Method for collecting asphalt smog in vibration formation process of prebaked anode

A technology of vibration forming and pre-baked anodes, which is applied in material forming presses, presses, manufacturing tools, etc., can solve the problems of poor collection effect of bitumen smoke pollution sources, and achieve less exhaust air, less mixing, and energy efficiency. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

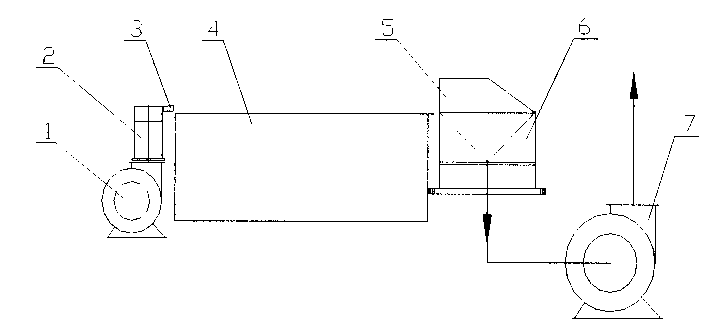

[0015] The flat air nozzle with the same width as the forming mold bucket is placed above the mouth of the vibrating forming mold of the prebaked anode, the air velocity is 5m / s, and the jet is blown into the airflow by a blower at 10° below the horizontal. The formed air curtain passes through the upper opening of the crane hopper or the mobile feeder of the vibration forming machine, and sends the asphalt fumes escaping from the hopper to the suction port, and the polluted air captured by the suction port is sent by a suction fan through the suction hood. To the purification system, the absorption rate of asphalt fume reaches 94%. .

Embodiment 2

[0017] The flat air nozzle with the same width as the forming mold bucket is placed above the mouth of the prebaked anode’s vibration forming forming mold, the air velocity is 8m / s, and the ejection is 6° below the horizontal level, and it will be blown into the air by a blower. The formed air curtain passes through the upper opening of the crane hopper or the mobile feeder of the vibration forming machine, and sends the asphalt fumes escaping from the hopper to the suction port, and the polluted air captured by the suction port is sent by a suction fan through the suction hood. To the purification system, the absorption rate of asphalt fume reaches 95%.

Embodiment 3

[0019] The flat air nozzle with the same width as the forming mold bucket is placed above the mouth of the vibrating forming mold of the prebaked anode, the airflow speed is 10m / s, and the spray is 10° below the horizontal level, and then it will be blown into the airflow by a blower. The formed air curtain passes through the upper opening of the crane hopper or the mobile feeder of the vibration forming machine, and sends the asphalt fumes escaping from the hopper to the suction port, and the polluted air captured by the suction port is sent by a suction fan through the suction hood. To the purification system, the absorption rate of asphalt fume reaches 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com