Patents

Literature

191results about How to "Good explosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methanol gasoline

InactiveCN102796574ANormal startImprove anti-corrosion performanceLiquid carbonaceous fuelsLiquid fuelFuel oil

Provided is methanol gasoline. The invention relates to the technical field of energy, and specifically relates to a methanol gasoline formula. The methanol gasoline formula includes adding a methanol gasoline compound additive to methanol by weight ratio of 0.05% for denaturation, and mixing 15-65 parts of methanol, 20-30 parts of 90 # gasoline, 10-30 parts of light aromatic hydrocarbons, and 10 parts of naphtha by weight after denaturation. The methanol gasoline is good in corrosion resistance, and generates chemical and physical adsorption to resist corrosion by inhibiting basic groups of molecules. The methanol gasoline is powerful in dynamic property, high in octane value, good in antiknock property, low in fuel consumption, and safe and reliable in use. The method makes alcohol and gasoline dissolve organically, and helps to enhance the stability without delamination and emulsification. The methanol gasoline can be used with ordinary gasoline by mixing or crossing. By using the methanol gasoline, motors are easy to start under the low temperature condition of -35 DEG C, and have no air resistance at high temperature, thereby being started normally. The methanol gasoline is suitable for gasoline and liquid fuels, and can help to save 10-25% of the fuel oil, to reduce the amount of smoke and exhaust gases, and to reduce pollution.

Owner:张伯义 +2

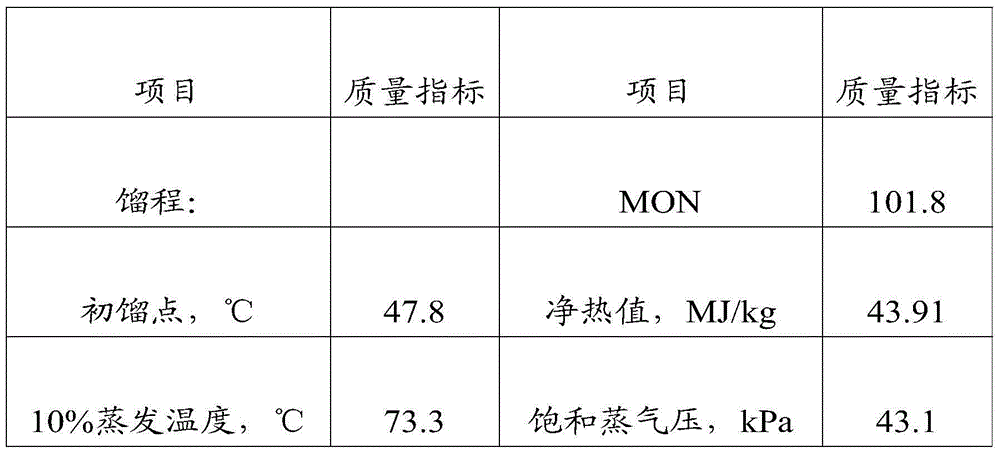

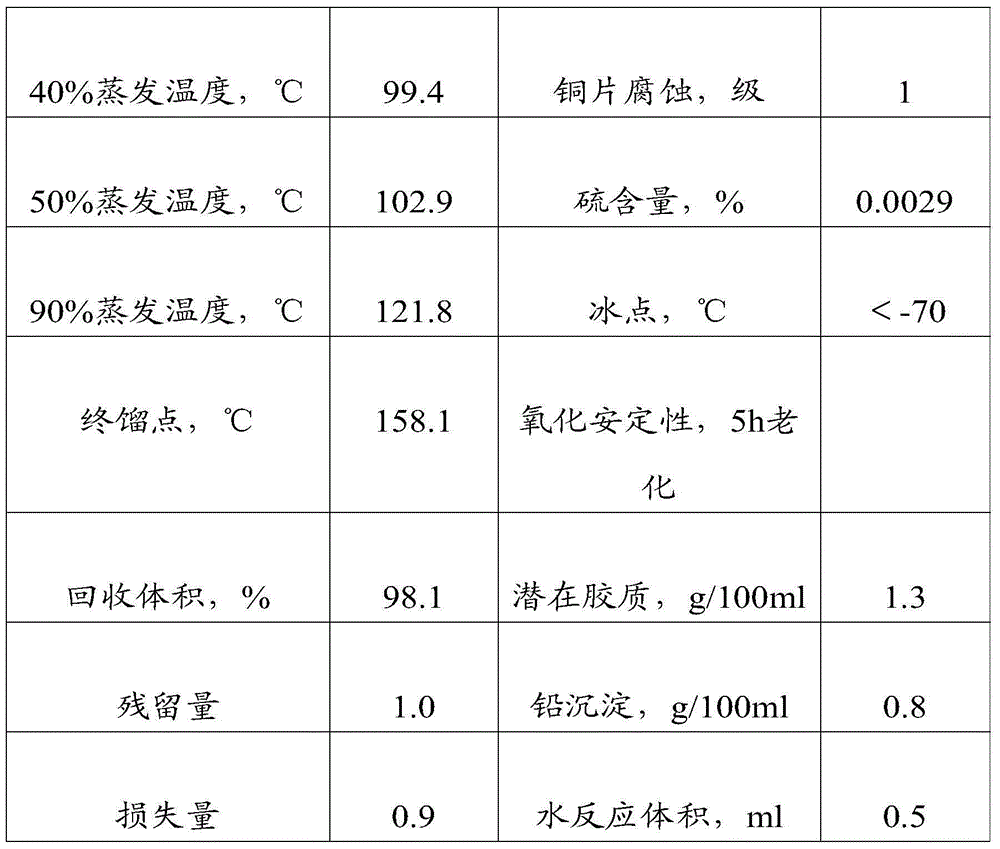

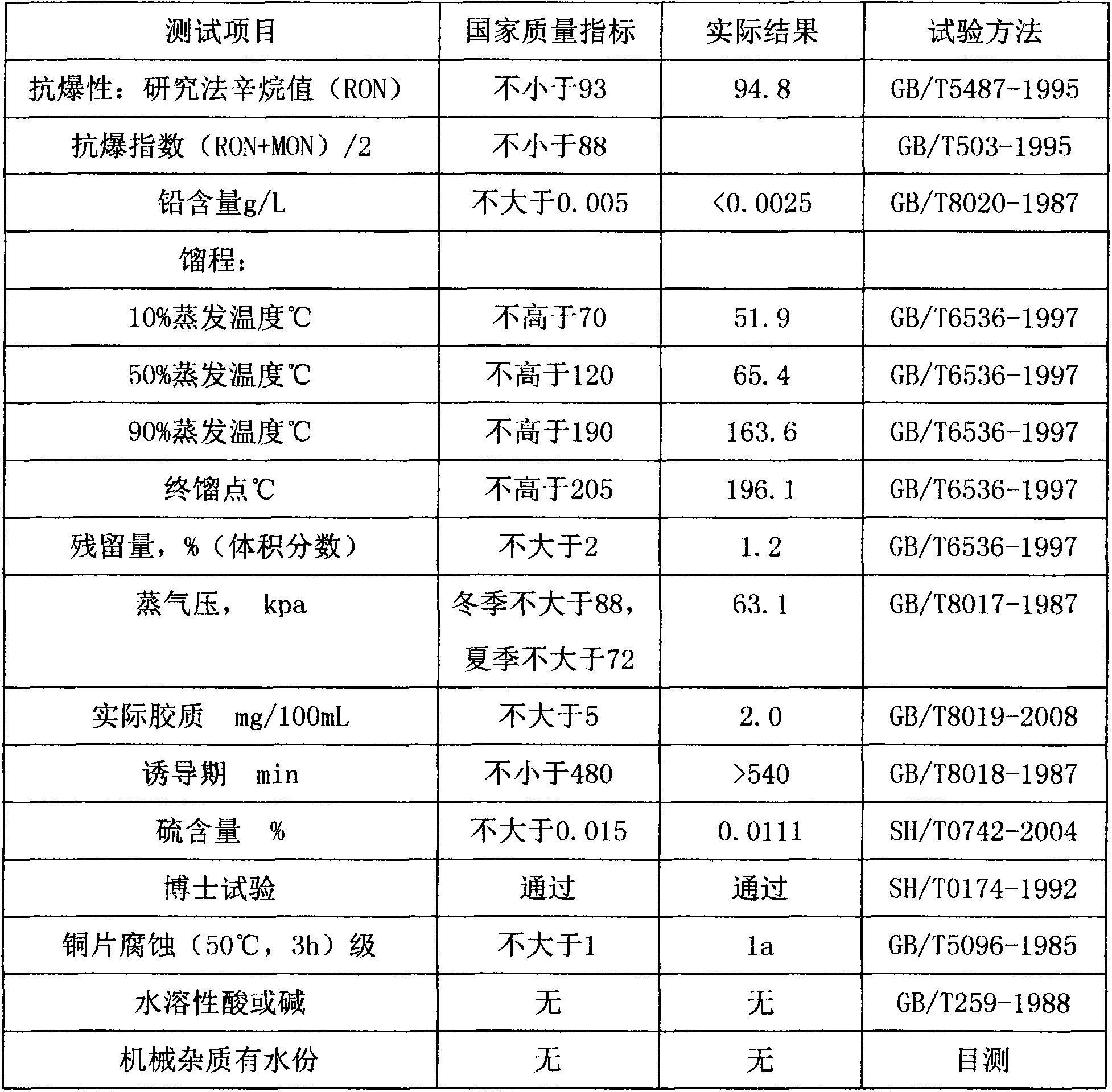

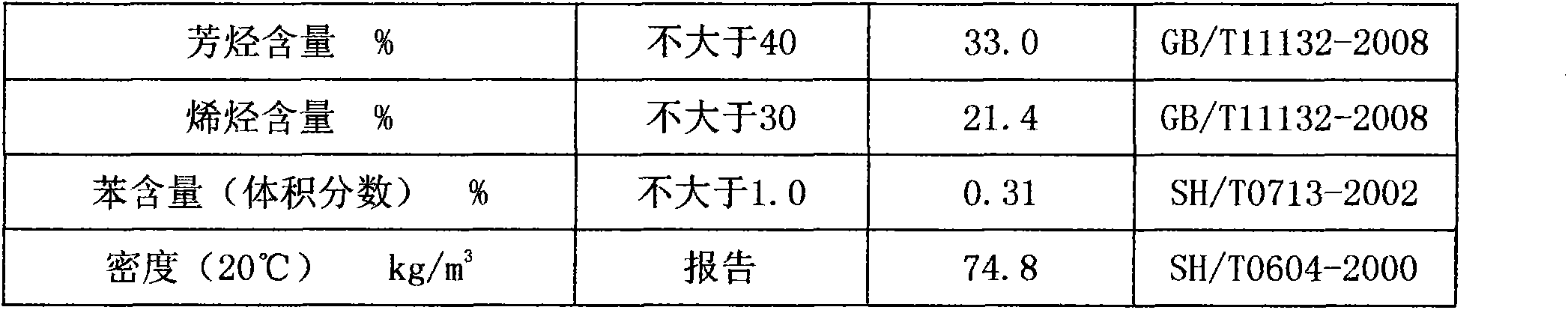

Low-lead aviation gasoline and preparation method thereof

The invention provides a low-lead aviation gasoline and a preparation method thereof. The low-lead aviation gasoline is composed of the following components in parts by weight: 40-90 parts of technical octane, 5-30 parts of isooctane-free alkane, 5-30 parts of aromatic hydrocarbon, 0.001-0.12 part of tetraethyl lead and 0.0008-0.0017 part of antioxidant. The number of carbon atoms of the alkane is C5-C9, and the number of carbon atoms of the aromatic hydrocarbon is C7-C9. The preparation method comprises the following steps: treating gasoline alkylate or isomerized gasoline in a distillation refinement mode to obtain higher-purity technical octane, and blending the technical octane, isooctane-free alkane, aromatic hydrocarbon, lead tetraethyl and antioxidant according to the formula to obtain the low-lead aviation gasoline. The low-lead aviation gasoline has the advantages of low lead content, low production cost and excellent combustion performance, and conforms to the standards GB 1787 and ASTM D910.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Environment-friendly lead-less gasoline and its preparation method

The invention relates to a kind of environment-friendly lead-free gasoline which includes the following ingredients: 25-35wt% part of gasoline (or light oil / naphtha), 25-35wt% part of methanol, 5-10wt% of n-butanol, 13-29wt% of avantin, 4-10wt% of absolute alcohol, 1-1.5wt% of acetone, 2-2.5wt% of oil benzene, 8-23wt% of di-isobutyl ether and 0.5-1wt% of nucleus additive. The mentioned additive includes the following ingredients: 20-25wt% of acetone, 10-21wt% of isobutanol, 5-15wt% part of kerosene, 25-40wt% part of dimethyl benzene and 6-14wt% part of the gasoline quieting, anti-oxygen, anti-detonate, and anti-corrosion agent. Adding the mentioned material according to the ratio to the reactor and agitating pots, synthesizing for 15-30 minutes; agitating the material in the static admixer to get the gasoline which has good evaporating ability, anti- detonate ability, safe charactiristic, anti-corrosion ability, compatibility and environment-friendly quality.

Owner:陈志红

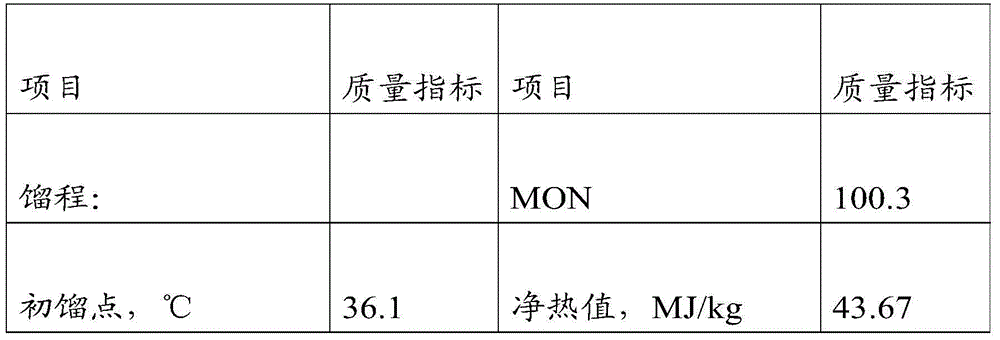

Alcohol ether fuel for diesel of vehicle and marine, and gas-liquid synthesizing method

InactiveCN101294109AReduce dosageImprove fuel economyLiquid carbonaceous fuelsCerium nitrateSynthesis methods

The invention discloses an alcohol-ether fuel for diesel engines of ships and vehicles as well as the gas-liquid synthesis method thereof. The alcohol-ether fuel comprises the following components (by weight): methanol 36 parts, diesel oil No.0 30 parts, solvent oil 31 parts, additives 2.5 parts, and dimethyl ether 0.5parts, wherein the additives include tert-butyl alcohol, tween-20, cerium nitrate, n-hexanol and nuclear magnetic resonance agent. The systhesis method comprises the following steps: sequentially adding methanol, diesel oil and solvent oil into a reaction tank, heating to 45 to 55 DEG C, stirring under a pressure of 0.2 kg for 12 to 18 min, adding the additives and dimethyl ether, mixing, stirring for 3 to 5 min, fine-filtering, and standing to obtain the final product. The alcohol-ether fuel has the advantages of no pollution, simple process, rich raw materials, low cost, no lead, high cetane number, and good anti-knock property, safety and stability, and can be used alone or mixed with common diesel oil for alcohol-ether ships and vehicles. The alcohol-ether fuel is an ideal product to substitute for the diesel oil No.0.

Owner:张元盛

Method for preparing gasoline from methanol

ActiveCN102746877AReduce olefin contentImprove stabilityCatalytic naphtha reformingLiquid hydrocarbon mixtures productionReaction temperatureSolid acid

The invention relates to a method for preparing gasoline from methanol and light petroleum distillates, and aims to mainly solve the problems that light petroleum distillates are unable or hard to be used to prepare gasoline, and during gasoline preparation process, without transforming an engine, methanol has a low incorporation amount and is easy to corrode equipment as well as result carbon deposition in the prior art. The method of the invention adopts a technical scheme consisting of: taking methanol or dimethyl ether and light petroleum distillates as the raw materials, and under the conditions of a reaction temperature of 300-500DEG C, a reaction pressure ranging from normal pressure to 10.0MPa, and a raw material weight hourly space velocity of 0.3-10h<-1>, contacting the raw materials with a solid acid catalyst, and making the methanol and the light petroleum distillates undergo an alkylation reaction on the catalyst so as to obtain a gasoline product with the weight concentration of oxygen-containing compounds less than 100ppm. The technical scheme of the invention well solves the problem, and can be used in the industrial production of gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

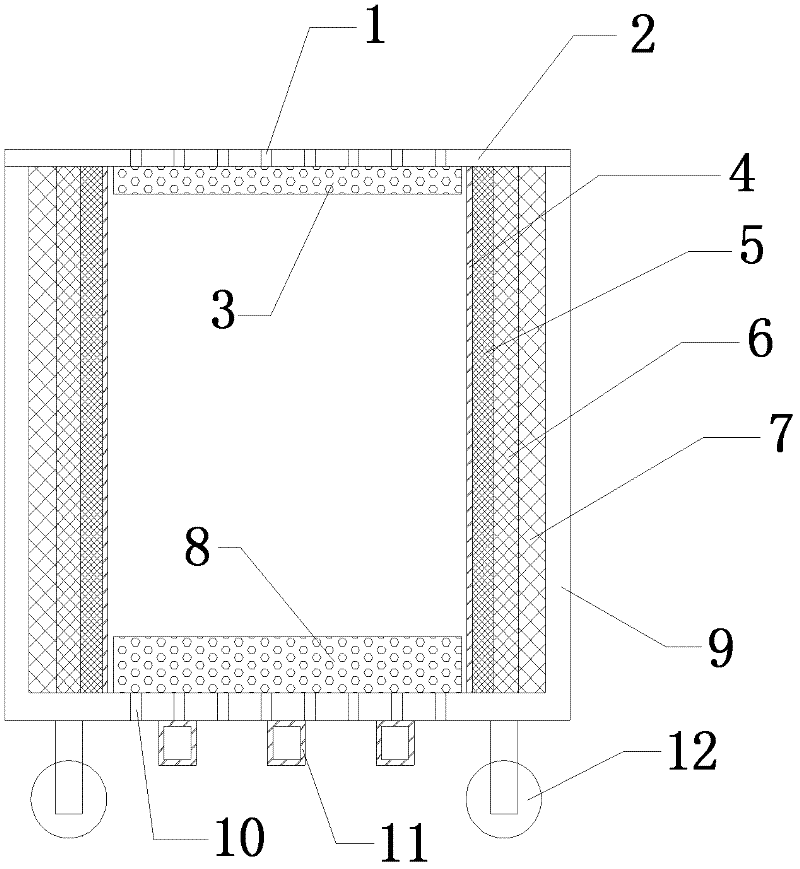

Gradient sandwiched anti-explosion pot

InactiveCN102538606AAvoid crack failureGood compression energy absorption performanceBlastingMetallic materialsMaterials science

The invention discloses a gradient sandwiched anti-explosion pot, comprising a pot body and a pot bottom, wherein the pot body is composed of an inner barrel, an inner buffer layer, a middle buffer layer, an outer buffer layer and an outer barrel; the inner buffer layer, the middle buffer layer and the outer buffer layer are made of closed cell foam metals and the density of the closed cell foam metal from the inner buffer layer, the middle buffer layer to the outer buffer layer is reduced gradually; a cover plate with a pressure relief hole is formed at the top of the pot body; the pot bottom is a bottom plate of the outer barrel; buffer base plates are installed on the upper part of the bottom plate of the outer barrel and the inner part of the inner barrel; a pressure relief hole is formed on the bottom plate of the outer barrel; buffer lining plates are installed at the lower part of the cover plate and the inner part of the inner barrel; the buffer lining plate and the buffer base plates are made of opening-hole foam metals; the thickness of the buffer base plate is more than that of the buffer lining plate; the thickness of the outer barrel is more than that of the inner barrel; the multilayer foam metal of which the density is reduced gradually from inside to outside is used as a sandwiched layer to improve the anti-explosion performance of the anti-explosion pot.

Owner:XI AN JIAOTONG UNIV

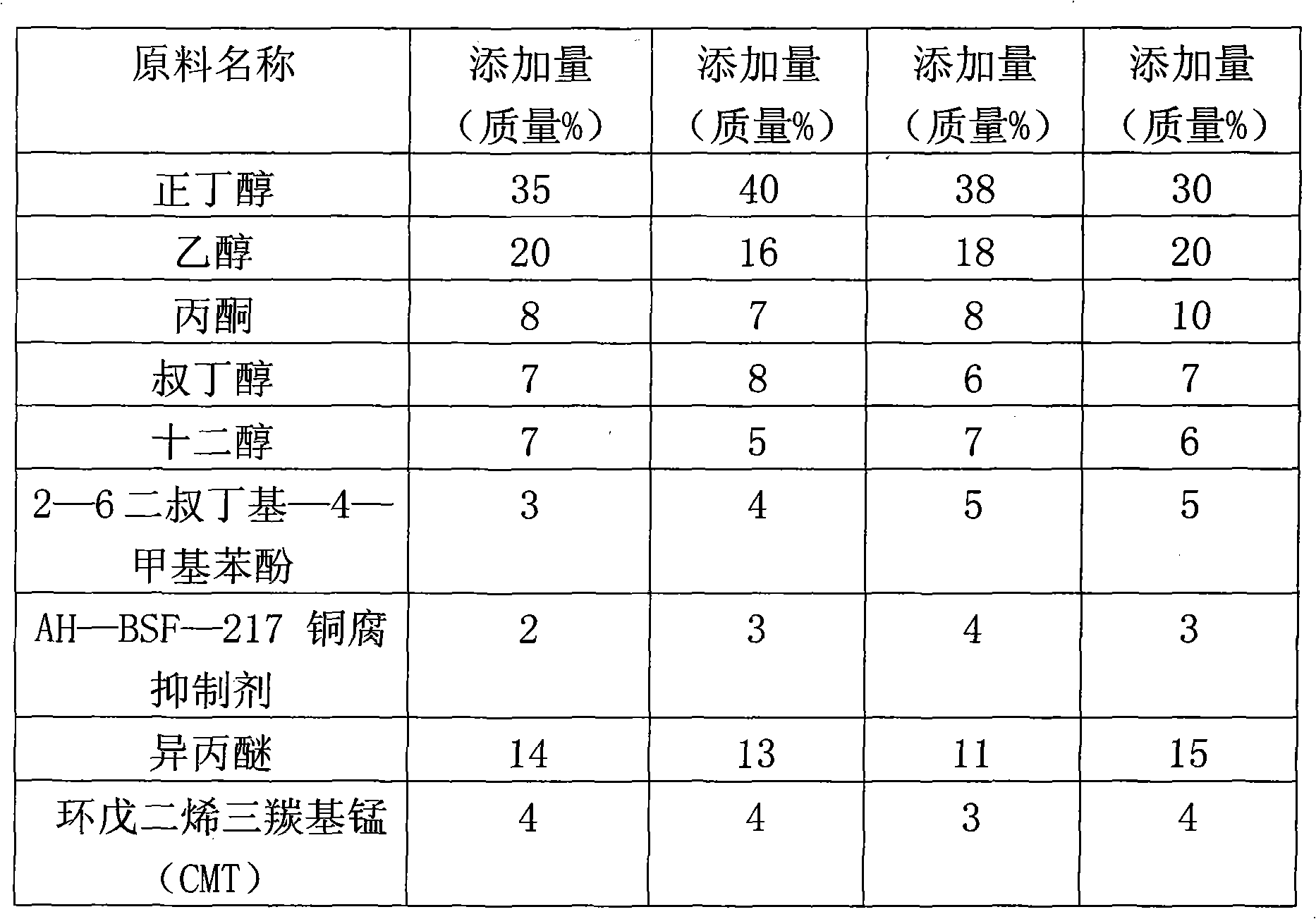

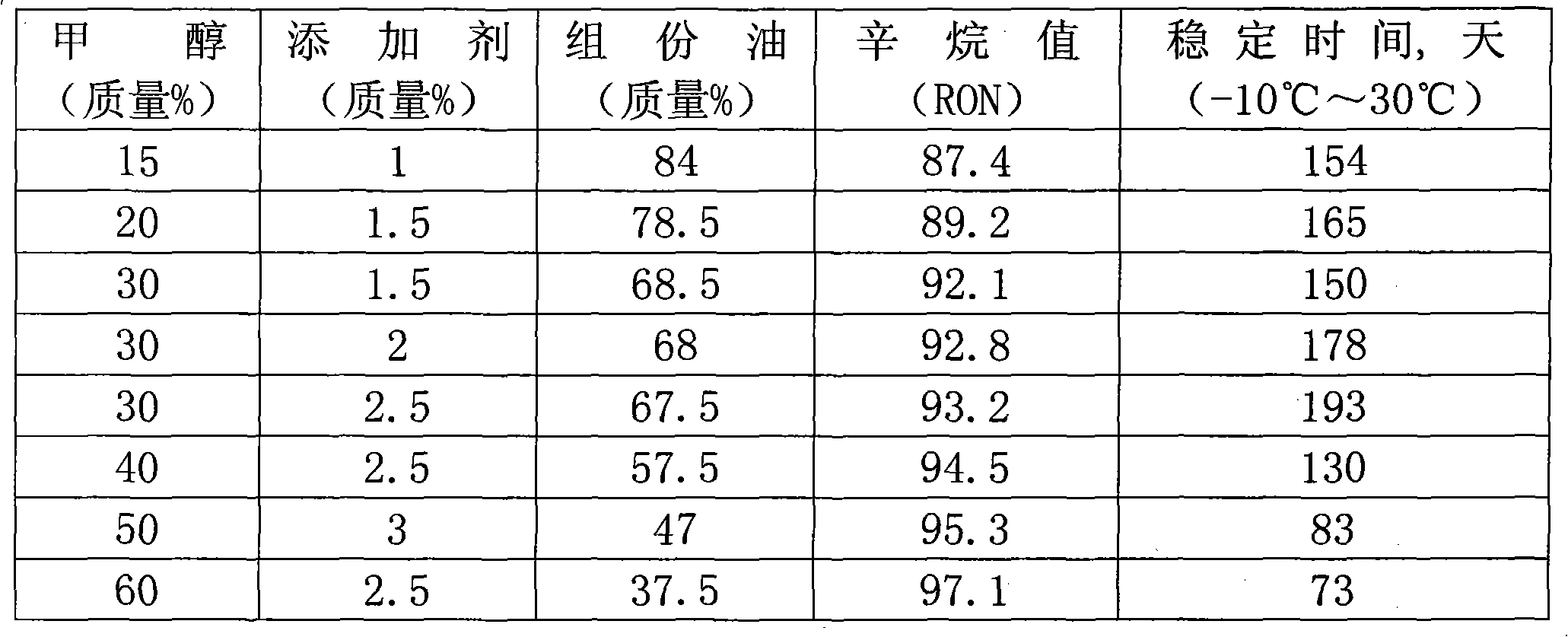

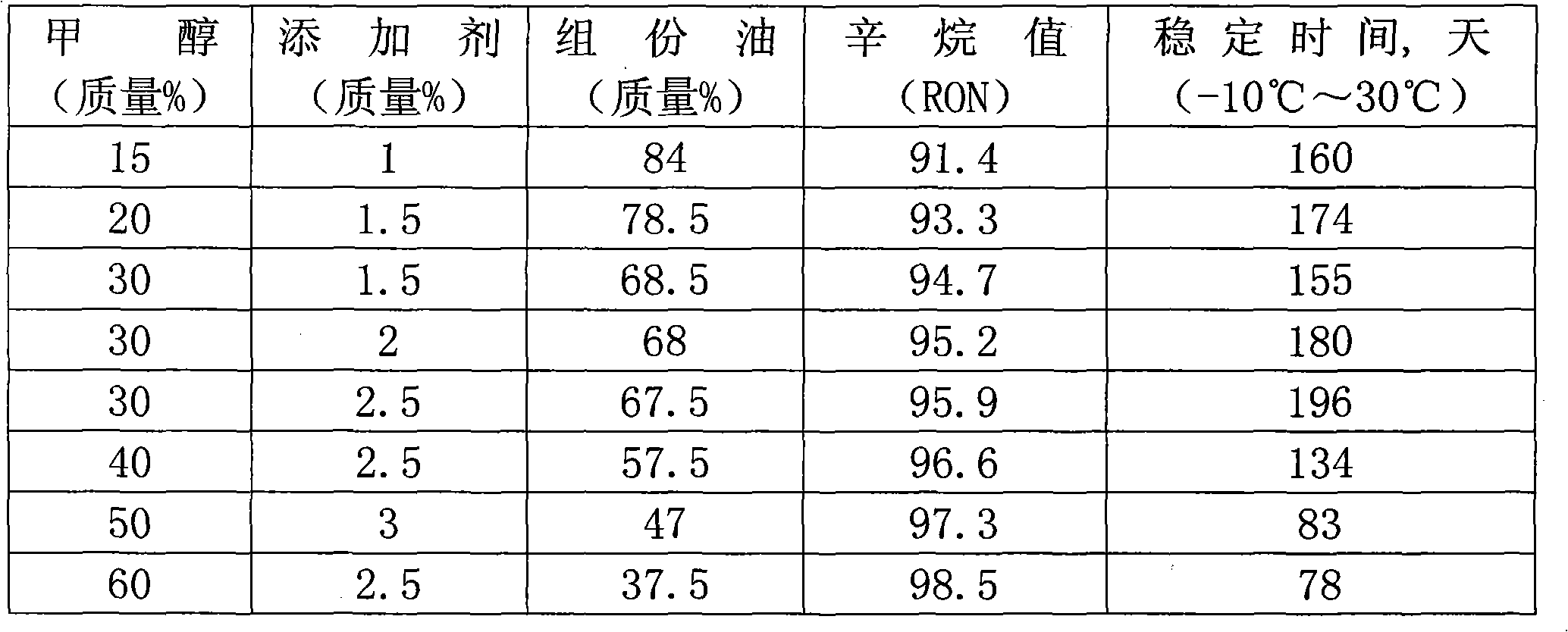

Methanol gasoline additive, methanol gasoline prepared from same and production methods for methanol gasoline additive and methanol gasoline

ActiveCN101886004ABoost octaneExtended storage timeLiquid carbonaceous fuelsFuel additivesOil additiveColor changes

The invention discloses a methanol gasoline additive, methanol gasoline prepared from same and production methods for the methanol gasoline additive and the methanol gasoline. The methanol gasoline additive is prepared from the following components in percentage by mass: 20 to 40 percent of n-butyl alcohol, 5 to 25 percent of ethanol, 3 to 13 percent of acetone, 2 to 10 percent of tertiary butanol, 4 to 9 percent of dodecanol, 2 to 6 percent of 2,6-di-tert-butyl-4-methylphenol, 1.5 to 5 percent of AH-BSF-217 copper corrosion inhibitor, 5 to 15 percent of isopropyl ether and 2 to 4 percent of cyclopentadienyl manganese tricarbonyl. The production method for the methanol gasoline additive comprises the following steps of: adding the raw materials in turn, fully stirring in a reaction kettlefor 30 to 60 minutes, sampling to observe color change, and stopping stirring when the liquid is changed to transparent yellow or rosiness; and putting into a finished product tank. The methanol gasoline is prepared from the following components in percentage by mass: 0.5 to 5 percent of methanol gasoline additive, 15 to 60 percent of methanol and 34.7 to 84 percent of component oil. The methanolgasoline prepared from the methanol gasoline additive has the advantages of high octane number, good anti-explosion, full combustion, reduction of discharge of automobile exhaust, no air blockage, easy cold start of the automobile and the like.

Owner:山东亿源石化有限公司 +1

High-clean methanol composite gasoline for vehicle and production thereof

The invention is about the high clearing methanol compound petrol which is composed of the methanol, the petrol, the acetone, the isopropyl ether, the isopropanol, the isoamylol, the tert-butyl alcohol and the synthetic addition agent. The addition agent is modulated by the ZnO, the Na2O2, the ferrum naphthenate and the isopropyl nitrate. The compound petrol can solve the problem of the corrosivity to the red copper and the swelling to the rubber. It can be mixed with the normal petrol arbitrarily and not need to change the structure of the engine, also it can remove the carbon and the colloid of the engine. The cost of the technique is low and the operability is high.

Owner:肖军

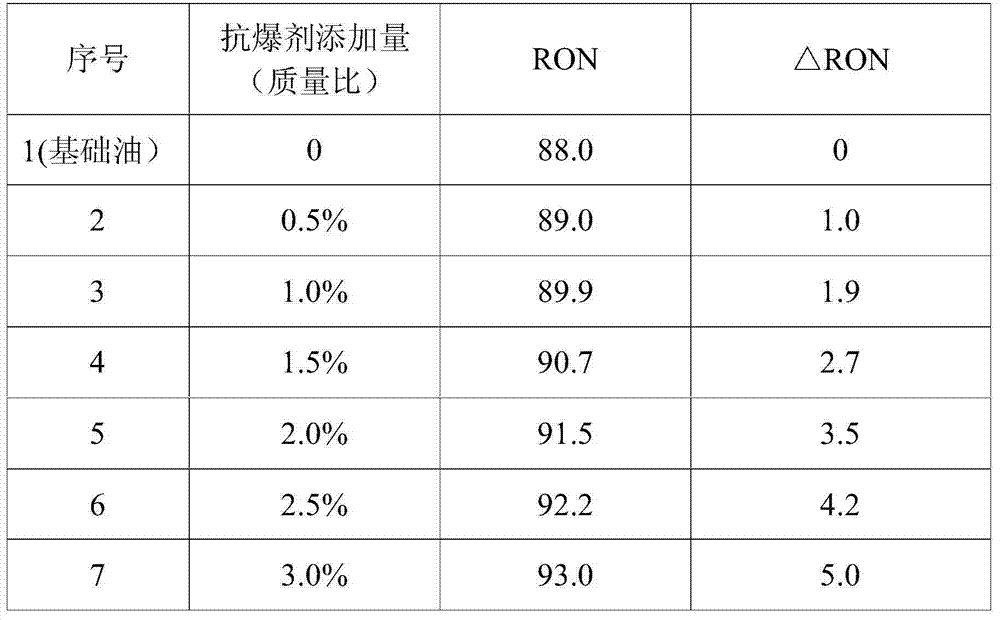

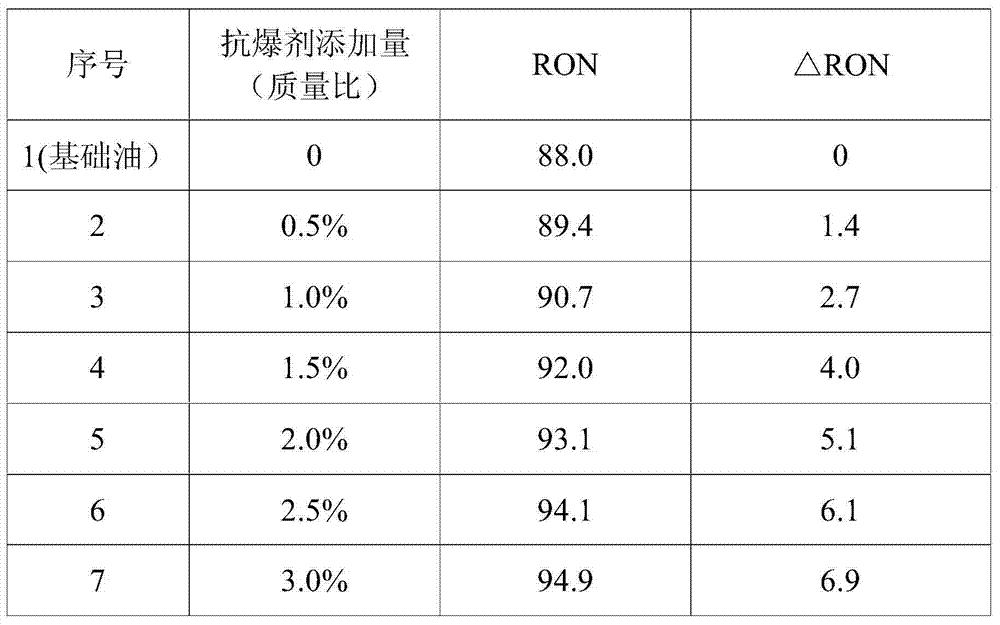

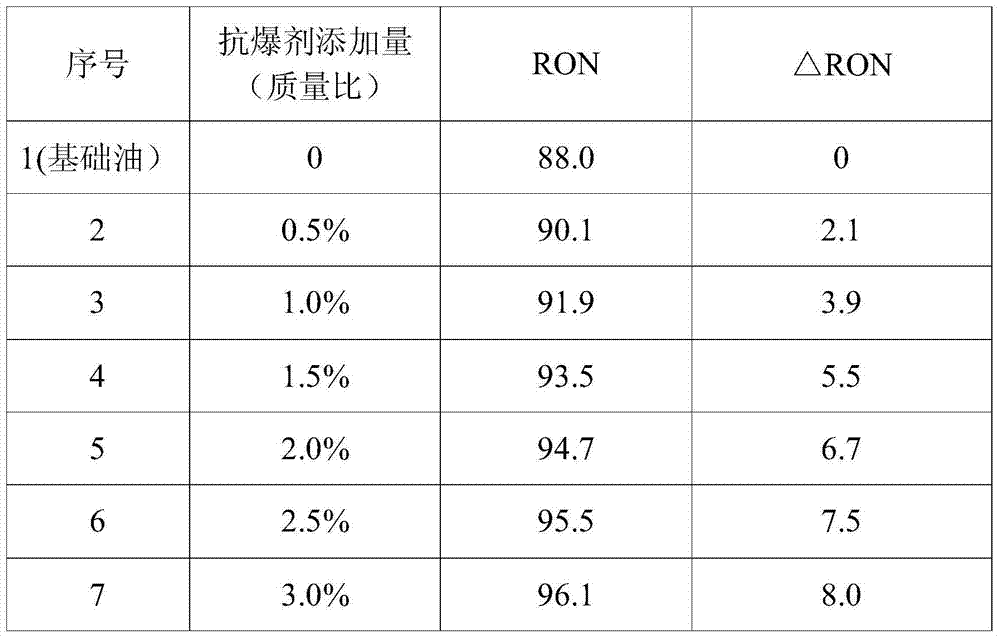

Nonmetallic gasoline antiknock

ActiveCN104711049AReduced knock intensityBoost octaneLiquid carbonaceous fuelsFuel additivesChemistryPetrochemical

The invention relates to the technical field of petrochemical engineering, in particular to a novel nonmetallic gasoline antiknock. The nonmetallic gasoline antiknock consists of the following components in parts by weight; 20 to 50 parts of an oxygen-containing arylamine compound, 50 to 80 parts of an ester compound and 0.01 to 1 part of a phenolic compound, and does not contain any metallic component. An experimental result of the antiknock shows that the octane value of gasoline can be increased by 1.0 to 8.0 units after 0.5 to 3 weight percent of the novel nonmetallic gasoline antiknock is added into gasoline and high antiknock performance is achieved; in addition, the novel nonmetallic gasoline antiknock has the advantages of low raw material cost, performance indexes consistent with a national V gasoline standard, no bad influence on a spark plug engine, capability of effectively reducing environmental hazards, and the like, and has high application value and good economic benefits.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

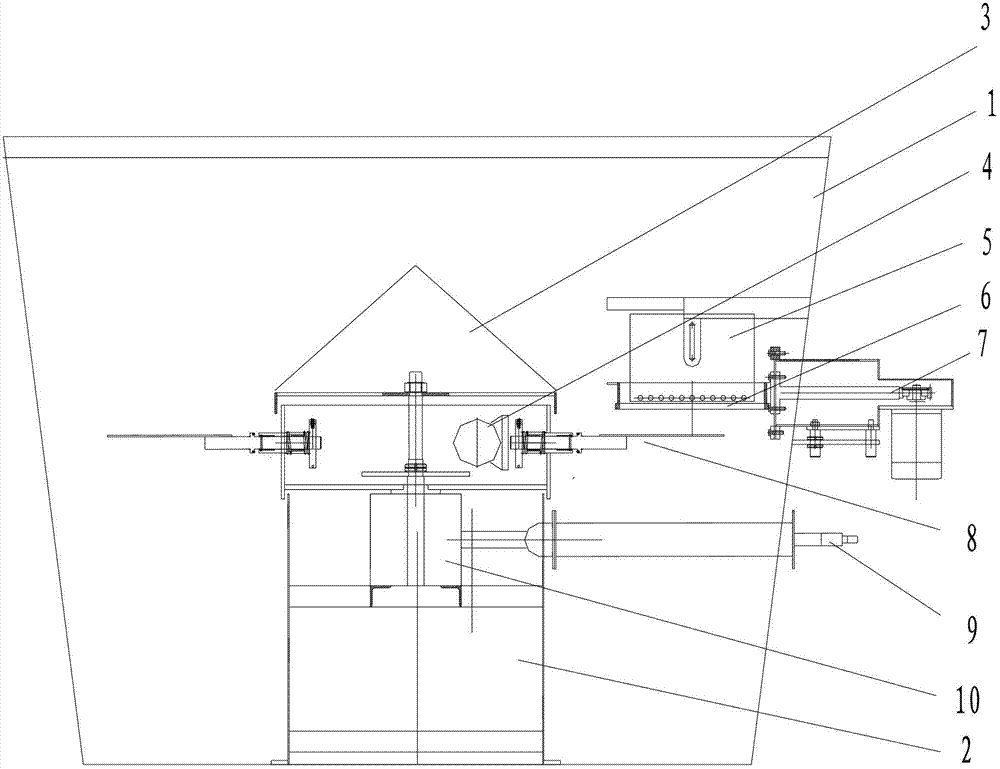

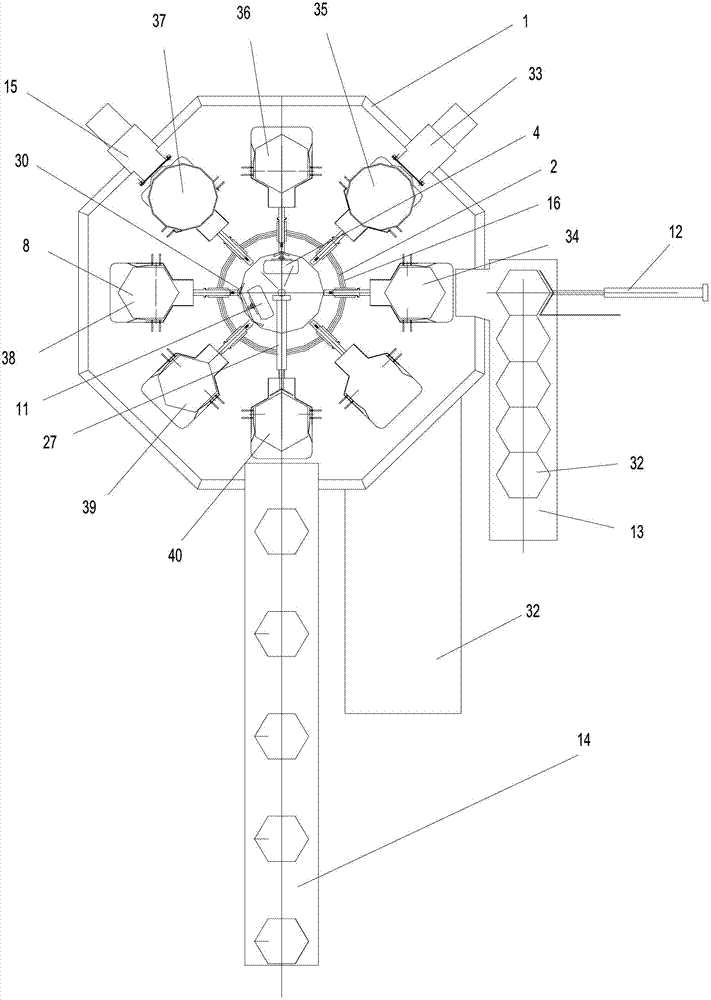

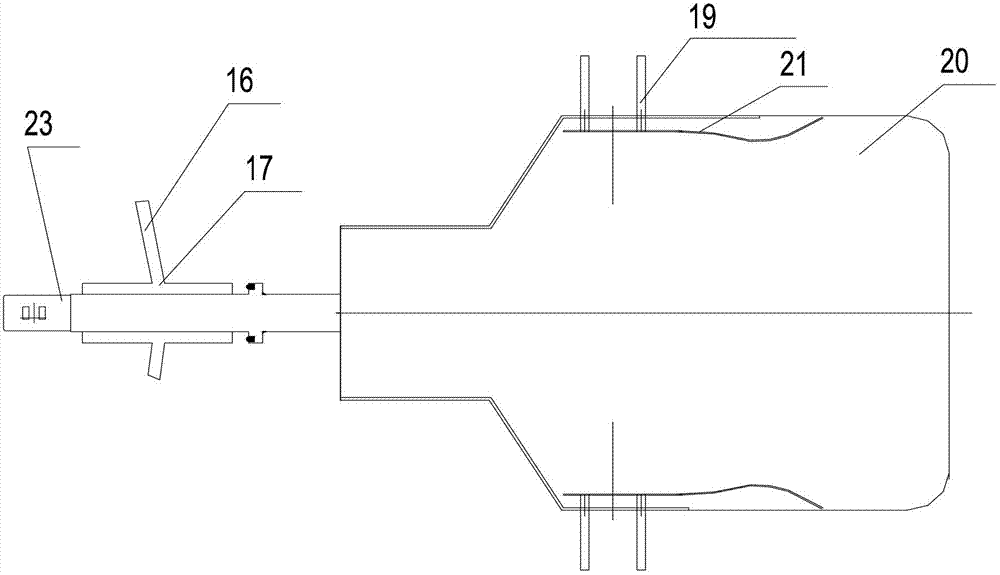

Machine for automatically charging gunpowder into firecrackers

The invention discloses a machine for automatically charging gunpowder into firecrackers. A turntable (16) is arranged on a frame (2); at least one workpiece tray unit (8) is arranged at the periphery of the turntable (16); a feeding station, a gunpowder charging station, a vibrating and residual gunpowder removing station and a discharging station are at least arranged on the frame (2) in sequence; a feeding conveying device and a conveying cylinder are butted with the feeding station; and a discharging conveying device is butted with the discharging station. The machine for automatically charging the gunpowder into the firecrackers is high in production efficiency, safety and measuring accuracy.

Owner:吴伟

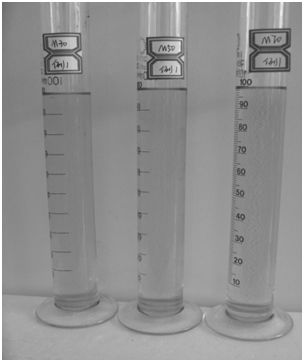

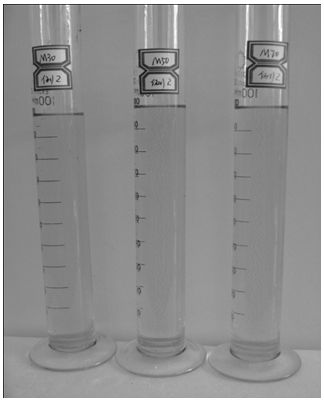

Moderate-proportion methanol gasoline additive

InactiveCN102304398AThe production process is simpleLow costLiquid carbonaceous fuelsHydrogen peroxideIsobutanol

The invention discloses a moderate-proportion methanol gasoline additive. The invention is characterized in that the additive is formed by mixing the following raw materials by volume percent: 5%-10% of ethanol, 10%-15% of isopropanol, 10%-15% of tertiary butanol, 5%-10% of benzene, 1%-5% of dimethylbenzene, 2%-5% of ethylbenzene, 5%-10% of petroleum ether, 1%-5% of hydrogen peroxide, 5%-10% of 3-ethyl toluene, 5%-10% of isobutanol, 1%-5% of ethyl ether, 1%-5% of isoamylol and 25%-30% of 120# solvent oil, wherein the volume percentage sum of the raw materials is 100%. In the moderate-proportion methanol gasoline additive, the physicochemical properties and combustion characteristic differences of different components are utilized, and substances of different systems are organically mixed and dissolved, thereby fully exerting the advantages of each component and overcoming the lacks of each component in property; and after the additive is added in the moderate-proportion methanol gasoline, the comprehensive performances of the moderate-proportion methanol gasoline, such as phase separation resistance, corrosion resistance, antiknock quality and antioxidation stability, can be effectively improved, wherein the effect of phase separation resistance is the most outstanding.

Owner:CHANGAN UNIV

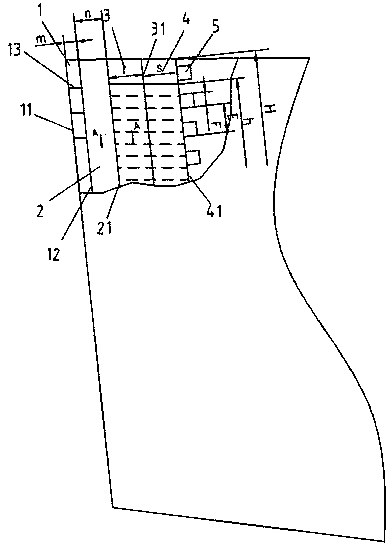

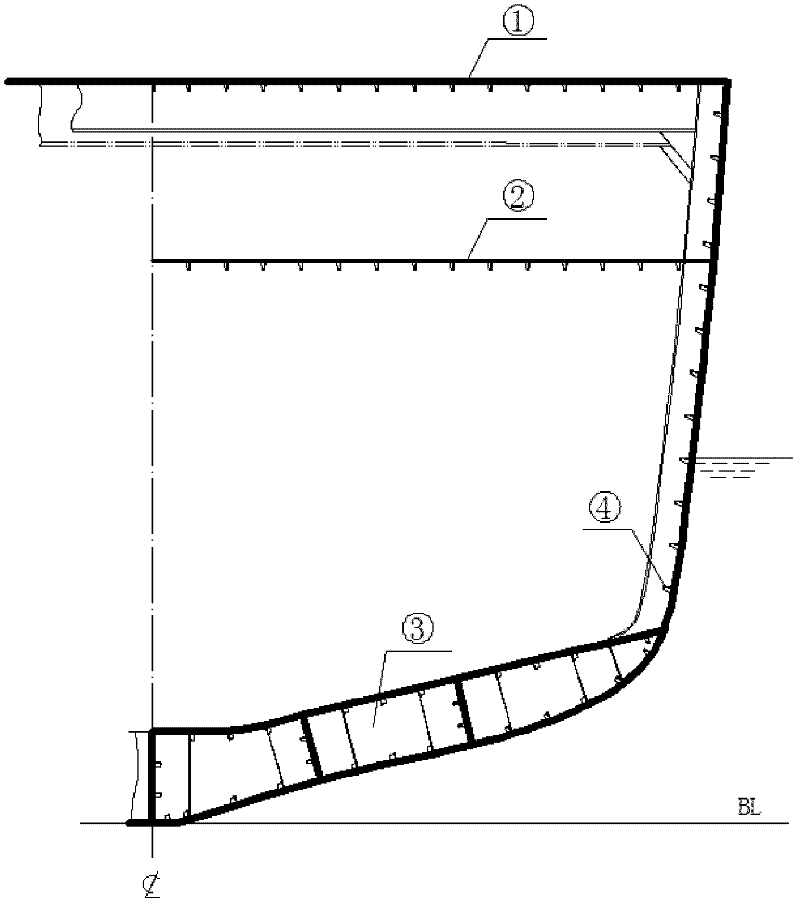

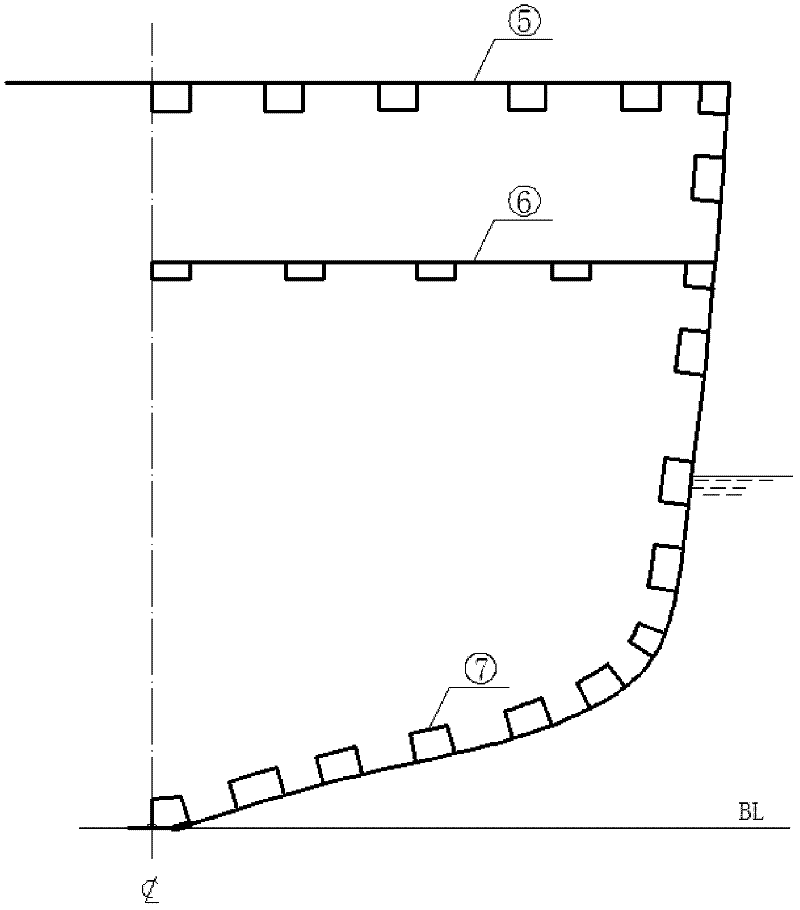

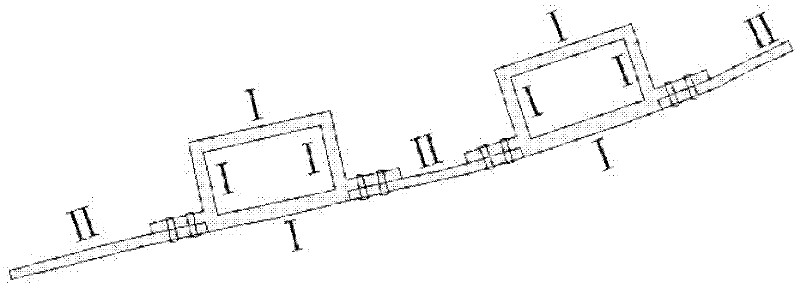

Warship board multilayer anti-detonation protection structure

ActiveCN103991518AIncreased damage areaReduce distortionVessel cleaningHullsDetonationUltimate tensile strength

The invention discloses a warship board multilayer anti-detonation protection structure. The warship board multilayer anti-detonation protection structure comprises a double-layer shell, a void compartment, a first liquid compartment and a second liquid compartment, wherein the double-layer shell, the void compartment, the first liquid compartment and the second liquid compartment are sequentially ranked from the outer side of a warship body to the inner side of the warship body, the water filling height h of the first liquid compartment and the water filling height h of the second liquid compartment are 70%-80% of a compartment height H, the void compartment is separated from the first liquid compartment through a first compartment separation plate, the first liquid compartment is separated from the second liquid compartment through a second compartment separation plate, the second liquid compartment is separated from an inner compartment of a warship through a third compartment separation plate, and the side, towards a compartment body, of the second liquid compartment is fixedly connected with a plurality of longitudinal box girders which are vertically ranked at intervals. The warship board multilayer anti-detonation protection structure with the structural style has the advantages of being light in weight, good in anti-detonation performance, high in residual intensity and the like, when a warship board is impacted by detonation, most detonation impact energy can be absorbed, the compartments of the warship are prevented from being damaged, and personal losses are avoided.

Owner:JIANGSU UNIV OF SCI & TECH

Methanol gasoline for vehicle and preparation method thereof

InactiveCN104004551AImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

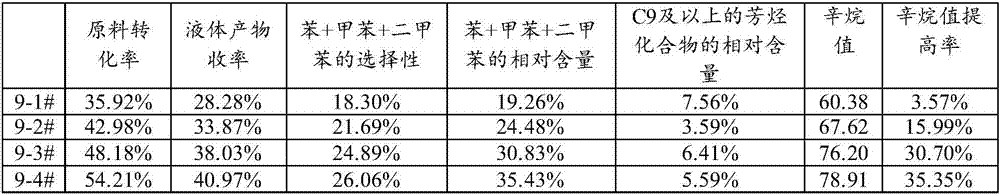

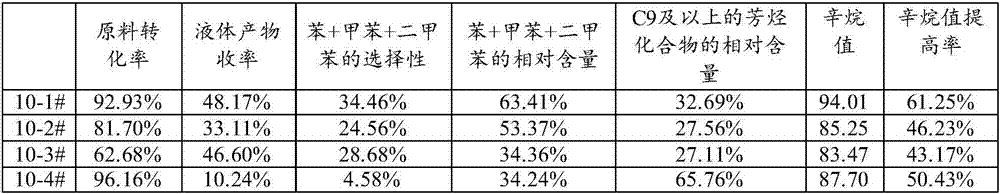

Preparation method of aromatic hydrocarbon oil

ActiveCN107418619AImprove conversion rateHigh yieldMolecular sieve catalystsHydrocarbon oils refiningAlkaneGasoline

The application provides a preparation method of aromatic hydrocarbon oil. Under a methane-containing atmosphere, raw oil rich in alkane components is subjected to an aromatization reaction under the action of an aromatization catalyst, so as to obtain the aromatic hydrocarbon oil. In the methane-containing atmosphere, the volume ratio of methane is 1 to 100 percent. The aromatization catalyst is a metal-supported ZSM-5 molecular sieve catalyst. The preparation method is simple and practicable, and facilitates large-scale production; moreover, according to the preparation method, the methane-containing atmosphere and the metal-supported ZSM-5 molecular sieve catalyst are combined, the catalytic action of the catalyst and the activation of the methane are cooperated and matched, the aromatization reaction of the raw oil can be promoted, the raw material conversion rate and the aromatic hydrocarbon yield are effectively improved, and the selectivity and yield of these light aromatic hydrocarbons such as benzene, methylbenzene and xylene therein are particularly improved; in addition, the aromatic hydrocarbon oil prepared according to the preparation method has a high octane number, the aromatic hydrocarbon oil serving as gasoline has good anti-detonating quality, and the engine power is improved and fuel is saved favorably.

Owner:SHANDONG JINGBO PETROCHEM +1

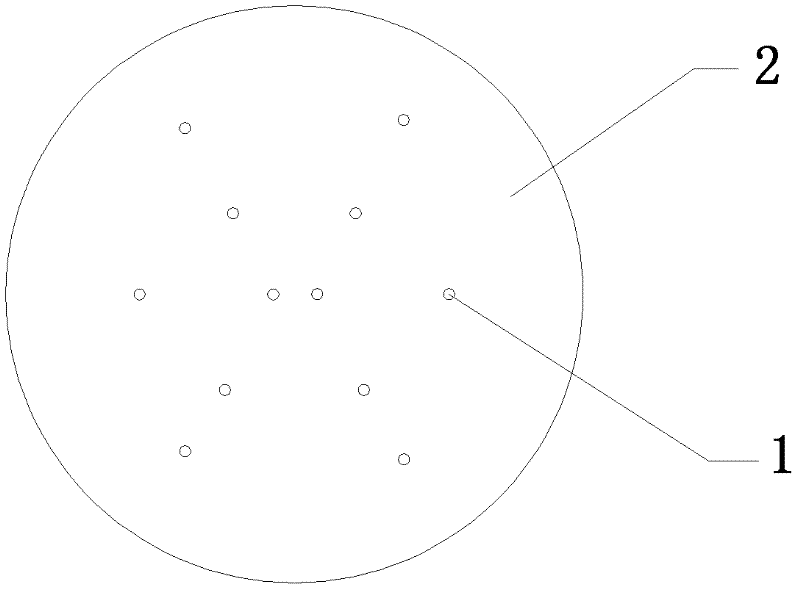

Light-weight safe battery cell support, and power battery pack

ActiveCN106252549ALight weightReduce manufacturing costSecondary cellsCell component detailsGlass fiberPower battery

The invention discloses a light-weight safe battery cell support, and a power battery pack. According to the light-weight safe battery cell support, a support main body is a noncombustible foamed block prepared from a macromolecule resin, a foaming agent, glass fiber, and stone powder via chemical foaming, air holes of the noncombustible foamed block formed after foaming are filled with inert gas such as carbon dioxide, nitrogen gas, and ammonia gas; first circular holes are uniformly distributed in the support main body, the support main body is penetrated by the first circular holes from top to bottom, and the first circular holes are formed in shaping process of the support main body. The core parts of the light-weight safe battery cell support comprise the support main body; the light-weight safe battery cell support is prepared via foaming of organic resins, is light, and can be recycled effectively; and production cost is reduced.

Owner:山东豪驰智能汽车有限公司

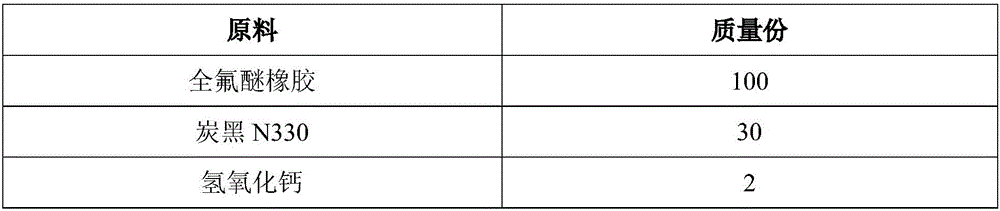

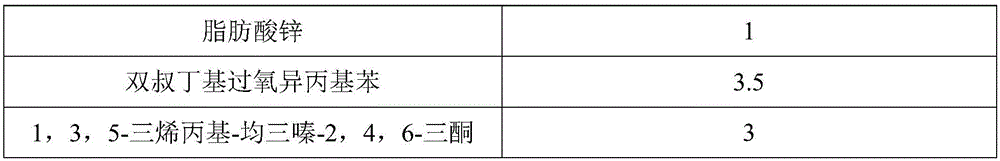

Anti-knock rubber O-ring material and preparation method thereof

The invention discloses an anti-knock rubber O-ring material and a preparation method thereof. The anti-knock rubber O-ring material is composed of the following raw materials in parts by mass: 100 parts of virgin rubber, 15-90 parts of reinforcing agent, 0.5-10 parts of acid acceptor, 0.5-4 parts of processing aid, 0.6-4 parts of vulcanizing agent and 1-6 parts of bridging aid. The preparation method comprises the following steps: adding the virgin rubber into an open mill or Banbury mixer, plasticizing, and adding the premixed reinforcing agent, acid acceptor and processing aid; after the powder is wetted, adding the vulcanizing agent and bridging aid, carrying out compounding and thin passing uniformly, discharging, and cooling to obtain the anti-knock rubber O-ring material. The anti-knock rubber O-ring material has the advantages of high hardness, high strength, high modulus, high tear resistance, excellent dispersity and the like. The O-ring prepared from the material has excellent anti-knock property, and can reach Grade 0000-1111 in NORSOK M-710 in an RGD test; and the compression deformation is small.

Owner:GUANGZHOU JST SEALS TECH

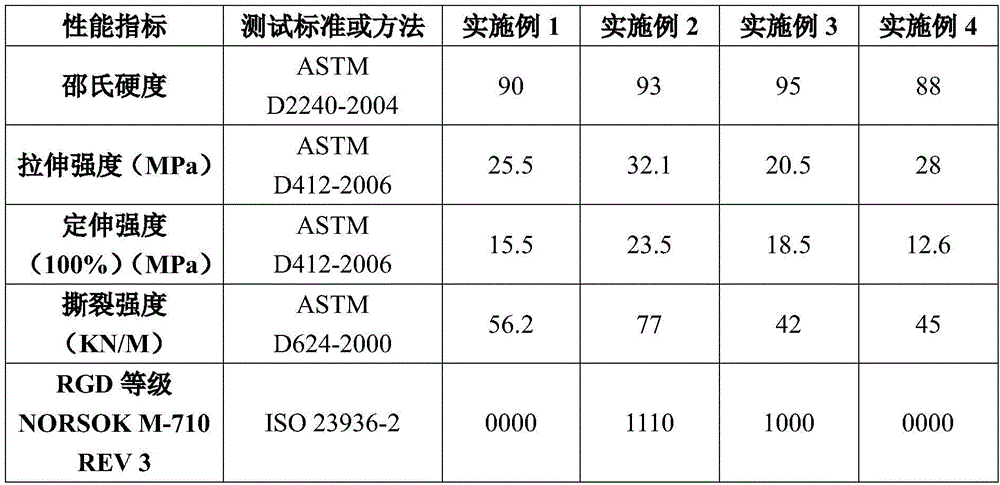

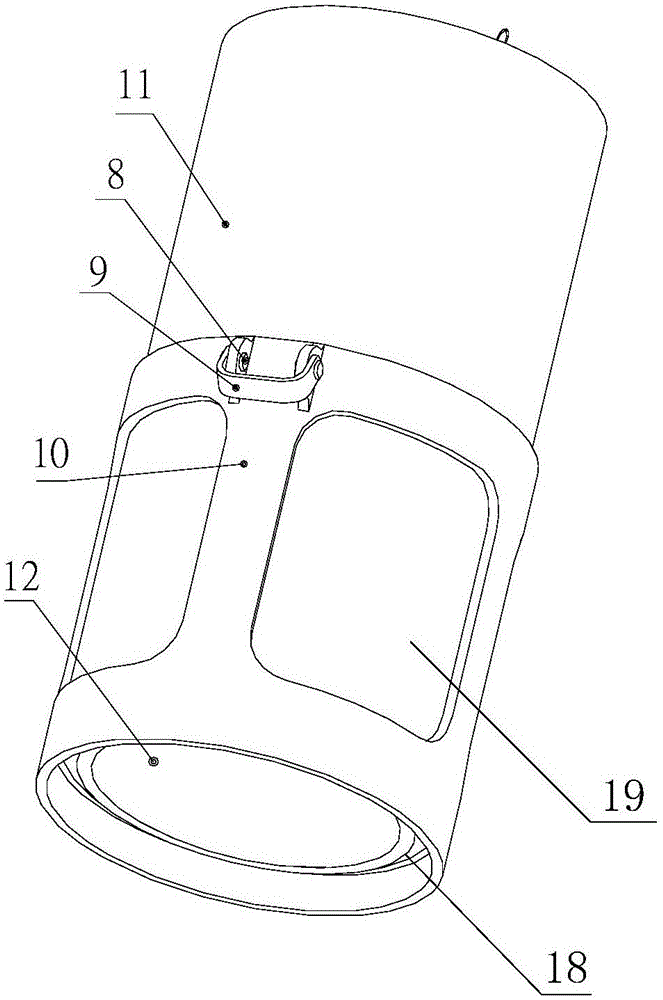

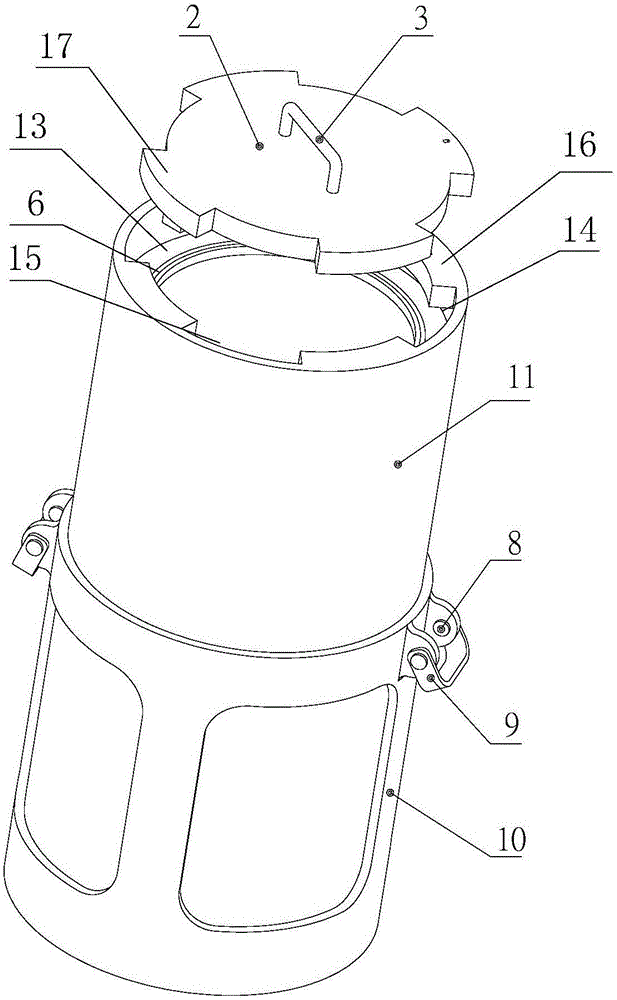

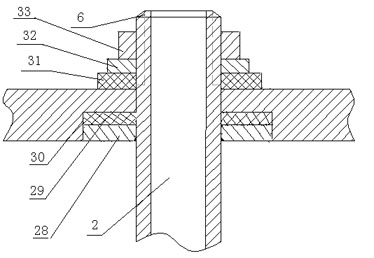

Anti-explosion container

ActiveCN106225608AGood explosion resistanceFast opening and closingAmmunition storageDesign technologyFlange

The invention discloses an anti-explosion container which mainly comprises a container body, a quick-opening end cover and a peripheral support. The container body mainly comprises a shell, an end flange and an ellipsoidal seal head, the end flange and the ellipsoidal seal head are respectively welded at two ends of the shell, and a concave clamp groove is formed in the flange by means of machining. The peripheral support sleeves the container body, so that a skirt support can be provided for the container, and the anti-explosion performance of the container body can be reinforced. Lugs are welded on the peripheral support, lifting handles are hinged to the lugs by dowels, and the container with the lugs is convenient to carry. The anti-explosion container with peripheral support reinforcement design technologies has the advantages of high anti-explosion equivalence, light weight, convenience in carrying and the like.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

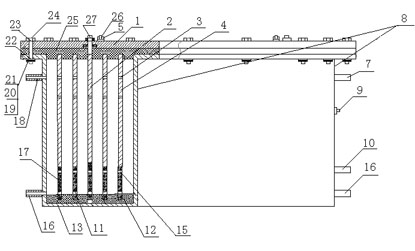

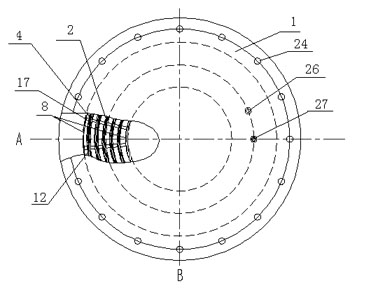

Design method of combined electrolytic tank

The invention relates to a design method of a water electrolysis hydrogen-oxygen generation device, in particular to a design method of a combined electrolytic tank. The electrolytic tank is characterized by being formed by sleeving and combining an anode, electrodes and a cathode in turn, particularly formed by sleeving two or eight tubular electrodes (4) with different tube diameters between a round anode (2) and a tubular cathode (8) at equal intervals in turn. The electrolytic tank has high anti-detonating property and sealing performance, a small sealing surface and a simple structure and is convenient to assemble and disassemble, electrolyte is difficult to leak, and the manufacturing cost is reduced.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

Clean fuel

A clean fuel is prepared from methanol or mixer of methanol and C5 fraction, alcohol, dimethyl ether, water, 120-200# gasoline, -5# diesel oil or plant oil, dimethyl carbonate and dimethylmethane. The prepared product can be used either for fuel or for oven gas with high heat value.

Owner:宋振中

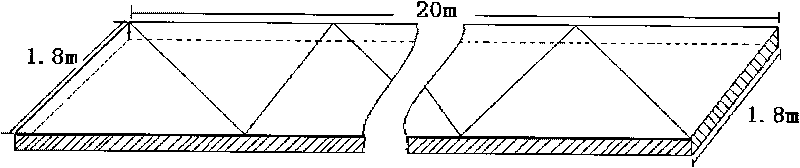

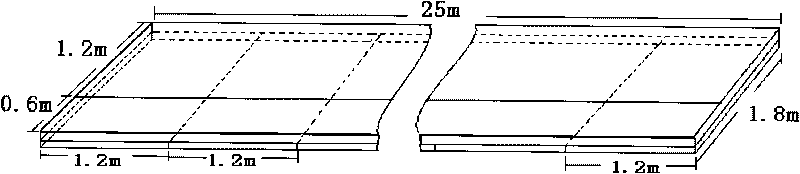

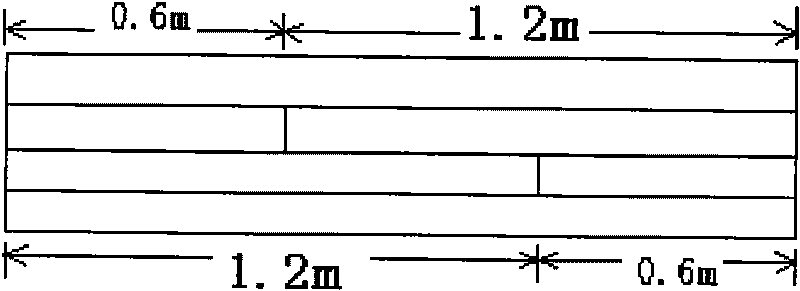

Car bomb explosion proof fence and use method thereof

The invention provides a car bomb explosion proof fence used for large quantities of explosive substances and large-size explosive substances and a use method thereof for preventing that the explosion of a car bomb or an irregular large-size suspected object damages surrounding people and environment. The width of the car bomb explosion proof fence is at least 1.8m, and the length is at least 20m. The car bomb explosion proof fence is formed by overlying at least 20 layers of high-performance fiber composite materials and sewing in a Z-shaped way, wherein high-performance fibers are preferable for high-strength high-modulus ultrahigh molecular weight polyethylene fibers. Both tail ends of the car bomb explosion proof fence are respectively provided with a connecting device such as a hole punching connecting device. When in use, a rigid inner bracket is used for enclosing the suspected object firstly, then the fence is wrapped and wound outside the inner bracket, and finally, the fence is bound by using the high-performance fibers.

Owner:SURREY HI TECH INC

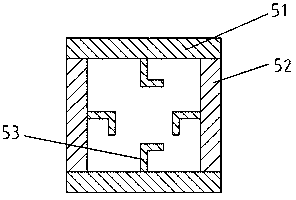

Anti-impact protection structure for box type beams of hull

InactiveCN102407920AGood strength propertiesTotal strength has no effectHull framesResidual strengthUltimate tensile strength

The invention aims at providing an anti-impact protection structure for box type beams of a hull. The anti-impact protection structure comprises box type beams, an upper deck, a lower deck and ship planking, wherein the box type beams are respectively arranged on the upper deck, the lower deck and the ship planking; the section of each box type beam is of a quadrilateral structure formed by an inner plate of the box type beam, an outer plant of the box type beam and two box type beam supporting plates, wherein the inner plate of the box type beam and the outer plate of the box type beam are opposite sides and the lengths of the opposite sides are a; the two box type beam supporting plates are opposite sides and the lengths of the opposite sides are b; the two box type beam supporting plates are respectively provided with connecting plates for connecting the upper deck, the lower deck and the ship planking; and the upper deck, the lower deck and the ship planking are made of composite materials. The anti-impact protection structure has the advantages of good intensity characteristic, good explosion-proof performance and high residual intensity, and is beneficial for reducing the weight of the hull, protecting important pipelines and cables, and improving construction speed, quality control and maintenance.

Owner:HARBIN ENG UNIV

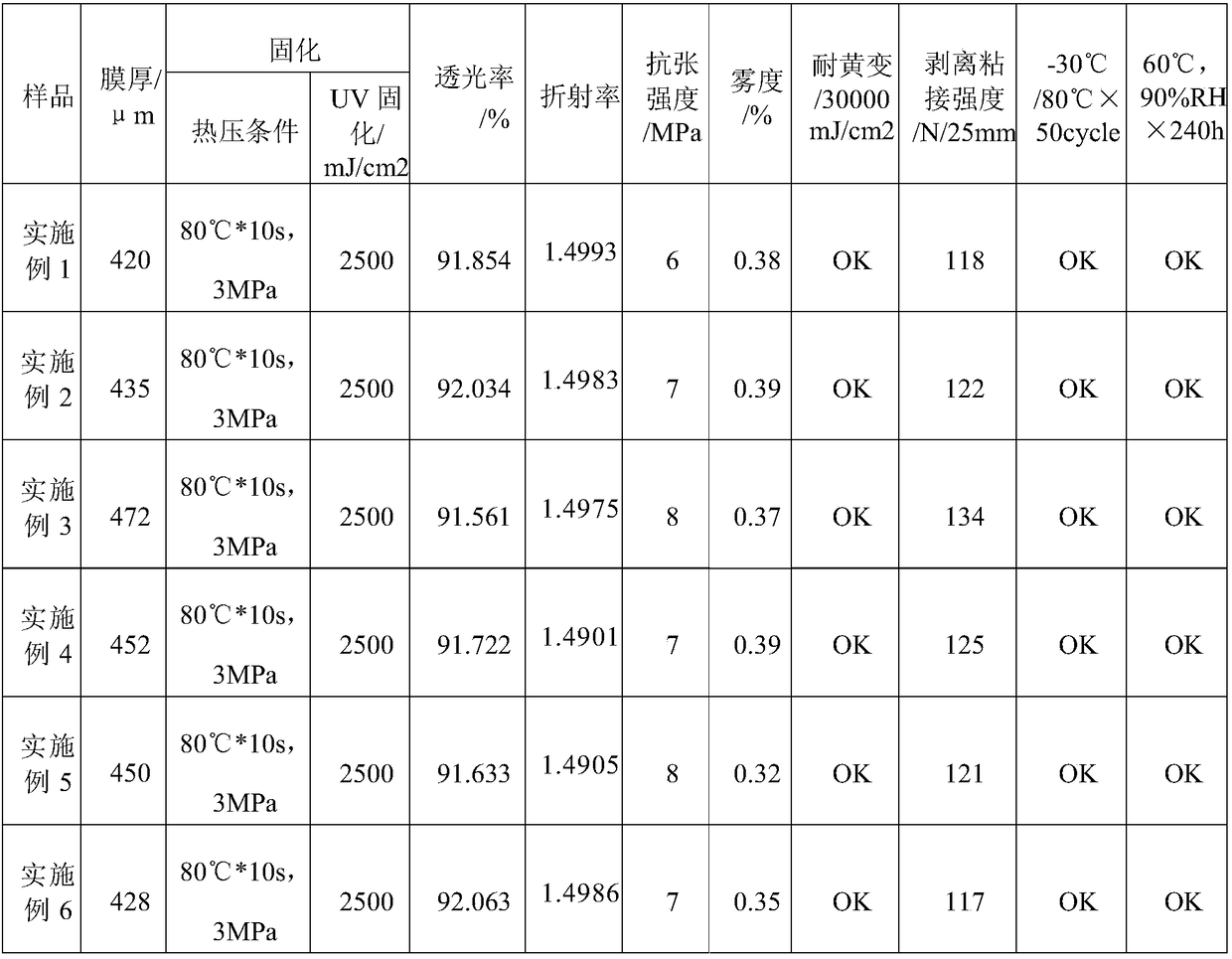

Hot-melting light-curing optical adhesive for laminating capacitance-type touch screen and preparation method

InactiveCN108329867AImprove securityImprove reliabilityNon-macromolecular adhesive additivesFilm/foil adhesivesCapacitanceAdhesive

The invention relates to hot-melting light-curing optical adhesive for laminating a capacitance-type touch screen. The hot-melting light-curing optical adhesive is prepared from the following components in parts by weight: 50 to 70 parts of main body resin, 10 to 30 parts of auxiliary resin, 10 to 15 parts of tackifier, 1 to 5 parts of light initiator, and 0.5 to 2 parts of antioxidant; the main body resin is vinyl-vinyl acetate copolymeric resin; the auxiliary resin is acrylate modified isoprene rubber resin; the tackifier is a mixture of one or two of the following substances: terpene resinand polybutadiene rubber resin; and the antioxidant is a mixture of one or more of the following substances: beta-(3,5-di-tert-butyl-4-hydroxyphenyl)N-octadecanol propionate, 1,1,3-tri(2-methyl-4-hydroxyl-5-tert-butylphenyl)butane, dilauroyl thiodipropionate and organic phosphite. The adhesive is suitable for laminating a large-sized CTP as well as fully laminating a panel computer, a computer, aliquid crystal display, an one-piece machine, a vehicle-mounted navigator and the like, and can provide a perfect visual effect for the display of the touch screen.

Owner:惠州市飞世尔实业有限公司

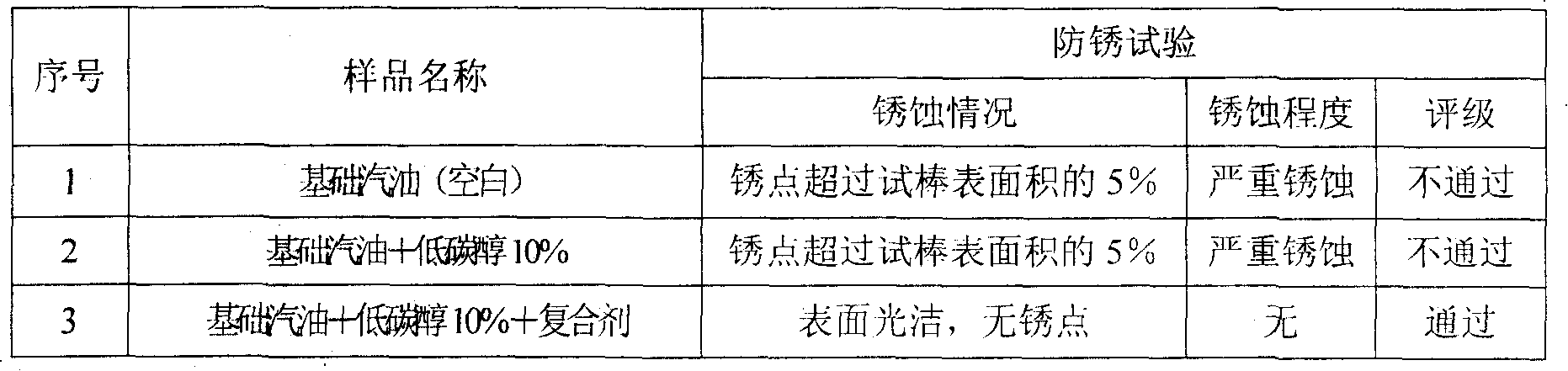

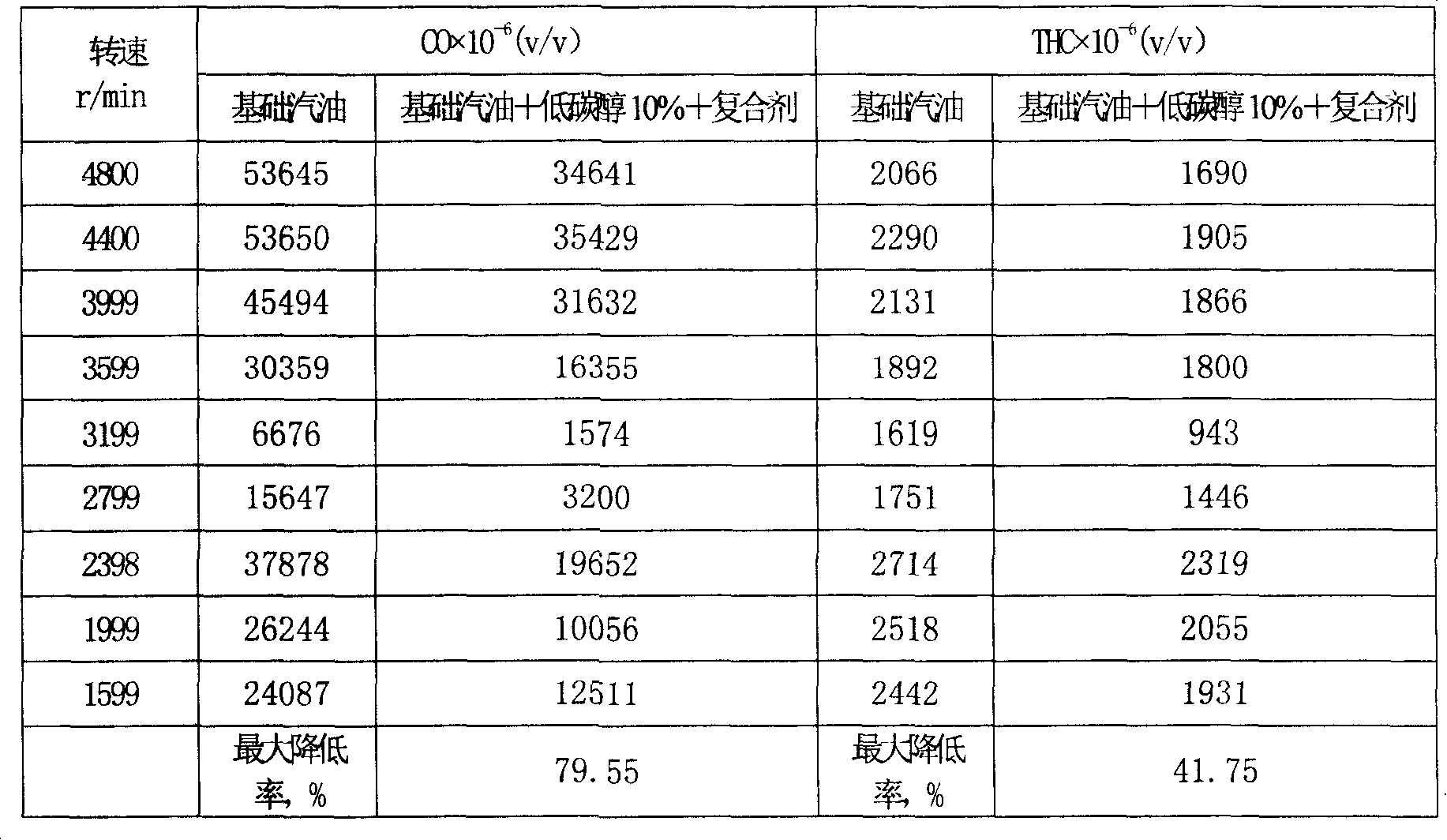

Low carbon mixture alcohol gasoline

ActiveCN101195769AEmission reductionImprove emission characteristicsLiquid carbonaceous fuelsAlternative fuelsInlet valve

The invention relates to high-octane unleaded synthetic gasoline-low carbon mixed alcohol gasoline, which belongs to the substitution fuel field. The invention adopts low- octane gasoline, high-octane low carbon mixed alcohol and auxiliary proper additive agent, therefore not only the invention can improve the octane value of gasoline, decrease the emission of CO and HC in the automobile exhaust, obviously reduce the generation of intake valve deposits, but also the allocated gasoline is not required to be added with any additive agent being helpful for dissolution, and the invention has good mutual solubility. The synthetic gasoline does not have bad corrosivity and corrosion, has the advantages of good oxidation resistance, good explosion resistance, good security, good stability and good detergency property, can directly replace the gasoline and is used for various vehicles, is very favorable for the environment protection and the energy conservation, and has good economic and social benefits. The manufacturing method is simple and feasible, and is easy for promotion.

Owner:PETROCHINA CO LTD

Intelligent concrete being good in durability

InactiveCN105837114ADefend against precision strikesIncreased durabilitySolid waste managementMetal fibersSelf sensing

The invention discloses intelligent concrete being good in durability, which includes, by weight, 27-38 parts of Portland cement, 8.5-9.5 parts of silica fume, 0-8 parts of quartz sand, 39-41 parts of fine sand, 5.5-8 parts of metal fibers, 0.5-1 part of a high-effective water reducer and 5.5-8 parts of water. In the invention, on the basis of the original components of the present concrete, an intelligent component is composited so that the concrete becomes a multifunctional material having the self-sensing, memory, self-adapting, self-repairing and ultra-strong properties. The concrete achieves great development of engineering materials, is ultra-high in durability and mechanical performances, and can effectively defense earthquake, earth penetration bombs and accurate strike of missiles, The concrete is good in durability, approximates steel structures in mechanical performance after proper bar reinforcement, has excellent anti-wear and explosion resistant performances, is suitable for high-span bridges, explosion resistant structures and thin wall structures, and also can be used in high-abrasion and high-corrosion environments.

Owner:四川锦顺兴新材料科技有限公司

Biomass clean gasoline

InactiveCN102161917ARatio increaseReduced blending ratioLiquid carbonaceous fuelsEngineeringMethanol

The invention discloses biomass clean gasoline and a preparation method thereof. The biomass clean gasoline is characterized by consisting of biological methanol, national standard gasoline or crude gasoline and auxiliaries (heat value synergist, combustion-supporting smoke-removing agent, stabilizer and the like). The preparation method of the biomass clean gasoline is performed at room temperature and normal pressure and has simple operation process is simple; raw material source is wide and cannot be exhausted, cost is low, the engine and other parts of the existing automobile do not need to be modified or updated, igniting property is good, starting is easy, the emission of tail gas reaches national standard and Europe standard III, the content of carbon monoxide is reduced by 98%, the content of a hydrocarbon compound is reduced by 30-40.5%, and the mark number can reach 90-120 standard.

Owner:雷菊花

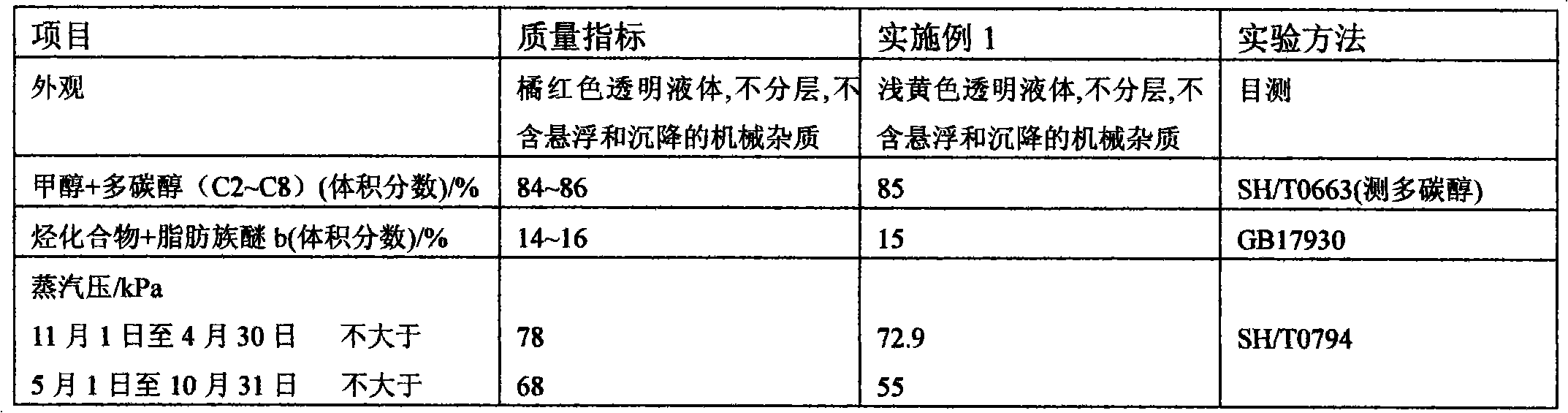

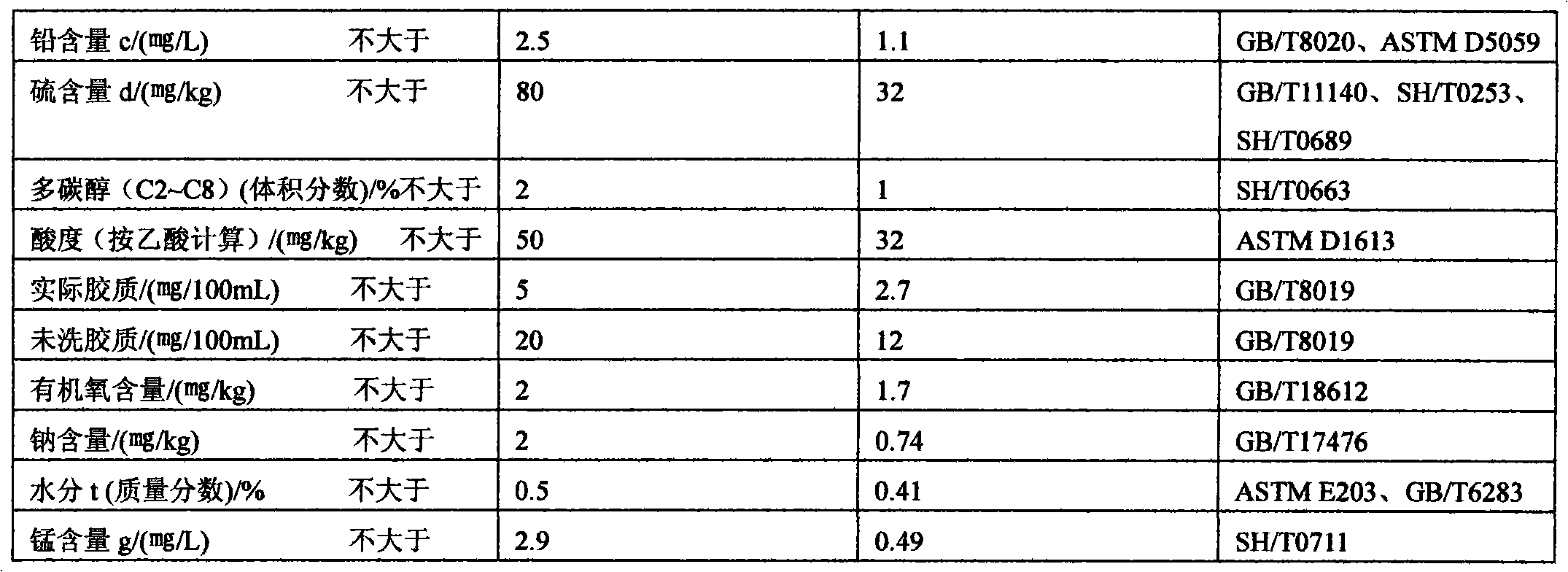

Vehicle high-proportion methanol gasoline and preparation method thereof

InactiveCN101955809ANo corrosionImprove cold start performanceLiquid carbonaceous fuelsAlcoholGasoline

The invention belongs to the field of fuels and relates to a vehicle high-proportion methanol gasoline and a preparation method thereof. The vehicle high-proportion methanol gasoline comprises the following components in percentage by weight: 85 to 90 percent of methanol, 3 to 4 percent of solvent oil, 5 to 10 percent of No. 90 national standard gasoline and 1 to 2 percent of additive, wherein the additive is prepared by blending sodium hexadecyl sulfonate, calcium hexadecyl sulfonate, liquid naphthenic acid, methylal, nitromethane and C3-C8 monohydric alcohol. The high-proportion methanol gasoline of the invention overcomes the disadvantages of the traditional high-proportion methanol gasoline under the condition of no change of the vehicles; each index completely meets the standard of vehicle methanol gasoline M85 of 'GB / T23799-2009'; and the vehicle high-proportion methanol gasoline can be well applied to vehicles.

Owner:于涛

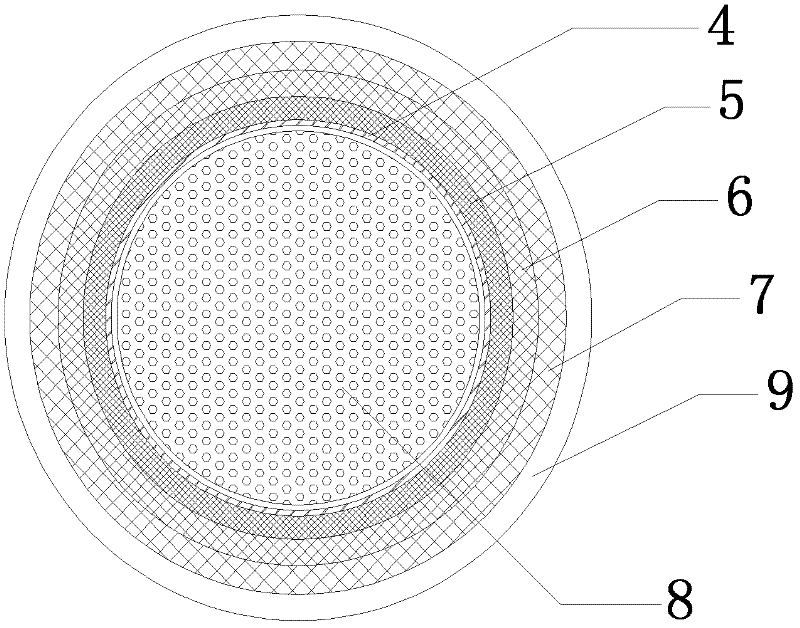

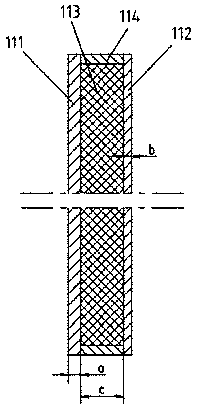

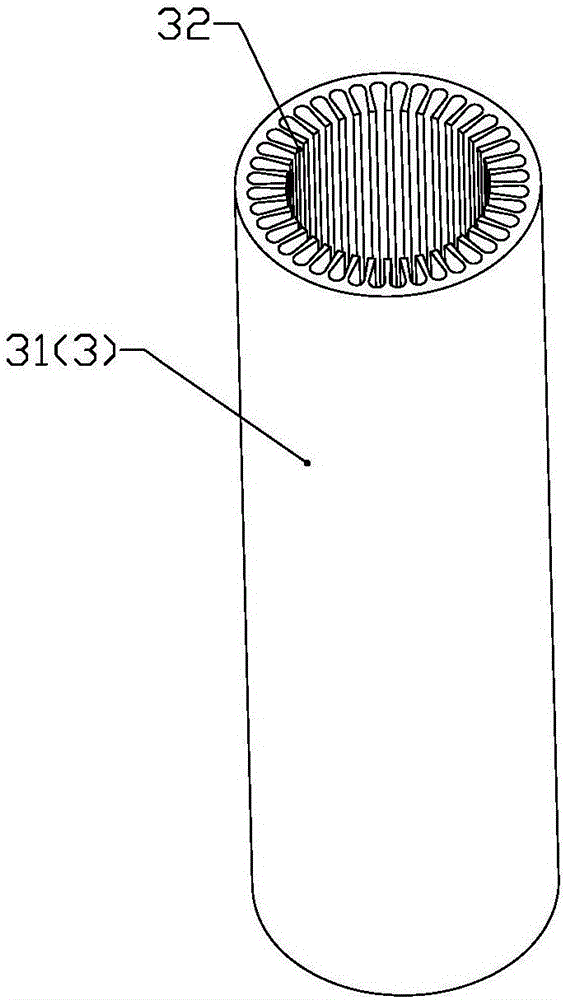

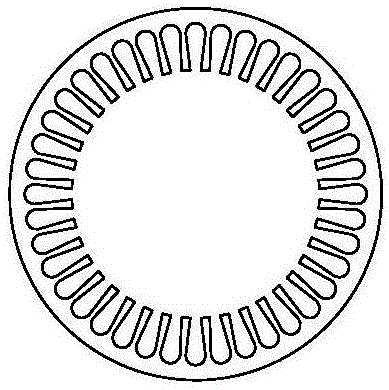

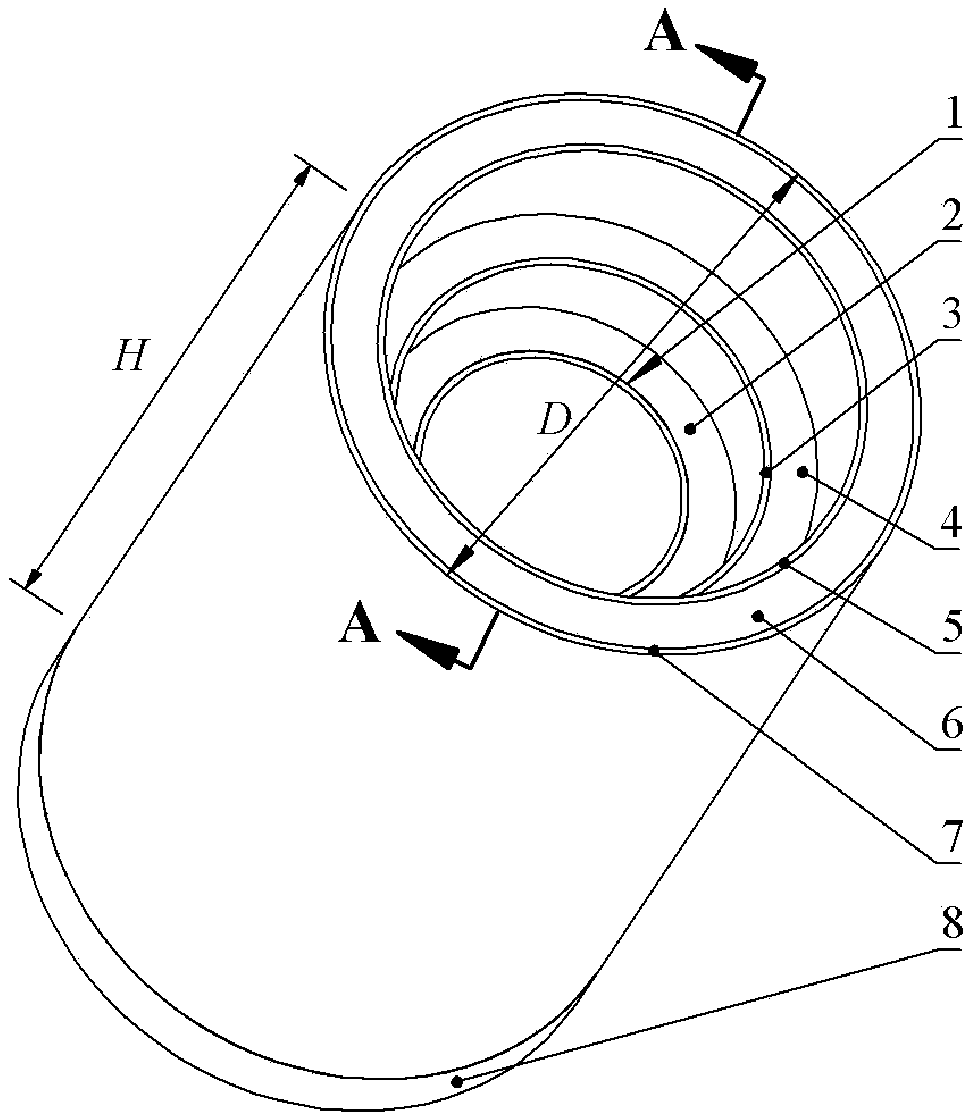

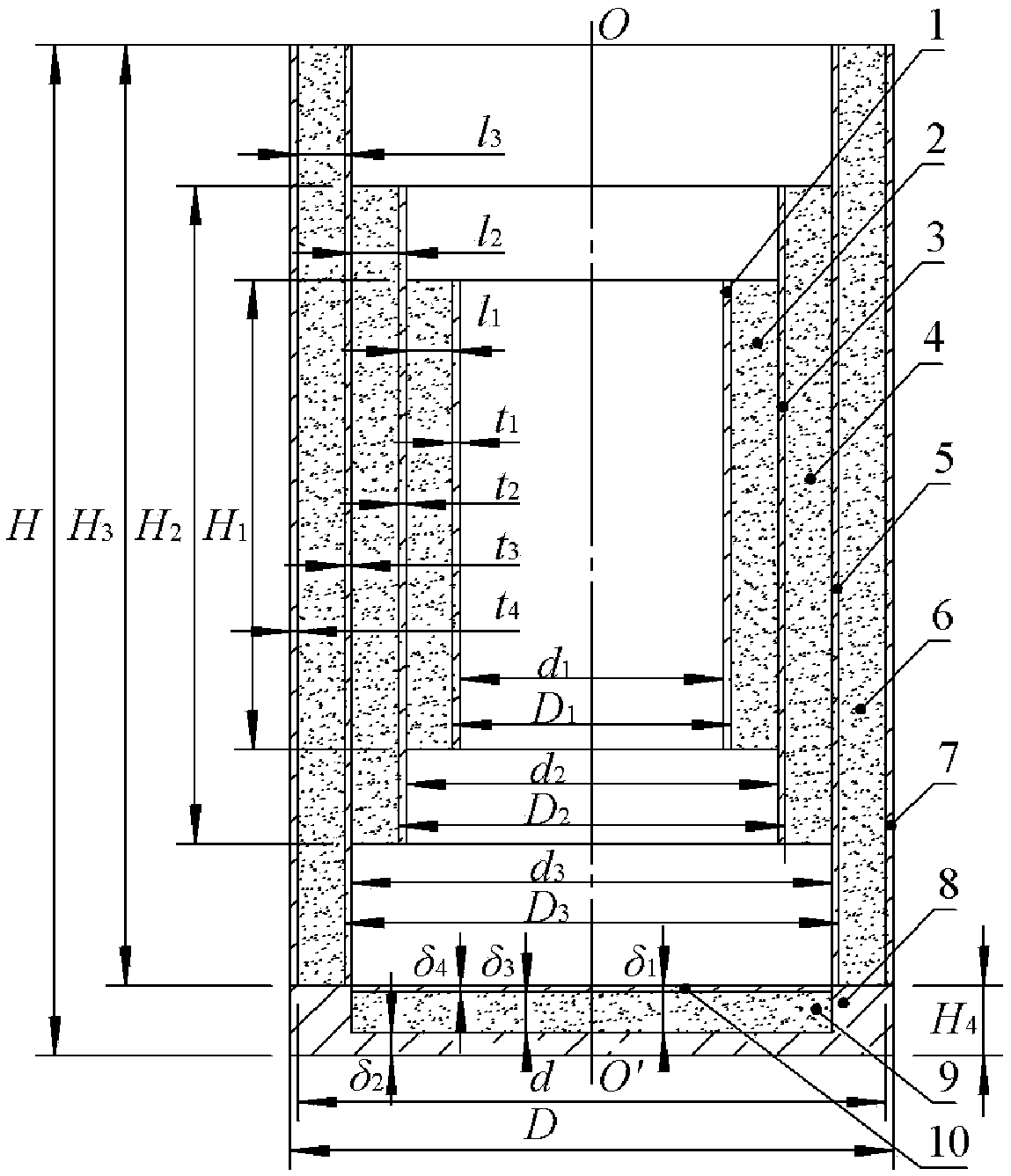

Variable-cross-section gradient foam core cylinder anti-explosion structure

The invention discloses a variable-cross-section gradient foam core cylinder anti-explosion structure. The variable-cross-section gradient foam core cylinder anti-explosion structure aims at reducingthe mass of the anti-explosion structure and improving the anti-explosion performance of the structure. The variable-cross-section gradient foam core cylinder anti-explosion structure is overall cylindrical, and is composed of an inner surface plate, an inner core, a middle surface plate, a middle core an outer surface plate, an outer core, a shell, a bottom cover, a bottom core and a bottom surface plate. According to the variable-cross-section gradient foam core cylinder anti-explosion structure, variable-cross-section multilayer gradient foam core structural design is adopted, the containing volume of detonation products can be increased, and the total mass of the structure can be reduced. A gradient foam core can five full play to the excellent buffering and energy absorption performance of a gradient metal foam material, and the core structure has excellent mechanical properties of low mass, high strength, high energy absorption efficiency and the like. Compared with a traditionalcylinder anti-explosion structure of a single material, the explosion resisting performance is better and the total mass of the structure is lower.

Owner:NAT UNIV OF DEFENSE TECH

Mixed green gasoline and its prepn

InactiveCN1810937AGood miscibilityGood explosion resistanceLiquid carbonaceous fuelsExhaust gasChemistry

The present invention provides one kind of mixed gasoline for motor vehicle and its compounding process. The mixed gasoline is compounded with gasoline 65-90 wt%, methanol 5-25 wt%, ethanol 5-25 wt% and co-solvent 0.3-3 wt%. It is compounded through adding methanol, ethanol, gasoline and co-solvent successively into some container and mixing. Compared with common gasoline, the mixed gasoline of the present invention has an 8 % lowered consumption and a 70 % reduced harmful gas exhaust.

Owner:何冬益

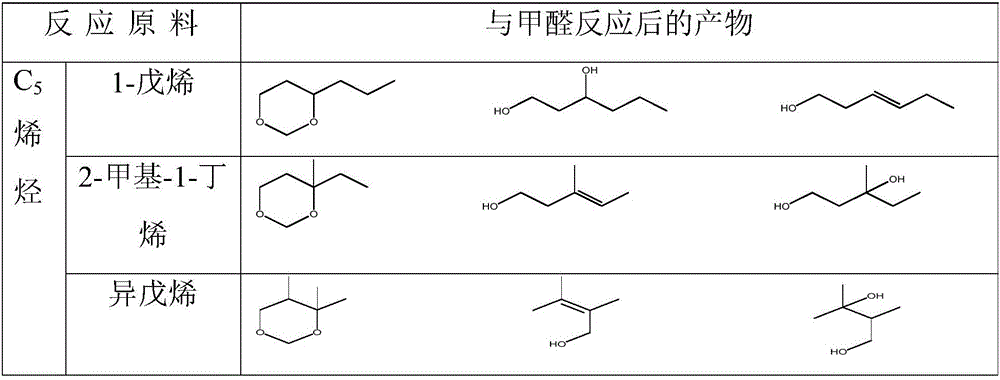

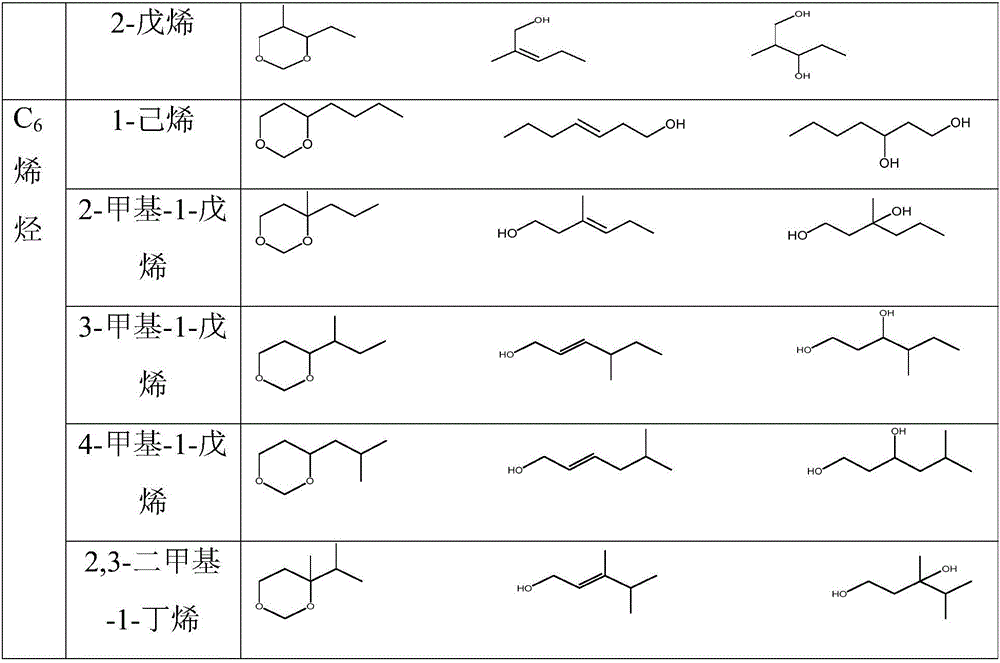

Method for reducing olefin content of catalytically cracked gasoline

ActiveCN106520180AReduce contentLow priceLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionMass ratioSolid acid

The invention relates to a method for reducing the olefin content of catalytically cracked gasoline. The method comprises the following steps: (1) adding C5-C6 fractions of the catalytically cracked gasoline and formaldehyde into a slurry-bed reactor according to a mass ratio, and adding a solid acid catalyst; carrying out a reaction under a protection atmosphere of inert gas; and (2) carrying out deacidification treatment, formaldehyde removing treatment and rectification dehydration treatment on a reaction product obtained by the step (1) to finally obtain a catalytically cracked gasoline product with the reduced olefin content. According to the method for reducing the olefin content of the catalytically cracked gasoline, provided by the invention, the olefin content in the catalytically cracked gasoline can be effectively reduced and the oxygen content of the gasoline is increased, so that the octane number of the gasoline is improved; and the method has the advantages that the cost is saved and the economic benefits are good.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Methanol gasoline

InactiveCN102899101AReduce consumptionAlleviate resource constraintsLiquid carbonaceous fuelsPollutant emissionsGasoline

The invention relates to an automobile fuel, in particular to an energy-saving and environment-friendly vehicle methanol gasoline. The methanol gasoline comprises the following components in percentage by weight: 20-40 percent of gasoline, 40-60 percent of methanol, 3-5 percent of cosolvent and 1-3 percent of additives. A product provided by the invention can be directly used as the automobile fuel, 50 percent of petroleum can be saved and over 60 percent of pollutant emission can be reduced, and the methanol gasoline has the double significance of energy conservation and emission reduction.

Owner:ZHENGZHOU GUOCHUANG ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com