Apparatus and method for production of aluminum nitride single crystal

A technology for manufacturing devices and aluminum nitride, which is applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., and can solve problems such as limited materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

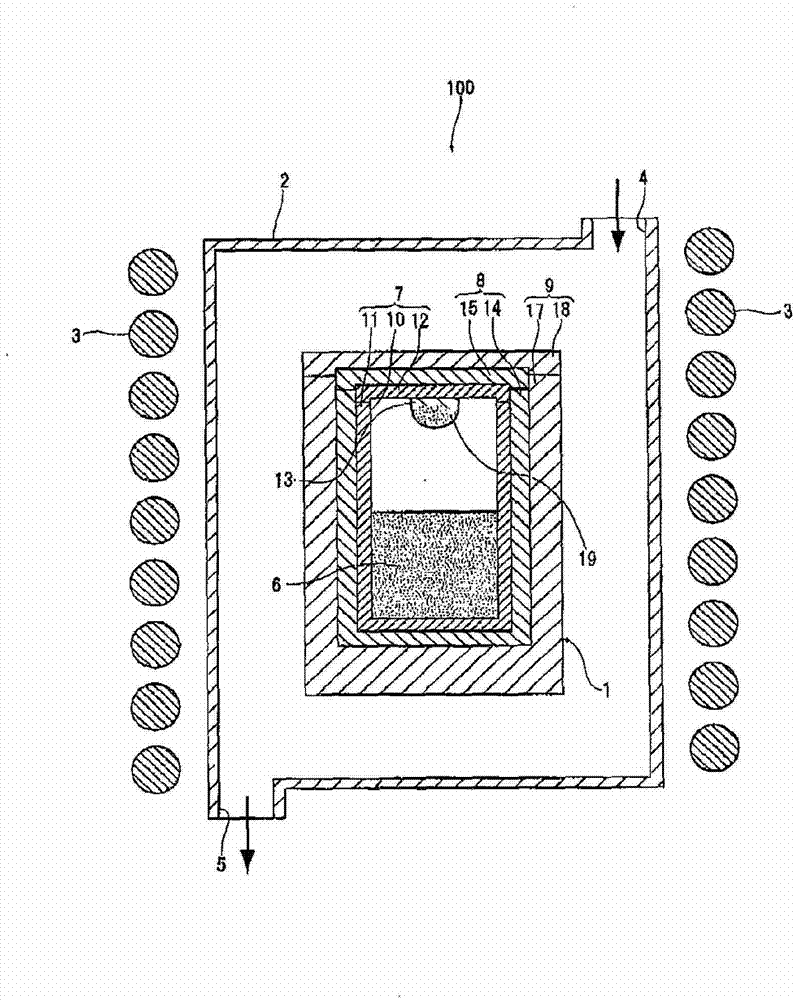

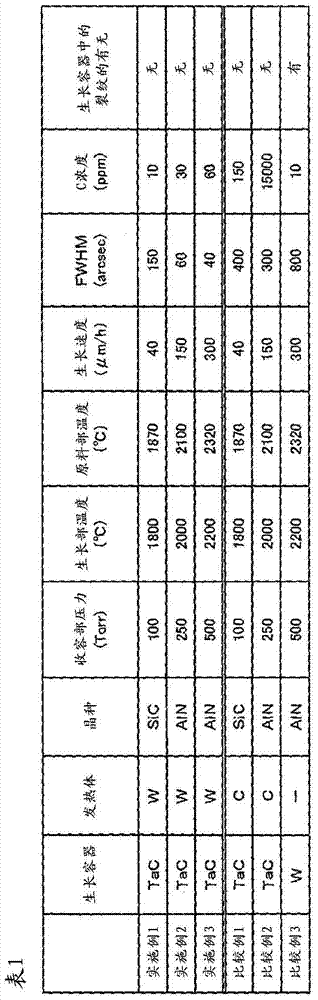

[0055] use figure 1 The production apparatus shown produces an aluminum nitride single crystal as follows. That is, firstly, it is assumed that the cover 18 of the heat insulating material 9 made of carbon is removed, the cover 15 of the heating element 8 made of simple tungsten is removed, and the cover of the growth container 7 made of tantalum carbide (TaC) is removed. 12. Then, aluminum nitride powder as a raw material is accommodated in the accommodation portion 10 of the growth vessel 7 . On the other hand, a seed crystal 13 having a diameter of 2 inches and a thickness of 0.5 mm was carried on the cover 12 with an adhesive. At this time, 6H-SiC (0001) was used as a seed crystal.

[0056] Then, the housing portion 10 of the main body portion 11 of the growth container 7 is sealed by the lid body 12 . Next, the main body 14 of the heating element 8 is sealed by the lid 15 , and finally the main body 17 is sealed by the lid 18 .

[0057] Then, the crystal growth unit ...

Embodiment 2)

[0060] As shown in Table 1, the seed crystal was changed to the aluminum nitride crystal produced in Example 1, the pressure in the housing part was changed to 250 Torr, the temperature of the growth part and the temperature of the raw material part were changed to 2000 ° C and 2100 ° C, respectively, except Otherwise, aluminum nitride crystals were grown in the same manner as in Example 1.

Embodiment 3)

[0062] As shown in Table 1, the seed crystal was changed to the aluminum nitride single crystal prepared in Example 1, the pressure in the housing part was changed to 500 Torr, and the temperature of the growth part and the raw material part were changed to 2200 ° C and 2320 ° C, respectively. Except for this, an aluminum nitride single crystal was grown in the same manner as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com