Catalytic conversion method for preparing high-octane number gasoline

A high-octane gasoline and catalytic conversion method technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of high gasoline yield and low coke yield, etc., and achieve the effect of increasing gasoline octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example illustrates the situation of producing high-octane gasoline in a small-scale continuous fluidized bed reactor by using the selected boiling range distillate of the present invention.

[0033] The distillate B listed in Table 1 with an initial boiling point greater than 165.6°C was used as the raw material for catalytic cracking, and catalyst D was used to carry out the experiment of catalytic conversion of distillate oil to produce high octane number in a small fluidized bed reaction operated by continuous reaction regeneration . Distillate B is mixed with preheated high-temperature steam and then enters the fluidized bed reactor. The reaction temperature is 500°C, the top pressure of the reaction is 0.2MPa, and the weight hourly space velocity is 9h. -1 , the ratio of agent to oil is 13, and the weight ratio of water vapor and raw material is 0.11, and the catalyst is contacted to carry out catalytic conversion to produce high-octane gasoline. The reactio...

Embodiment 2

[0037] This example illustrates the production of high-octane gasoline by using vacuum gas oil (VGO) to recuperate fractions with a distillation range of 180° C. to 245° C. on a medium-sized riser device.

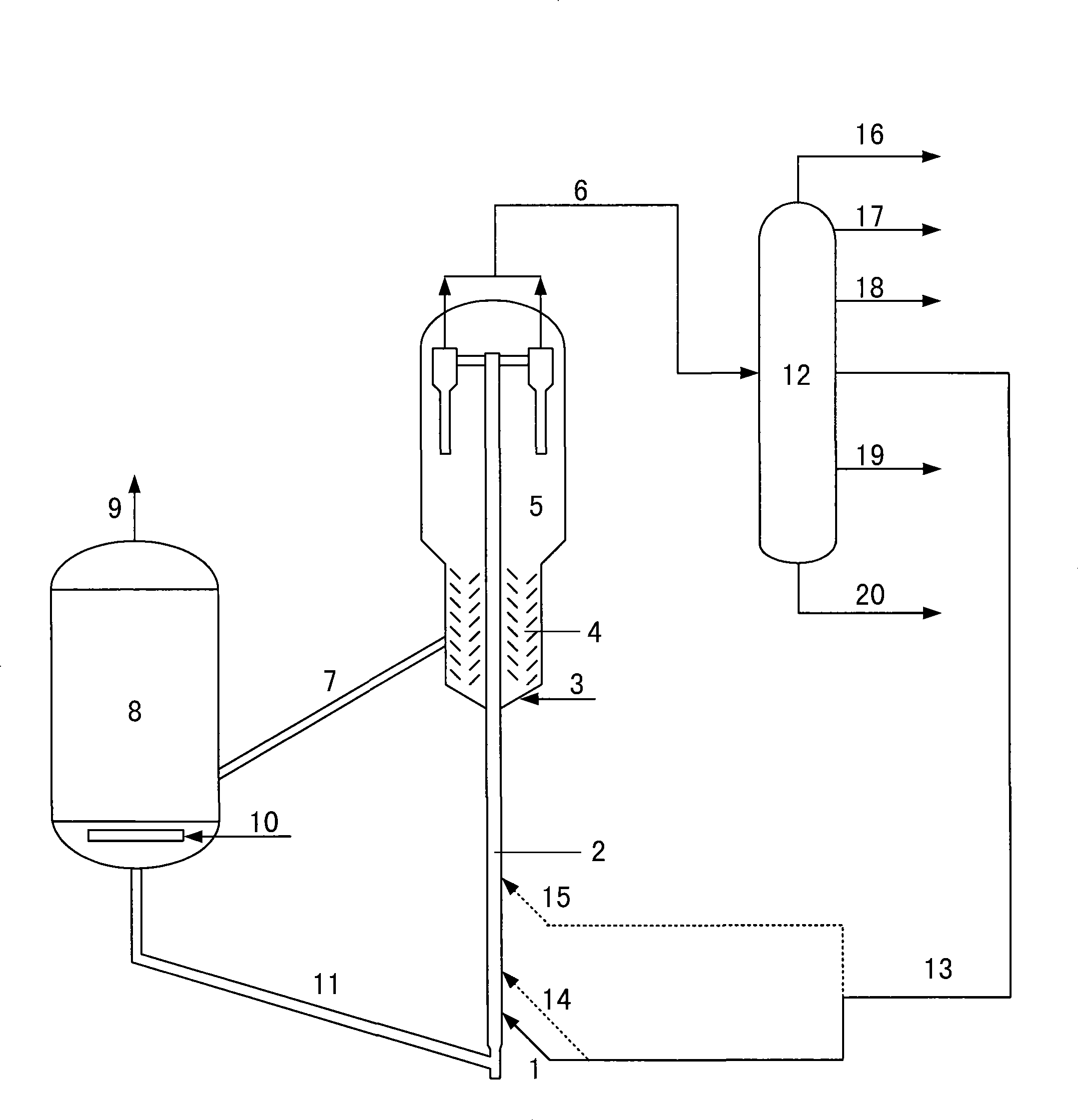

[0038] Using the fraction A listed in Table 1 as the raw material, and using the catalyst D in Table 2, the experiment of distillate oil back refining to produce high-octane gasoline was carried out on a medium-sized riser catalytic cracking unit operated by continuous reaction regeneration. As shown in the figure, the pre-lift steam enters from the bottom of the riser reactor 2 through the pipeline 1, and the regenerated catalyst from the pipeline 11 accelerates upward along the riser under the lifting effect of the pre-lift steam, and the preheated and atomized raw material A enters the riser 2 through the pipeline 14, and is mixed with the existing flow of the riser reactor. The refractory fraction with a distillation range of 180°C-245°C is atomized by steam and injected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com