Internal combustion engine with fuels being mixed and ignited on the spot and control method thereof

An internal combustion engine and fuel technology, which is used in fuel injection control, engine control, electrical control, etc., and can solve problems such as easy knocking, narrow operating conditions, and easy fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment has done following experiment to various working conditions:

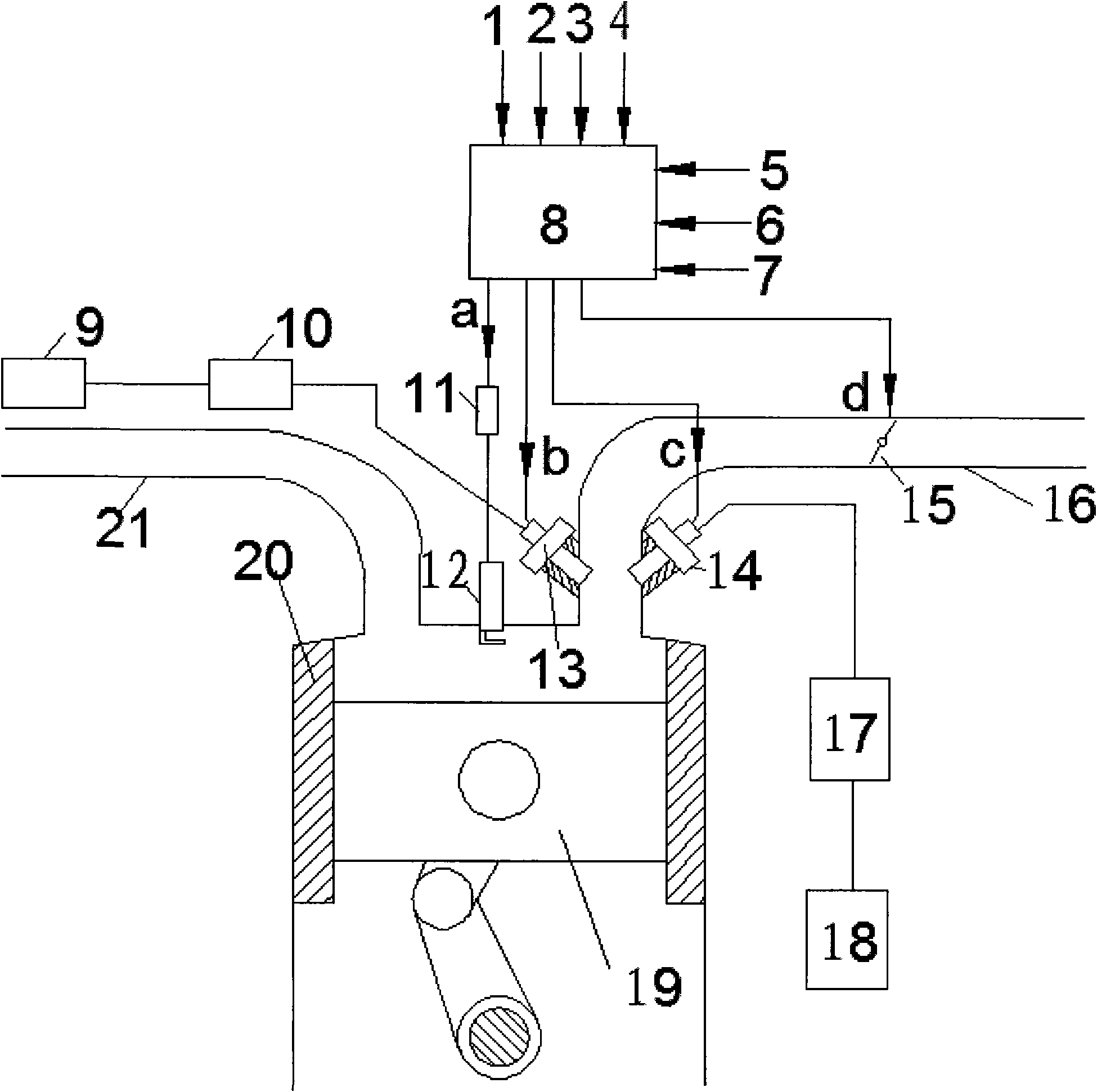

[0029] The experimental internal combustion engine is an in-line 4-cylinder 1.6L EFI gasoline engine, according to figure 1 Shown is an ignition engine retrofitted to high cetane and high octane fuel field mix. The high cetane number fuel used in the experiment is dimethyl ether (C 2 h 6 O), the high-octane fuel is propane (C 3 h 8 ). Use a Horiba-7100DEGR emission analyzer produced by Horiba Co., Ltd. to measure HC, CO and NO in each operating condition of the internal combustion engine x emission.

[0030] 1) Start experiment

[0031] The mixed fuel electronic control unit 8 according to the cooling water temperature T w Determine the mix ratio for high cetane and high octane fuels. The electronic control unit 8 drives the high-octane number fuel nozzle 13 to inject the high-octane number fuel and the high cetane number fuel nozzle 14 with the fuel injection quantity of 0.007g / cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com