Non-intermittent industrial oil refining treatment technology and automatic refining system

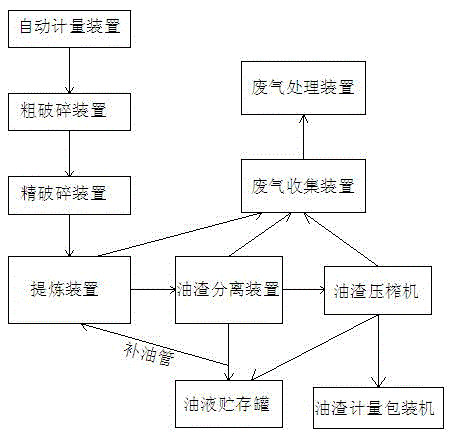

A treatment process, non-intermittent technology, applied in the direction of fat oil/fat production, fat generation, etc., can solve the problems of non-intermittent production, insufficient treatment of waste gas and oil residue, and more impurities in oil, etc., to achieve non-stop Intermittent operation, reducing the amount of oil residue mixed, and the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] ① Measuring, the frozen raw material or fresh animal fat is weighed and measured through an automatic measuring device;

[0056] ②, crushing, step ① The measured raw materials are transported to the coarse crushing device and the fine crushing device through the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 10mm;

[0057] ③. Refining, step ② The crushed granular raw materials are sent to the refining tank of the refining device through the material conveying dragon. In the refining tank, the first 30 minutes are heated, and the temperature of the heat transfer oil is 240 ° C, so that the temperature of the material is raised to 150 ° C. 30-60min is for oil output, the temperature of heat transfer oil is 240°C, the material temperature is 200°C and a large amount of oil is started, 60-90min is for boiling, the material temperature is controlled at 160°C, 90-120min is for output, and the material temperature is 120 ℃,...

Embodiment 2

[0063] ① Measuring, the frozen raw material or fresh animal fat is weighed and measured through an automatic measuring device;

[0064] ②, crushing, step ① The measured raw materials are transported to the coarse crushing device and the fine crushing device through the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 8mm;

[0065] ③. Refining, step ② The crushed granular raw materials are sent to the refining tank of the refining device through the material conveying dragon. In the refining tank, the first 30 minutes are heated, and the temperature of the heat transfer oil is 260 ° C, so that the temperature of the material is raised to 150 ° C. 30-60min is for oil output, the temperature of the heat transfer oil is 230°C, and a large amount of oil is started when the material temperature is 200°C, 60-90min is for boiling, the material temperature is controlled at 170°C, 90-120min is for output, and the material temperature is...

Embodiment 3

[0071] ① Measuring, the frozen raw material or fresh animal fat is weighed and measured through an automatic measuring device;

[0072] ②, crushing, step ① The measured raw materials are transported to the coarse crushing device and the fine crushing device through the automatic conveyor belt for crushing, and the crushed raw materials are particles with a diameter of 12mm;

[0073] ③. Refining, step ② The crushed granular raw materials are sent to the refining tank of the refining device through the material conveying dragon. In the refining tank, the first 30 minutes are heated, and the temperature of the heat transfer oil is 220 ° C, so that the temperature of the material is raised to 150 ° C. 30-60min is for oil output, the temperature of the heat transfer oil is 250°C, the material temperature is 200°C and a large amount of oil is produced, 60-90min is for boiling, the material temperature is controlled at 150°C, 90-120min is for output, the material temperature is 125 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com