Hot-melting light-curing optical adhesive for laminating capacitance-type touch screen and preparation method

A capacitive touch screen and light-curing technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve problems such as difficult lamination, difficult removal of air bubbles, easy flow of glue, etc., to achieve excellent shock resistance and explosion resistance Performance, maintenance stability and long-term, superior moisture resistance, heat resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

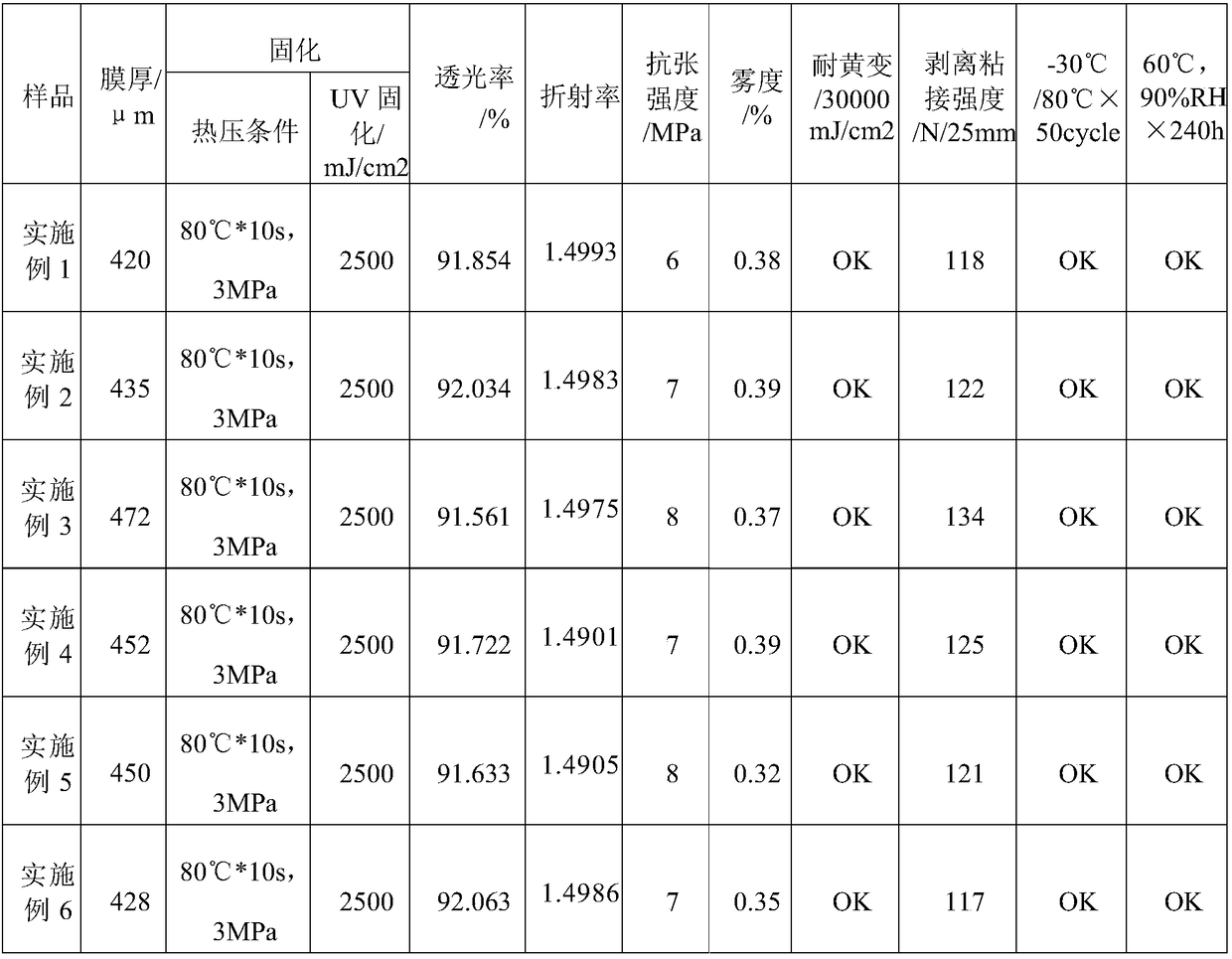

Examples

preparation example Construction

[0029]The present invention also proposes a method for preparing the above-mentioned hot-melt light-curable optical adhesive for laminating the capacitive touch screen, comprising the following steps:

[0030] Step 1: According to parts by weight, weigh 50-70 parts of main resin, 10-30 parts of auxiliary resin, 10-15 parts of tackifier, 1-5 parts of photoinitiator, and 0.5-2 parts of antioxidant.

[0031] Step 2: Mix the weighed components with an open mill to obtain a uniformly dispersed rubber mix.

[0032] Step 3: Put the compounded rubber into the laminating machine to melt and form a film to obtain a hot-melt light-curable optical adhesive product for laminating the capacitive touch screen.

Embodiment 1

[0034] Take the following components:

[0035] 50g of main resin (50g of EVA resin of Dupont 150 grade is selected);

[0036] Auxiliary resin 30g (select the 15g grade to be the acrylate modified isoprene rubber resin of Kuraray LIR-102 and the 15g grade to be the acrylate modified isoprene rubber resin of Kuraray LIR-203);

[0037] Tackifier 15g (select 10g trade mark to be the terpene resin of Pinova PiccolyteS115 and the 5g trade mark to be the polybutadiene rubber resin of Kuraray LBR-305);

[0038] Photoinitiator 3g (select 3g photoinitiator 184 for use);

[0039] Antioxidant 2g (select 2g antioxidant 1076).

[0040] Mix the weighed components with an open mill to obtain a uniformly dispersed rubber mix.

[0041] Put the mixed glue into the laminating machine, melt and form the film, and obtain the hot-melt light-curable optical adhesive product for laminating the capacitive touch screen.

Embodiment 2

[0043] Take the following components:

[0044] 65g of main resin (select 65g of Mitsui 40W EVA resin);

[0045] Auxiliary resin 23g (select 23g brand to be the acrylate modified isoprene rubber resin of Kuraray LIR-203);

[0046] Tackifier 10g (select the terpene resin of Pinova PiccolyteS115 and the polybutadiene rubber resin of Kuraray LBR-300 for use with the 5g trade mark for use);

[0047] Photoinitiator 1g (select 1g photoinitiator TPO);

[0048] Antioxidant 1g (choose 1g antioxidant CA).

[0049] Mix the weighed components with an open mill to obtain a uniformly dispersed rubber mix.

[0050] Put the mixed glue into the laminating machine, melt and form the film, and obtain the hot-melt light-curable optical adhesive product for laminating the capacitive touch screen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| curing dosage | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com