Sublevel caving collaborative mining method with flexible isolating course as artificial roof

A technology of segmented caving and mining methods, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of poor effect of single-head ventilation tunnels and high rock mixing rate, and reduce the dilution rate and loss rate. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

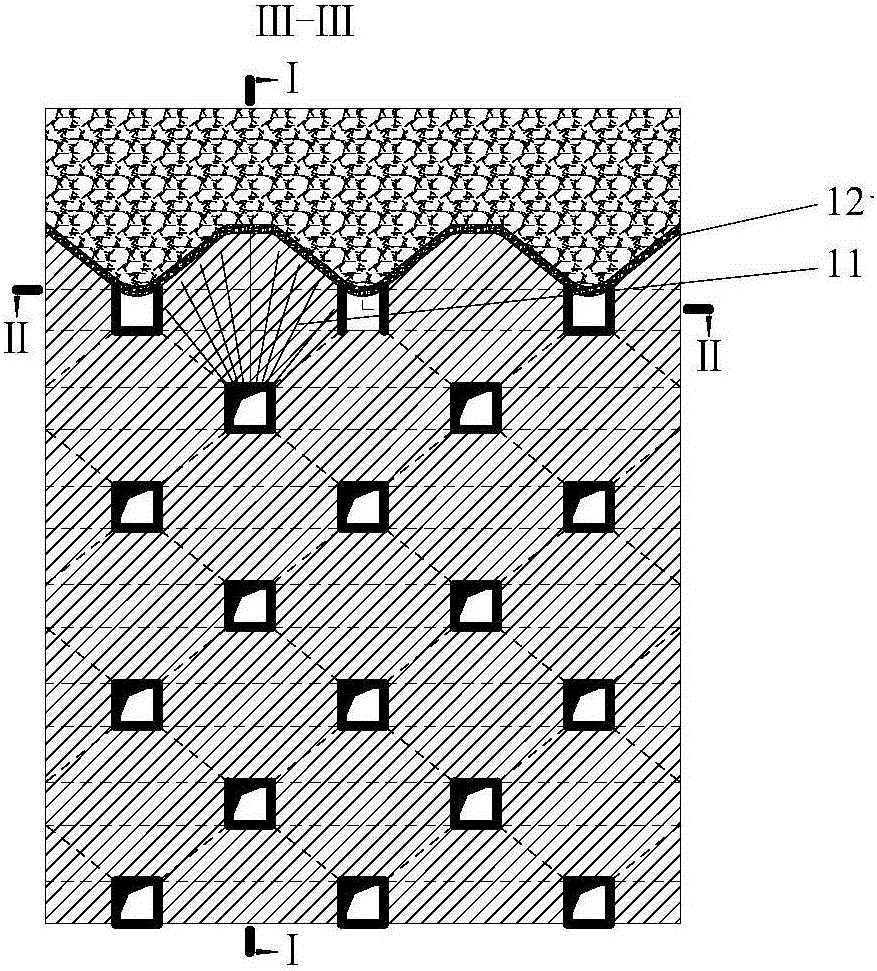

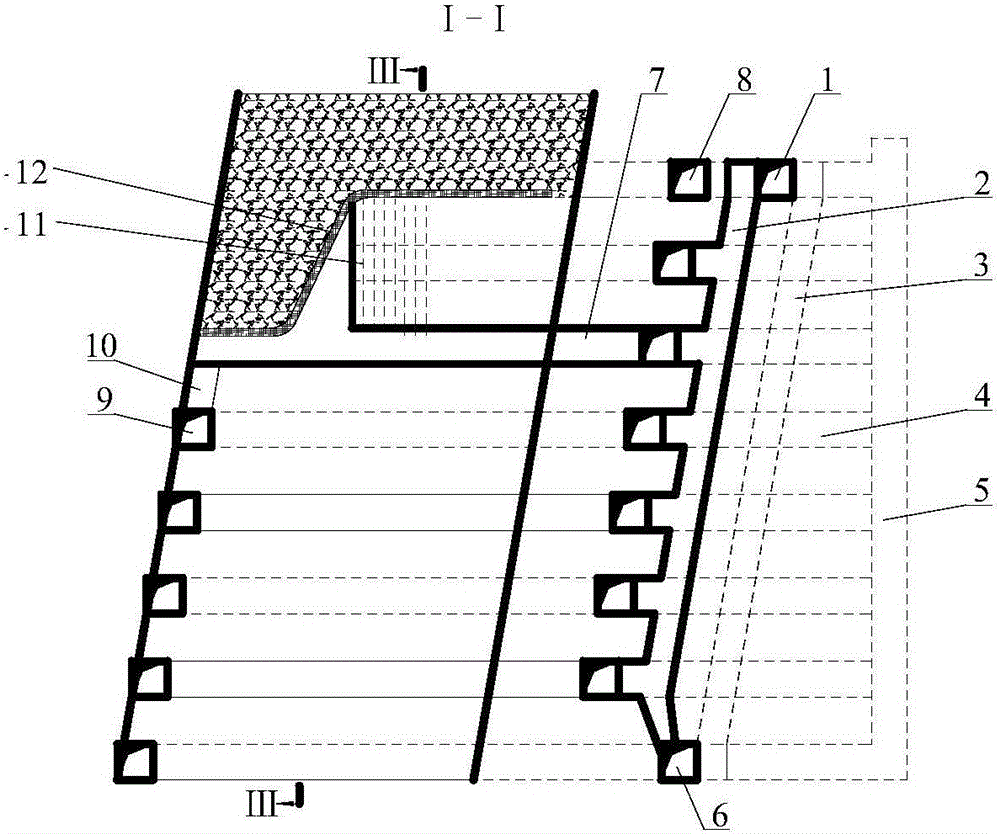

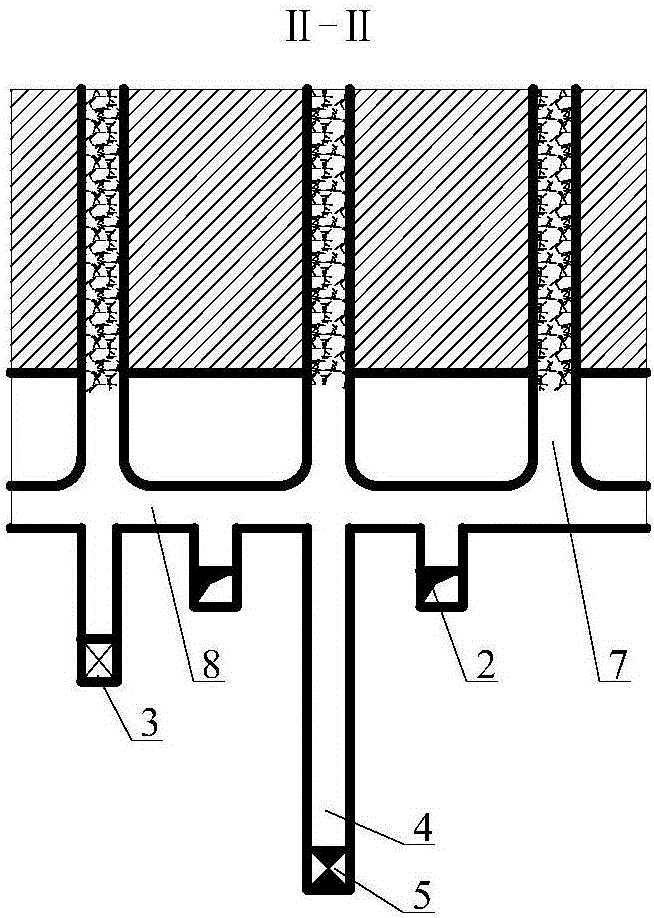

[0023] refer to figure 1 , figure 2 with image 3 , the present embodiment carries out mining for the steeply inclined thick ore body with solid ore body, comprising the following steps:

[0024] (1) Divide the steeply inclined thick ore body into stages, and divide the stages into ore blocks along the strike. The ore blocks are 60m long and 20m wide, and they are layered according to 7-8m; a 3m-high formation is mined by the pillar method on the upper part of the ore block. The top space, and flexible materials are laid on the bottom plate in the order of steel wire rope, metal mesh and polyester fiber, and then the covering is lowered to form a covering layer.

[0025] (2) From the stage along the vein transportation roadway 6, a ventilated pedestrian patio 3 with a size of 2m×2m and an ore chute 2 with a size of 2m×2m are excavated upwards to connect the upper stage along the vein transportation roadway 1, and 3m×3m is excavated from the ore chute 2 The sub-level transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com