Car bomb explosion proof fence and use method thereof

A technology for bombs and fences, applied in blasting and other directions, can solve the problem of inability to apply explosion-proof lethality, and achieve the effects of excellent anti-explosion performance, easy portability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

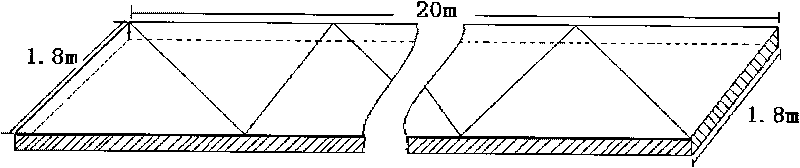

[0034] Such as figure 1 As shown, the car bomb explosion-proof fence has a width of at least 1.8m and a length of 20m; it is composed of 20 layers of high-strength, high-modulus ultra-high molecular weight polyethylene fiber non-weft composite materials, and adopts "Z" type overall sewing. Sewing machine for sewing. Each layer of the non-weft cloth composite material is composed of at least two layers of non-weft cloth orthogonally superimposed.

Embodiment 2

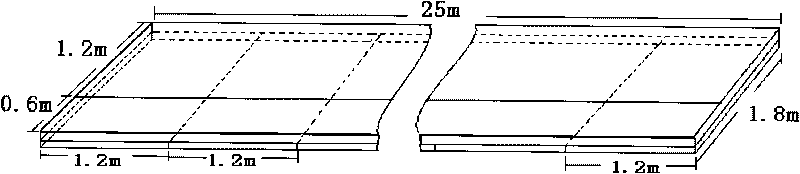

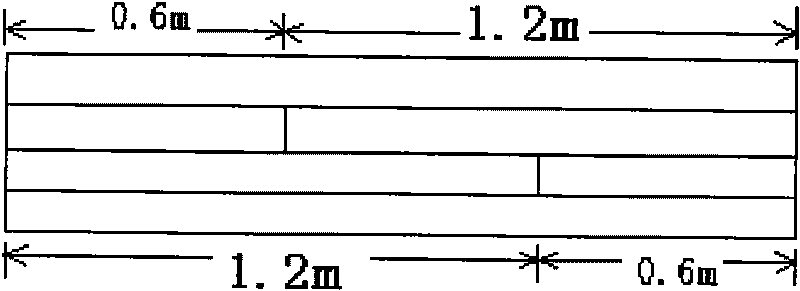

[0036] see figure 2 , image 3 , the car bomb explosion-proof fence width is at least 1.8m, and the length is 25m. The high-strength and high-modulus polyethylene fiber composite continuous roll with a width of 1.2m is used as the basic material, which is divided into two units with a total of 40 layers. The materials are arranged as shown in the figure: the first unit, the 10th floor is 0-degree direction, 1.8m wide, and 1.2m+0.6m composite sheet is used for sewing seams; the 10th floor is 90-degree direction, 1.2m wide×1.8 The m-long composite sheets are spliced continuously. The second unit: the 10th floor is 0 degree direction, 1.8m wide, using 1.2m+0.6m composite sheet to sew the seam, the seam is in the opposite direction to the first unit seam; the 10th floor is 90 degree direction, using 1.2m Sheets of width × 1.8m length are spliced continuously.

[0037] The above-mentioned 40-layer composite coil material superimposed adopts "Z" type integral sewing as a wh...

Embodiment 3

[0039] A method of using an explosion-proof fence for a car bomb,

[0040] Including step 1. Use the continuous roller shutter aluminum alloy fence as a bracket to surround large suspicious explosives,

[0041] Step 2. Surround the explosion-proof fence of the car bomb on the outside of the above-mentioned aluminum alloy inner bracket. According to the TNT explosive equivalent, it can surround the multi-layer explosion-proof fence, and each fence is connected through the buckle interface at its respective end.

[0042] Step 3. Bind with four high-performance fiber tapes on the outermost layer, and the high-performance fiber tapes are evenly distributed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com