Concrete cushion resuing stoping method for narrow veins

A backfill mining method and a technology of concrete cushion, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of restricting the development of mines, increasing the cost of ore upgrading and beneficiation, and large losses of high-grade powder ore, and reducing high The effect of the loss of grade ore powder, reducing the labor intensity of workers and increasing the amount of caving ore

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

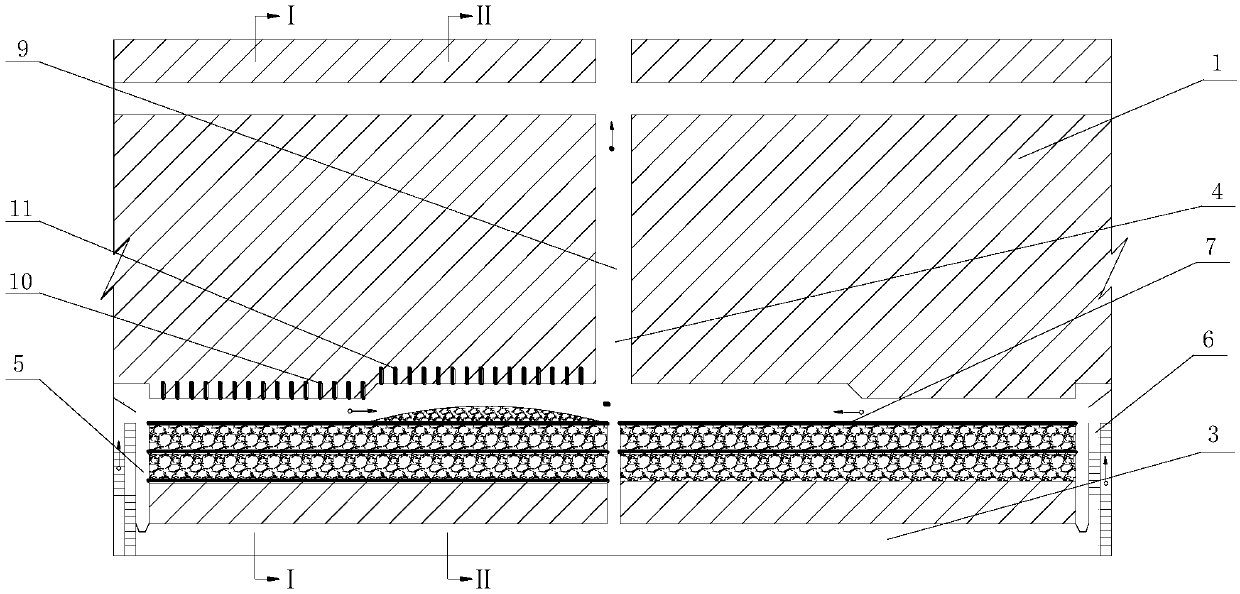

[0020] Such as figure 1 As shown, the present invention provides a thin ore vein concrete cushion wall cutting and filling mining method, which is to apply the technology of two consecutive ore droppings, one wall cutting and filling, mechanized centralized transportation and laying of concrete cushions in the mining process of ore blocks to realize High-efficiency and low-loss mining of ore, the specific process is as follows:

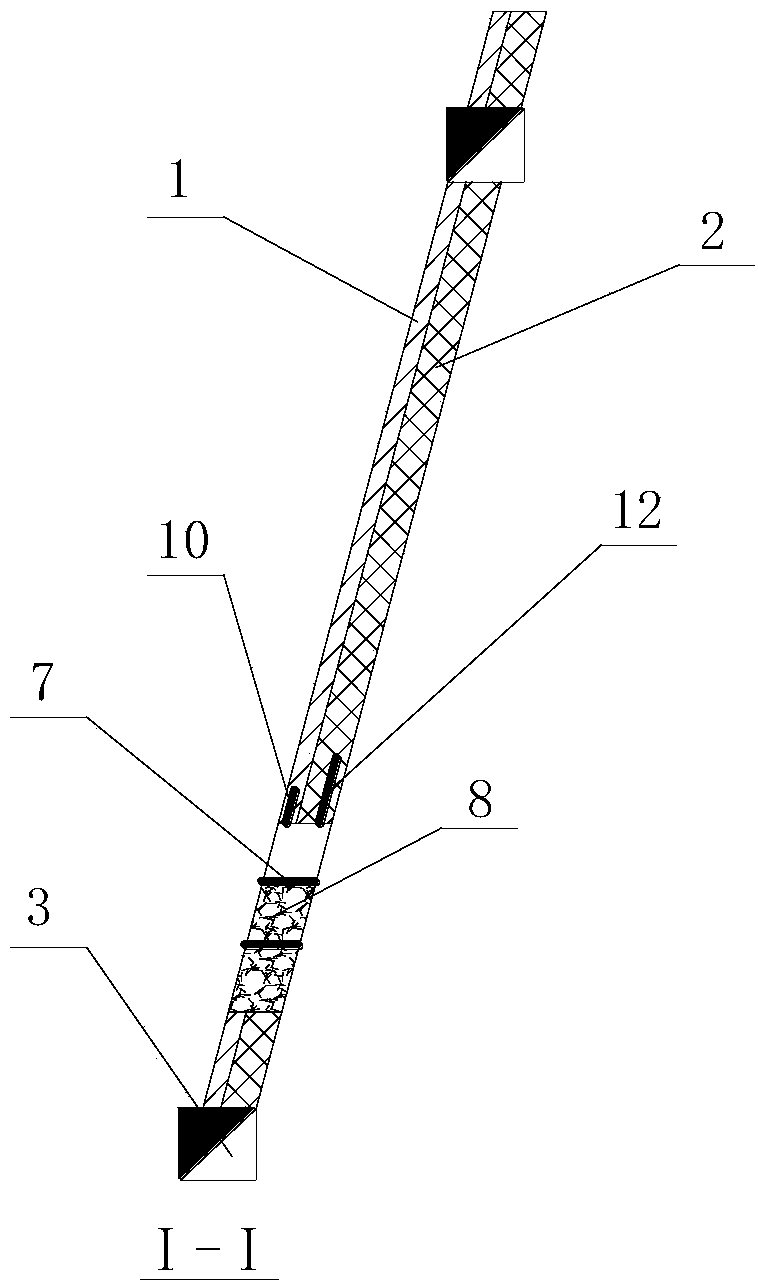

[0021] First, if figure 1 with figure 2 As shown in Fig. 1, drill wall cutting blastholes in the surrounding rock of the wall to be cut or the footwall, drill a blast hole in the ore vein, directly charge the charge to detonate, and implement a blast hole blasting;

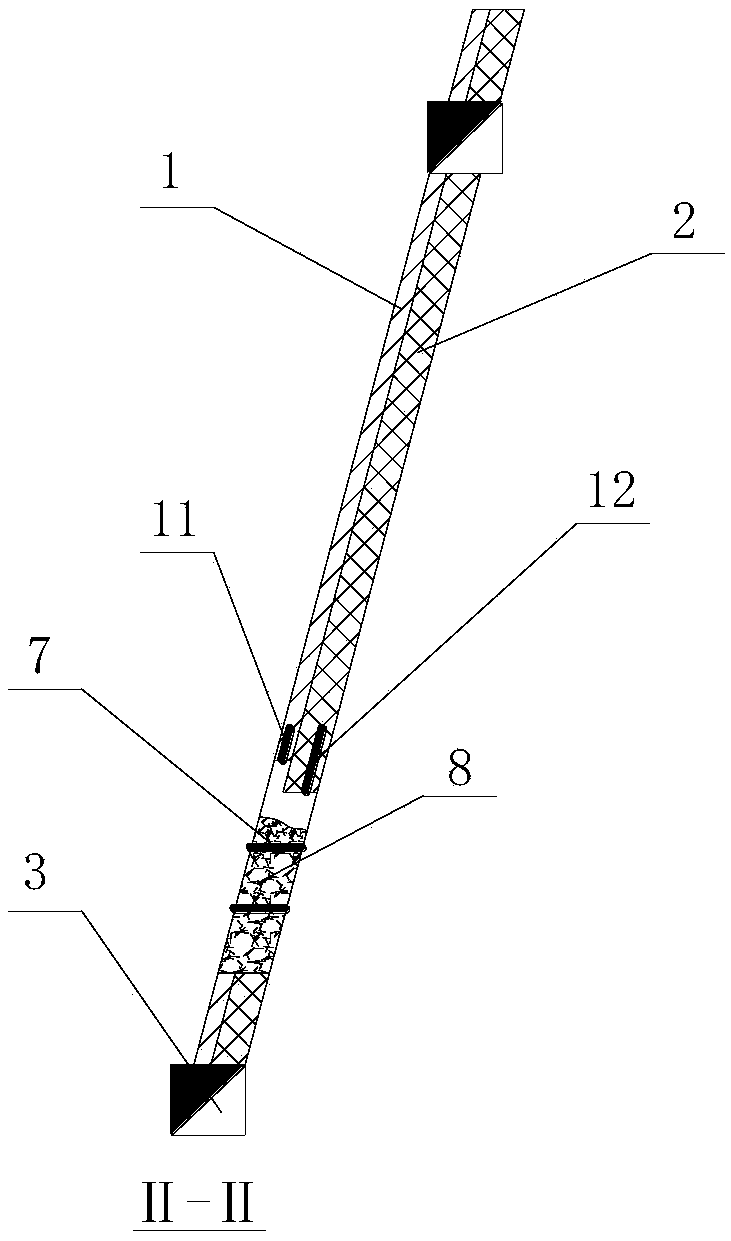

[0022] Then, if figure 1 with image 3 As shown, after the first ore drop, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com