Blasting control method for improving ore breaking efficiency of wall-cutting filling method

A technology for controlling blasting and ore falling. It is applied in blasting, filling, ground mining, etc. It can solve the problems of restricting mine development, less ore falling, and low production efficiency, so as to reduce the amount of waste rock mixed in and increase the amount of caving ore. , The effect of improving the efficiency of falling ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

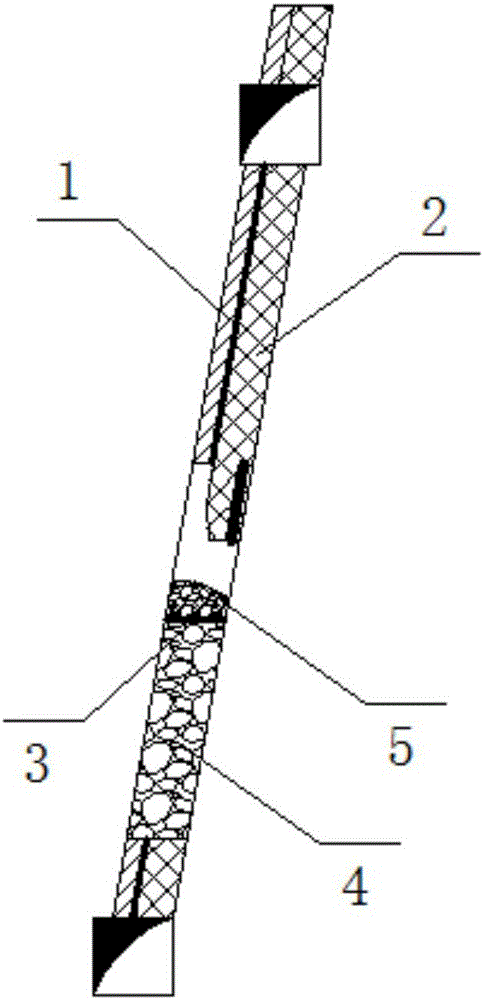

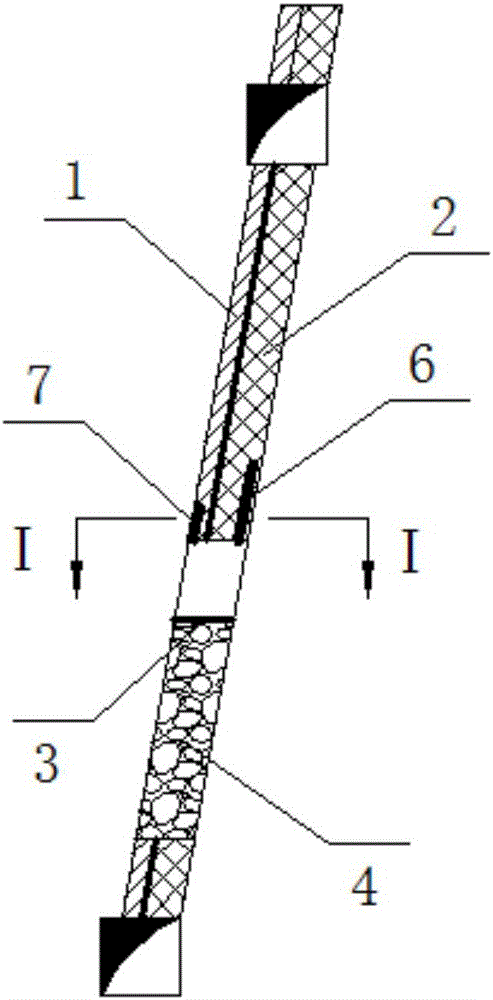

[0022] Such as figure 1 As shown, the present invention provides a kind of controlled blasting method that improves the ore-cutting efficiency of wall-cutting filling method, and described controlled blasting method is to introduce the controlled blasting technology of twice dropping ore once-cutting wall in existing wall-cutting filling method, and specific process is as follows :

[0023] First, if figure 2 As shown in Fig. 1, drill a blast hole in the ore lode, drill a blast hole in the surrounding rock of the wall or footwall, directly charge and detonate in the blast hole, and implement blasting in the blast hole once;

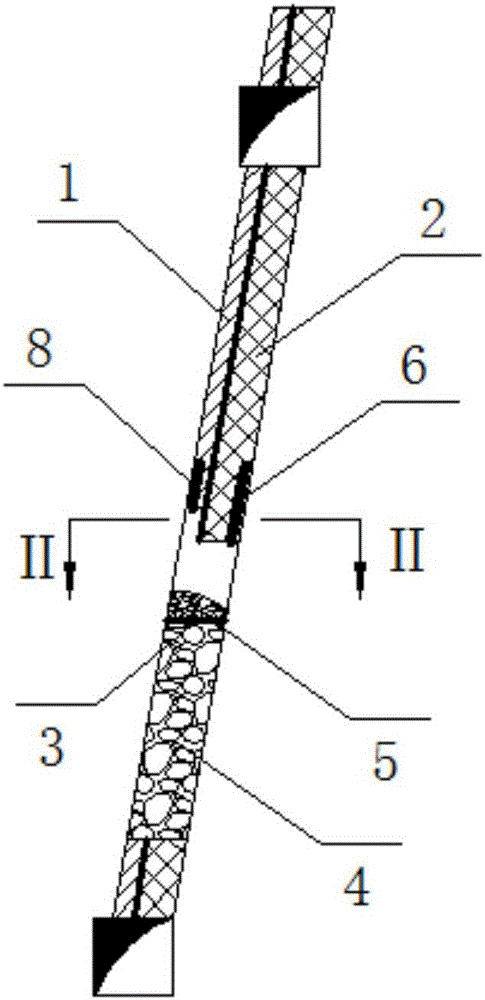

[0024] Then, if image 3 Shown, after one ore falling, ventilate through enough time, continue to drill second time ore falling blasthole on the once...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com