Vegetable hydroponic nutrient solution containing amino acids as well as preparation method and application thereof

A vegetable water and nutrient solution technology, applied in the field of plant growth, can solve the problems of high nitrate content in vegetables, which is not good for health, and achieve the effects of maintaining calcium element activity, improving crop quality, and improving stress resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

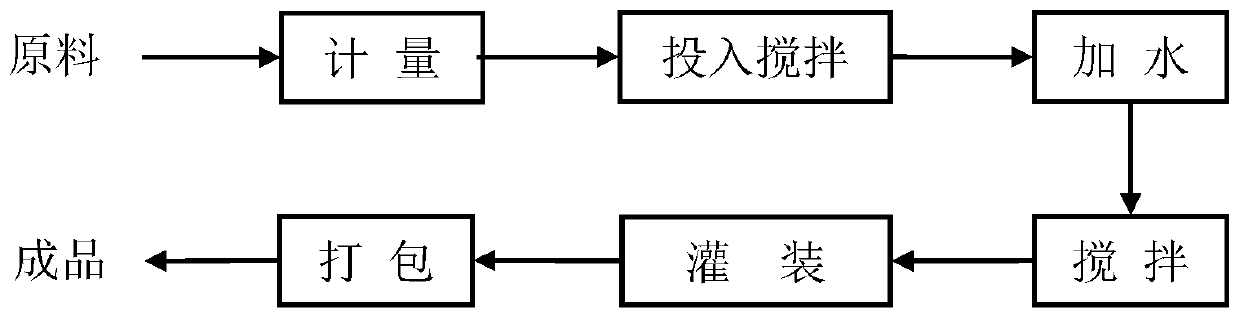

[0030] The present invention also provides a preparation method of the vegetable hydroponic nutrient solution described in the above technical solution, comprising the following steps:

[0031] Mix amino acid liquid, calcium sugar alcohol, calcium nitrate, potassium nitrate, EDTA-Fe and water to obtain liquid A;

[0032] Mix monoammonium phosphate, potassium dihydrogen phosphate, ammonium sulfate, anhydrous magnesium sulfate, manganese sulfate, boric acid, zinc sulfate, copper sulfate, ammonium molybdate and water to obtain liquid B;

[0033] The liquid A and the liquid B are stored separately and packaged to obtain the vegetable hydroponic nutrient solution.

[0034] In the present invention, the amino acid solution is preferably a compound amino acid, and the free amino acid content in the amino acid solution is preferably above 300 g / L.

[0035] In the present invention, the amino acid liquid preferably includes glutamic acid, proline, glycine, alanine, serine, aspartic ac...

Embodiment 1

[0045] A vegetable hydroponic nutrient solution containing amino acids, including elements of the following concentrations: nitrogen 43.29g / L (containing organic nitrogen 2.16g / L), phosphorus 16.63g / L, potassium 67.13g / L, calcium 29.661g / L (with chelated calcium 4.32g / L), magnesium 8.519g / L, iron 0.697g / L, manganese 0.187g / L, boron 0.178g / L, zinc 0.018g / L, copper 0.007g / L, molybdenum 0.004 g / L.

[0046] Preparation of liquid A: Weigh potassium nitrate, calcium nitrate and EDTA-Fe into the mixing tank according to the formula requirements, add water and stir to fully dissolve, weigh amino acid solution and sugar alcohol calcium according to the formula requirements, continue to add into the mixing tank, and mix well;

[0047] Preparation of liquid B: Weigh monoammonium nitrate phosphate, potassium dihydrogen phosphate, and ammonium sulfate into the mixing tank according to the formula requirements, add water and stir to fully dissolve, weigh anhydrous magnesium sulfate, mangane...

Embodiment 2

[0050] The nutrient content of liquid A and B is: nitrogen 48.10g / L (containing organic nitrogen 2.4g / L), phosphorus 18.48g / L, potassium 74.59g / L, calcium 32.96g / L (containing chelated calcium 4.8g / L), magnesium 9.47g / L, iron 0.774g / L, manganese 0.207g / L, boron 0.198g / L, zinc 0.02g / L, copper 0.008g / L, molybdenum 0.004g / L.

[0051] Production technology is with " embodiment 1 ".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com