High-refractive-index and low-dispersion optical glass and preparation method thereof

A technology of optical glass and high refractive index, applied in the field of optical glass, can solve the problems of high price, high cost and high content, achieve the effect of reasonable distribution and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

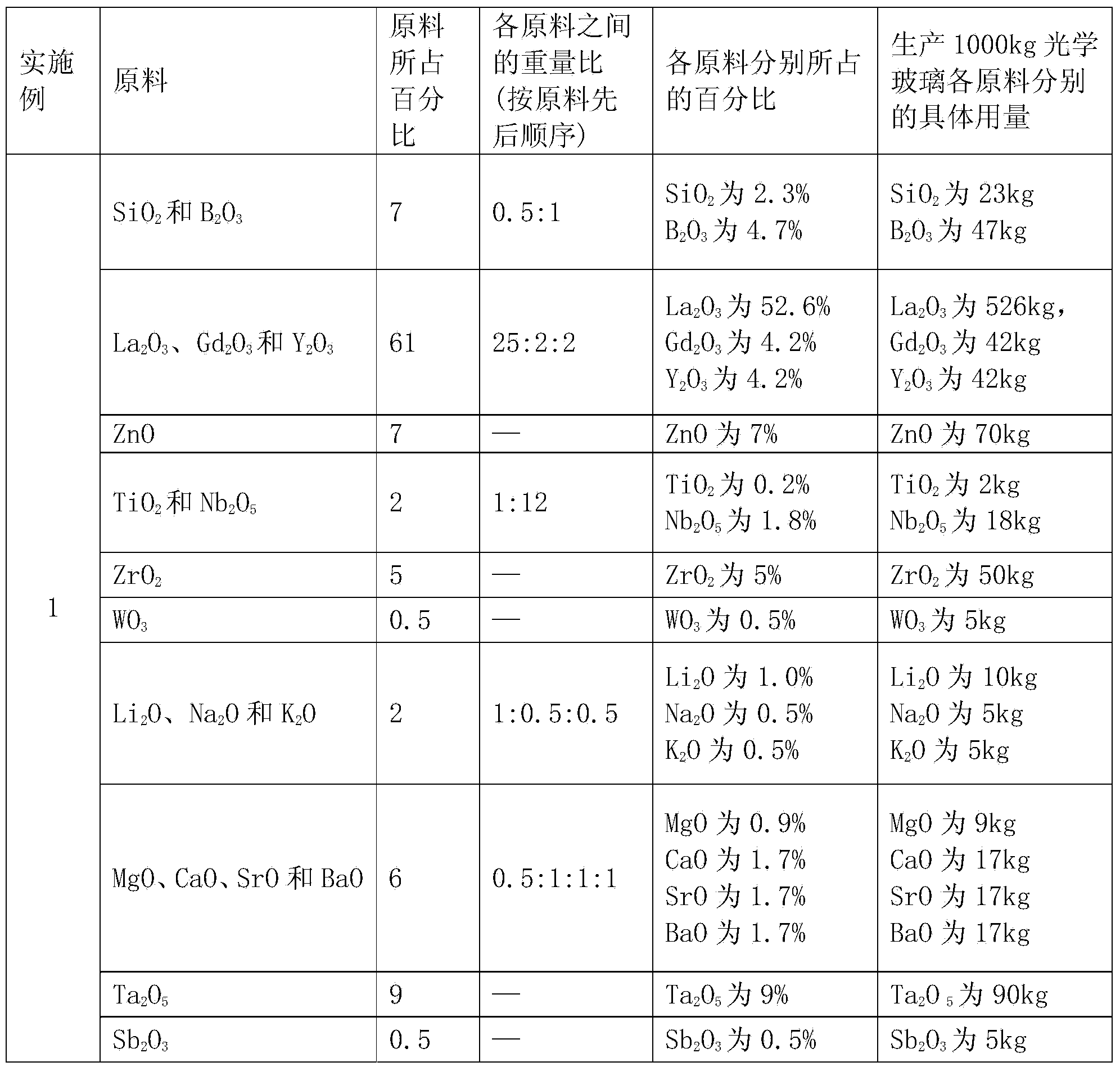

Embodiment 1

[0082] 1.1 An optical glass with high refractive index and low dispersion, whose refractive index is 1.87≤nd≤1.89, Abbe number is 38.5≤νd≤42, and glass coloring degree is λ70≤390nm. The optical glass is listed in Table 1 below The raw material composition that shows weight percent produces 1000kg high refractive index of the present invention, the concrete consumption of each raw material of low dispersion optical glass is also as shown in table 1 respectively:

[0083] Table 1 Example 1

[0084]

[0085] 1.2 Preparation method:

[0086] After weighing all the raw materials according to the proportion, mix them thoroughly and evenly, then put them into a platinum crucible, melt and clarify at 1400°C, cool down to 1320°C after homogenization, pour them into preheated molds, and heat them at 500°C The glass is annealed at ℃ to obtain finished optical glass.

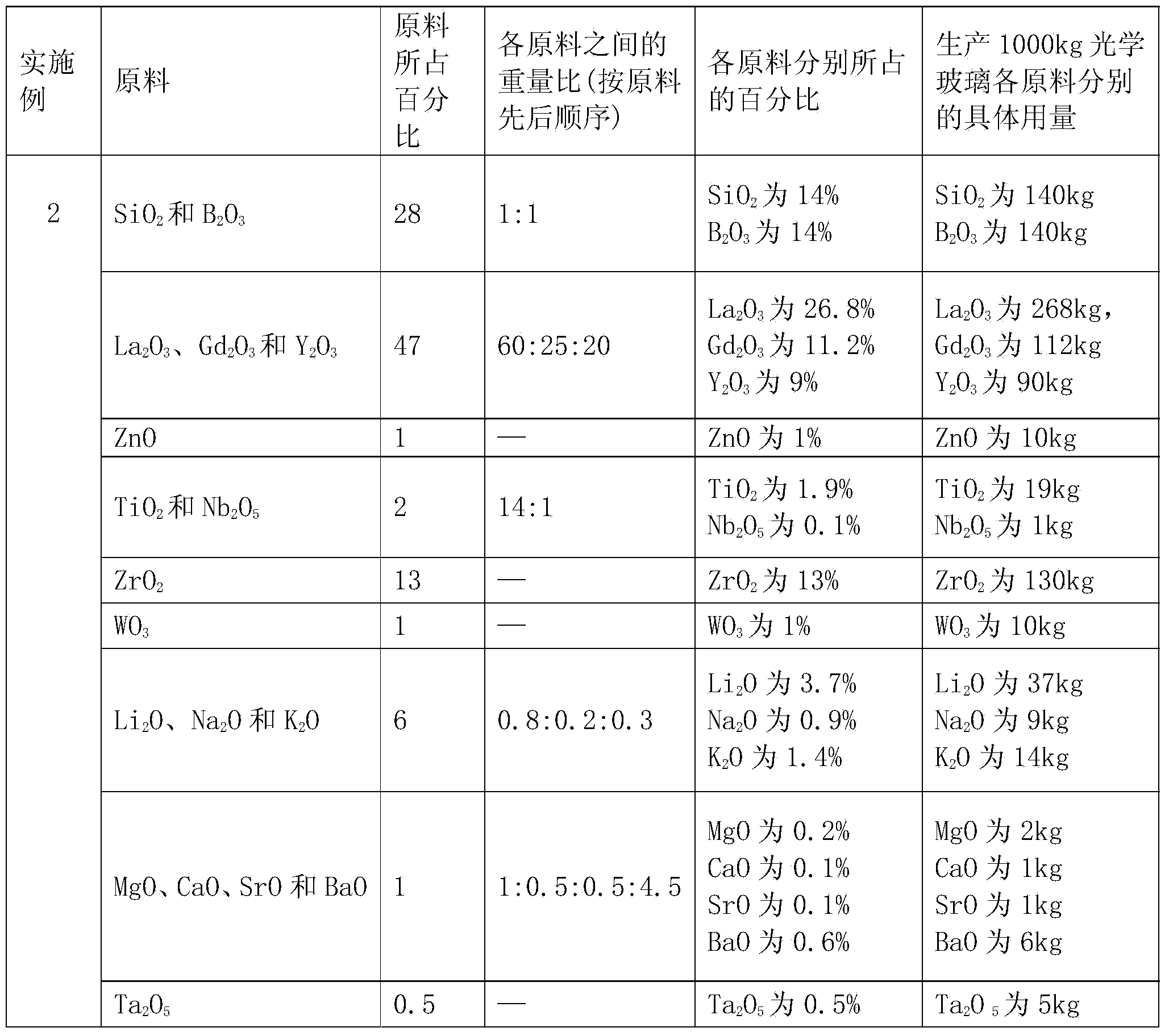

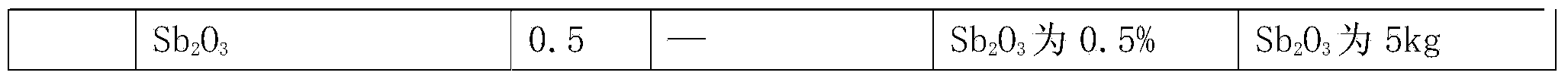

Embodiment 2

[0088] 2.1 An optical glass with high refractive index and low dispersion, whose refractive index is 1.87≤nd≤1.89, Abbe number is 38.5≤νd≤42, and glass coloring degree is λ70≤390nm. The optical glass is listed in Table 2 below Show the raw material composition of weight percentage, produce 1000kg high refractive index of the present invention, the concrete consumption of each raw material of low dispersion optical glass is also shown in following table 2 respectively:

[0089] Table 2 Example 2

[0090]

[0091]

[0092] 2.2 Preparation method:

[0093] After weighing all the raw materials according to the proportion, mix them thoroughly and evenly, then add them into a platinum crucible, melt and clarify them at 1450°C, cool down to 1300°C after being homogenized, pour them into preheated molds, and heat them at 60°C The glass is annealed at ℃ to obtain finished optical glass.

Embodiment 3

[0095] An optical glass with a high refractive index and low dispersion, the refractive index is 1.87≤nd≤1.89, the Abbe number is 38.5≤νd≤42, and the glass coloring degree is λ70≤390nm. The optical glass is shown in Table 3 below Composition of raw materials in weight percent, production of 1000kg high refractive index of the present invention, the specific consumption of each raw material of low dispersion optical glass is also shown in table 3 below:

[0096] Table 3 Example 3

[0097]

[0098]

[0099] 3.2 Preparation method:

[0100] After weighing all the raw materials according to the proportion, mix them well, then put them into a platinum crucible, melt and clarify them at 1420°C, cool down to 1350°C after homogenization, pour them into preheated molds, and heat them at 700°C The glass is annealed at ℃ to obtain finished optical glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com