Combined process for comprehensively utilizing partial hydrogenation C5 fraction

A technology of C5 fractionation and combined process, which is applied in the field of production of methyl tert-amyl ether from cyclopentene, cyclopentane and pentane, and can solve problems affecting chemical utilization and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

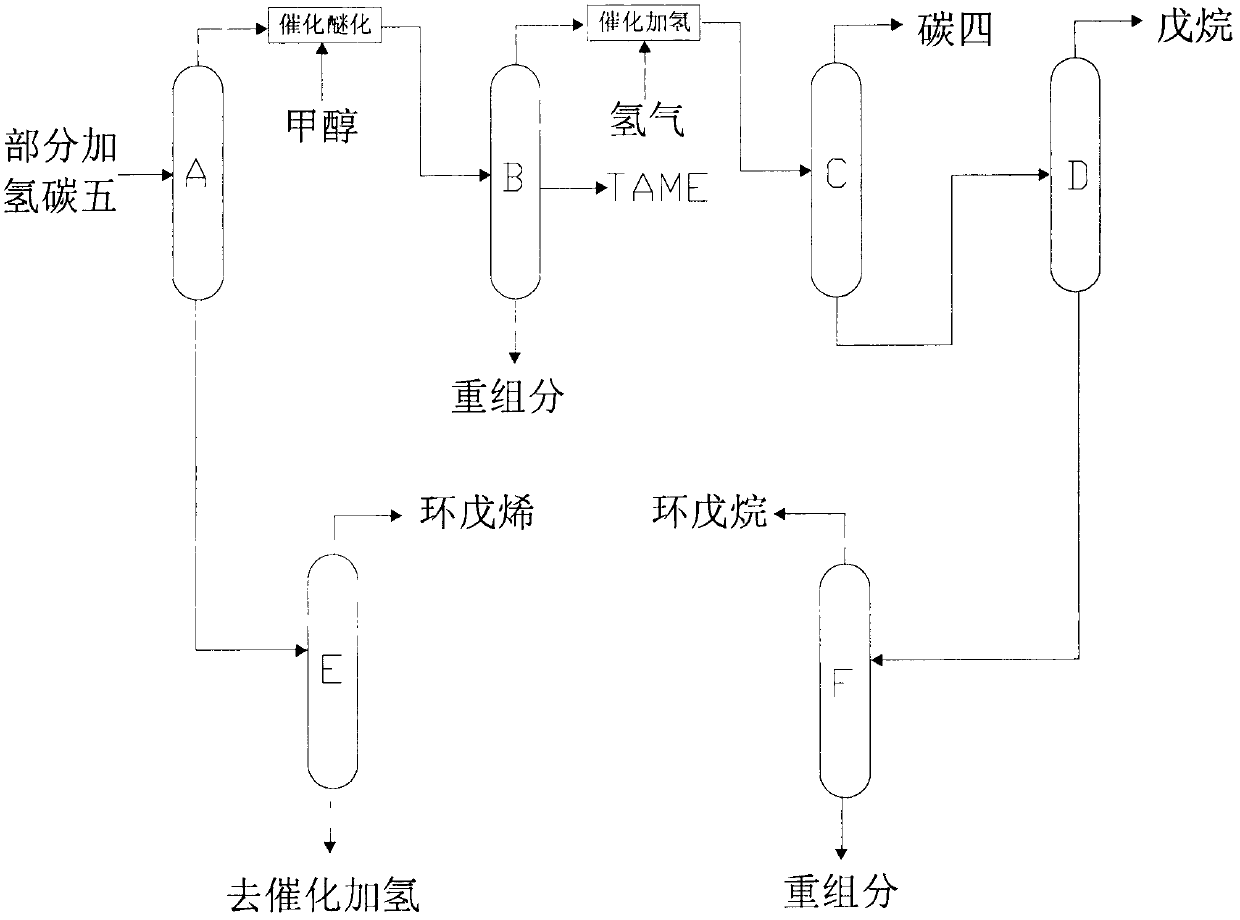

[0031] Examples, see figure 1 Shown:

[0032] The partly hydrogenated C5 fraction with the composition shown in Table 1 was rectified in rectification tower A at a feed rate of 6250.00 kg / hour. The rectification column A is a packed column with a theoretical plate number of 90-110. Partially hydrogenated C5 fraction is fed from the fiftieth plate of rectification tower A when it is preheated to 45-55°C. The temperature at the top is 45-55°C, the reflux ratio is 8-15, 4505.80 kg / hour of crude isopentene is produced at the top of the tower, and 1744.19 kg / hour is discharged from the tower kettle. The main purpose of this step is to separate the light component crude isopentene in Table 1 with a boiling point lower than 38.57°C (2-methyl-2-butene boiling point) from the top of rectification column A, while the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com