No.94 lead-free aviation gasoline and production method thereof

A technology of aviation gasoline and base oil, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., and can solve problems such as low octane number, no reference to motor octane number value, and inability to meet the performance requirements of aero-engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] In some embodiments, the preparation method of the aviation gasoline composition of the present invention further includes the step of obtaining blending component A. The step of obtaining the blending component A may be: distilling the alkylation reaction product of C4 olefins and isobutane, and obtaining a component whose initial boiling point and final boiling point meet the requirements of the aforementioned blending component A as a blending group Point A. The composition and distillation range of this component can meet the relevant requirements mentioned above. The temperature of the alkylation reaction can be 4-10°C, the pressure can be 0.4-0.45MPa, the alkene ratio can be 8-12:1, and the acid-ene ratio can be 1-1.2:1. The alkylation reaction is carried out in the presence of a catalyst. The catalyst may be an acid, for example, one or more selected from sulfonic acid, hydrofluoric acid, and concentrated sulfuric acid. The molar ratio of catalyst to C4 olefin...

Embodiment 1

[0087]Alkylate modified oil of 64% by mass (see Table 1-1 for its properties), 21% by mass of industrial isopentane (see Table 1-2 for its properties) and 15% by mass m-xylene (see Table 1-2 for its properties) Table 1-3) mix, and then add other various additives according to Table 1-4, after reconciling evenly, obtain aviation gasoline, the property of this aviation gasoline is as shown in Table 1-5 below.

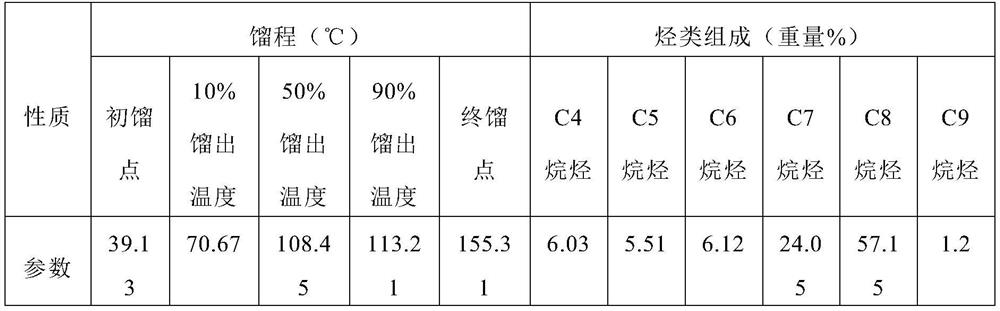

[0088] Table 1-1

[0089]

[0090] Table 1-2

[0091]

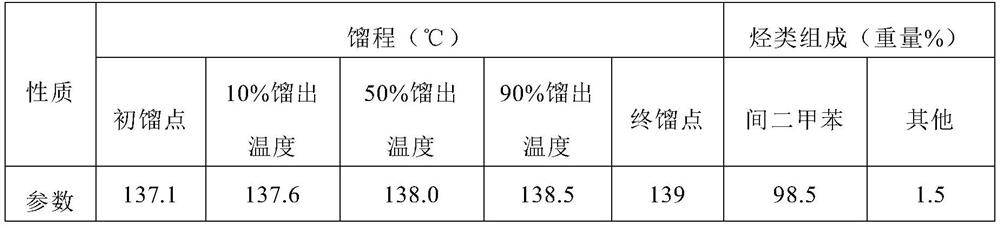

[0092] Table 1-3

[0093]

[0094] Table 1-4

[0095]

[0096] Table 1-5

[0097]

Embodiment 2

[0099] Alkylate modified oil of 52% by mass (see Table 2-1 for its properties), 25% by mass of industrial isopentane (see Table 2-2 for its properties) and 23% by mass m-xylene (see Table 2-2 for its properties) Table 2-3) mix, and then add other various additives according to Table 1-4, after reconciling evenly, obtain aviation gasoline, the property of this aviation gasoline is as shown in Table 2-4 below.

[0100] table 2-1

[0101]

[0102]

[0103] Table 2-2

[0104]

[0105] Table 2-3

[0106]

[0107] Table 2-4

[0108]

[0109]

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| motor octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com