Patents

Literature

47 results about "Tert-Amyl methyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tert-Amyl methyl ether (TAME) is an ether used as a fuel oxygenate. TAME derives from C5 distillation fractions of naphtha. It has an ethereous odor. Unlike most ethers, it does not require a stabilizer as it does not form peroxides on storage.

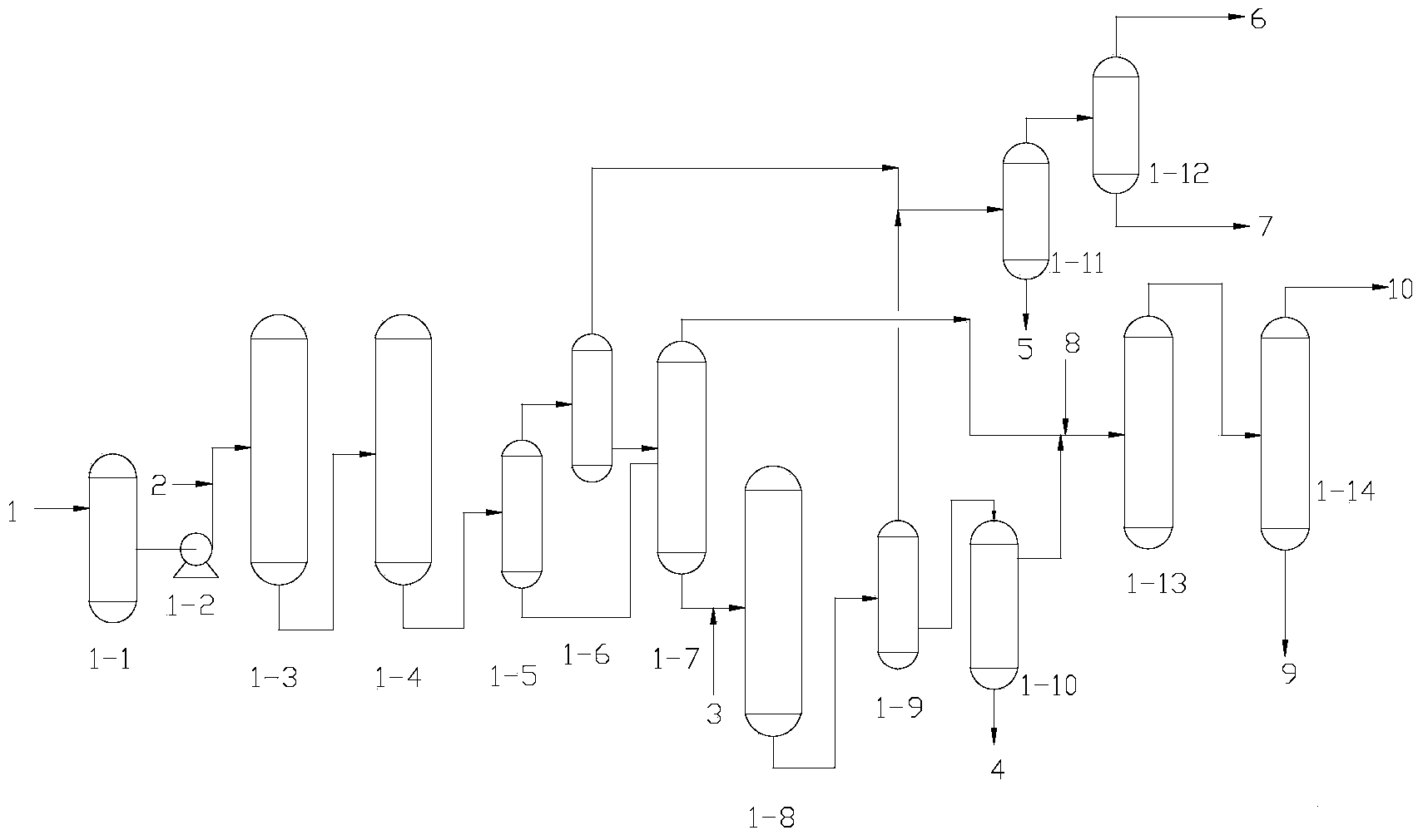

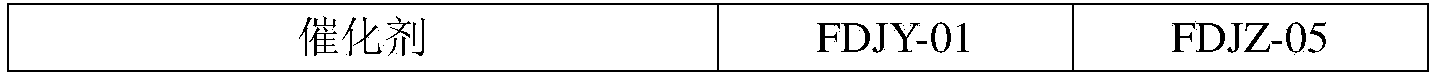

Combined process of catalytic gasoline selective hydrodesulfurization and light gasoline etherification

ActiveCN103525460ABoost octaneHigh content of tertiary olefinsTreatment with hydrotreatment processesTert-Amyl methyl etherHydrodesulfurization

The invention relates to a combined process of catalytic gasoline selective hydrogenation process and light gasoline etherification. The process innovatively unites catalytic gasoline selective hydrogenation hydrogen and light gasoline etherification as one. The selective hydrogenation process is employed for removing sulfur and nitrogen; the separated light gasoline component with high tertiary olefin content is then subjected to a methanol etherification with methanol to generate tert-amyl methyl ether, thus effectively reducing the olefin content of the light gasoline component and increasing octane number of the light gasoline. The sulfide removal rate is greater than 90%; dialkene is almost removed; and after etherification unit, the octane number can be increased by 2-6 units. The combined process shortens the process, saves equipment investment cost and operation cost and reduces land occupation of equipment.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Coal chemical phenol-containing waste water dephenolization method

InactiveCN102336451AReduction of recycling energy consumptionImprove recycling efficiencyWater/sewage treatment by extractionSolventPhenol

The invention discloses a coal chemical phenol-containing waste water dephenolization method, which comprises the following steps of: using tert-amyl methyl ether as a main extractant, extracting the coal chemical phenol-containing waste water and the extractant in an extraction tower or a multistage mixing clarifier to obtain a solvent phase and a raffinate phase; carrying out rectification on the solvent phase, and recovering a solvent and crude phenols; distilling the raffinate phase, and recovering a residual extraction solvent; and recycling the recovered extractant. In comparison with the prior art, the method provided by the invention has advantages of simple process flow, less equipment investment, low energy consumption of solvent recovery and high phenol recovery efficiency; in addition, petroleum hydrocarbon and tar pollutants can be simultaneously and efficiently removed. By the adoption of the method, subsequent biochemical load can be more effectively mitigated so as to guarantee standard discharge or reuse of waste water.

Owner:QINGDAO JUNYANG CHEM TECH

Method for preparing tert-amyl methyl ether

ActiveCN103787843ARegulate acidityRegulatory activityEther preparation by compound additionMetal/metal-oxides/metal-hydroxide catalystsTert-Amyl methyl etherReaction temperature

The invention discloses a method for preparing tert-amyl methyl ether. The method is as follows: raw materials of 2-methylbutene and methanol, a catalyst of a heteropolyacid / titanium based composite oxide as, volume space velocity of 2-methylbutene of 0.5-5.0 / h, molar ratio of methanol and 2-methylbutene of 1.0:1.0-5.0:1.0, reaction temperature of 80-200 DEG C, and reaction pressure of 0.5-5.0 MPa. Compared with the prior art, the method has the advantages of long running period, good stability and high selectivity of tert-amyl methyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

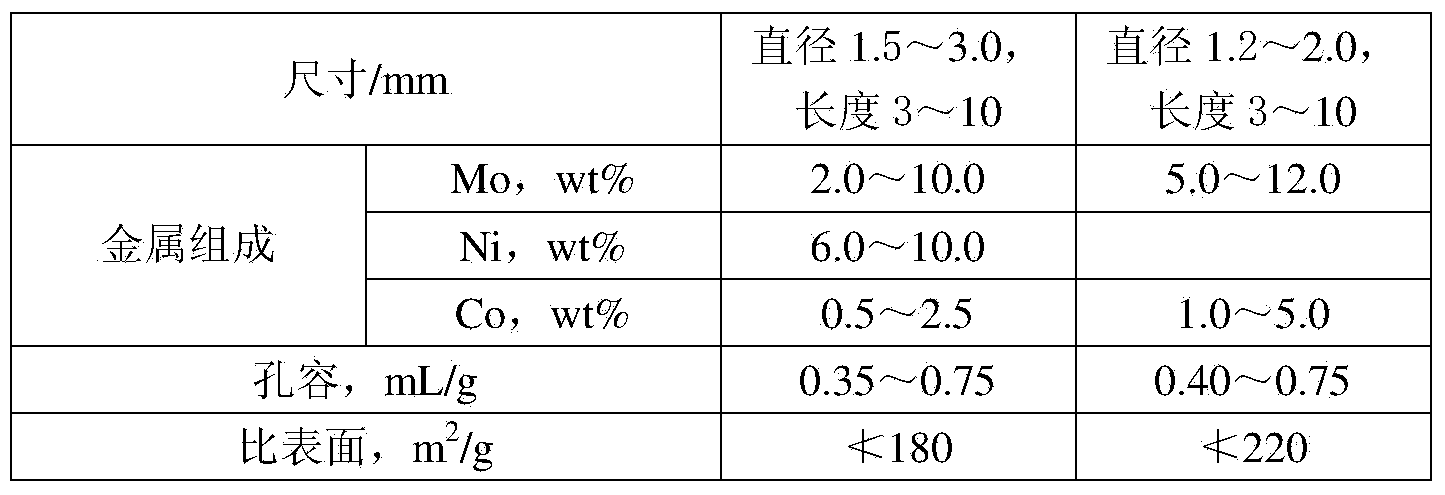

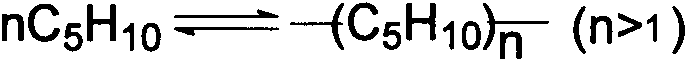

Combined process for comprehensively utilizing partial hydrogenation C5 fraction

InactiveCN103304382AHigh purityDistillation purification/separationHydrocarbonsPentaneTert-Amyl methyl ether

The invention relates to a combined process for comprehensively utilizing a partial hydrogenation C5 fraction, in particular to a method for producing tert amyl methyl ether (TAME), cyclopentadiene, cyclopentane and pentane from the partial hydrogenation C5 fraction raw material through a combined process of a series of rectification and reaction. The combined process comprises etherification reaction, hydrogenation reaction and a multi-tower continuous rectification process. According to the combined process for comprehensively utilizing the partial hydrogenation C5 fraction, the partial hydrogenation C5 fraction with low added value can be used for simultaneously producing the four main products with high added value, i.e., the TAME, the cyclopentadiene, the cyclopentane and the pentane, the product purity can generally reach over 98 percent, and all the byproducts can be used as fuel.

Owner:上海博润石化科技发展有限公司 +1

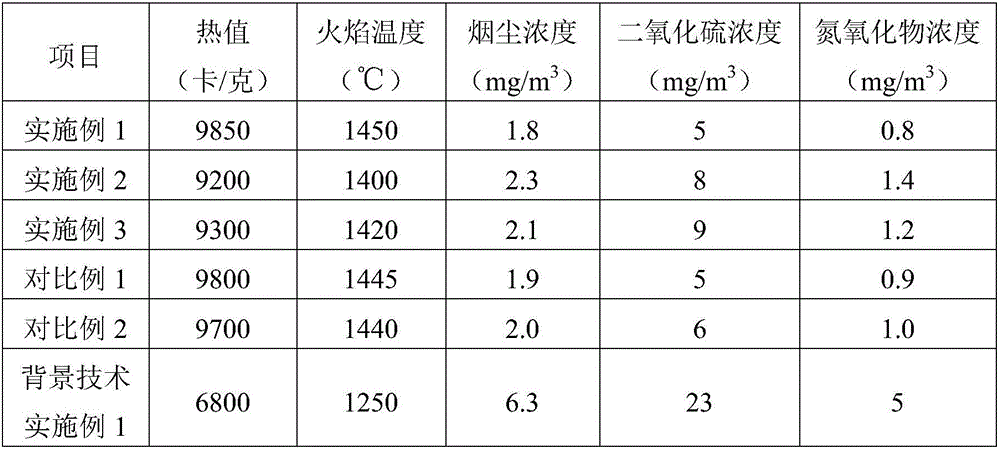

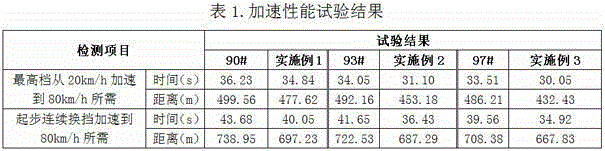

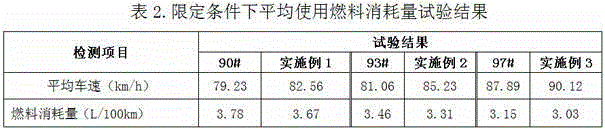

Methanol gasoline for vehicle and preparation method thereof

InactiveCN104004551AImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

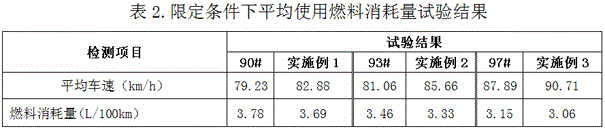

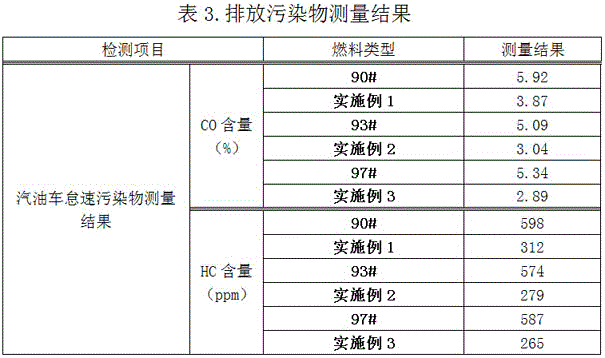

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

Method for preparing tert-amyl methyl ether

ActiveCN103787842AModerate surface areaRegulate acidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTert-Amyl methyl etherAmyl methyl ketone

The invention discloses a method for preparing tert-amyl methyl ether. The method is as follows: 2-methylbutene and methanol as raw materials, a heteropolyacid / aluminium based composite oxide as a catalyst, volume space velocity of 2-methylbutene of 1.0-5.0 / h, molar ratio of methanol and 2-methylbutene of 1.0:1.0-3.0:1.0, reaction temperature of 60-120 DEG C, and reaction pressure of 0.05-3.0 MPa. Compared with the prior art, the method has the advantages of long running period, good stability and high selectivity of tert-amyl methyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing tert-amyl methyl ether by etherifying C5 raffinate

ActiveCN102557887AReduce distractionsAvoid generatingOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation by compound additionTert-Amyl methyl etherIon-exchange resin

The invention relates to method for preparing tert-amyl methyl ether by etherifying C5 raffinate. A catalyst consists of a major catalyst, an aid and an acid carrier, wherein the major catalyst is one or more of Ru, Rh, Co, Mo, Ni or a corresponding soluble salt thereof; the content of the major catalyst is 0.1-10 percent based on the weight of the catalyst; the aid is one or more of third or fourth main family elements in a periodic table of elements; the content of the aid is 0.05-1 percent based on the weight of the catalyst; the carrier is macroporous networked styrene-series acid cation exchange resin; the carrier is treated through an alcohol solution; a major catalyst soaking liquid is an acid solution; the H<+> concentration is 0.1-2.0 mol / L; and the catalyst has the advantages of high activity, high functionality, and the like.

Owner:PETROCHINA CO LTD

Catalyst for preparing isoamylene by splitting decomposition of t-amyl-methyl ether and preparation method and application thereof

ActiveCN103041834AHigh selectivityLow reaction temperaturePhysical/chemical process catalystsOrganic compound preparationDecompositionChemistry

The invention discloses a multicomponent (X / Z2O3 / YO4 / Al2O3) catalyst for preparing isoamylene and a preparation method thereof. According to the method, the catalyst comprises the following components by weight percent: 20% to 95% of Al2O3, 0.1% to 20% of Z2O3, 0.1% to 50% of YO4 and 0.1% to 40% of X. The catalyst can take a reaction to prepare the isoamylene by the splitting decomposition of t-amyl-methyl ethe at a temperature lower than that of the existing catalyst of the same type. Under the condition that the high selection on the isobutene and the methanol and the high conversion rate of the splitting decomposition of the t-amyl-methyl ether are guaranteed, as compared with the existing catalyst of the same type, the catalyst provided by the invention has the effects that the space velocity of liquids in the reaction is improved exponentially, and water and other inert substances are not required to be added into a splitting decomposition reaction system of the t-amyl-methyl ether. Therefore, under the condition of unchanging the existing reaction equipment, the energy consumption in the industrial production is lowered, and the equipment utilization rate is improved exponentially.

Owner:EAST CHINA UNIV OF SCI & TECH

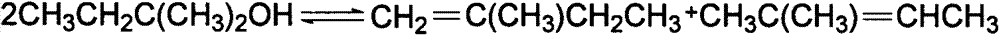

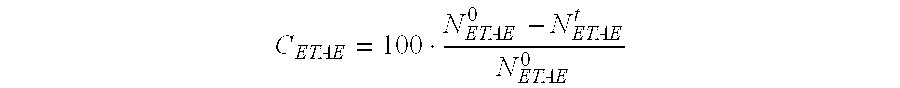

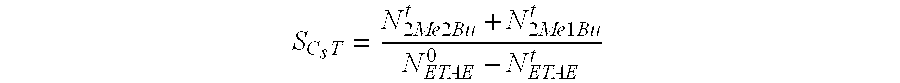

Process for cracking tert-alkyl ethers that use a mesostructured hybrid organic-inorganic material

InactiveUS20090326300A1Facilitated DiffusionImprove performanceMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTert-Amyl methyl etherMaximum diameter

A process for cracking tert-alkyl ether(s) selected from among tert-amyl methyl ether (TAME) and ethyl tert-amyl ether (ETAE) for the production of tertiary olefins comprising bringing said tert-alkyl ether(s) into contact with at least one catalyst that is formed by at least one mesostructured hybrid organic-inorganic material that consists of at least two spherical elementary particles, whereby each of said spherical particles consists of a mesostructured matrix with a silicon oxide base to which are linked organic groups with acid terminal reactive functions, said groups representing less than 20 mol % of said matrix that is present in each of said spherical elementary particles, which have a maximum diameter of between 50 nm and 200 μm.

Owner:INST FR DU PETROLE

High-performance alcohol-based fuel

The invention discloses high-performance alcohol-based fuel which is prepared from the following components in parts by weight: 60 to 70 parts of methanol, 2 to 4 parts of isopropanol, 3 to 6 parts of allyl alcohol, 1 to 3 parts of isooctane, 2 to 4 parts of isobutyl ketone, 1 to 3 parts of ditertbutyl paracresol, 1 to 3 parts of polyoxymethylene dimethyl ether, 0.4 to 0.8 part of tert-amyl methyl ether, 2 to 5 parts of hydrogen peroxide, 0.4 to 0.6 part of potassium chlorate, 0.01 to 0.03 part of ammonium cerous sulfate, 0.02 to 0.04 part of isobutyllithium, 0.3 to 0.7 part of glycerinum, 0.01 to 0.03 part of sodium lignin sulfonate, 2 to 4 parts of a complexing agent, 0.2 to 0.5 part of ethyl acetate, 0.4 to 0.7 part of nano-magnesium powder and 0.2 to 0.4 part of nano-ferric oxide. The high-performance alcohol-based fuel has the characteristics of high combustion property, low corrosivity, high stability and the like, and is fuel with a development prospect.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Vehicle fuel composition

InactiveUS7534274B2Minimizing carbon accumulationImprove propertiesLiquid carbonaceous fuelsInternal combustion engineChemistry

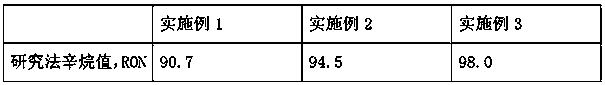

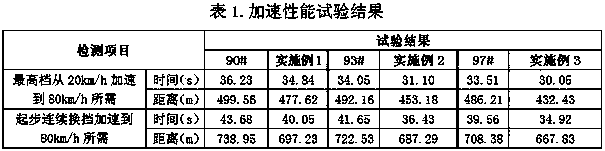

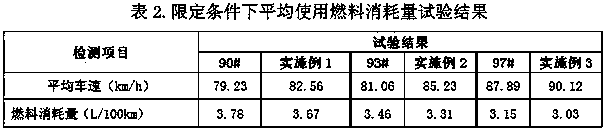

A vehicle fuel composition comprises: a light or low-carbon hydrocarbon or pentane fraction; a non-lead anti-knocking agent including methyl tert-butyl ether, tert-amyl methyl ether, anhydrous methanol and anhydrous ethanol; a fluorocarbon cation surfactant and / or a fluorocarbon non-ionic surfactant; which are thoroughly blended to obtain a motor fuel having a research octane number of more than ninety for enhancing anti-knocking property and also for minimizing carbon accumulation in a combustion engine system.

Owner:LEE MAO SHENG

Alcohol-based fuel with high calorific value

InactiveCN106350125AReduce volatilityImprove flammabilityLiquid carbonaceous fuelsPolyethylene glycolCarvacryl acetate

The invention discloses an alcohol-based fuel with a high calorific value. The alcohol-based fuel is prepared from the following components in parts by weight: 75 to 85 parts of methanol, 2 to 4 parts of isopropyl alcohol, 1 to 3 parts of isoamyl alcohol, 0.4 to 0.8 part of polyethylene glycol, 1 to 3 parts of petroleum ether, 0.6 to 0.8 part of tert-amyl methyl ether, 1 to 3 parts of cumene hydroperoxide, 0.01 to 0.03 part of ethylene-vinyl acetate copolymer, 0.02 to 0.04 part of calcium stearate, 0.2 to 0.5 part of ethyl acetate, 0.3 to 0.7 part of nanometer magnesium powder and 0.2 to 0.4 part of nanometer iron oxide. The alcohol-based fuel with the high calorific value has the characteristics of good combustion performance, low corrosivity, high stability and the like and has good development prospects, and especially, the calorific value is high.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Vehicle fuel composition

InactiveUS20060174538A1Minimizing carbon accumulationImprove propertiesLiquid carbonaceous fuelsInternal combustion engineEthanol

A vehicle fuel composition comprises: a light or low-carbon hydrocarbon or pentane fraction; a non-lead anti-knocking agent including methyl tert-butyl ether, tert-amyl methyl ether, anhydrous methanol and anhydrous ethanol; a fluorocarbon cation surfactant and / or a fluorocarbon non-ionic surfactant; which are thoroughly blended to obtain a motor fuel having a research octane number of more than ninety for enhancing anti-knocking property and also for minimizing carbon accumulation in a combustion engine system.

Owner:LEE MAO SHENG

Solvent de-waxing method

ActiveCN103102988AHigh yieldSpeed up filteringTreatment with plural serial refining stagesMineral wax recovery/refiningTert-Amyl methyl etherFiltration

The invention relates to a solvent de-waxing method. According to the invention, a solvent is added into a fused de-waxing raw material, an obtained mixture is cooled to a de-waxing temperature, a multi-point dilution method or a one-step full dilution method is employed for addition of the solvent, and filtration and separation are carried out at the de-waxing temperature so as to obtain de-waxed oil and de-waxed cerate, wherein the solvent is a mixture of tert amyl methyl ether and C3-C6 aliphatic ketone. Compared with the prior art, the method provided by the invention can improve a filtration speed of solvent de-waxing and yield of the de-waxed oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alcohol-based fuel additive for vehicles

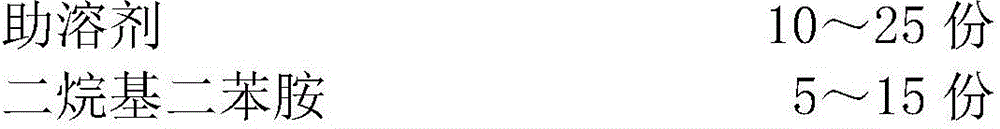

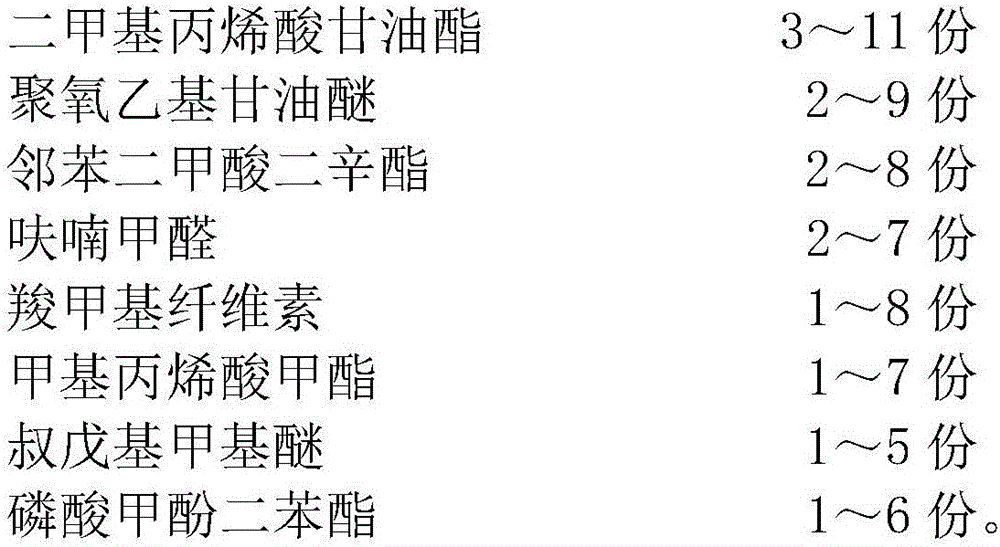

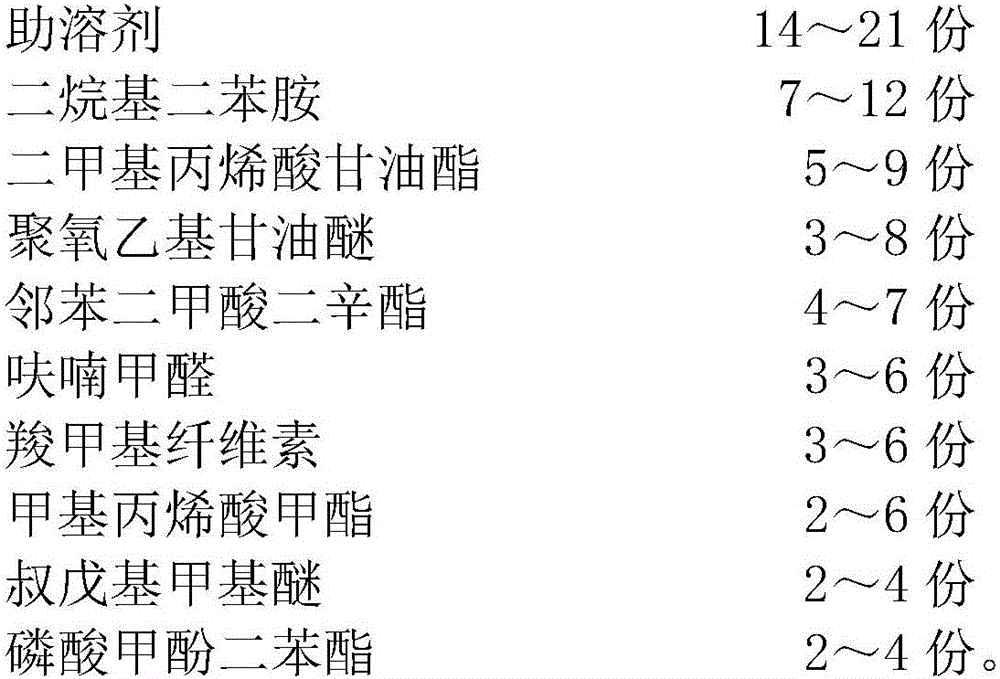

The invention belongs to the technical field of fuel additives and particularly relates to an alcohol-based fuel additive for vehicles. The alcohol-based fuel additive is prepared from raw materials in parts by weight as follows: 10-25 parts of a cosolvent, 5-15 parts of dialkyl diphenylamine, 3-11 parts of glycerol dimethacrylate, 2-9 parts of glyceryl polyoxyethyl ether, 2-8 parts of dioctyl phthalate, 2-7 parts of furan formaldehyde, 1-8 parts of carboxymethyl cellulose, 1-7 parts of methyl methacrylate, 1-5 parts of tert-Amyl methyl ether and 1-6 parts of diphenyl cresol phosphate. With the adoption of the alcohol-based fuel additive for the vehicles, fuel is enabled to be combusted sufficiently, the combustion efficiency is improved, fuel is saved, the cost is reduced, and effects of emission reduction and environment protection are realized.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Dimethoxymethane gasoline based on various non-national-standard gasoline components

The invention discloses dimethoxymethane gasoline based on various non-national-standard gasoline components. The dimethoxymethane gasoline comprises the following components by weight percent: 10-30% of vehicle fuel for blending combustion, 40-70% of naphtha and 10-30% of high-octane gasoline component, wherein the vehicle fuel for blending combustion comprises 88-95 parts of dimethoxymethane, 5-8 parts of tert-amyl methyl ether and 2-5 parts of functional additive; the functional additive comprises 50-65 parts of polyisobutylene succinimide, 30-40 parts of fatty acid and 5-10 parts of cerium oxide. By combining the dimethoxymethane compound of the fuel for blending combustion, naphtha and the high-octane gasoline component, the usage amount of the gasoline components is reduced, the cost is saved, the thermal utilization rate of the fuel oil is increased, emission of harmful gases in the vehicle exhaust is reduced, and the defects existing when dimethoxymethane independently serves as the fuel for blending combustion are overcome.

Owner:CHENGDU TIANFENG CLEANING ENERGY DEV CO LTD

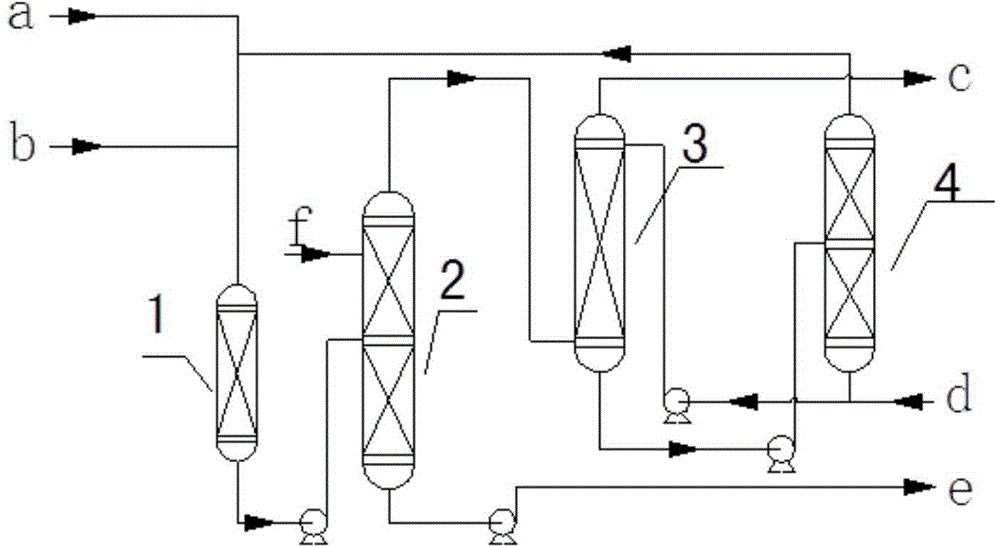

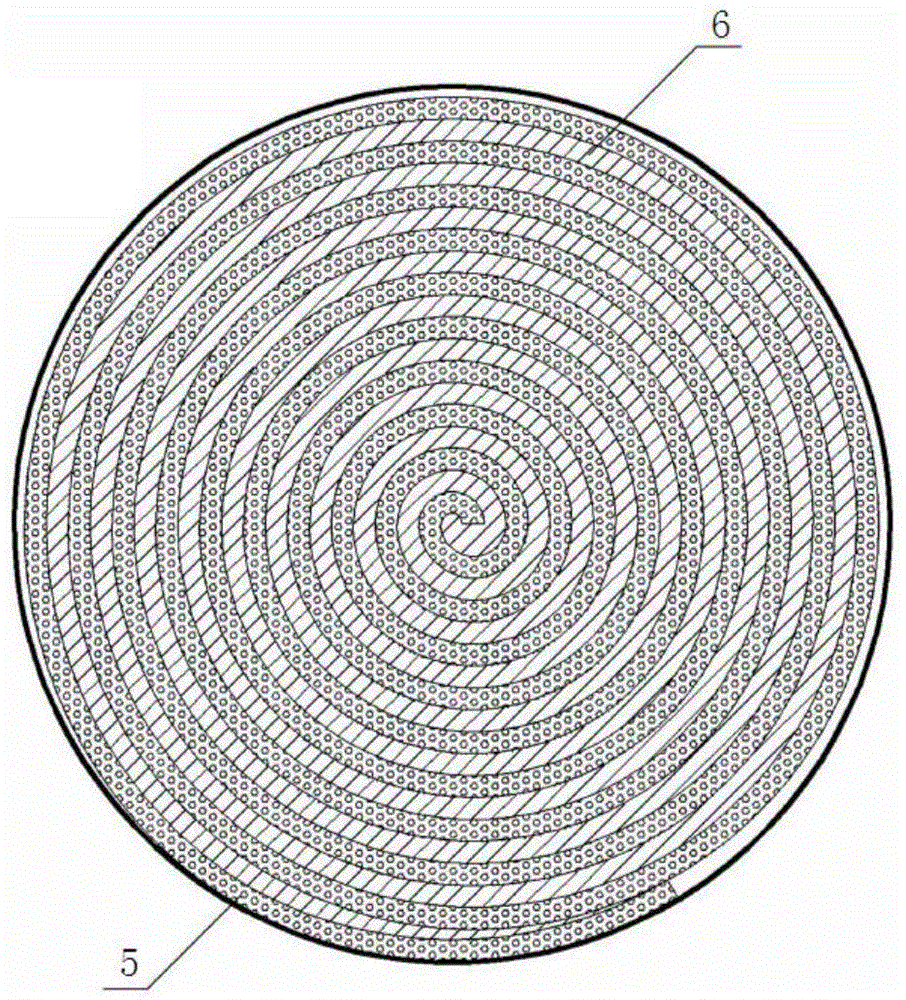

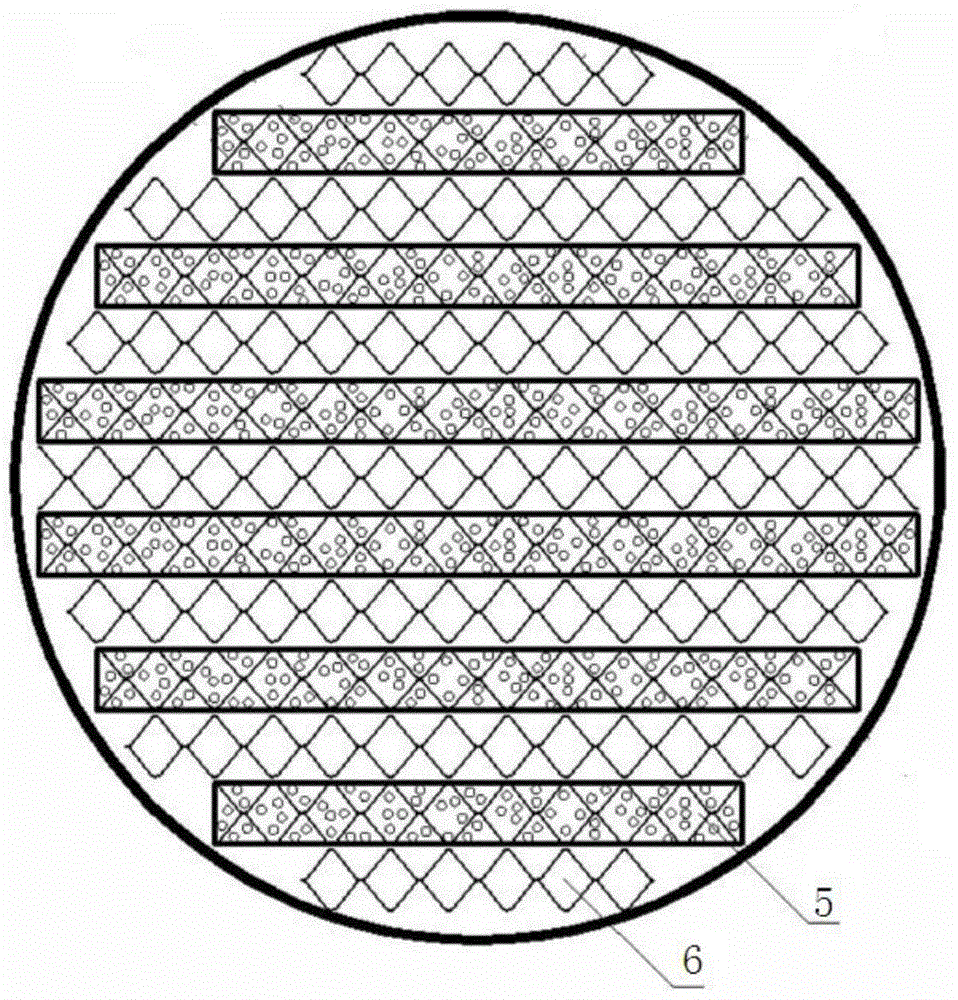

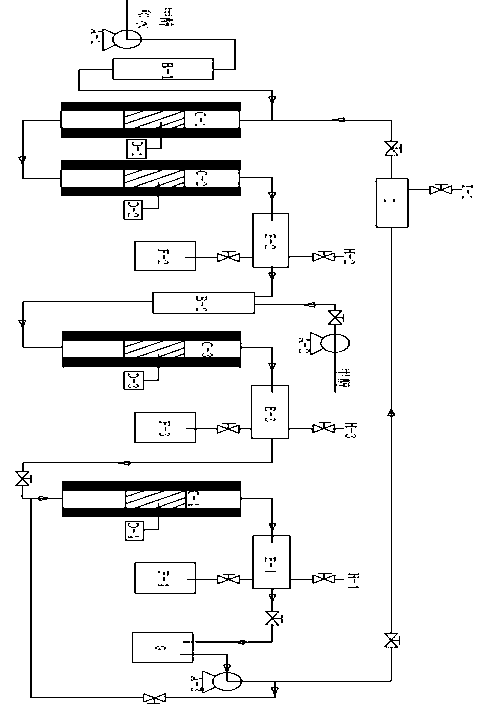

Light gasoline catalytic rectification etherification device and technique

InactiveCN104560148ALarge mass transfer areaIncrease mass transfer rateTreatment with plural serial refining stagesTert-Amyl methyl etherMethanol water

The invention discloses a light gasoline catalytic rectification etherification device and technique. The device comprises a pre-reactor, a catalytic reaction rectification tower, a methanol extraction tower and a methanol refinement tower. The technique comprises the following steps: a light gasoline raw material containing active olefins is mixed with methanol in the pre-reactor to perform etherification reaction so as to generate TAME (tert amyl methyl ether); the reaction product is pumped to the catalytic reaction rectification tower; new methanol is supplemented into the tower, so that the active olefins perform etherification reaction with the methanol, wherein the total conversion rate is 99.5% above; under the rectifying action, the TAME and other heavy components are distilled off from the tower bottom, the unreacted active olefins, methanol and other light components are distilled off from the tower top and enter the methanol extraction tower; and water enters via the upper part of the methanol extraction tower, the methanol water solution is discharged from the tower bottom and enters the methanol refinement tower, the methanol is discharged from the top of the methanol refinement tower and returns to the pre-reactor, and the water from the tower bottom returns to the upper part of the methanol extraction tower, thereby implementing recycling. The method is simple, has the advantages of favorable effect and high conversion rate of active olefins, and is beneficial to lowering the olefin content and enhancing the octane number of the oil product in the field of etherification of light gasoline.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD

A kind of preparation method of methyl tert-amyl ether

ActiveCN103787842BModerate surface areaImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationTert-Amyl methyl etherReaction temperature

Owner:CHINA PETROLEUM & CHEM CORP +1

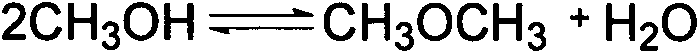

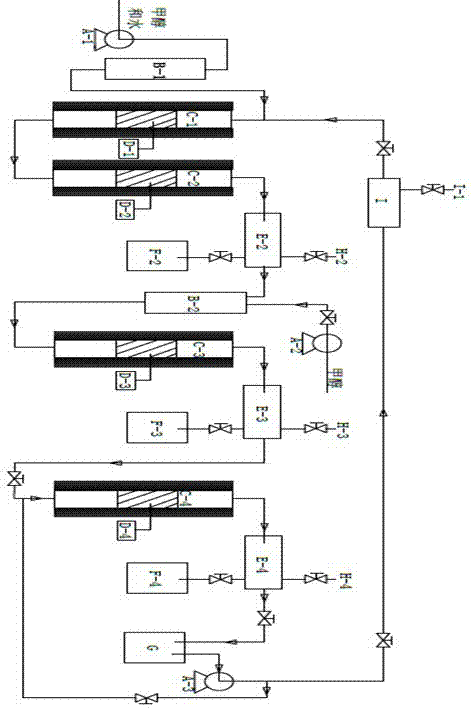

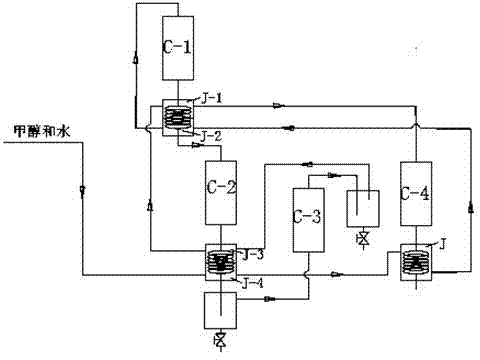

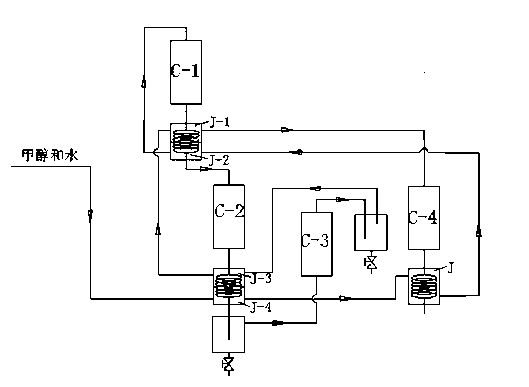

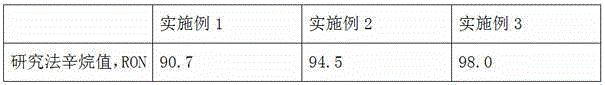

Process for preparing high-octane high-cleanness gasoline with methanol by using multi-element catalysis method

ActiveCN103242884BBoost octaneIncrease productionLiquid hydrocarbon mixture productionBio-feedstockLight hydrocarbonsRaw material

The invention relates to a process for preparing high-octane high-cleanness gasoline with methanol by using a multi-element catalysis method. The process comprises the following steps of: producing gasoline and light hydrocarbon in a reactor under the action of a catalyst by using methanol and water as the raw materials; carrying out catalytic reaction continuously on the light hydrocarbon in another reactor, selectively superposing the gasoline and concentrating isobutene and isoamylene; carrying out catalytic reaction on the concentrated isobutene and isoamylene and methanol in a third reactor to produce methyl tert butyl ether (MTBE) and tert amyl methyl ether (TAME); and further carrying out catalytic reaction on the remained hydrocarbon components in a fourth reactor to produce gasoline. The gasoline produced by the multi-element catalysis method has an octane value of more than 95, and is called as a high-quality and high-cleanness gasoline in the 21st century because the gasoline is sulfur-free, nitrogen-free and heavy-metal-free and the oxygen content is greater than 2%. The process is reliable, the operation is simple, continuous production is realized, the operation energy consumption is remarkably reduced, the public engineering order is lowered, and the gasoline is environment-friendly. Thus, the process has remarkable practicability, huge economic benefit and a wide application prospect.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +2

Process for preparing high-octane high-cleanness gasoline with methanol by using multi-element catalysis method

ActiveCN103242884ARaise the reaction temperatureEfficient use ofLiquid hydrocarbon mixture productionBio-feedstockRaw materialLight hydrocarbons

The invention relates to a process for preparing high-octane high-cleanness gasoline with methanol by using a multi-element catalysis method. The process comprises the following steps of: producing gasoline and light hydrocarbon in a reactor under the action of a catalyst by using methanol and water as the raw materials; carrying out catalytic reaction continuously on the light hydrocarbon in another reactor, selectively superposing the gasoline and concentrating isobutene and isoamylene; carrying out catalytic reaction on the concentrated isobutene and isoamylene and methanol in a third reactor to produce methyl tert butyl ether (MTBE) and tert amyl methyl ether (TAME); and further carrying out catalytic reaction on the remained hydrocarbon components in a fourth reactor to produce gasoline. The gasoline produced by the multi-element catalysis method has an octane value of more than 95, and is called as a high-quality and high-cleanness gasoline in the 21st century because the gasoline is sulfur-free, nitrogen-free and heavy-metal-free and the oxygen content is greater than 2%. The process is reliable, the operation is simple, continuous production is realized, the operation energy consumption is remarkably reduced, the public engineering order is lowered, and the gasoline is environment-friendly. Thus, the process has remarkable practicability, huge economic benefit and a wide application prospect.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +2

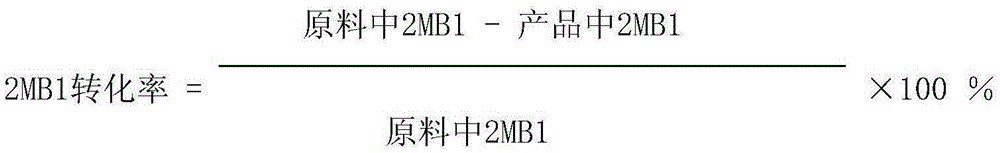

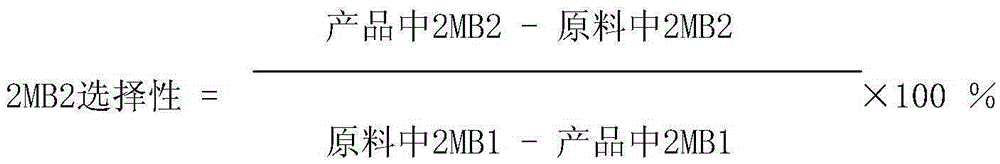

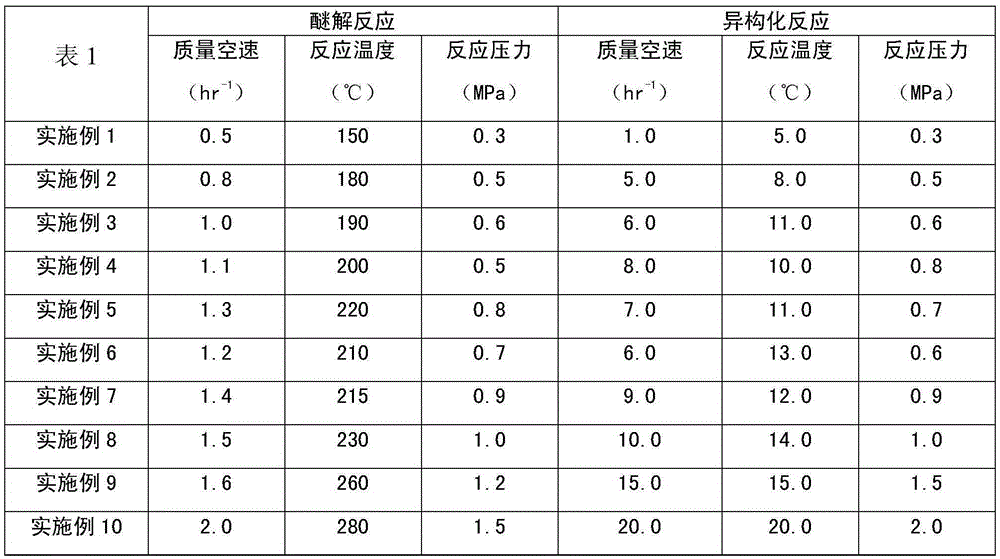

Method for improving content of 2-methyl-2-butylene

ActiveCN106588550AImprove quality ratioThe isomerization reaction goes wellHydrocarbon by isomerisationCatalystsTert-Amyl methyl etherIsomerization

The invention discloses a method for improving the content of 2-methyl-2-butylene and particularly relates to a method for improving the content of 2-methyl-2-butylene in isopentene by taking tert-amyl methyl ether as a raw material and adopting methods for ether reaction, isomerization reaction and purification by rectification. Through the technical processes, the mass ratio of 2-methyl-2-butylene to 2-methyl-1-butylene in isopentene can be improved to (8-14):1, so that the quality requirements for subsequent processing are met.

Owner:CHINA PETROLEUM & CHEM CORP +1

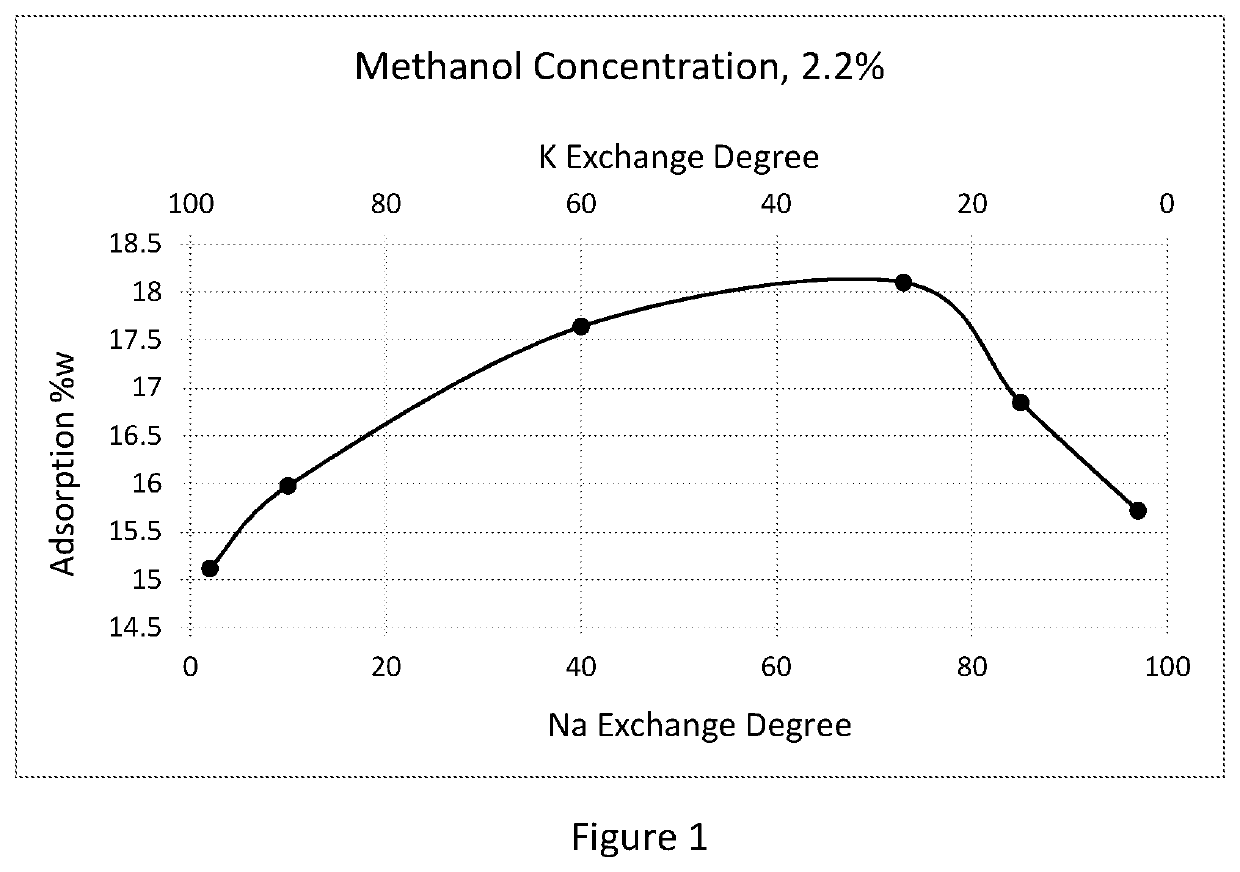

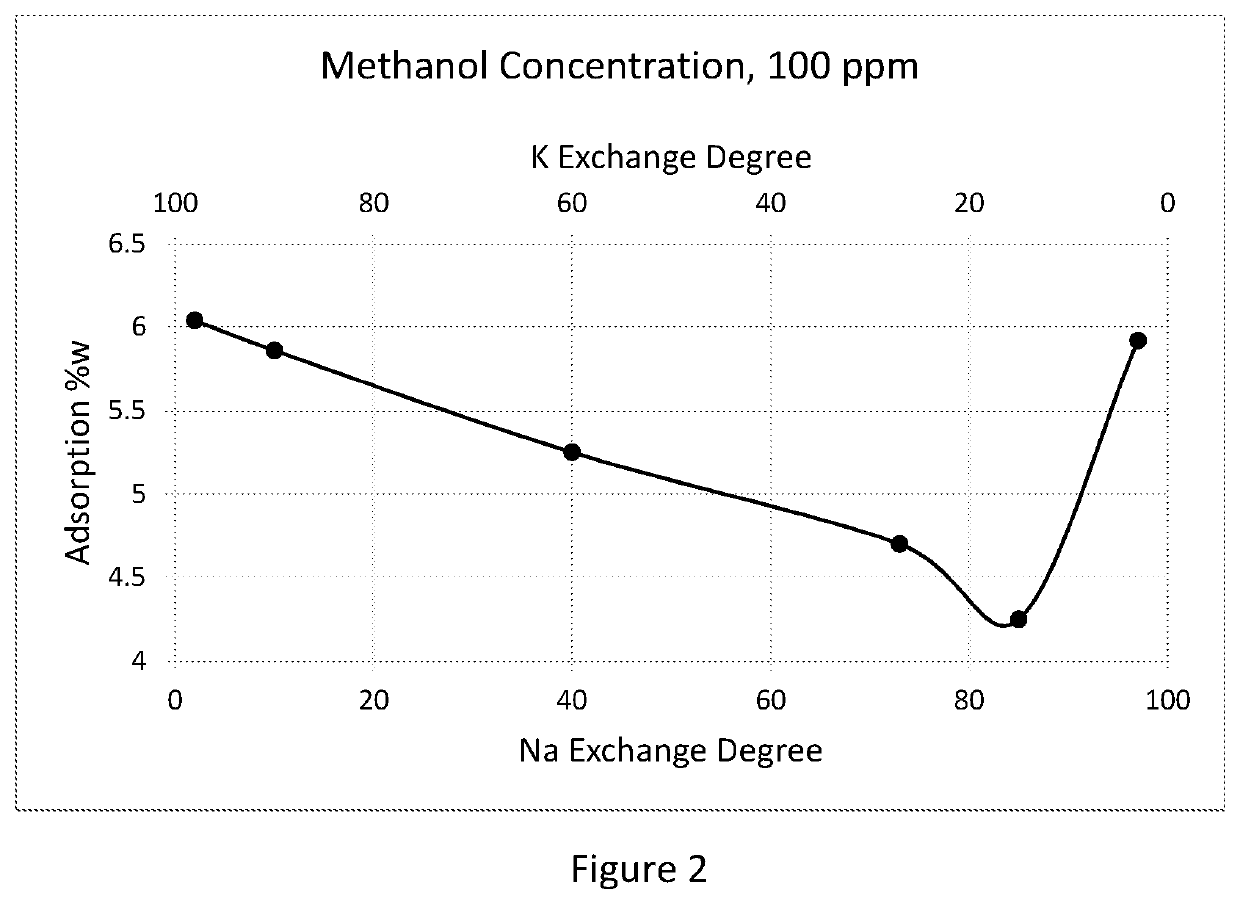

Adsorbent and process for methanol and oxygenates separation

InactiveUS20200063056A1Increase capacityHigh selectivityGas treatmentMethane captureMethacrylateAlkaline earth metal

An adsorbent separates methanol and other alcohols from gas and liquid oxygenates and hydrocarbon streams with a low silica faujasite (LSX) in a mono-, bi, or tri-cation alkali and / or alkaline-earth metal forms. The LSX has silicon to aluminum ratio from about 0.9 to about 1.15 and an ion exchange degree for each alkali or alkaline-earth metal in the range of about 10 to about 99.9% equiv. The gas streams for treatment include natural gas, individual hydrocarbons, or vaporized alkyl esters of carboxylic acids, or methyl tert-alkyl ethers and their mixtures with hydrocarbons. The liquid streams include liquefied natural gas (LNG), liquefied petroleum gas (LPG), natural gas liquid (NGL), individual hydrocarbons C3-C5, and monomers, alkyl esters of carboxylic acids including methyl acetate, methyl, ethyl, butyl acrylates and methacrylate, methyl tert-alkyl ethers including methyl tert-butyl ether (MTBE) and methyl tert-amyl ether (TAME). The adsorbent is especially suited for temperature swing or pressure swing adsorption processes.

Owner:M CHEM CO

A dimethoxymethane gasoline based on various non-national standard gasoline components

The invention discloses dimethoxymethane gasoline based on various non-national-standard gasoline components. The dimethoxymethane gasoline comprises the following components by weight percent: 10-30% of vehicle fuel for blending combustion, 40-70% of naphtha and 10-30% of high-octane gasoline component, wherein the vehicle fuel for blending combustion comprises 88-95 parts of dimethoxymethane, 5-8 parts of tert-amyl methyl ether and 2-5 parts of functional additive; the functional additive comprises 50-65 parts of polyisobutylene succinimide, 30-40 parts of fatty acid and 5-10 parts of cerium oxide. By combining the dimethoxymethane compound of the fuel for blending combustion, naphtha and the high-octane gasoline component, the usage amount of the gasoline components is reduced, the cost is saved, the thermal utilization rate of the fuel oil is increased, emission of harmful gases in the vehicle exhaust is reduced, and the defects existing when dimethoxymethane independently serves as the fuel for blending combustion are overcome.

Owner:CHENGDU TIANFENG CLEANING ENERGY DEV CO LTD

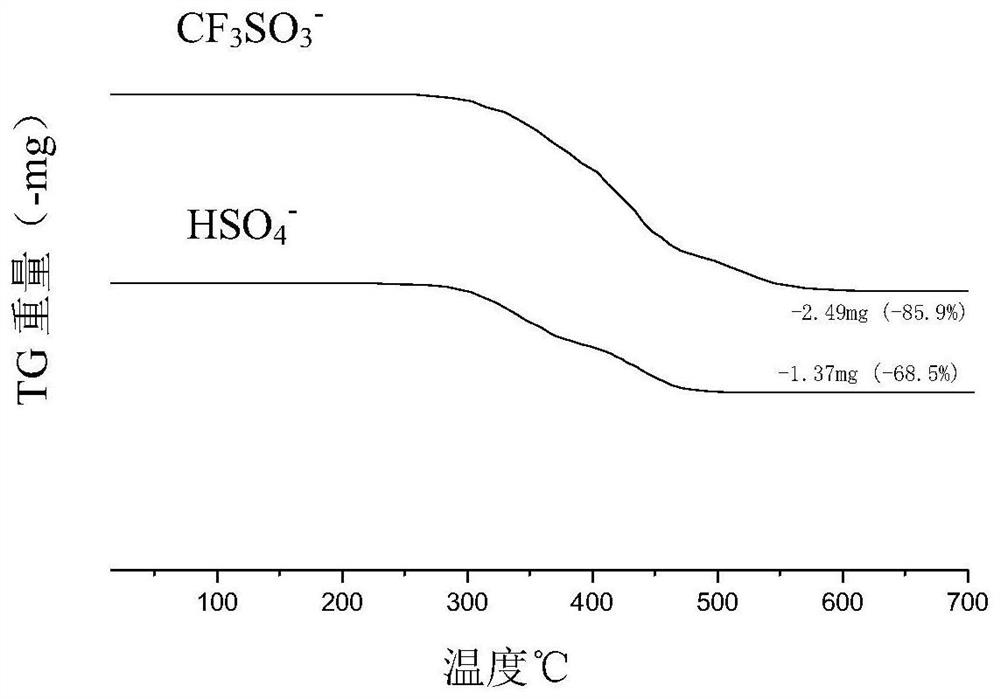

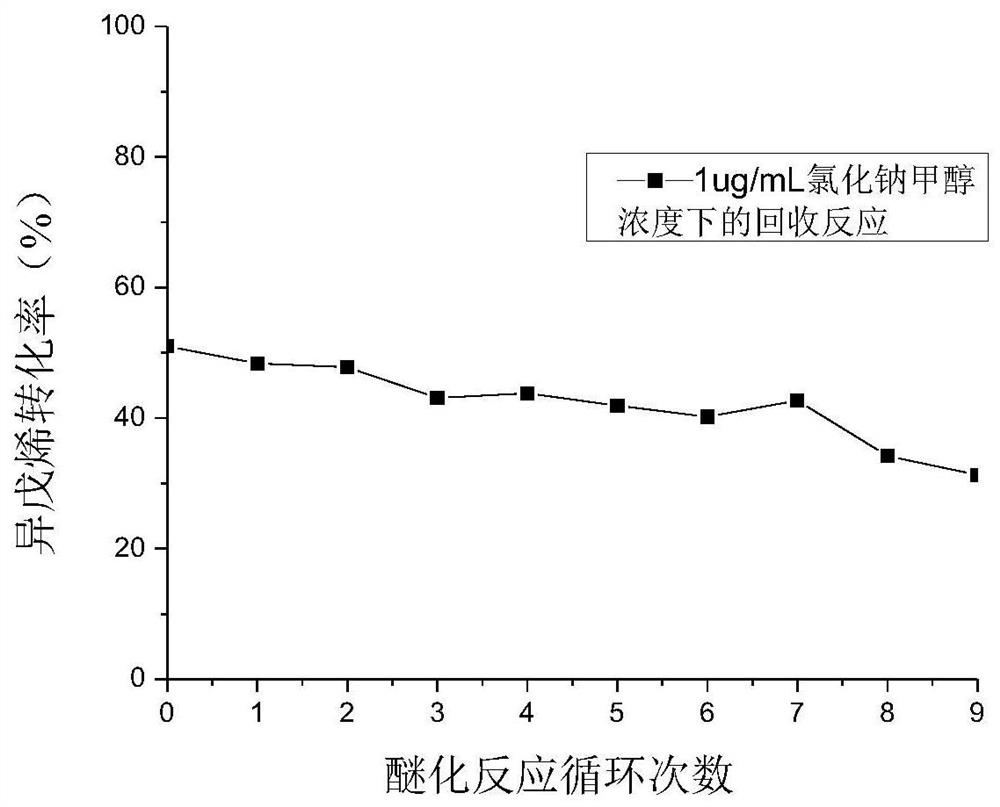

A kind of preparation method of methyl tert-amyl ether and a kind of upgrading method of light gasoline

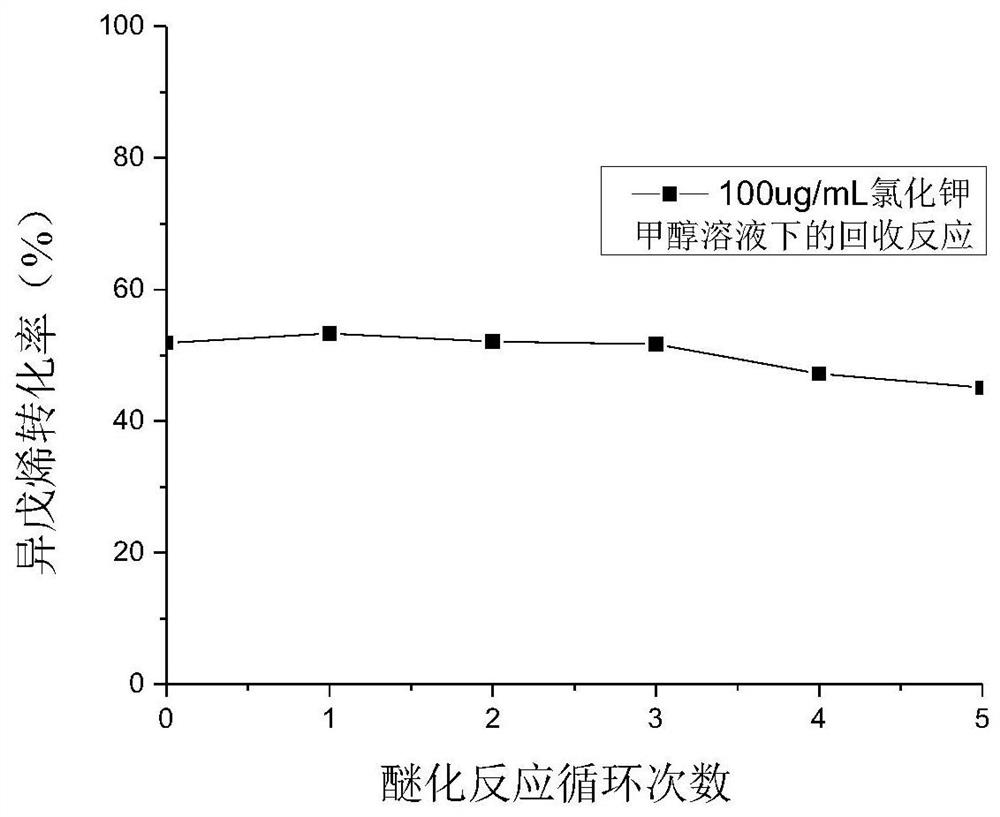

ActiveCN107935821BStable conversion rateBoost octaneOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsTert-Amyl methyl etherPolymer science

The invention discloses a tert-amyl methyl ether preparation method and a light gasoline modification method. The tert-amyl methyl ether preparation method comprises that methanol and isopentene contact an etherification catalyst under an etherification reaction condition to obtain the reaction product containing tert-amyl methyl ether, wherein the etherification catalyst is a polymer supported ionic liquid catalyst, and has a structure represented by a formula (I) or a formula (II). With the method of the present inventin, the tert-amyl methyl ether preparation reaction can maintain the highreactivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paper and paperboard surface finishing agent

InactiveCN104294706AMoisture-proofHas anti-mildew effectPaper coatingPaper/cardboardIsobutanolPaperboard

The invention relates to a paper and paperboard surface finishing agent. The paper and paperboard surface finishing agent contains 10-25% of linseed oil, 3-7% of sodium hydroxide, 8-10% of calcium hydroxide, 10-15% of addition polymerization resin, 5-10% of alkene unsaturated acid, 10-17% of triethanolamine butyraldehyde, 10-15% of tert-amyl methyl ether, 12-25% of isobutanol, 5-15% of polyoxyethylene nonylphenol ether and 10-25% of a water-soluble cellulose derivative, and the water-soluble cellulose derivative is composed of an etherified sulfomethyl group and an acidified sulfoethyl group. A molar ratio of the etherified sulfomethyl group to the acidified sulfoethyl group is 1:2-1:4. The water-soluble cellulose derivative has the dual effects of moisture resistance and mildew resistance, and has a wide, efficient and lasting sterilization and inhibition ability on moulds and yeasts.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

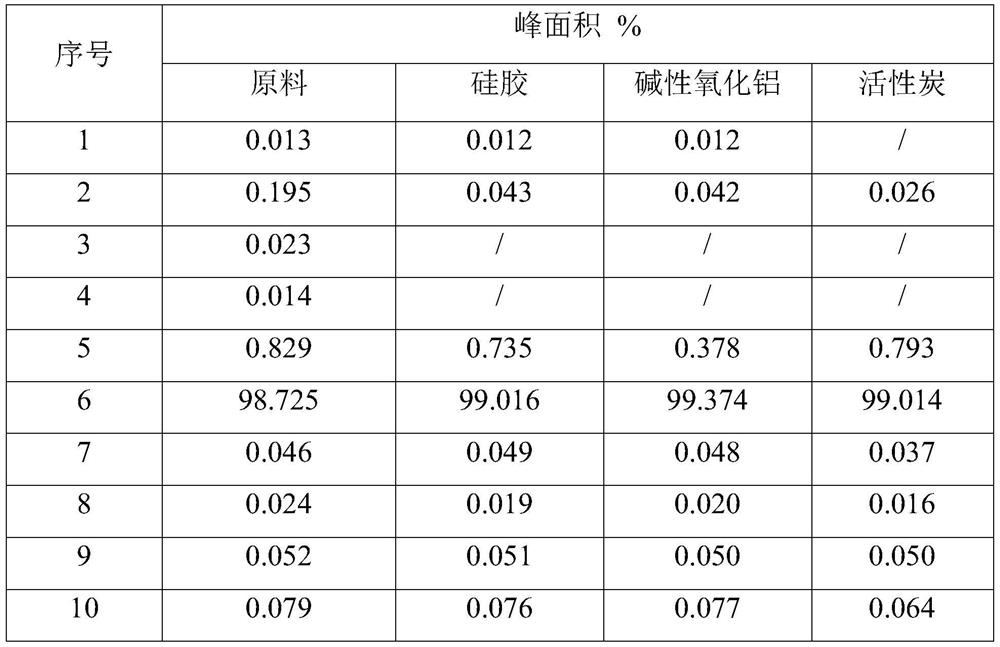

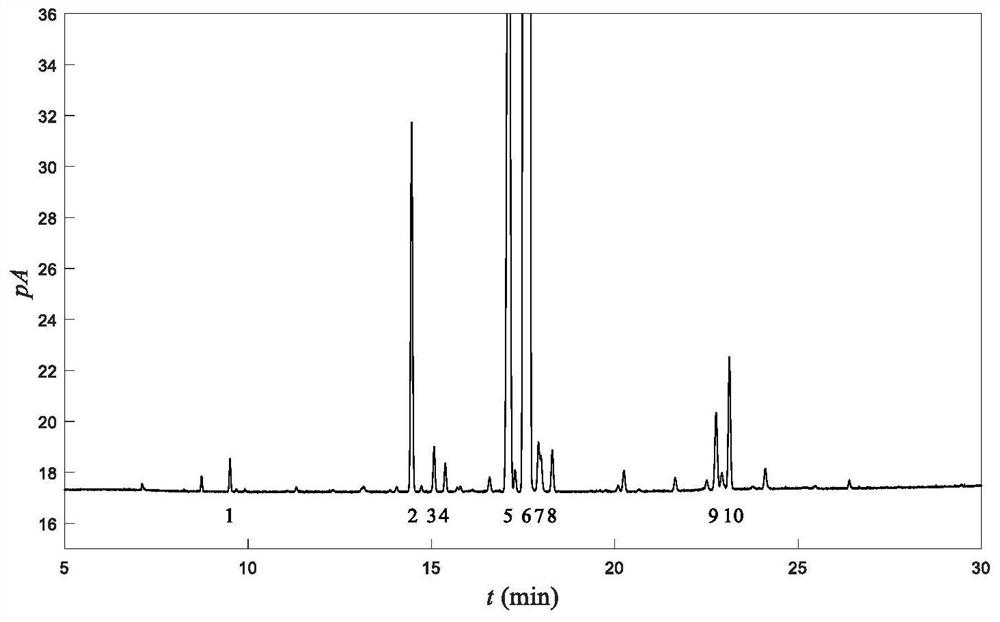

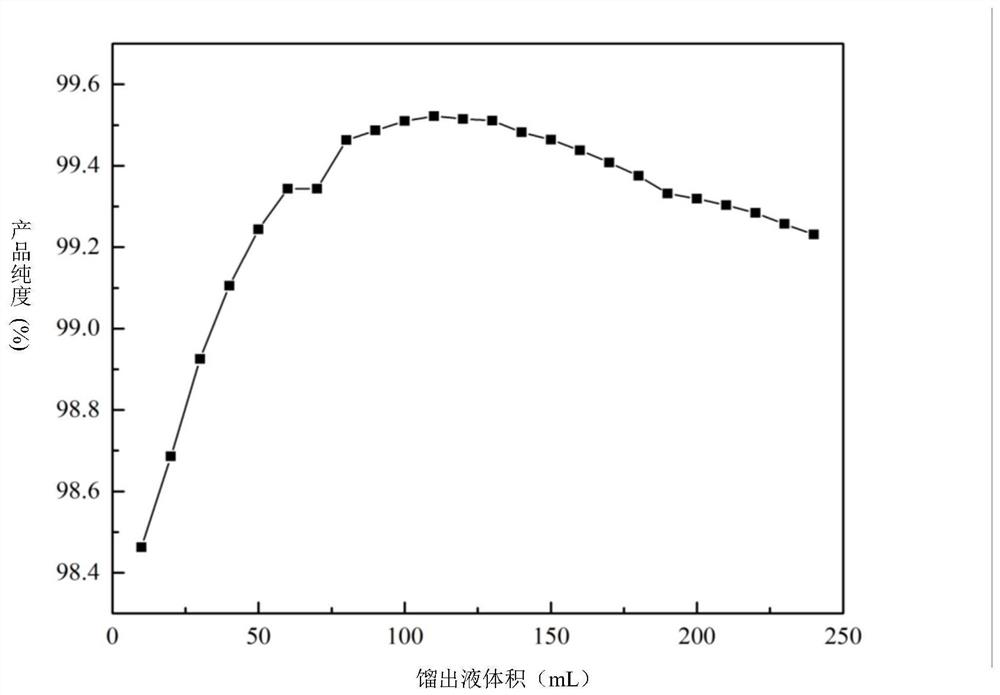

A kind of purification technology of methyl tert-amyl ether purity standard substance raw material

ActiveCN109400451BHigh purityImprove product qualityEther separation/purificationTert-Amyl methyl etherPhysical chemistry

The invention provides a purification technology of methyl tert-amyl ether purity standard substance raw material, comprising steps: (1) precision rectification: under normal pressure, adding industrial-grade methyl tert-amyl ether into a rectification tower, the rectification tower Built-in packing, obtain the methyl tert-amyl ether product from the top of the rectification tower, discard the front fraction with more impurities to obtain the sample to be adsorbed; (2) adsorption: at normal temperature, transfer the sample to be adsorbed obtained in step (1) to Adsorption tower, the adsorption tower has a built-in adsorbent, and the methyl tert-amyl ether product is obtained from the bottom of the adsorption tower; (3) Filtration: at normal temperature, the methyl tert-amyl ether product obtained in step (2) is passed through an organic microporous membrane Filter to obtain high-purity methyl tert-amyl ether. The purification technology of the present invention can solve the difficulty in the prior art that various trace impurities are difficult to remove, and the obtained methyl tert-amyl ether has a purity higher than 99.9%, less impurities and can be used as a standard substance.

Owner:NAT INST OF METROLOGY CHINA

Dimethoxymethane composition as a blending fuel for vehicles

InactiveCN103952194BGuaranteed uptimeOvercoming the difficulty of high saturated vapor pressureLiquid carbonaceous fuelsTert-Amyl methyl etherGasoline

The invention discloses a dimethoxymethane (DMM) composition used as blended fuel for a vehicle. The DMM composition comprises the components in parts by weight: 88-95 parts of DMM, 5-8 parts of tert-amyl methyl ether (TAME) and 2-5 parts of functional additive, wherein the functional additive comprises the following raw materials in parts by weight: 50-65 parts of polyisobutylene succinimide, 30-40 parts of fatty acid and 5-10 parts of cerium oxide. The DMM composition disclosed by the invention is used as the blended fuel for the vehicle, so that the consumption of gasoline can be reduced, the heat utilization ratio of fuel oil can be increased, the emission of harmful gas in automobile exhaust can be reduced, and the defect existing when DMM is independently used as the blended fuel is overcome.

Owner:CHENGDU TIANFENG CLEANING ENERGY DEV CO LTD

A kind of method for preparing methyl tert-amyl ether

ActiveCN103787843BRealize continuous productionImprove conversion rateEther preparation by compound additionMetal/metal-oxides/metal-hydroxide catalystsTert-Amyl methyl etherReaction temperature

The invention discloses a method for preparing tert-amyl methyl ether. The method is as follows: raw materials of 2-methylbutene and methanol, a catalyst of a heteropolyacid / titanium based composite oxide as, volume space velocity of 2-methylbutene of 0.5-5.0 / h, molar ratio of methanol and 2-methylbutene of 1.0:1.0-5.0:1.0, reaction temperature of 80-200 DEG C, and reaction pressure of 0.5-5.0 MPa. Compared with the prior art, the method has the advantages of long running period, good stability and high selectivity of tert-amyl methyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of methanol gasoline for vehicles and preparation method thereof

InactiveCN104004551BImprove combustion characteristicsIncrease profitLiquid carbonaceous fuelsAlternative fuelsTert butyl

The invention discloses methanol gasoline for a vehicle and a preparation method thereof. The methanol gasoline is prepared from the following raw materials in parts by weight: 60-70 parts of methanol, 15-25 parts of 90# gasoline, 10-15 parts of dipropylene glycol methyl ether acetate, 5-10 parts of tert amyl methyl ether, 5-10 parts of dimethyl carbonate, 4-8 parts of diethylene glycol dimethyl ether, 3-6 parts of 2,2-dimethoxypropane, 1-2 parts of ferrocene, 0.5-1.5 parts of methyl cyclopentadiene tricarbonyl manganese, 0.8-1.4 parts of 2,5-di-tert-butyl hydroquinone, 0.4-0.8 part of glycerol monolaurate, 0.5-1 part of sodium petroleum sulfonate, 0.3-0.6 part of N-Polyoxyethylated-N-tallow-alkylamine, 5-10 parts of wood tar, 3-6 parts of isopropanol, 2.5-4.5 parts of fish meal, 2-3 parts of bone meal, 1-2 parts of stearic acid and 0.5-1 part of urotropine. The methanol gasoline disclosed by the invention is favorable in combustion characteristic, high in utilization ratio, favorable in anti-detonating quality, low in corrosivity, high in safety and reliability, energy-saving and environment-friendly, can be used instead of any of 90#, 93#, 97# and 98# gasoline for a vehicle, is novel environment-friendly alternative fuel, and can reduce pollutant emission and carbon emission; and the combustion emission of the methanol gasoline meets the standards in Europe and America. The methanol gasoline has excellent economic benefits and far-reaching social benefits.

Owner:BEIJING DAMING QIAOHUA ENERGY SCI & TECH

A kind of dimethoxymethane gasoline based on national standard gasoline components

InactiveCN103952191BGood miscibilityPowerfulLiquid carbonaceous fuelsTert-Amyl methyl etherCombustion

The invention discloses dimethoxymethane gasoline based on a national standard gasoline component. The dimethoxymethane gasoline comprises the following components in percentage by weight: 10-30% of blending combustion fuel for a vehicle and 70-90% of national standard gasoline, wherein the blending combustion fuel for the vehicle comprises 88-95 parts of dimethoxymethane, 5-8 parts of tert-amyl methyl ether and 2-5 parts of functional additive, and the functional additive comprises 50-65 parts of polyisobutylene succinimide, 30-40 parts of fatty acid and 5-10 parts of cerium dioxide. According to the invention, a blending combustion fuel dimethoxymethane composition is added into the component of the national standard gasoline, so that the usage amount of the national standard gasoline is reduced, the heat utilization ratio of the fuel is increased, the emission of harmful gases in automobile exhaust is reduced, and the defect existing when dimethoxymethane is independently used as the blending combustion fuel is overcome.

Owner:CHENGDU TIANFENG CLEANING ENERGY DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com