Mining method for steep-inclination unstable thin ore body

A mining method and thin ore body technology, applied in the field of steeply inclined and unstable thin ore body mining, can solve problems such as ore body caving and safety hazards, achieve high efficiency, improve ore falling efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

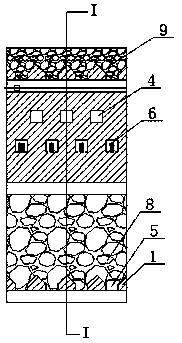

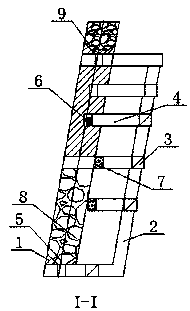

[0017] A method for mining steeply inclined unstable thin ore bodies, comprising the following steps:

[0018] A. The ore body is divided into ore blocks, the height of the ore block is 45m, and the width of the ore block is 60m; there is no spacer and top pillar in the ore block, only the bottom pillar 1, and the thickness of the bottom pillar 1 is 5m;

[0019] B. Mining and cutting: First, excavate the pedestrian patio 2, which is arranged at the footwall of the ore body 10m away. The pedestrian patio 2 is excavated from the pedestrian patio 2 at intervals of 5m to excavate the footwall layered along the vein transportation lane 3, and the footwall is layered along the vein The transportation roadway 3 excavates layered rock drilling piercing veins 4 every 6m to the middle of the ore body, and the adjacent layered rock drilling piercing veins 4 are arranged in a staggered manner. The space between the bodies also provides blasting compensation space for the first stratified ...

Embodiment 2

[0024] A method for mining steeply inclined unstable thin ore bodies, comprising the following steps:

[0025] A. Divide the ore body into ore blocks, the height of the ore block is 80m, and the width of the ore block is 100m; there is no spacer and top pillar in the ore block, only the bottom pillar 1, and the thickness of the bottom pillar 1 is 10m;

[0026] B. Mining and cutting: First, excavate the pedestrian patio 2, which is arranged at the footwall of the ore body 15m away. The pedestrian patio 2 is excavated from the pedestrian patio 2 at intervals of 10m to excavate the footwall layered along the vein transportation lane 3, and the footwall is layered along the vein The transportation roadway 3 excavates layered rock-drilling veins 4 every 10m to the middle of the ore body, and the adjacent layered rock-drilling veins 4 are arranged in a staggered manner. The space between the bodies also provides blasting compensation space for the first stratified recovery work;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com