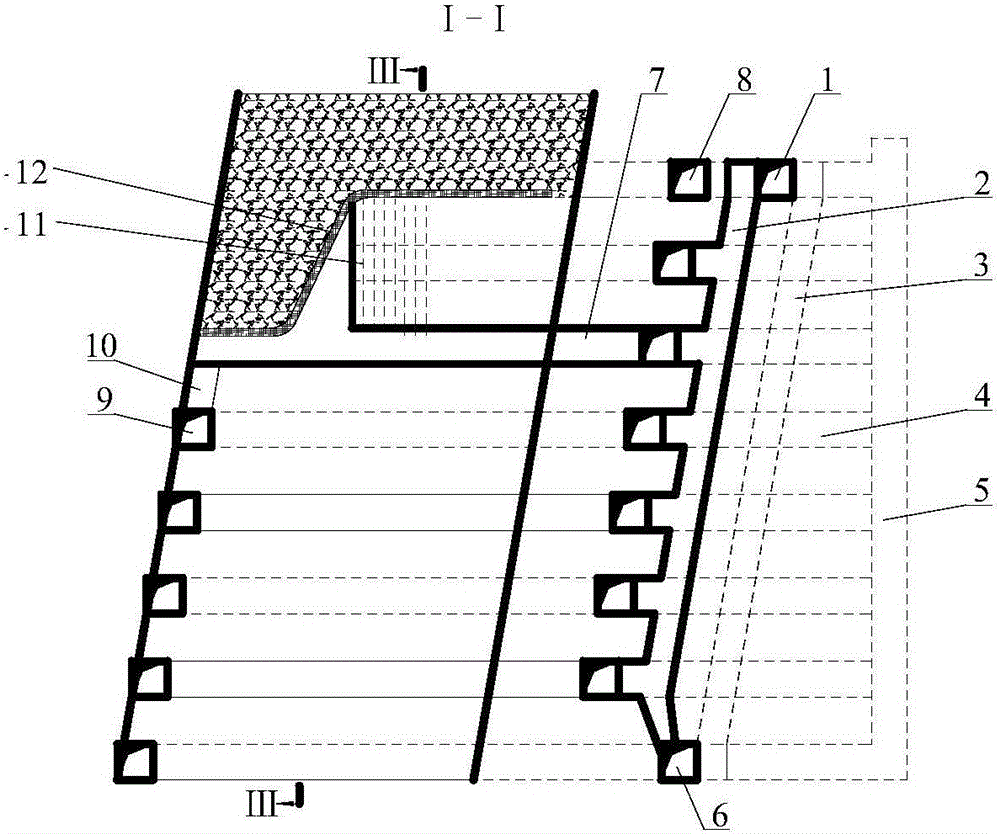

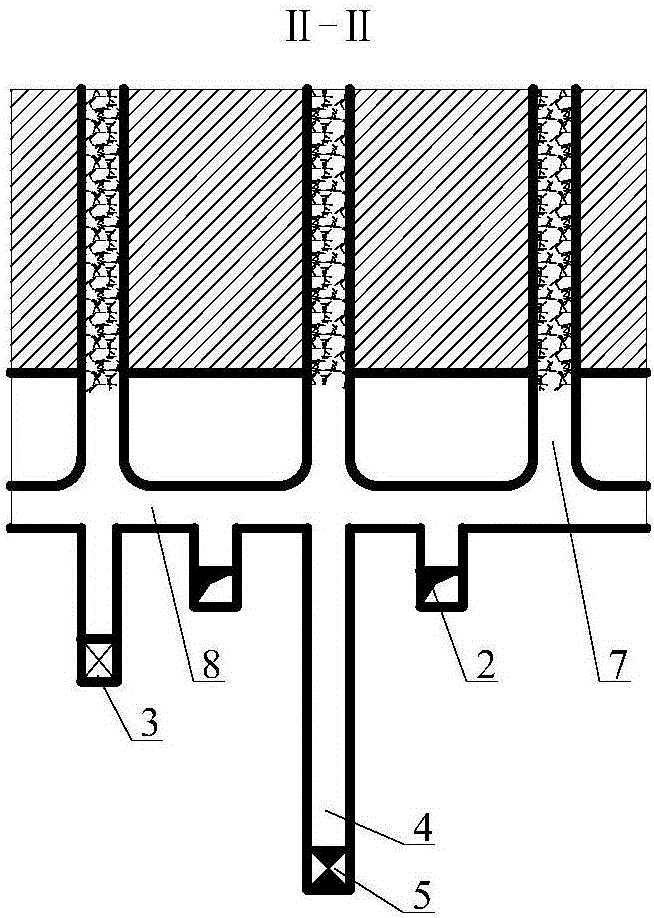

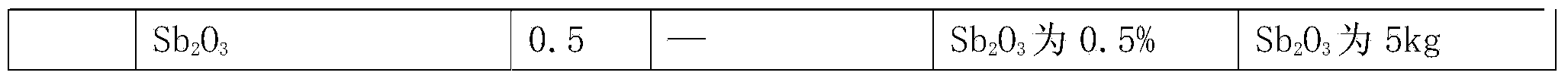

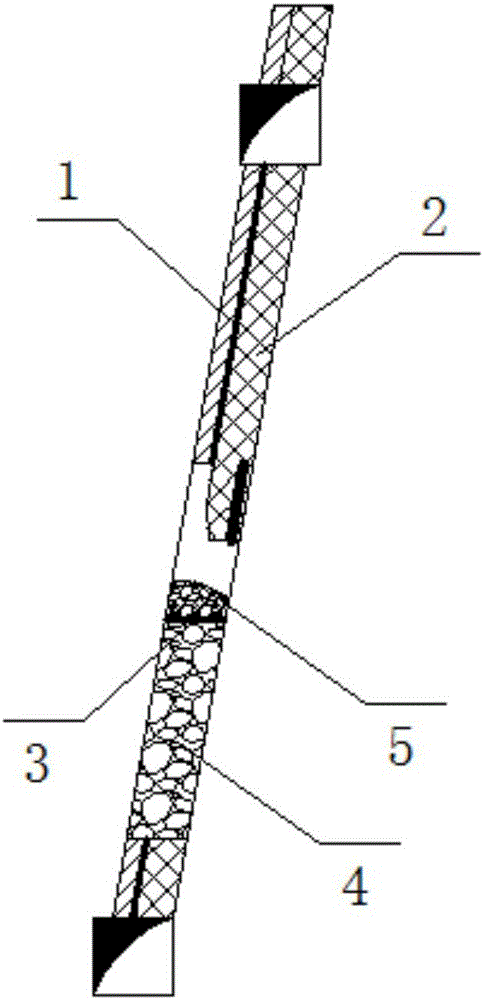

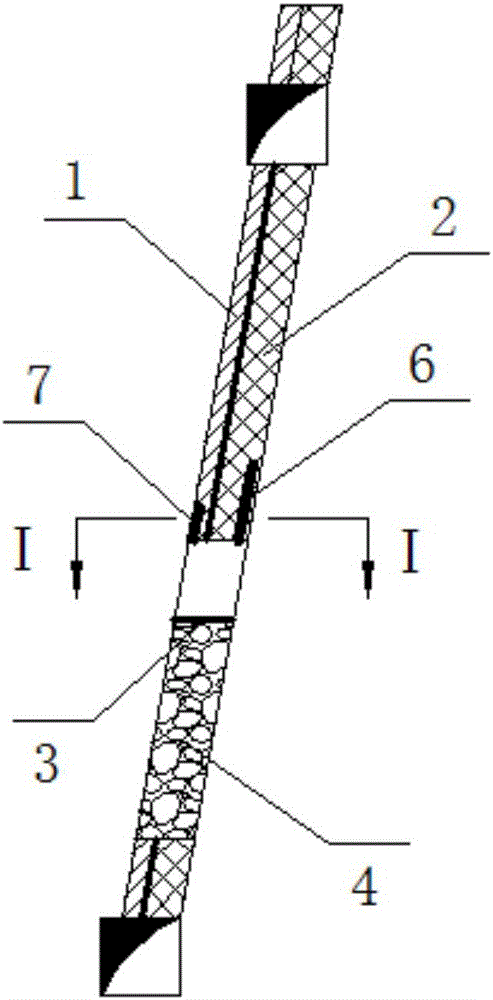

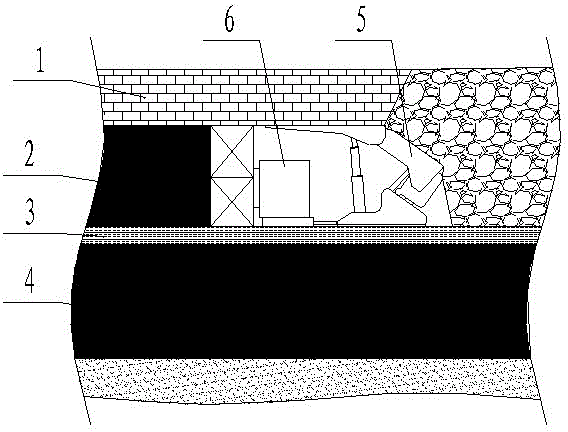

Concrete cushion resuing stoping method for narrow veins

InactiveCN108678745AReduce labor intensityReduce the amount of mixingUnderground miningBlastingVeinSocial benefits

The invention provides a concrete cushion resuing stoping method for narrow veins. The method comprises the following steps: drilling resuing blast holes in a hanging wall or heading wall surroundingrock of a virtual cliff; continuously drilling ore breakdown blasting holes on a vein twice; respectively blasting the ore breakdown blasting holes; concentrating machines for ore mining; filling a stope; laying a concrete cushion on a flattened waste heap; circulating the processes until stoping of the whole ore block is finished. The concrete cushion resuing stoping method provided by the invention reduces the quantity of orepasses, reduces engineering quantity, reduces labor intensity of workers, increases the amount of caved ores, reduces the amount of mixed waste rocks, realizes mechanized transportation and mining, improves production capacity of the stope, reduces loss of ore fines, reduces depletion of ores, and contributes to control of a ground pressure of the stope to a certainextent by introducing twice continuous ore breakdown and concrete cushion laying process; the concrete cushion resuing stoping method maximizes use of resources while ensuring production safety, and has relatively high economic benefits and social benefits.

Owner:CHANGCHUN GOLD RES INST

Dendrobium officinale culture substrate and preparation method

The invention discloses a dendrobium officinale culture substrate and a preparation method therefore. The culture substrate is prepared from the five materials of bark, brick granules, sphagna, wood dust and maize straw, wherein the bark adopts defatted pine bark with the size ranging from 1 cm to 3 cm, the brick granules adopt smashed red bricks with the size ranging from 1 cm to 2 cm, the sphagna adopts dried sphagna, the wood dust adopts sawdust and is soaked with water and stacked layer by layer for one month for natural fermentation, and the size of the wood dust ranges from 1 cm to 3 cm; the maize straw is smashed to the size ranging from 2 cm to 3 cm and sprayed with diluted nitrogen fertilizer water to keep the straw moist, the straw is stacked layer by layer and covered with a plastic thin film, natural fermentation of the straw can be achieved after 1-2 months, and the fermented straw is smashed to the size ranging from 2 cm to 3 cm. The five materials are cooked separately, carbendazim with the effective ingredient concentration equal to 25% is added to prepare liquid diluted by 500 times, disinfection is conducted for one hour, and natural cooling is conducted; the bark, the brick granules, the sphagna, the wood dust and the maize straw are evenly mixed according to the volume ratio of three to two to one to one to one, and the substrate is prepared.

Owner:GUIZHOU BOTANICAL GARDEN (GUIZHOU INST OF HORTICULTURAL SCI GUIZHOU INST OF BOTANY)

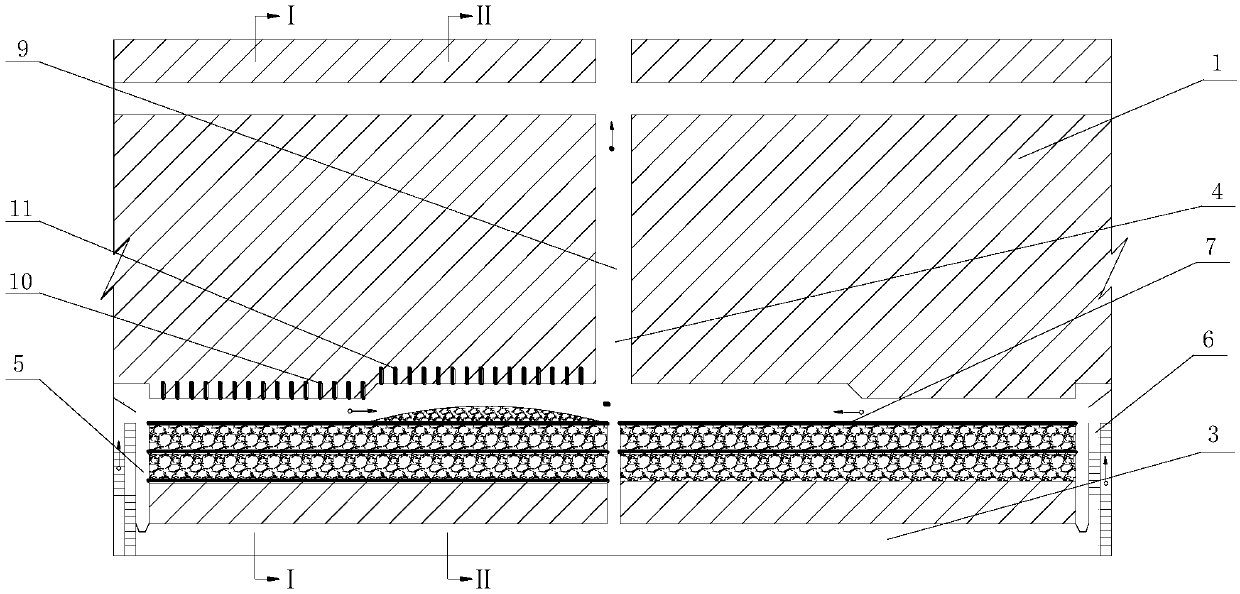

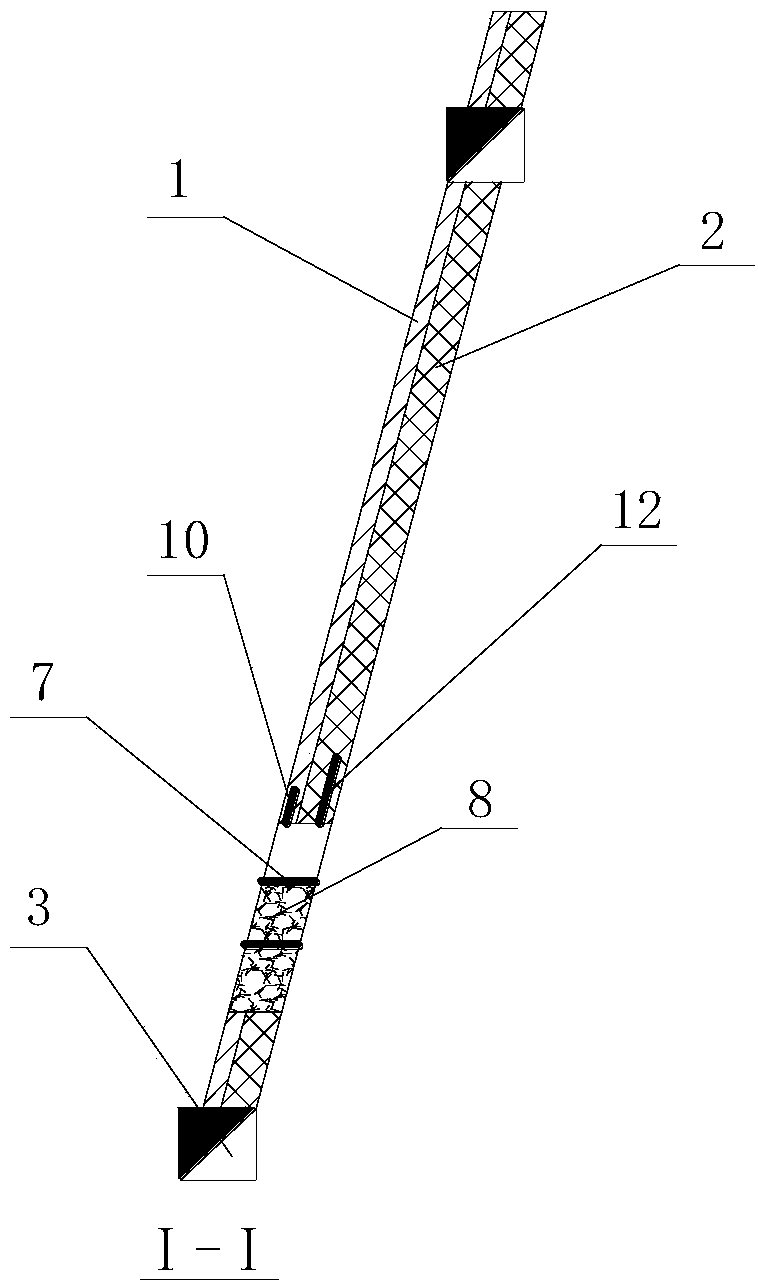

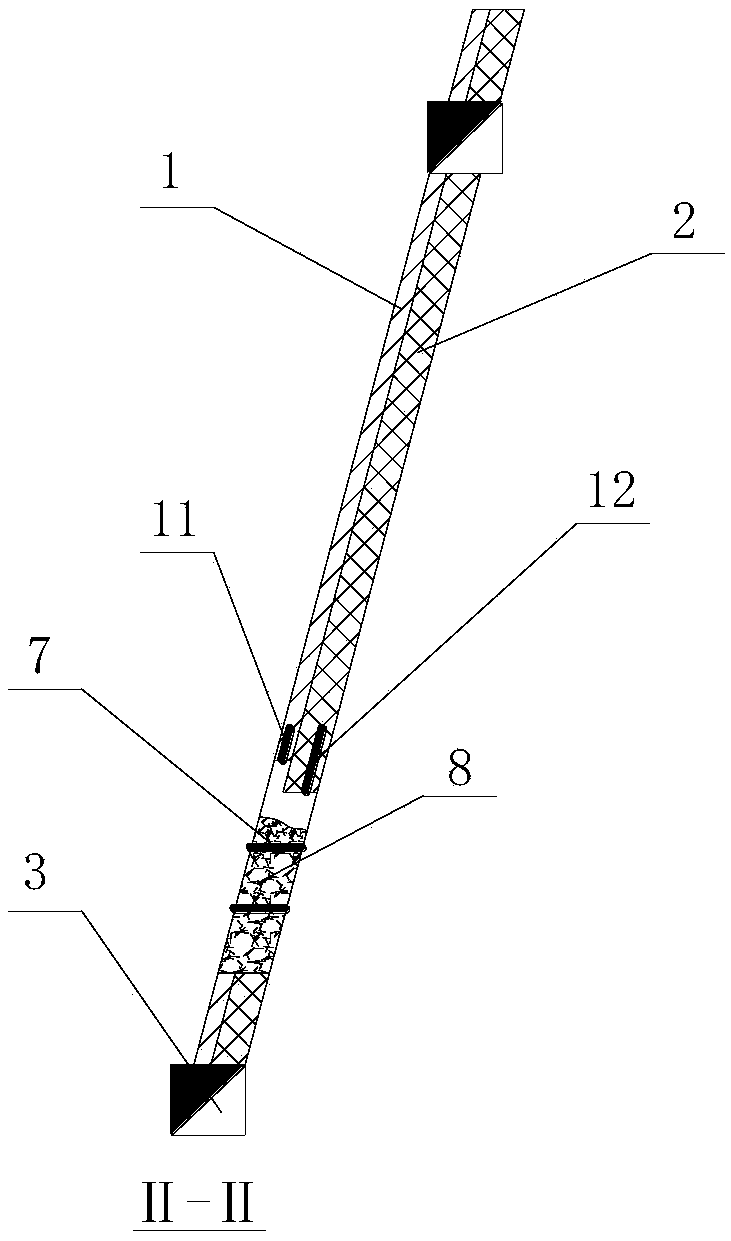

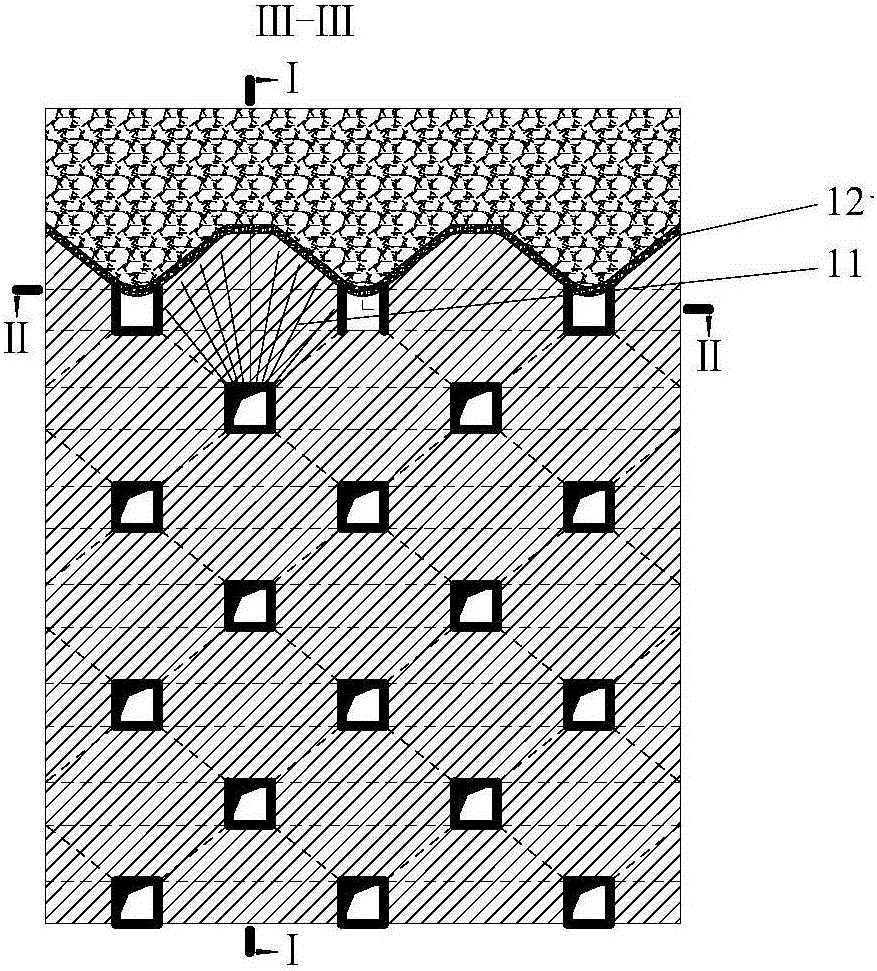

Sublevel caving collaborative mining method with flexible isolating course as artificial roof

ActiveCN106089209AReduce the amount of mixingReduce loss rate and dilution rateUnderground miningTunnel/mines ventillationEngineeringBreathing

The invention discloses a sublevel caving collaborative mining method with a flexible isolating course as an artificial roof. The sublevel caving collaborative mining method comprises the specific steps that firstly, a roof building space is formed on the upper portion of an ore block in a pulling mode with a supporting column method, the flexible isolating course artificial roof is spread on a bottom plate, and when roof building work is promoted, meanwhile, caving is conducted on upper surrounding rock to form a covering layer; and secondly, mining field stoping operation is conducted according to the sublevel caving method, specifically, a stoping drift is arranged to be rhombic, rock chiseling and ore caving are conducted in a mode from a shallow hole to a medium-length hole, and ore is transported out through a scraper. According to the sublevel caving collaborative mining method with the flexible isolating course as the artificial roof, compared with existing sublevel caving methods, the waste stone mix rate is decreased, the ore recovery rate is increased, and the ventilation effect is improved; and meanwhile, the sublevel caving collaborative mining method has the advantages of being high in production efficiency and ore block production capacity.

Owner:GUANGXI UNIV

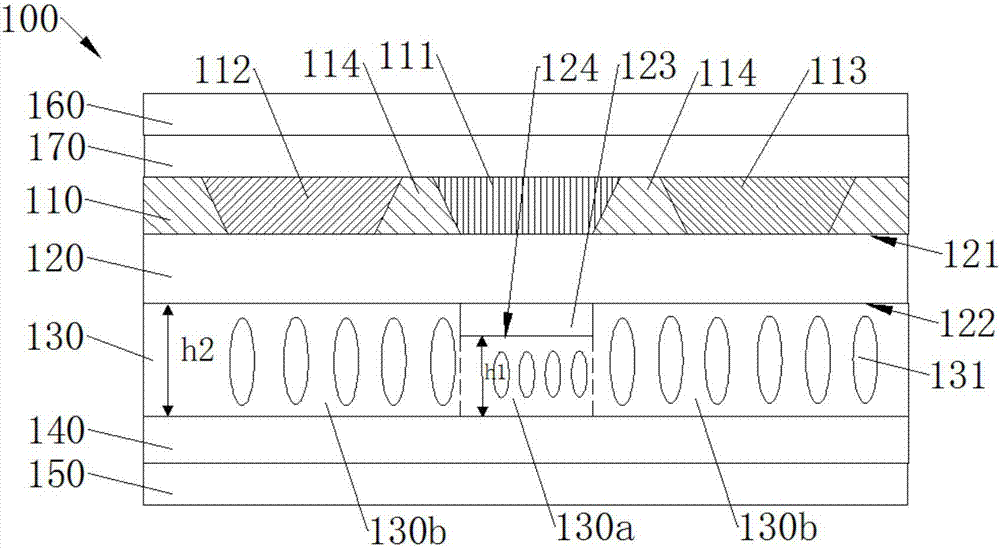

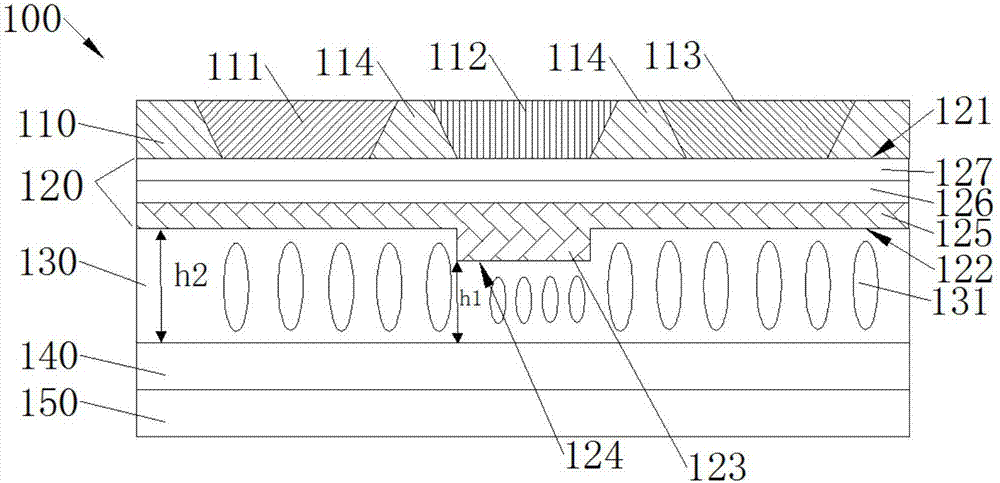

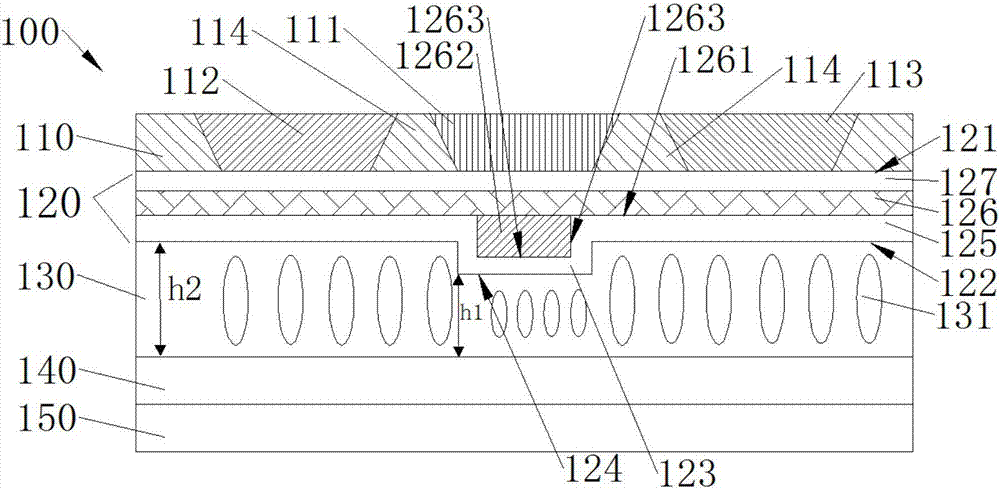

Display panel and display device

ActiveCN107219673AImprove viewing angleEasily damagedNon-linear opticsDisplay deviceComputer science

The invention provides a display panel. The display panel includes a colour filtering layer, a functional layer and a liquid crystal layer which are successively arranged in a stack mode, the functional layer is provided with an upper end and a lower end, where in the upper end and the lower end are oppositely arranged, the colour filtering layer is arranged at the upper end, the colour filtering layer has a blue sub-pixel area, the blue sub-pixel area is used for making blue light penetrate through, the liquid crystal layer is arranged at the lower end, the lower end is provided with a bulge structure, the bulge structure extends into the liquid crystal layer, the liquid crystal layer is divided into a first area and a second area by the bulge structure, the projective area of the first area to the colour filtering layer covers the blue sub-pixel area, and the thickness of the liquid crystal cell of the first area is smaller than that of the second area. The invention further provides a display device. The display panel and display device solve the problem o visual-angle colour shifts occuring in the blue pixel area and improves the picture quality of the display panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

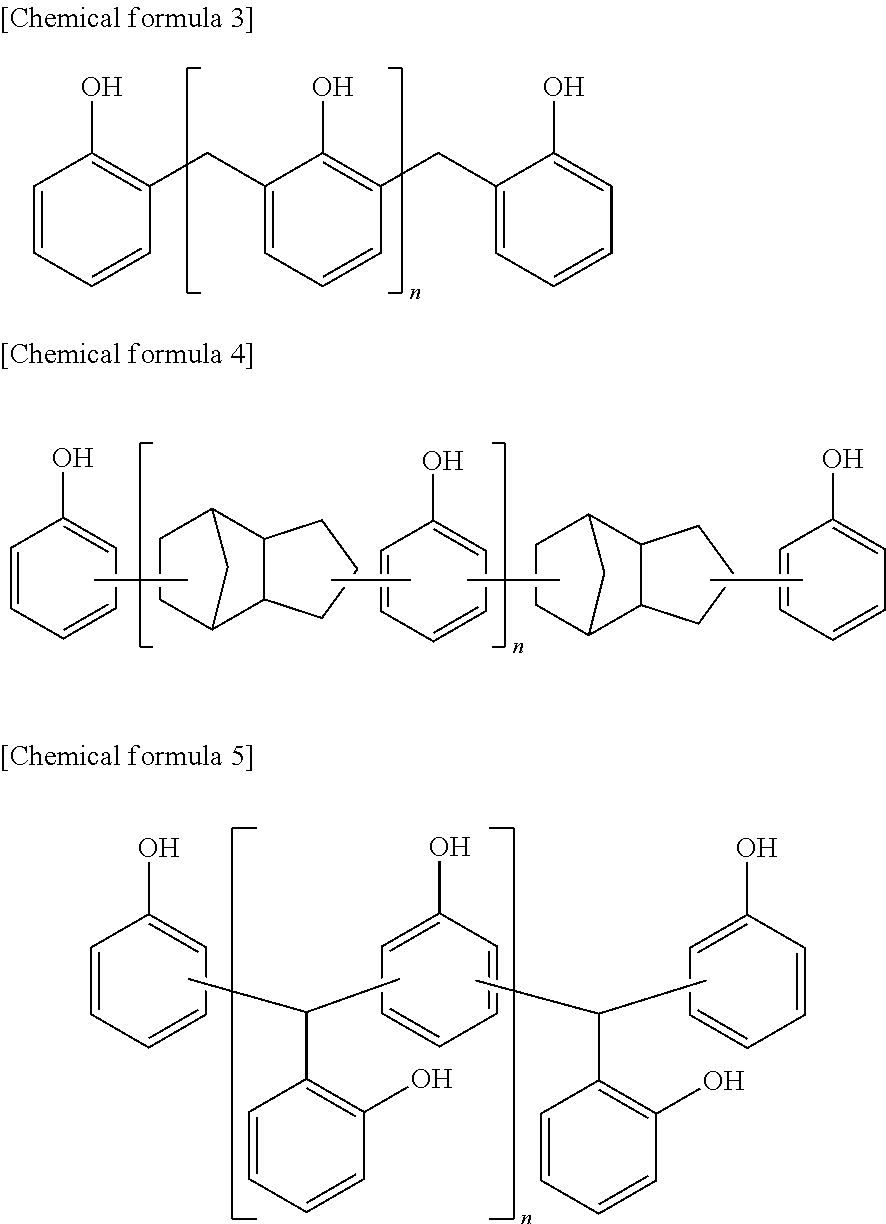

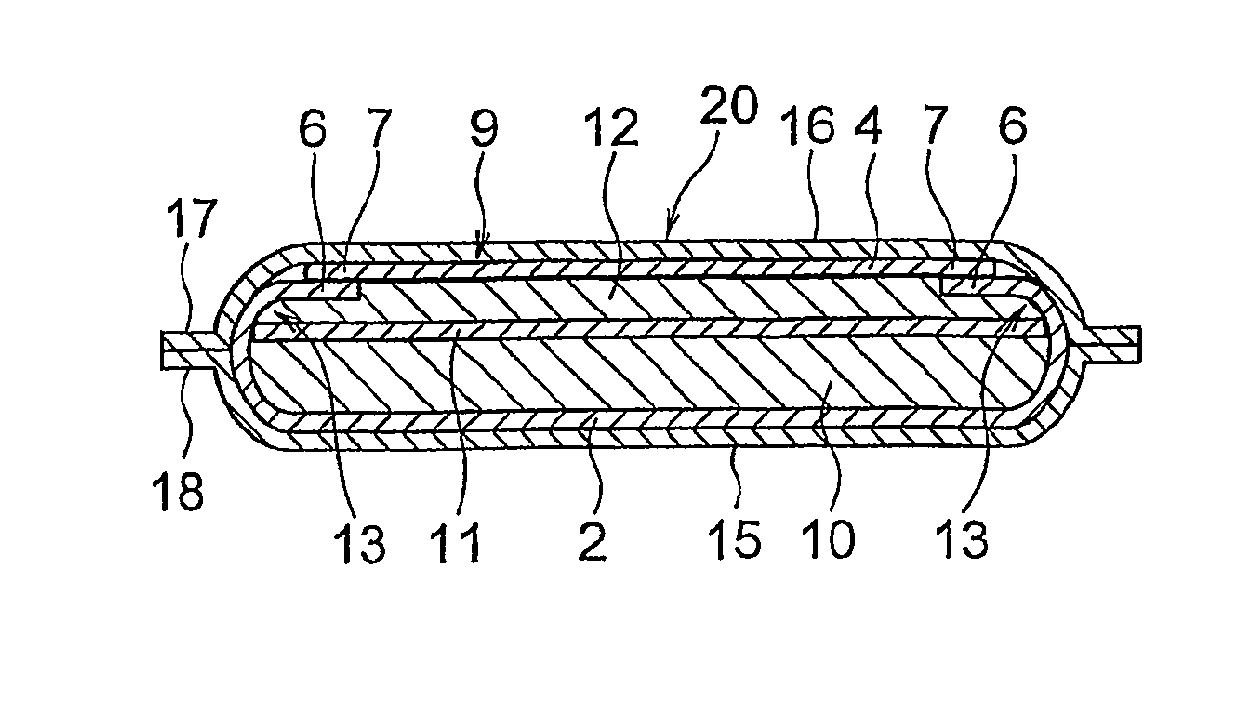

Electric wire coating material composition, insulated electric wire, and wire harness

ActiveUS20180112096A1Reduced characteristicsGood retarding effectFireproof paintsPlastic/resin/waxes insulatorsPtru catalystPolyolefin

A flame-retardant electric wire coating material composition that can improve heat resistance without using electron beam cross-linking, has no risk of reducing the mechanical characteristics and chemical resistance due to no metal hydroxides being added thereto as flame retardants, and can suppress the formation of die lip build-up and the like during manufacturing to achieve favorable productivity, and an insulated electric wire and a wire harness. The electric wire coating material composition may include:a silane-grafted polyolefin (A);an unmodified polyolefin (B);a modified polyolefin (C);a bromine-based flame retardant and antimony trioxide (D);a cross-linking catalyst batch (E);zinc oxide and an imidazole-based compound modified with a mercapto group, or zinc sulfide (F);an antioxidant, a metal deactivator, and a lubricant (G);silicone oil (H); andno metal hydroxides.

Owner:AUTONETWORKS TECH LTD +2

Antidrift composition

InactiveUS9034960B2Reduce the amount of mixingBiocideGroup 4/14 element organic compoundsAdjuvantMedicine

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

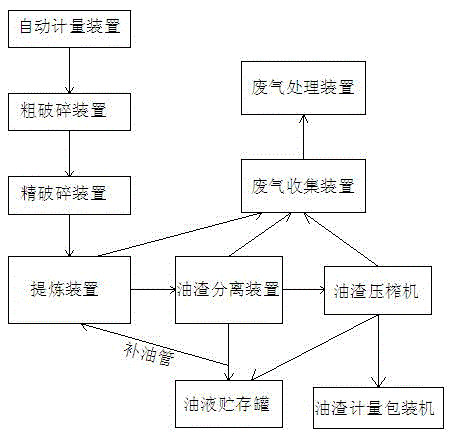

Non-intermittent industrial oil refining treatment technology and automatic refining system

ActiveCN105219514APrevent scorching etc.Batchless RefiningFatty-oils/fats productionOil and greaseAutomatic control

The invention relates to a non-intermittent industrial oil refining treatment technology. The technology comprises the steps of metering, crushing, refining, oil residue separation, squeezing, waste gas collection, waste gas treatment and the like. The invention further relates to an automatic refining system for non-intermittent industrial oil refining. The system is characterized by comprising an automatic metering device, a coarse crushing device, a fine crushing device, a refining device, an oil residue separating device, an oil residue squeezing machine, a waste gas collecting device, a waste gas treating device, an oil residue metering packaging machine, an oil liquid storage pot and an automatic control system. By the adoption of the non-intermittent industrial oil refining treatment technology and the automatic refining system, non-intermittent oil refining can be achieved, the temperature in different stages of the refining process is better controlled, the oil refining quality is improved, oil residues and waste gas are treated, environmental protection is achieved, and meanwhile oil residue utilization rate is improved.

Owner:HUNAN XIANGBO COMML GREASE CO LTD

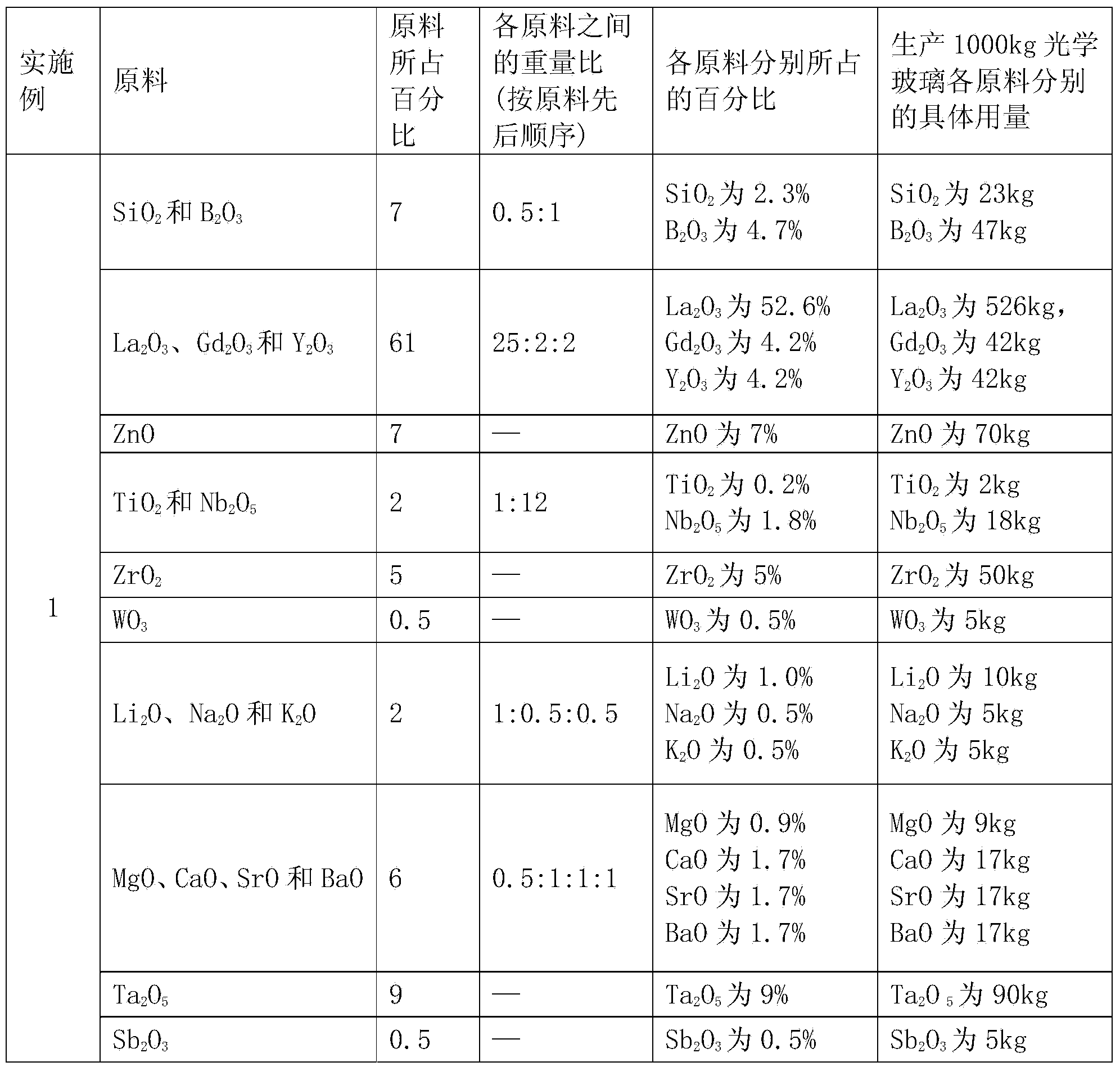

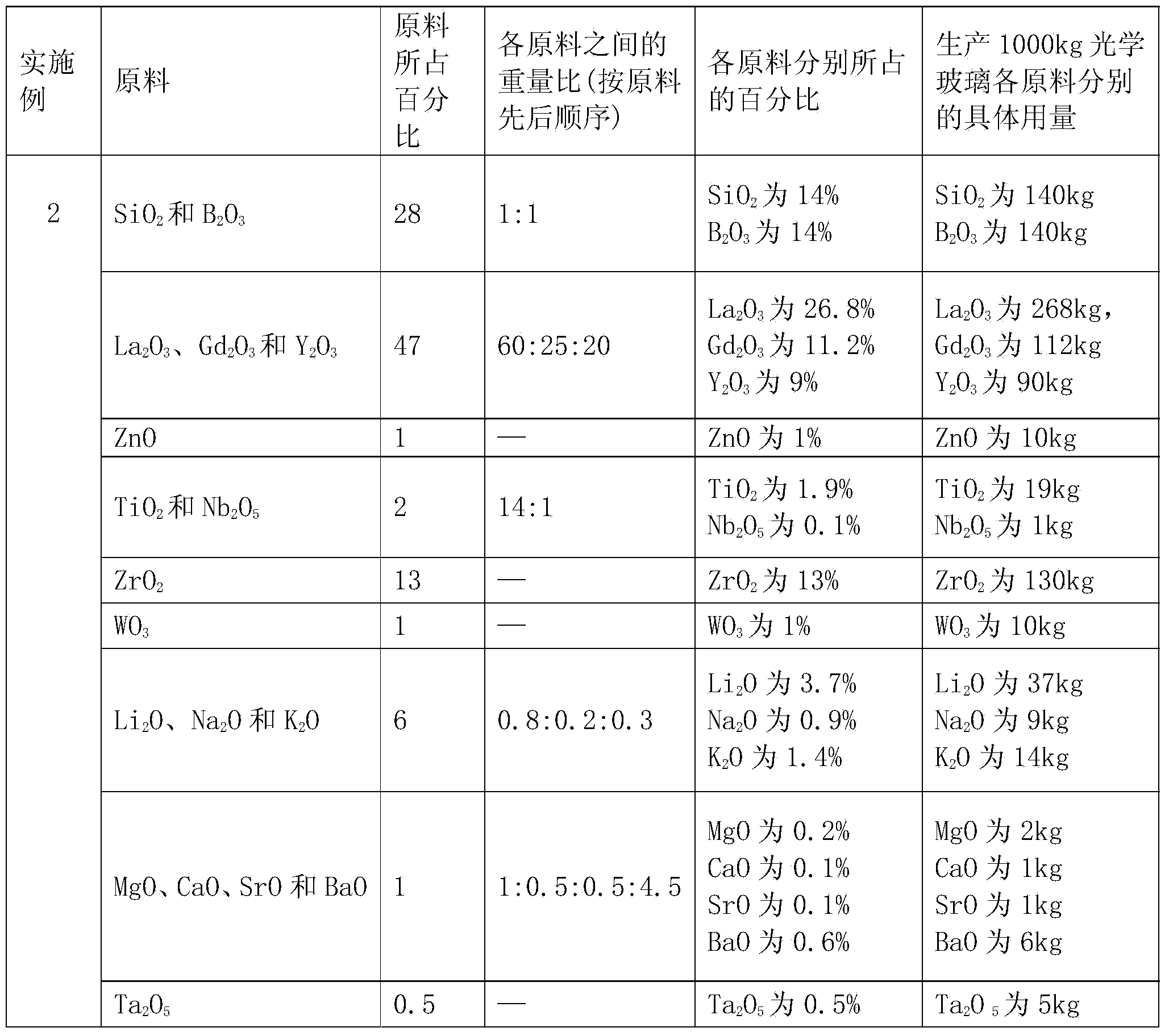

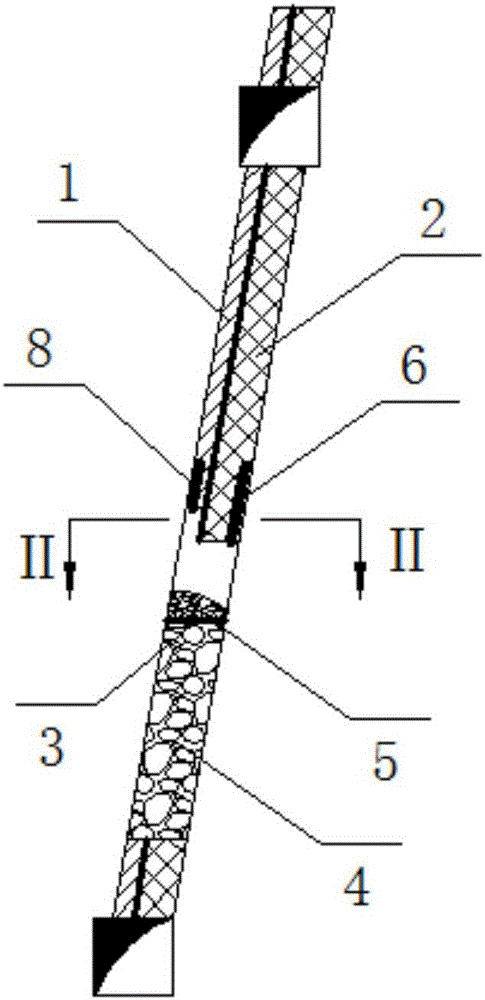

High-refractive-index and low-dispersion optical glass and preparation method thereof

The invention provides high-refractive-index and low-dispersion optical glass. The optical glass consists of the following raw materials in percentage by weight: 5-32 percent of SiO2 and B2O3, 45-65 percent of La2O3, Gd2O3 and Y2O3, 0.5-10 percent of ZnO, 1-20 percent of TiO2 and Nb2O5, 0-15 percent of ZrO2, 0-2 percent of WO3, 0-10 percent of Li2O, Na2O and K2O, 0-10 percent of MgO, CaO, SrO and BaO, 0-12 percent of Ta2O5 and 0-1 percent of Sb2O3. Compared with the prior art, the high-refractive-index and low-dispersion optical glass has the beneficial effects of higher internal color penetration degree, small specific weight, low smelting process temperature, smaller adding amounts of Ta2O5 and Gd2O3 and lowered cost.

Owner:SICHUAN RUITIAN OPTICAL

Clothes washing method and detergent composition used for the same

InactiveUS20090119847A1Improve washing effectImprove compactnessInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAdditive ingredientSurfactant free

Owner:MIZ CO LTD

Blasting control method for improving ore breaking efficiency of wall-cutting filling method

ActiveCN107524444AImprove ore falling efficiencyReduce the amount of mixingUnderground miningBlastingMineralogyMixed waste

The invention discloses a blasting control method for improving the ore breaking efficiency of a wall-cutting filling method. The blasting control method comprises the steps that a wall-cutting blast hole is drilled in hanging side surrounding rock or heading side surrounding rock of a to-be-cut wall, a first-time ore breaking blast hole is drilled in a vein, and blasting of the first-time ore breaking blast hole is carried out; a secondary ore breaking blast hole is drilled in the vein, blasting of the secondary ore breaking blast hole is carried out, and concentrated ore drawing is conducted; blasting of the wall-cutting blast hole is carried out, and a stope is filled; and circulation is conducted in this way till stoping of a whole ore block is completed. According to the blasting control method, by introducing the blasting control technology of two-time ore breaking and one-time wall-cutting in the wall-cutting filling method, the quantity of the caved ores is greatly increased, the mixed waste ore quantity is obviously decreased, and the ore breaking efficiency of the wall-cutting filling method is promoted.

Owner:CHANGCHUN GOLD RES INST

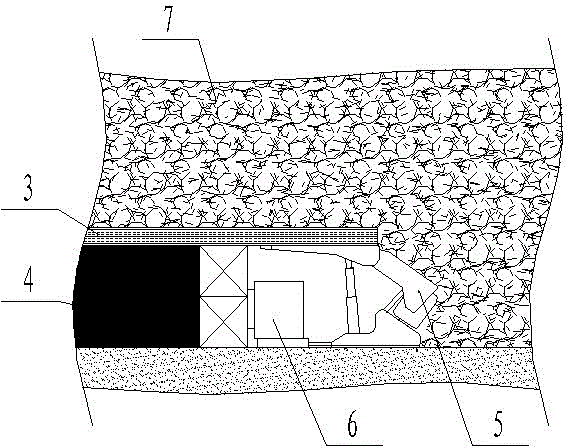

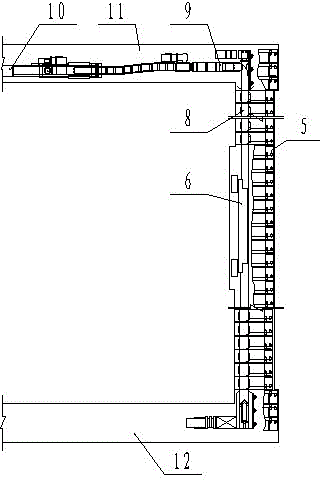

Longwall downward stratified coal gangue false roof coal mining method

ActiveCN104088641AReduce the amount of mixingReduce consumptionUnderground miningSurface miningUltimate tensile strengthCoalbed methane

The invention relates to a coal mining method, and in particular relates to a longwall downward stratified coal gangue false roof coal mining method, aiming at providing the longwall downward stratified coal gangue false roof coal mining method which takes a stone band as a false roof and is simple, convenient and low in percentage of shale content of raw coal. The method adopts the technical scheme that the stone band which has stable coalbed methane is taken as the false roof, so that the mixing quantity of gangue in the raw coal can be reduced, green mining is realized, the process of laying a metal net or a plastic net during slicing mining can be omitted, the labor intensity of workers can be lightened, the consumption of material is reduced, the comprehensive efficiency of coal mining is increased, and the method is widely applied to coal mining.

Owner:TAIYUAN DESIGN RES INST FOR COAL IND

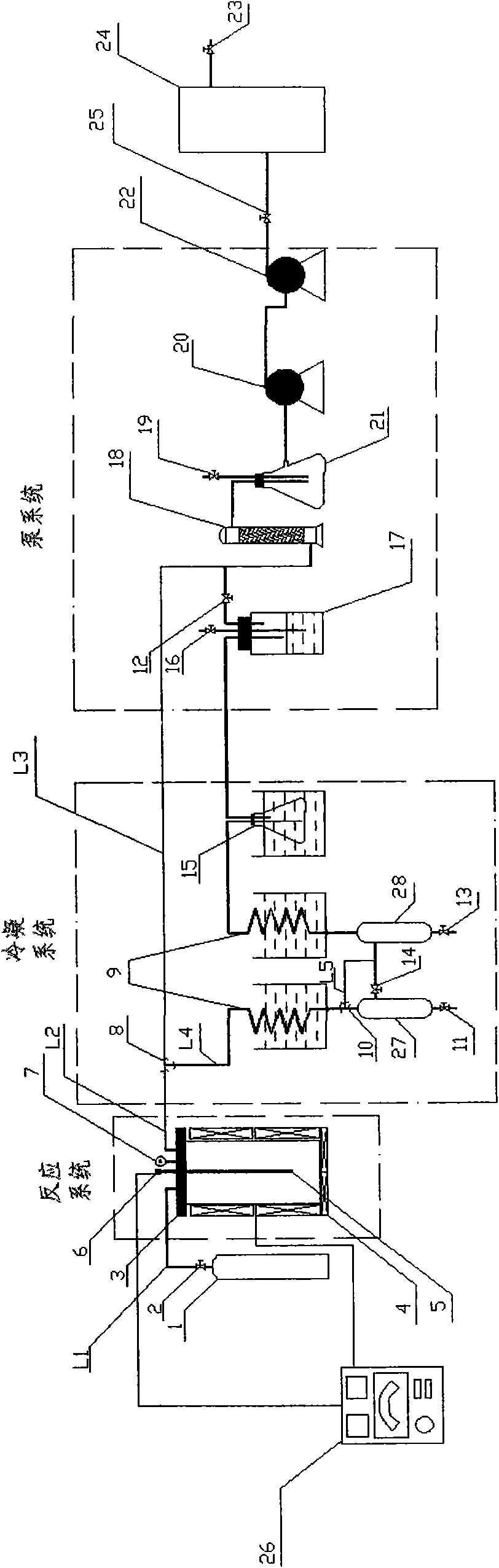

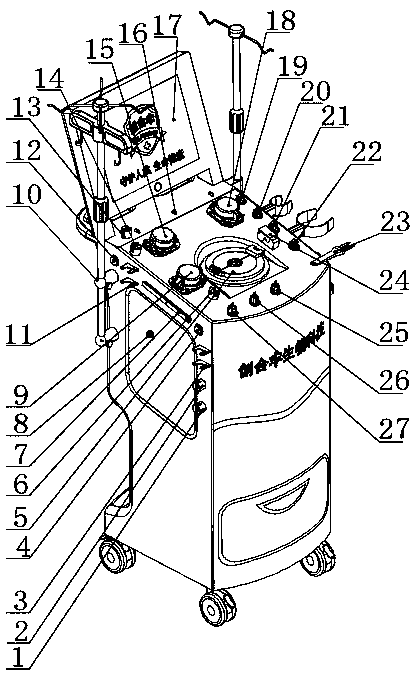

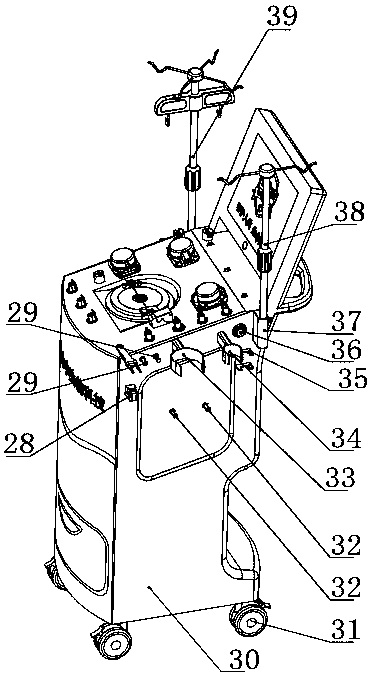

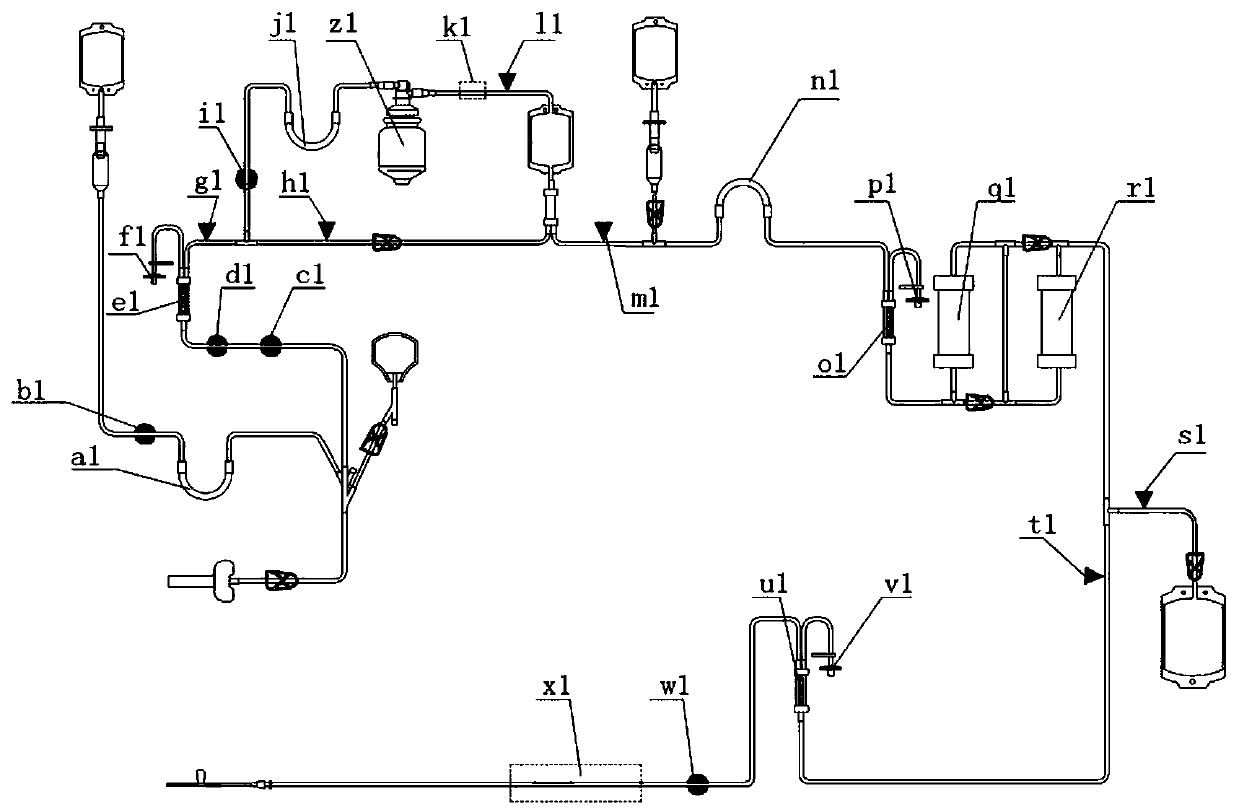

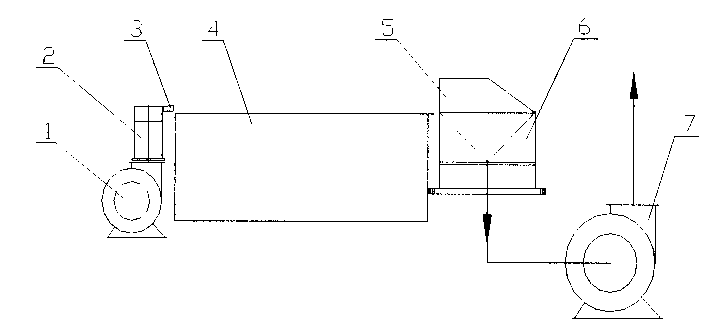

Blood separation comprehensive therapy apparatus complete machine

PendingCN109568700AThe separation effect is thoroughReduce the amount of mixingOther blood circulation devicesCentrifugationRed blood cell

The invention relates to the field of medical instruments, and discloses a blood separation comprehensive therapy apparatus complete machine. The blood separation comprehensive therapy apparatus complete machine comprises a rack, wherein the rack is provided with an anti-coagulant pump, a blood pump, a plasma pump, an anti-coagulant hanger, a normal saline hanger, a centrifugal machine, a pipelinedetector, therapeutic apparatus hoops, a plurality of pressure detectors, a plurality of ultrasonic air detectors and a plurality of pinch-off valves; the centrifugal machine is located in the central position of the rack; the blood pump and the pipe detector are arranged beside the centrifugal machine; the anti-coagulant hanger and the normal saline hanger are arranged at two sides of the rack.According to the blood separation comprehensive therapy apparatus complete machine disclosed by the invention, by utilizing the matching of the centrifugal machine and a separation cup in a purification system and adopting a centrifugation technology, blood is separated into blood cells and plasma, a membrane used for separating the blood is replaced, and the production cost is greatly reduced; functional components such as a heater, a cuff connector, an electronic scale, a heat sealing machine and the like are integrated, and medical staff can conveniently operate and use.

Owner:成都创合丰生物科技有限公司

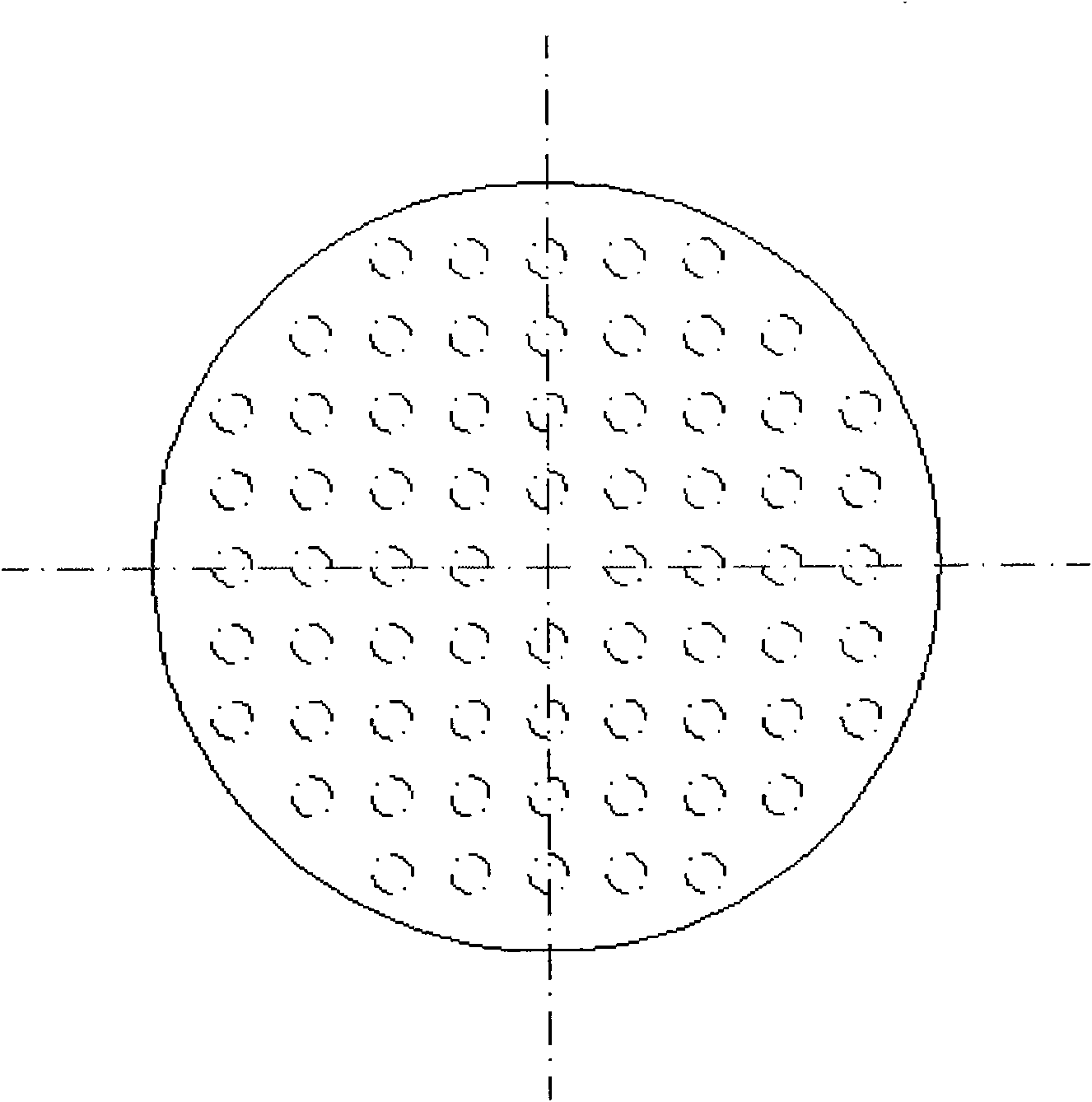

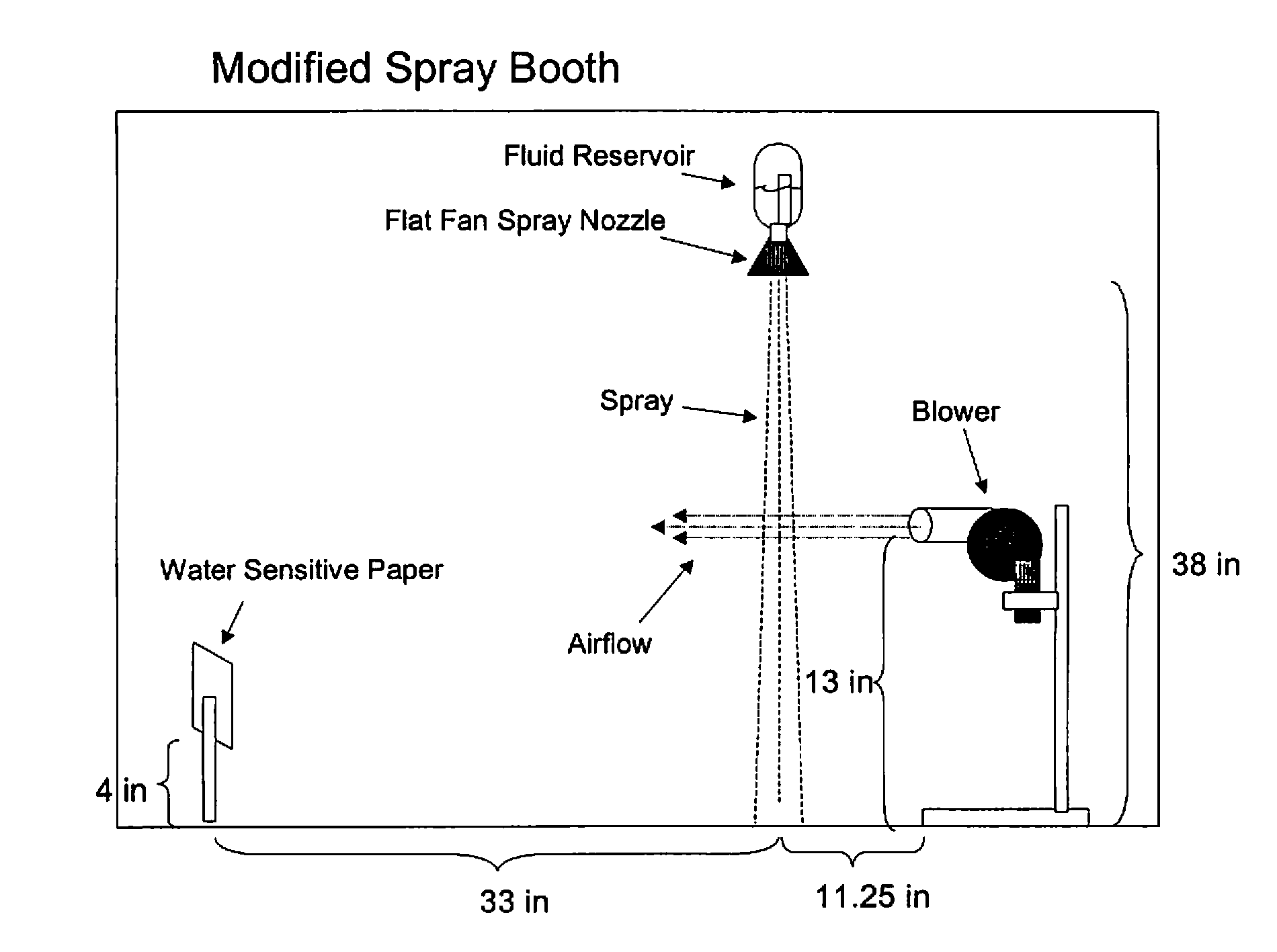

Method for collecting asphalt smog in vibration formation process of prebaked anode

InactiveCN1418989AReduce the amount of mixingReduce exhaust air volumeShaping pressAir volumeForming gas

The method for collecting usphalt smog in the course of vibration forming process of precalcined anode is characterized by that a jet gas flow with plane distribution is blown into the upper portion of vibration forming die bucket for precalcined anode, and a gas curtain is formed over the die bucket, a gas cuaking cover is placed on another side to suck and collect the gas flow. Said jet gas flow can be jetted out from a flat jet nozzle whose width is identical to that of forming die bucket, its gas flow speed is 5-10 m / s, and the jet gas flow is 0-10 deg. below horizontal level, its one side is used for sucking gas and another side is used for blowing gas so as to form gas curtain so as to remove harmful substances.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

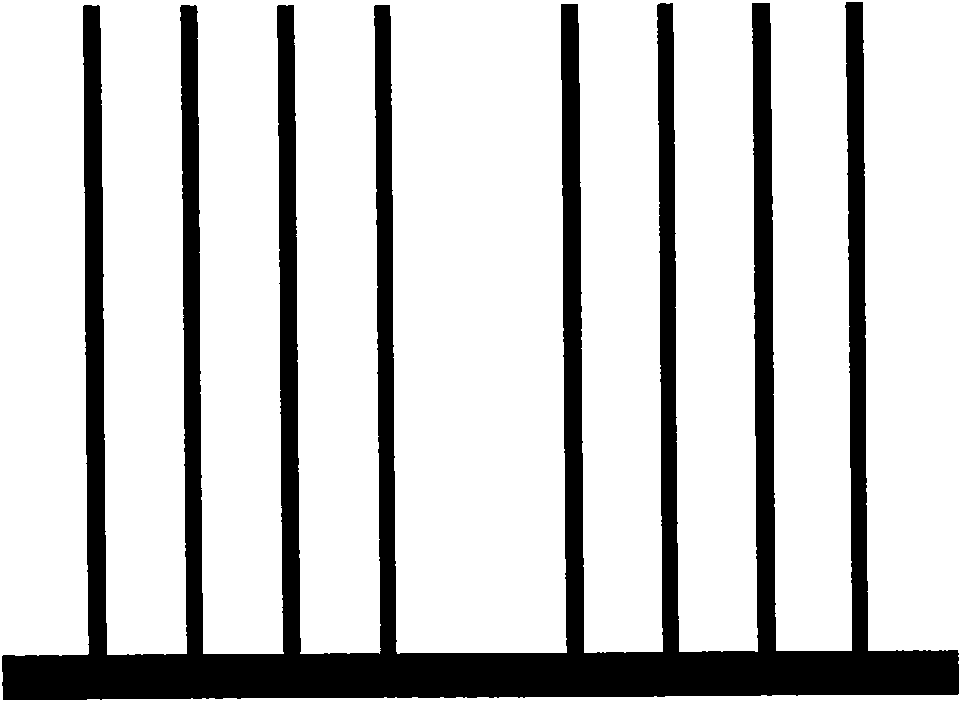

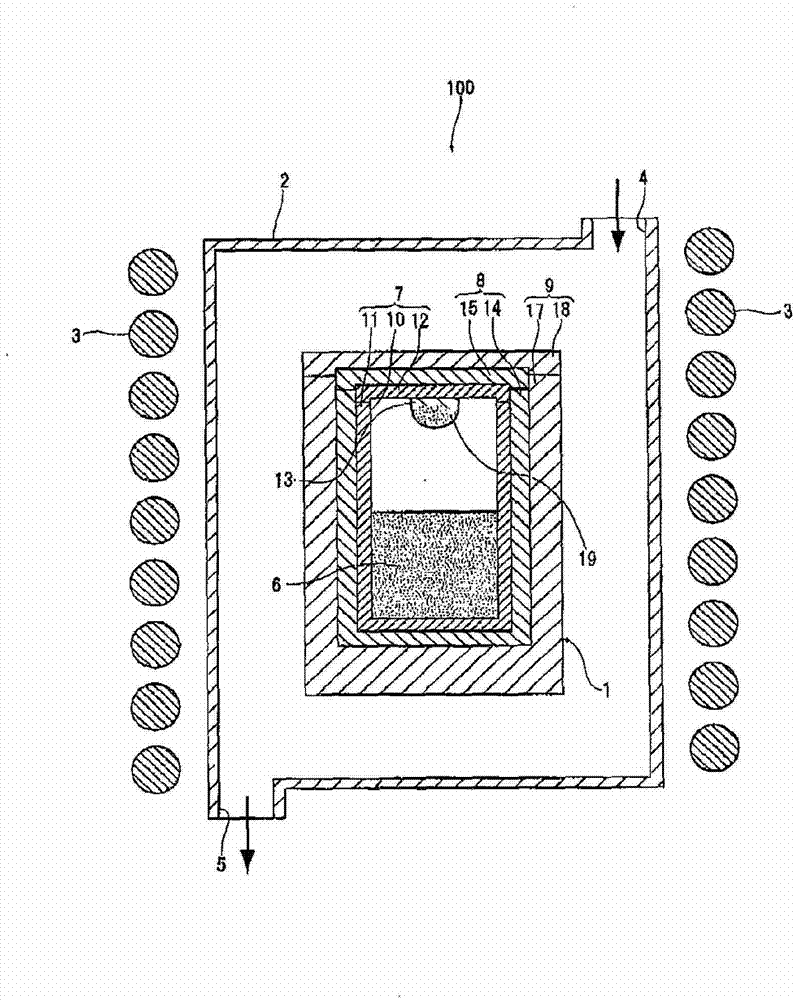

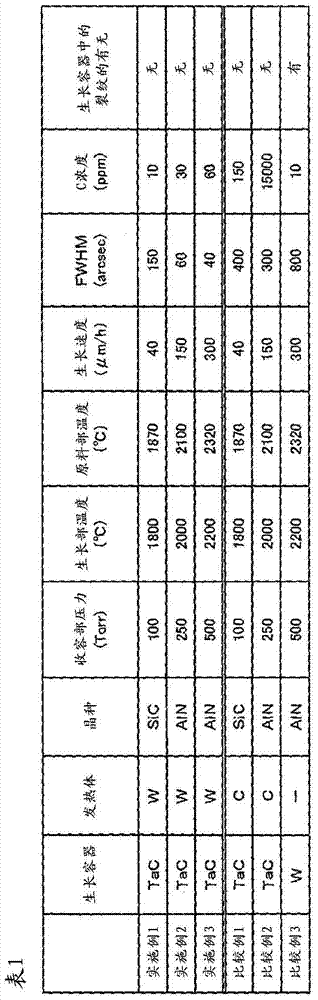

Apparatus and method for production of aluminum nitride single crystal

InactiveCN103249877AReduce the amount of mixingPolycrystalline material growthFrom condensed vaporsMetallic materialsSeed crystal

The invention is an apparatus for production of an aluminum nitride single crystal that produces the aluminum nitride single crystal by heating an aluminum nitride raw material to sublimate the raw material, thereby to recrystallize the aluminum nitride onto a seed crystal, which includes a growth vessel that accommodates the aluminum nitride raw material, and is composed of a material that has corrosion resistance with respect to the aluminum gas generated upon sublimation of the aluminum nitride raw material, and a heating element that is arranged on the outside of the growth vessel, and heats the aluminum nitride raw material through the growth vessel, wherein the growth vessel includes a main body which has an accommodation section that accommodates the aluminum nitride and a lid which seals the accommodation section of the main body hermetically, and wherein the heating element is composed of a metal material containing tungsten.

Owner:FUJIKURA LTD +1

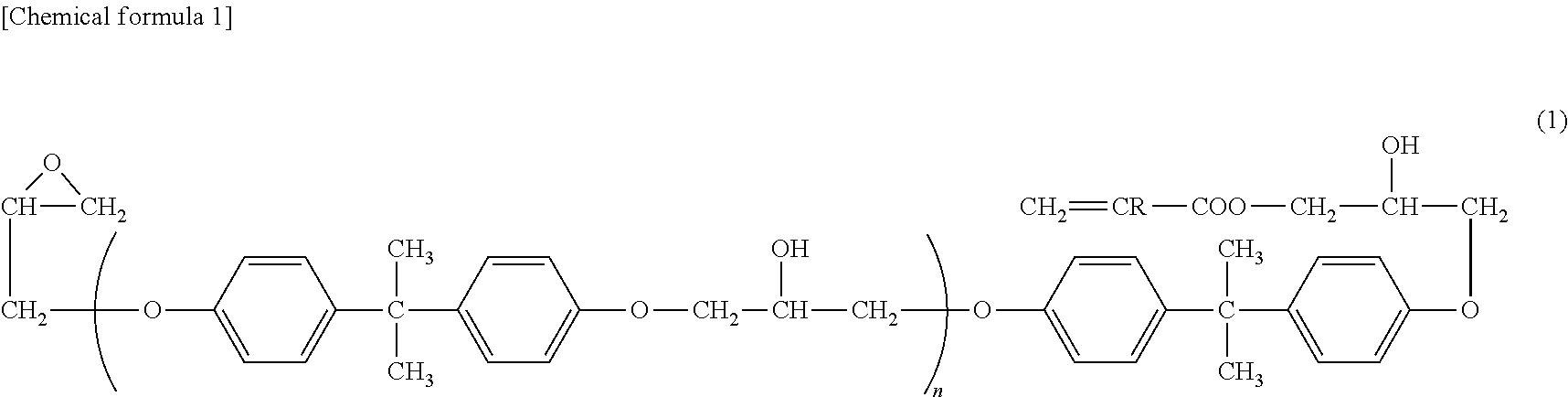

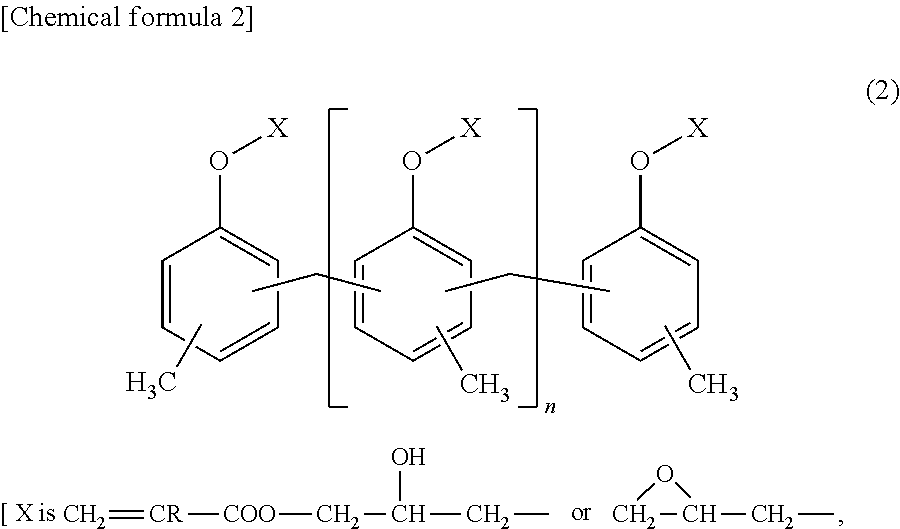

Adhesive agent composition, adhesive sheet, and method for manufacturing semiconductor device

InactiveUS20160086908A1Reduce thicknessLow adhesivenessFilm/foil adhesivesSemiconductor/solid-state device detailsEpoxyDouble bond

An adhesive composition includes an acrylic polymer (A), a heat curable resin (B) having a reactive double bond group, and a filler (C) having a reactive double bond group on a surface thereof. The acrylic polymer (A) has a weight average molecular weight of 500,000 or more, and the heat curable resin (B) comprises an epoxy resin and a heat curing agent, in which at least one of the epoxy resin and the heat curing agent has the reactive double bond group.

Owner:LINTEC CORP

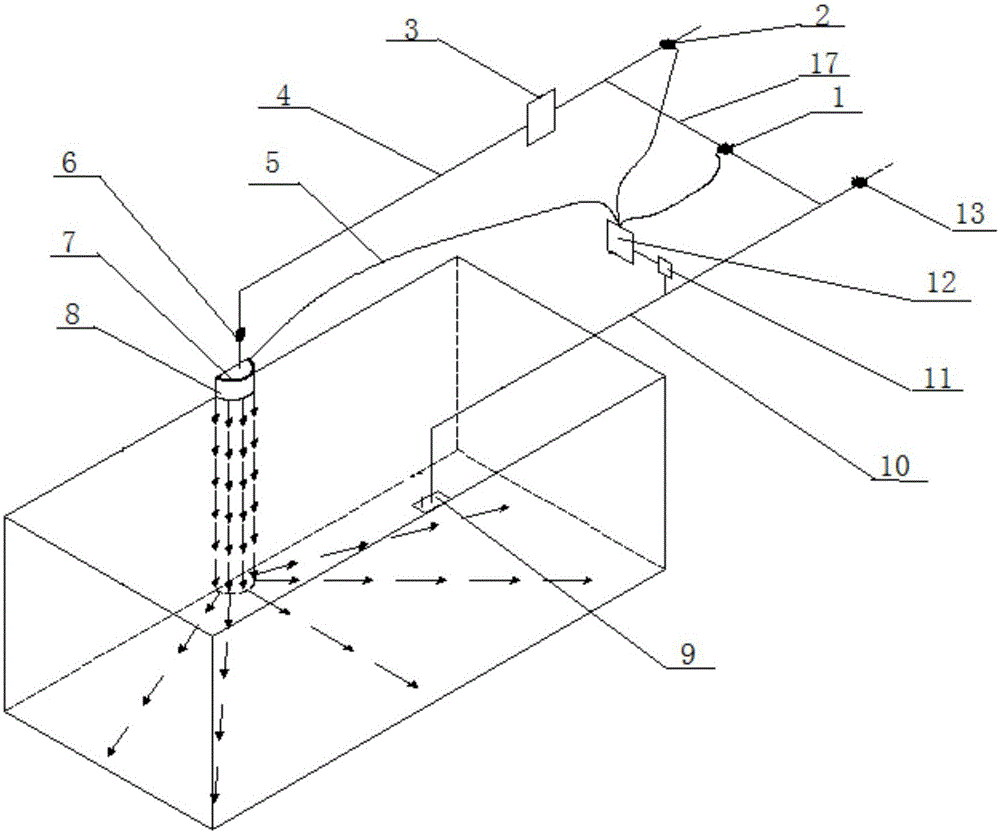

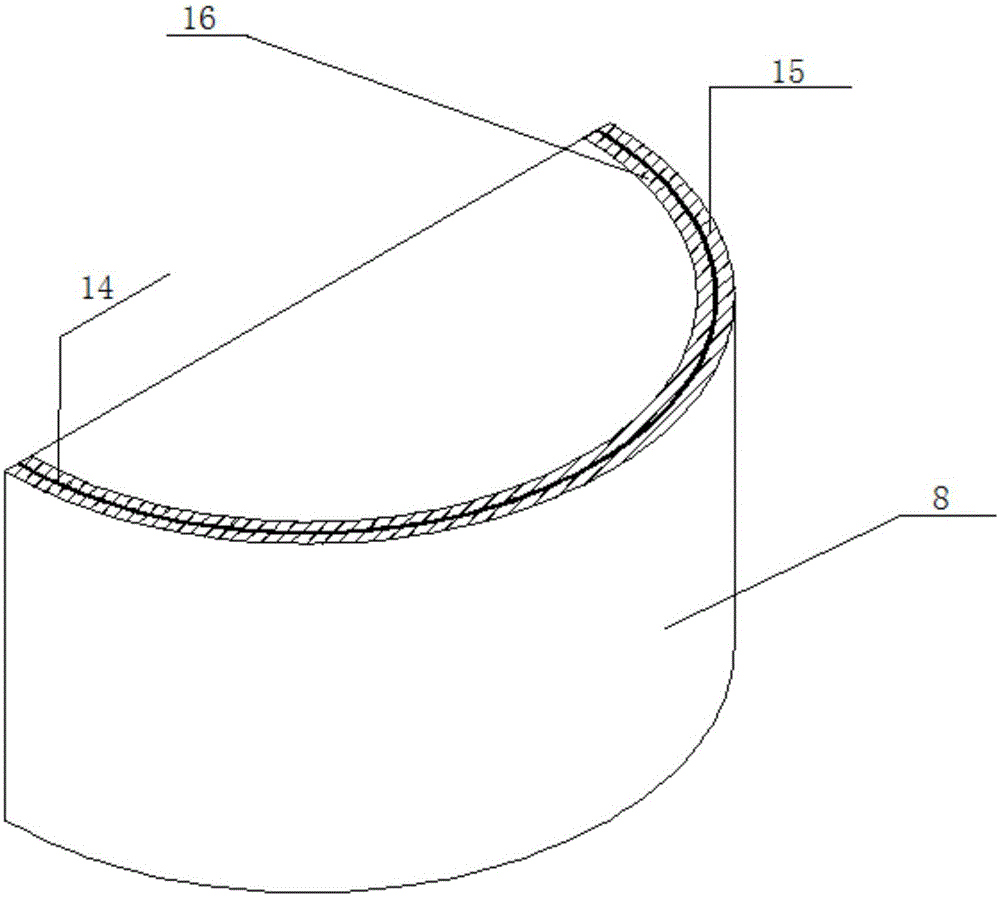

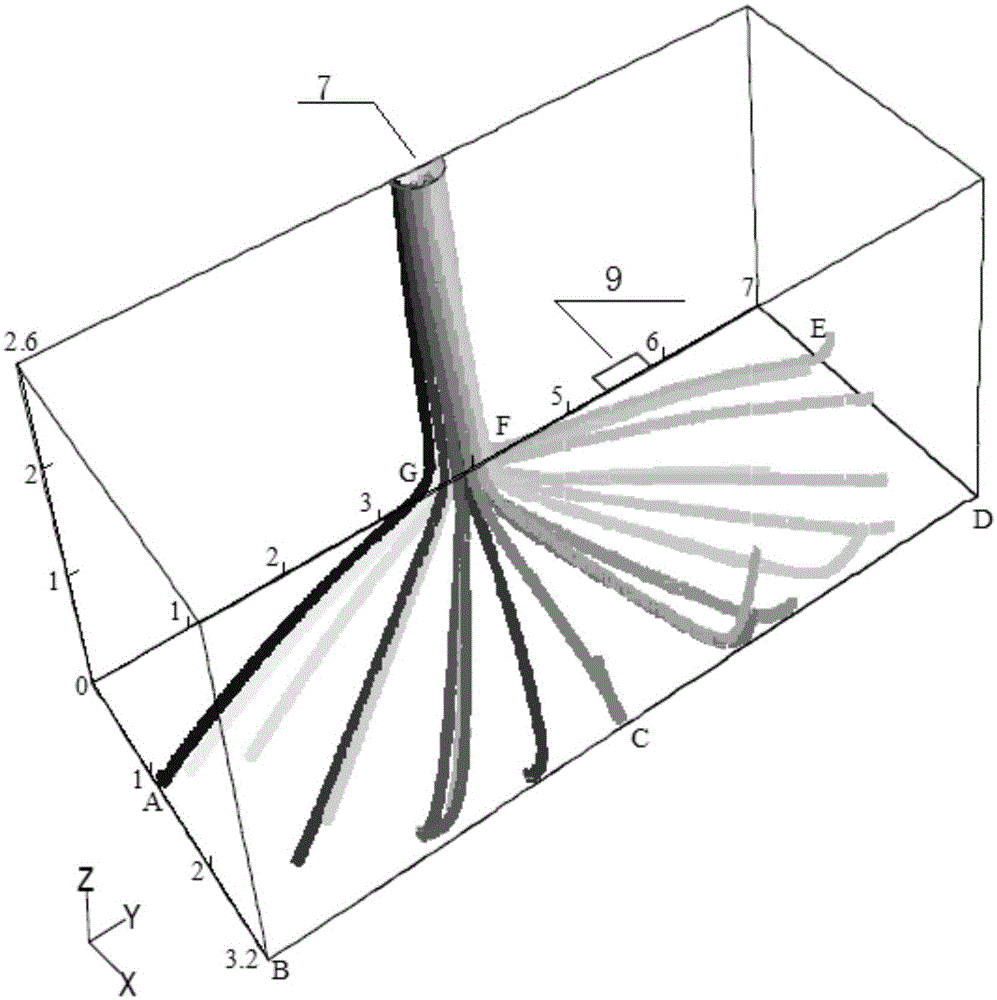

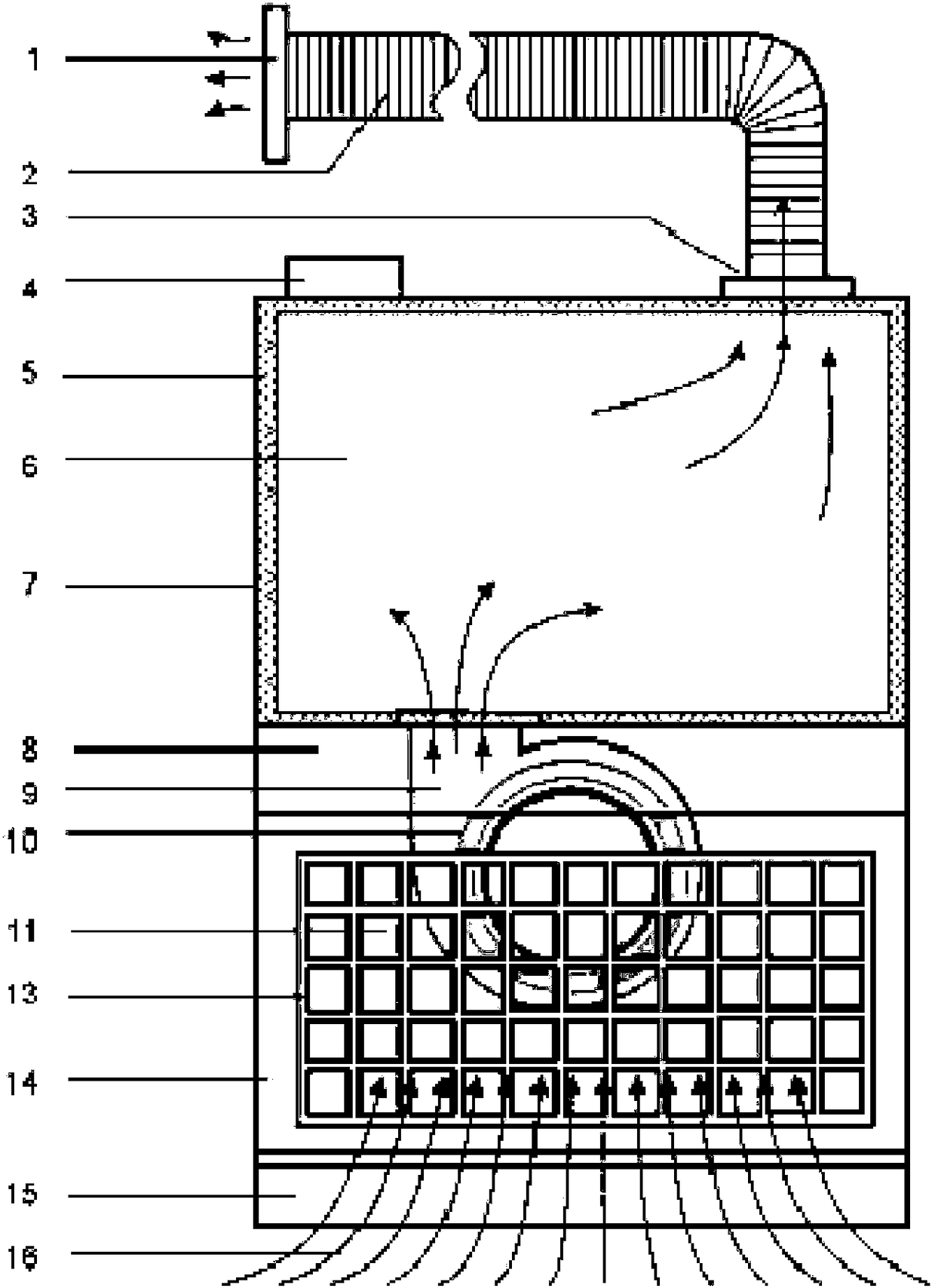

Ventilation device forming airflow organization of air pool, and control method of ventilation device

ActiveCN105135586AImprove qualityReduce entrainmentSpace heating and ventilation safety systemsLighting and heating apparatusCold airDevice form

The invention discloses a ventilation device forming an airflow organization of an air pool, and a control method of the ventilation device. The ventilation device comprises a ventilation duct which is vertically mounted at the top of a room and close to a side wall of the room, wherein the ventilation duct communicates with the room, and the cross section of the ventilation duct is semicircular; the plane of the ventilation duct in the vertical direction is parallel to the side wall of the room, on which the ventilation duct is mounted, an air supply outlet in the top end of the ventilation duct is in external connection with an air supply device; an air exhaust device is also arranged at the top of the room, and communicates with the room. Through the adoption of the ventilation device disclosed by the invention, the mixing amount of the air in the ventilation device with indoor polluted air or hot air is reduced, and the air supply quality is improved; the coverage of a formed cold air pool is extensive, and the supplied airflow is applied to a whole working region at the greatest extent, so that the air freshness of the whole working region is guaranteed; therefore, the air quality of the working region and the temperature and humidity of the working region meet requirements for comfort.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

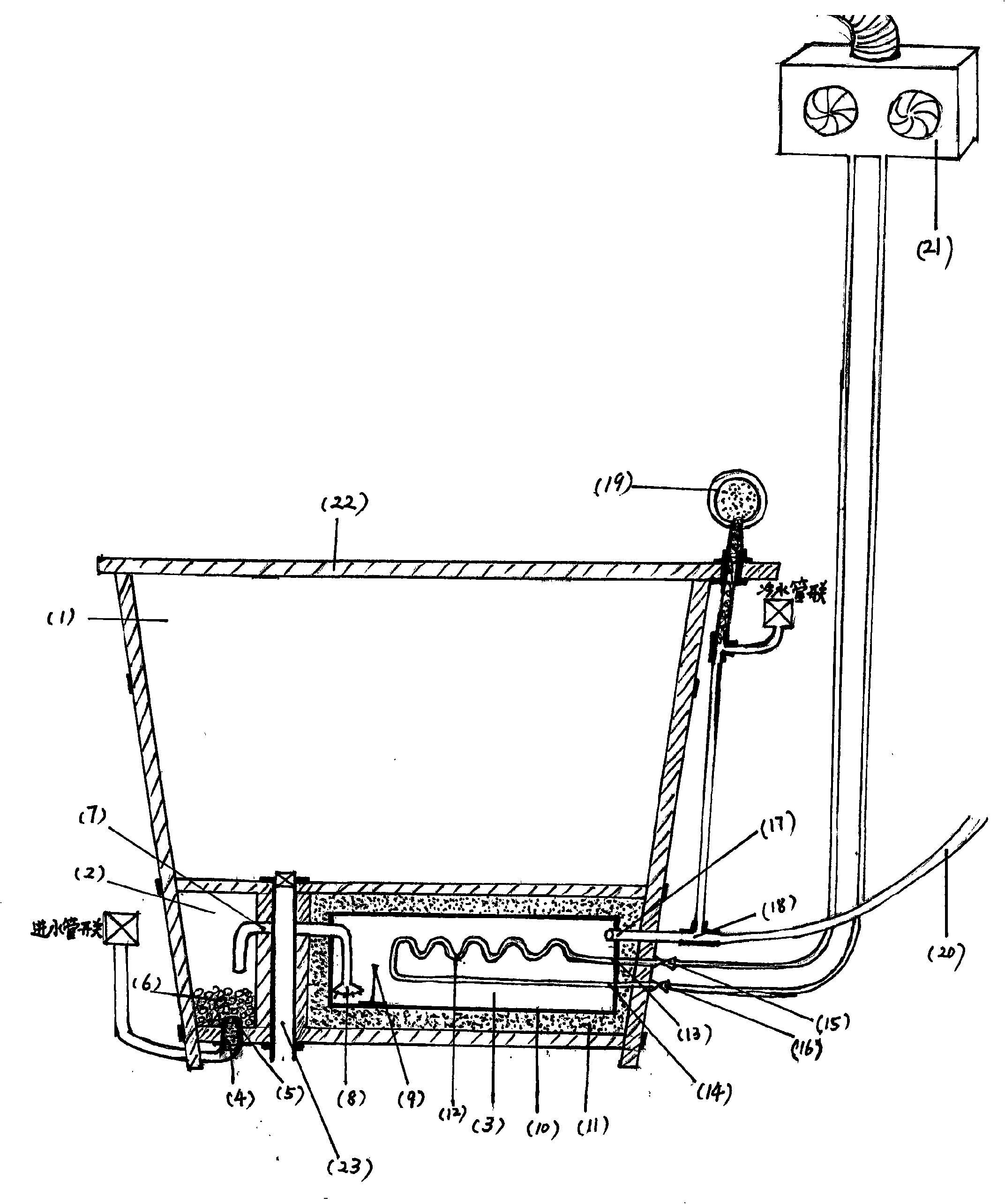

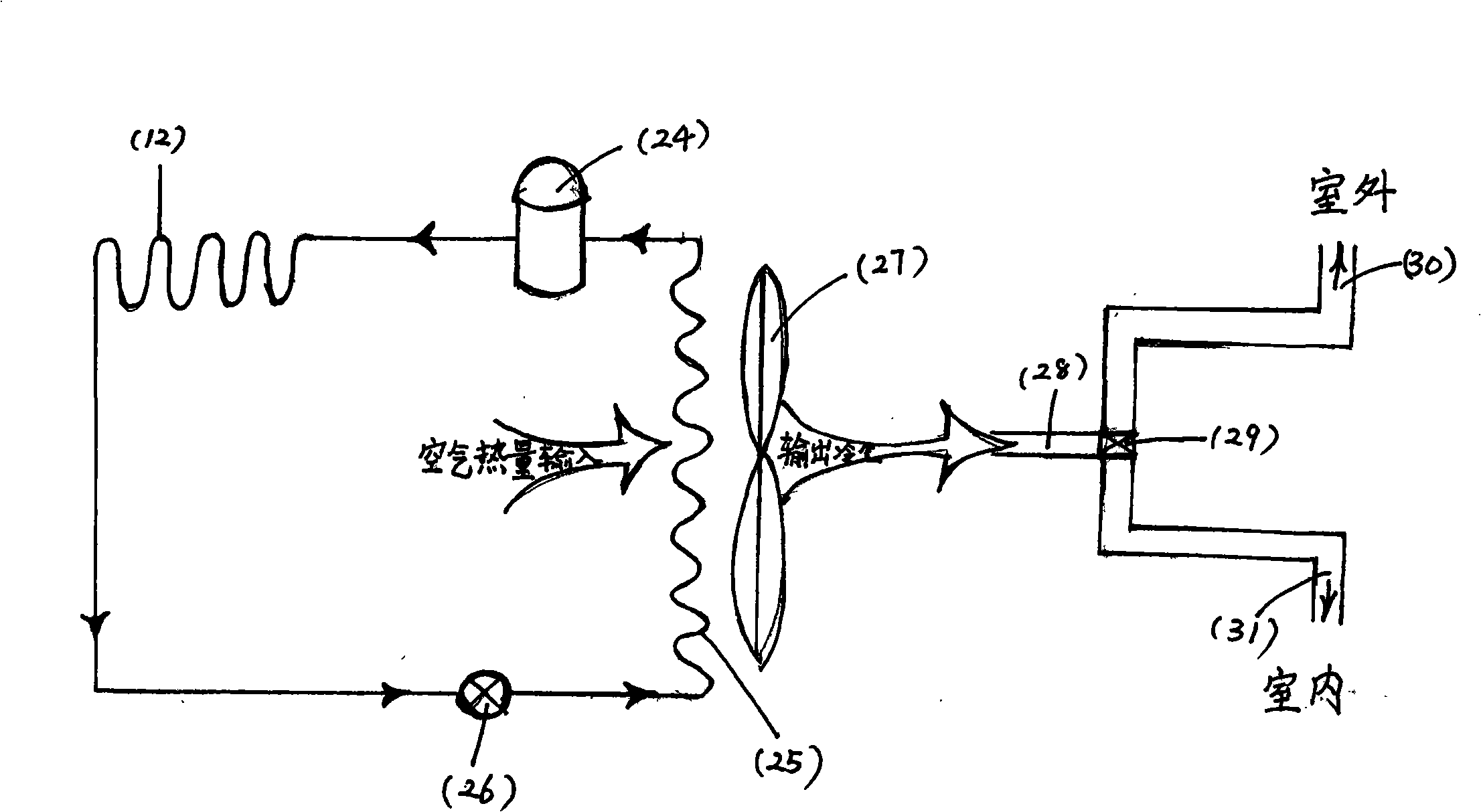

Hot water system of air-source heat pump hot well tub

InactiveCN101332057AReduce areaSolve the problem of large amount of hot waterLighting and heating apparatusBathsWater useHot spring

The invention provides a novel device combining an air source heat pump system and a barrel bath device. By using the bottom space of the wood bath barrel, a double-layer structure is arranged at the bottom part of the wood barrel, wherein, a double bottom interlayer is separately divided into a left bin (2) and a right bin (3) which are connected with each other by a U-shaped pipe. The left bin is provided with a water inlet (5) at the bottom part; a mineral and water filtering device is arranged inside the bin to ensure domestic water to meet the efficacy of thermal water. The right bin is internally provided with a metal thermal insulation bearing water tank (10); a condenser (12) is arranged inside the water tank and connected with an air source heat pump mainframe (21) to produce hot water; the right bin is provided with an water outlet (17) connected with the water using end such as a shower, and the like, by a tee joint regulator. An uplift side jacket top cover (22) is arranged at the top end of the wood barrel. The invention provides the air source heat pump thermal water wood barrel hot water system and by using an indoor air changing principle, the system has the advantages of absorbing the heat storage in the outdoor discharging exhaust, producing domestic water with low cost and intensifying indoor space, thus expanding the application range of the air source heat pump.

Owner:郭兴海 +1

Vegetable hydroponic nutrient solution containing amino acids as well as preparation method and application thereof

InactiveCN111592429AIncrease productionWell developed root systemMagnesium fertilisersAlkali orthophosphate fertiliserNutritionNutrient solution

The invention provides a vegetable hydroponic nutrient solution containing amino acids as well as a preparation method and application thereof, and belongs to the field of plant growth. The inventionprovides the organic and inorganic composite nutrient solution, which breaks through the conventional pure inorganic mineral nutrient solution and is supplemented with organic components such as aminoacids. The disclosed hydroponic nutrient solution contains compound amino acids, has the fertilizer efficiency higher than that of simple substance amino acids, and has the effects of strengthening root systems, promoting greening, increasing tillering and improving stress resistance, thereby improving the crop yield. The amino acids have a special promotion effect on root development of crops,can be directly absorbed by a root system in a complete molecular form and can be assimilated in crop bodies through transamination, deamination and other processes to synthesize protein or form metabolism energy, and form organic acids, carbohydrate and other nutrients; in addition, amino acids can promote the activity of nitrate reductase in crop leaves, and meanwhile, the amino acids are used as a nitrogen source to partially replace nitrate, so that the content of nitrate in crops can be reduced, and the quality of the crops can be improved.

Owner:漳州三炬生物技术有限公司

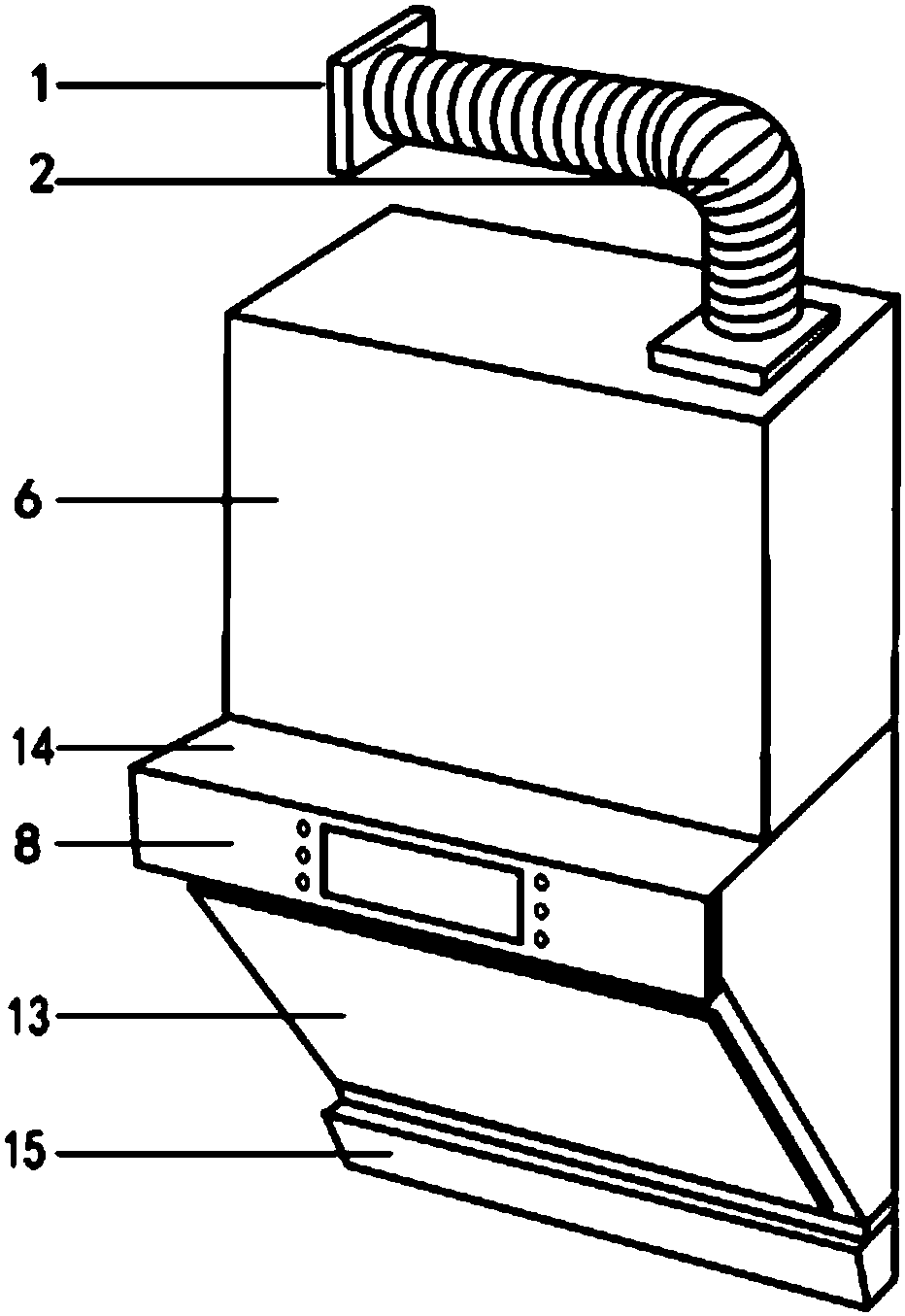

High-static-pressure cooking lampblack treatment device and range hood

PendingCN108286725AAvoid resistanceIncrease effective energyDomestic stoves or rangesLighting and heating apparatusEngineeringCheck valve

The invention belongs to the technical field of cooling lampblack exhaust and discloses a high-static-pressure cooking lampblack treatment device and a range hood. The high-static-pressure cooking lampblack treatment device comprises a lampblack suction structure, a lampblack grease and particle removal structure, a lampblack exhaust structure and a silencing structure, wherein the lampblack suction structure is composed of a condenser plate, a negative-pressure distribution filter and a lampblack suction fan; the lampblack grease and particle removal structure is composed of the negative-pressure distribution filter; the lampblack exhaust structure is composed of the lampblack suction fan, a static pressure tank, an exhaust pipeline and a check valve; and the silencing structure is composed of the negative-pressure distribution filter, the static pressure tank and a lining sound absorption material. According to the high-static-pressure cooking lampblack treatment device, the static pressure tank is arranged at an air outlet of the lampblack suction fan, the flowing pressure of gas discharged from the lampblack suction fan is further converted into static pressure; under the condition of not increasing the power of the range hood, effective energy of resistance of the exhaust pipeline is overcome to the maximum extent to achieve complete exhaustion of lampblack; meanwhile, through reasonable arrangement of the negative-pressure distribution filter and the lining sound absorption material of the static pressure tank, the high-static-pressure cooking lampblack treatment device achieves the effects of high efficiency, silence and environmental protection.

Owner:ZHONGSHAN CALCULUS SCI & TECH LTD

Absorber comprising pulp, tea dregs and water absorbent resin; sanitary articles using the absorber and production method thereof

InactiveUS8581018B2Reduce the amount of mixingSlight non-uniformityLaminationLamination apparatusFiberPulp and paper industry

Owner:DAIKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com