Patents

Literature

492 results about "Cyclopentanes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A group of alicyclic hydrocarbons with the general formula R-C5H9.

Substituted-pent-4-ynoic acids

InactiveUS6037367AImprove the level ofSuppressing inappropriate activationBiocideOrganic chemistryMethyl groupCarbon atom

PCT No. PCT / US96 / 11613 Sec. 371 Date Sep. 14, 1998 Sec. 102(e) Date Sep. 14, 1998 PCT Filed Jul. 12, 1996 PCT Pub. No. WO97 / 03945 PCT Pub. Date Feb. 6, 1997Compounds of formula (I) wherein: R1 is -(CR4R5)nC(O)O(CR4R5)mR6, -(CR4R5)nC(O)NR4(CR4R5)mR6, (CR4R5)nO(CR4R5)mR6, or -(CR4R5)rR6: W is alkynyl or 2 carbon atoms; R3 is H or R7; Z is C(O)R13, (CH2)0-1C(O)OR13, (CH2)0-1C(O)NR10R13, (CH2)0-1C(R8R8)OR8, -NHC(O)R7, (CH2)0-1NR10R13, NH[C(O)C(O)OR8], CH2NH[C(O)CNR10R13], CH2S(O)qR7, CH[S(O)qR7]2, dithiolane, (tetrazol-5-yl), thiazol-2-yl, [1,2,4]thiadiazol-5-yl, [1,3,4]oxadiazol-2-yl, imidazol-2-yl, oxazol-2-yl, or (3- or 5-oxadiazolyl[1,2,4]; R7 is -(CR4R5)qR11 or C1-6 alkyl wherein the R11 or C1-6 alkyl group is unsubstituted or substituted one or more times by methyl or ethyl unsubstituted or substituted by 1-3 fluorines, -NR8R10, -CO2R8, -O(CH2qR8, -NR8C(O)R8 or R12; or the pharmaceutically acceptable salts thereof.

Owner:SMITHKLINE BECKMAN CORP

Cyclopentane and cyclopentene compounds and use for detecting influenza virus

New cyclopentane and cyclopentene compounds are provided along with their use in method for detecting influenza virus.

Owner:BIOCRYST PHARM INC

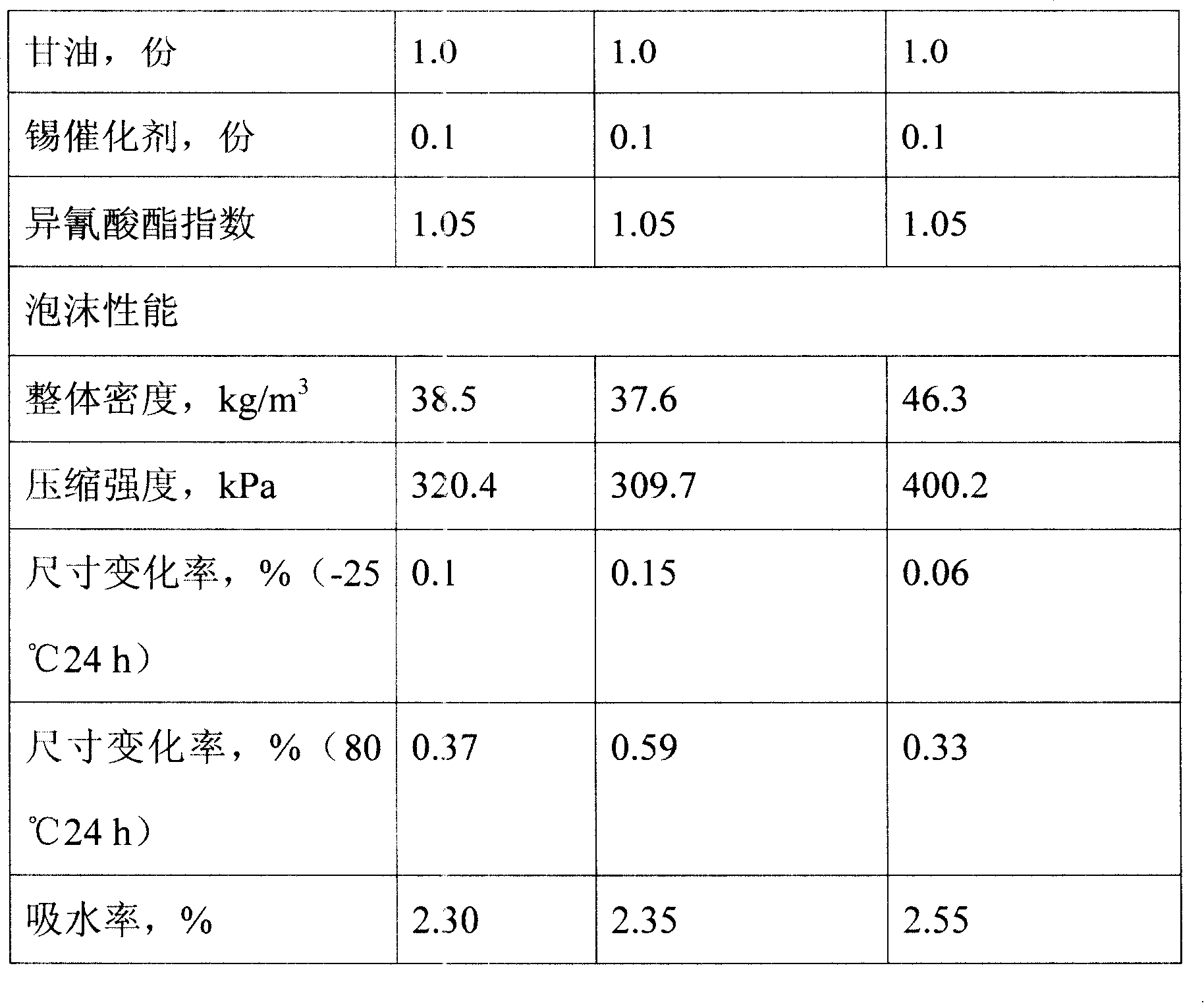

Substituted cyslopentane and cyclopentene compounds useful as neuraminidase inhibitors

Owner:BIOCRYST PHARM INC

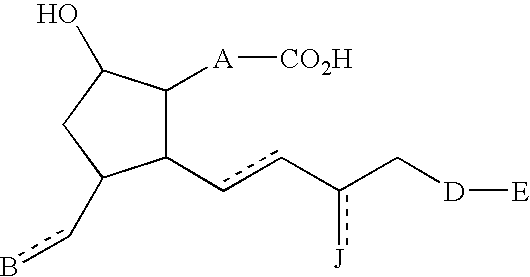

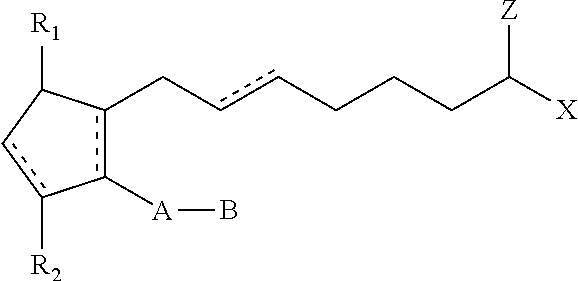

Compositions and methods for stimulating hair growth

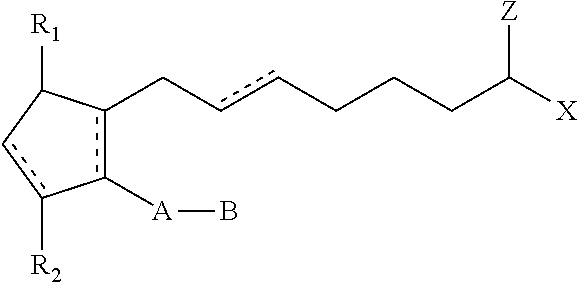

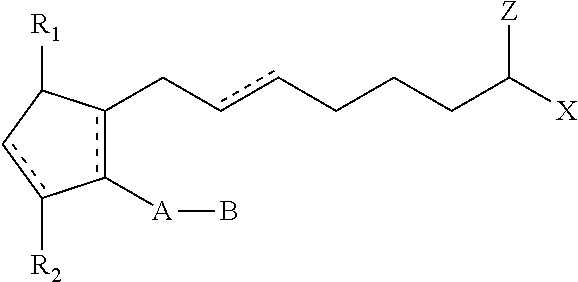

Methods and compositions for stimulating the growth of hair are disclosed wherein said compositions include a cyclopentane heptanoic acid, 2-cycloalkyl or arylalkyl compound represented by the formula Iwherein the dashed bonds represent the presence or absence of a double bond which can be in the cis or trans configuration and A, B, Z, X, R1 and R2 are as defined in the specification and a penetration enhancer. Such compositions are used in stimulating hair growth of human or non-human animals.

Owner:ALLERGAN INC

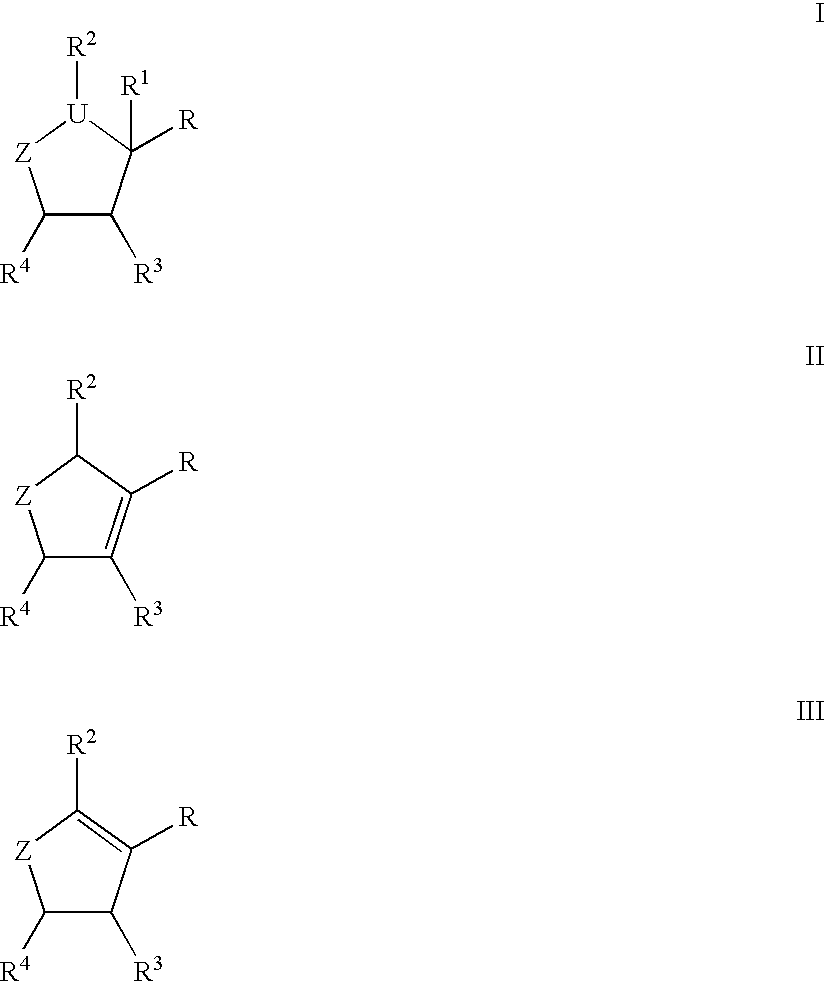

Substituted cyclopentane and cyclopentene compounds useful as neuraminidase inhibitors

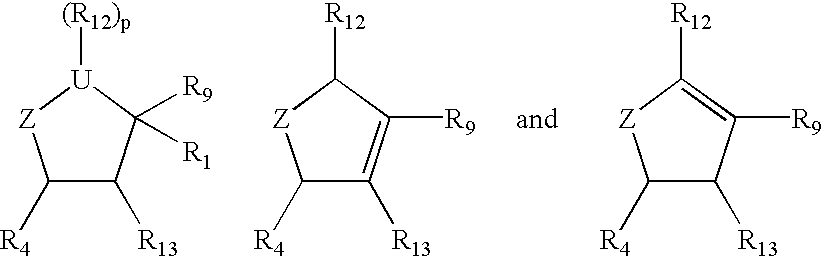

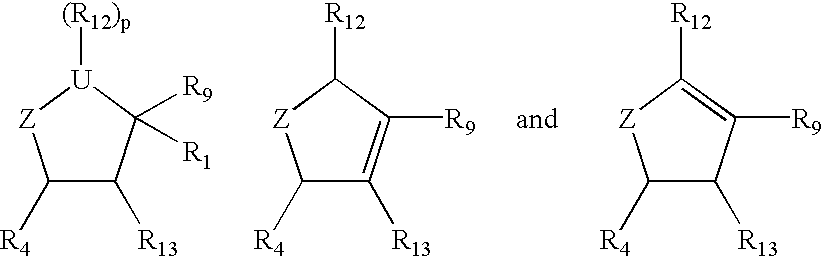

Compounds I-III wherein U is CH, O, or S; Z is mono- or di-substituted carbon; R is (CH2)nCO2H, (CH2)nSO3H, (CH2)nPO3H2, (CH2)nNO2, CH(SCH3)3, esters; R1 is H, hydroxyalkyl, aminoalkyl, alkoxyalkyl; RR1 is O; n is 0-4; R2, R3 is H, hydroxyalkyl, aminoalkyl, alkoxyalkyl, haloalkyl; R4 is (CH2)nOH, (CH2)nNH2, substituted alkyl were prepd. as neuraminidase inhibitors. Thus, (1R,3R,4R,1'S)-(-)-(1'-acetylamino-2 '-ethyl)butyl-4-(aminoimino)methylaminocyclopentan-1-carboxylic acid was prepd. and tested in vitro as neuraminidase inhibitor (IC50<1.mu.M).

Owner:BIOCRYST PHARM INC

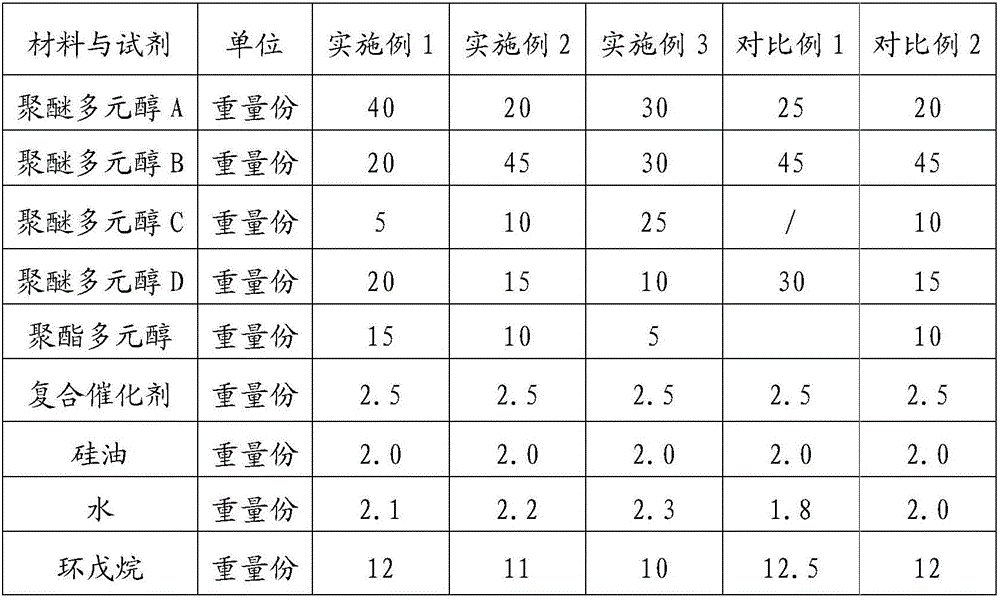

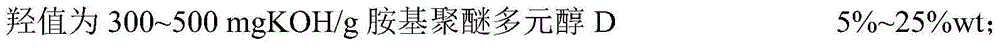

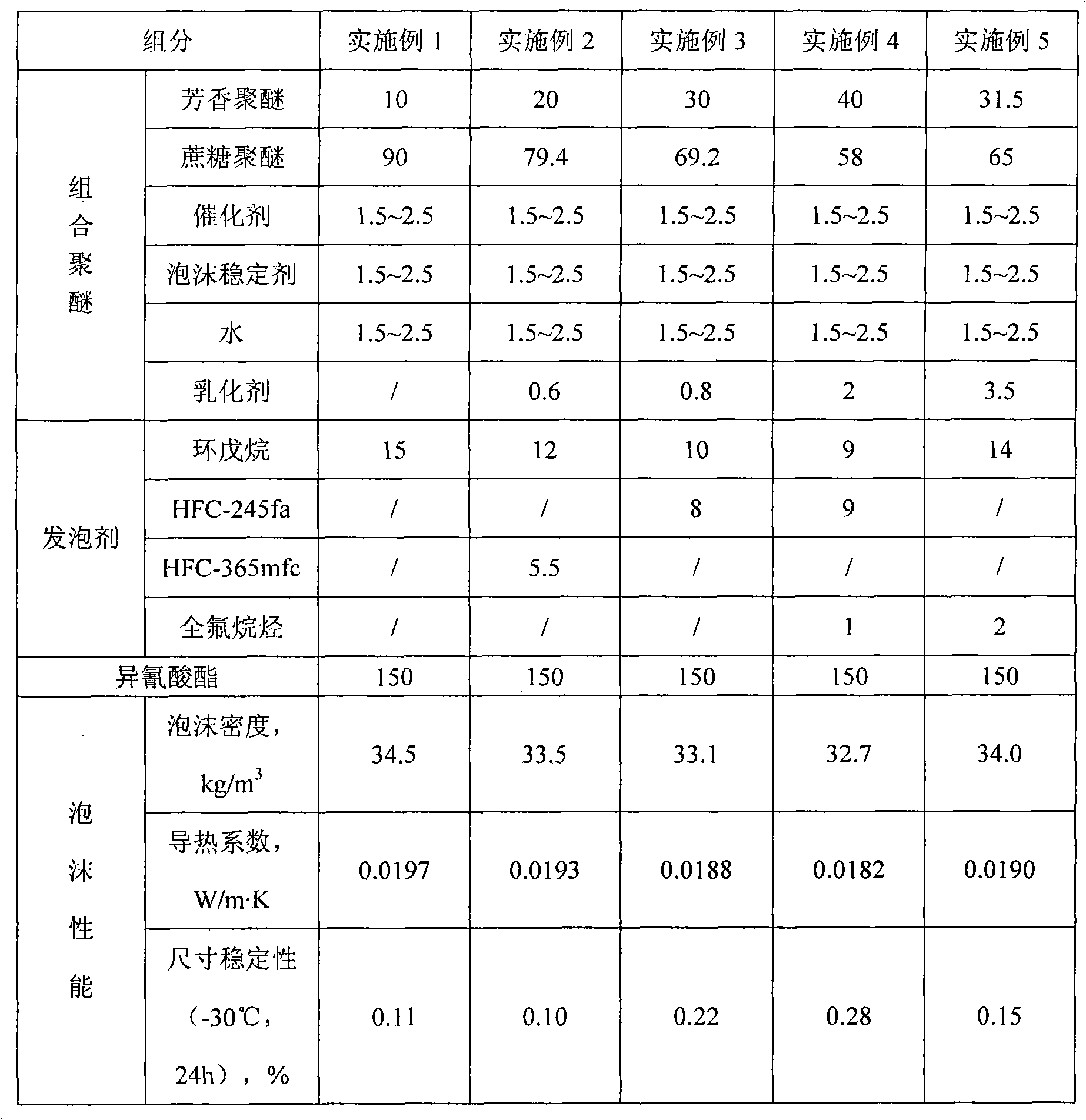

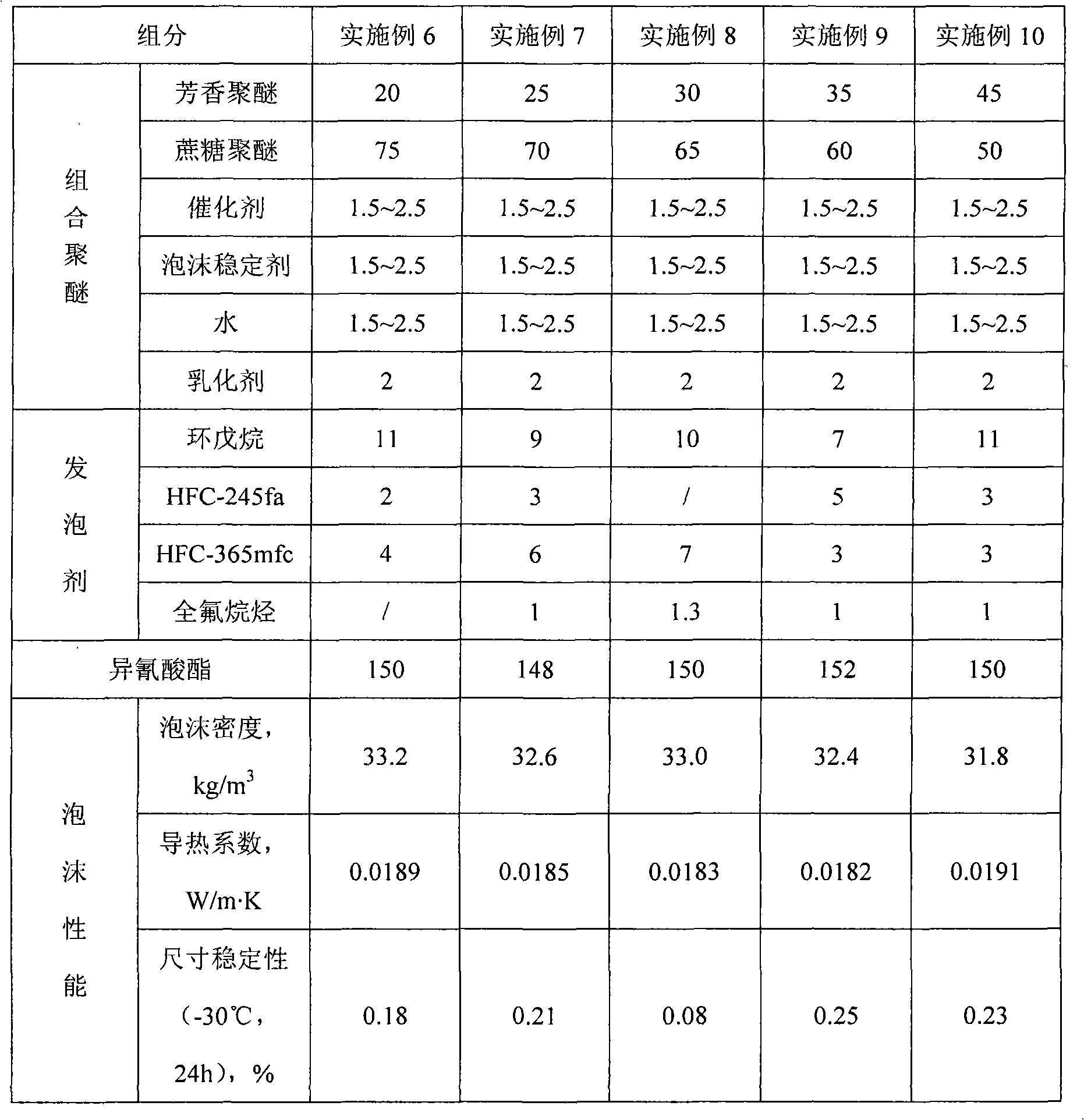

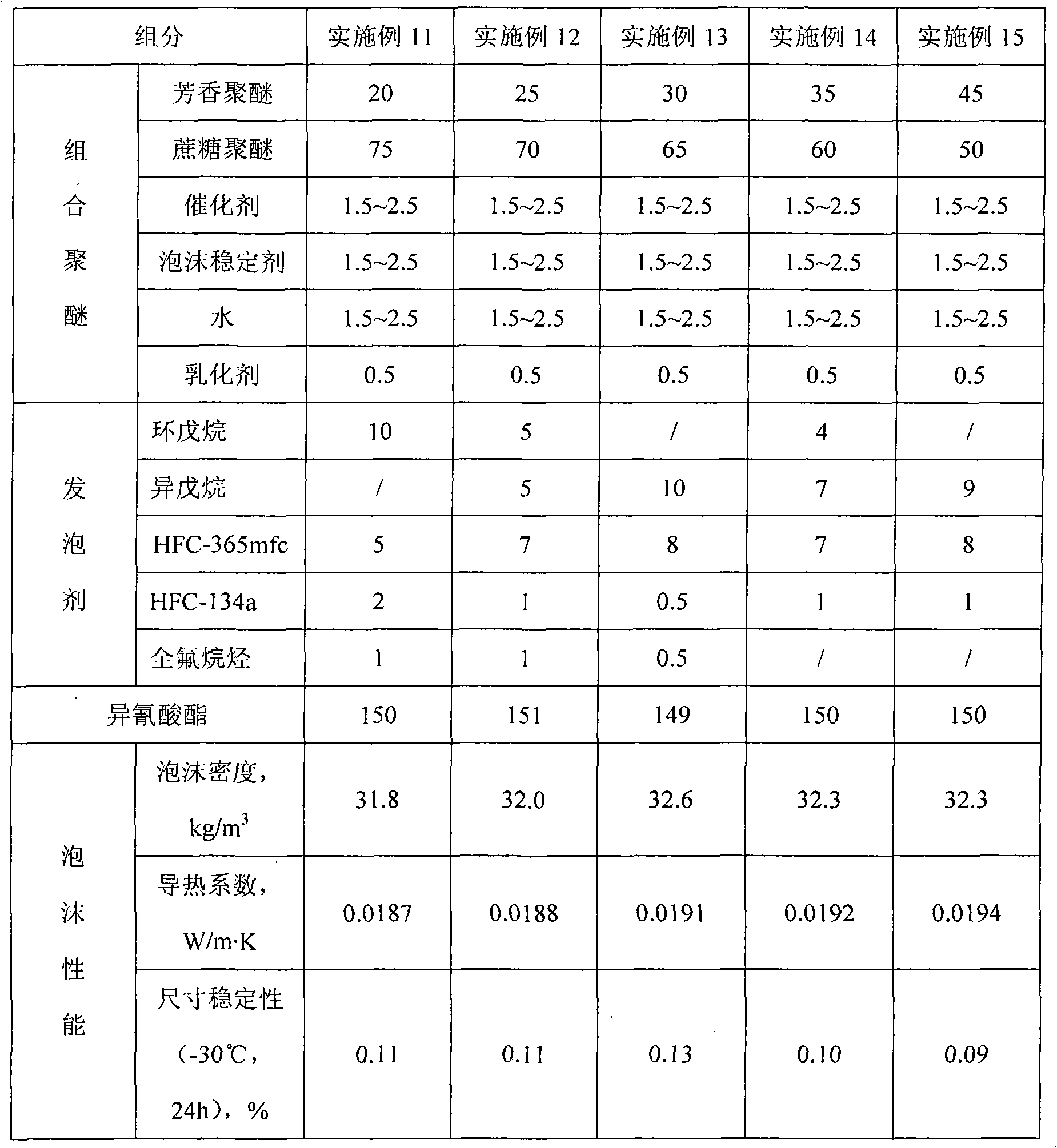

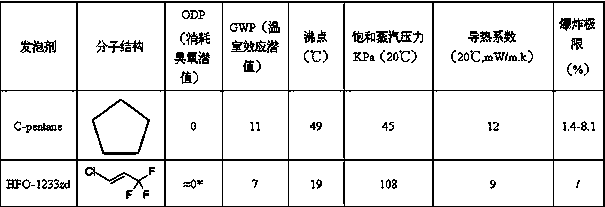

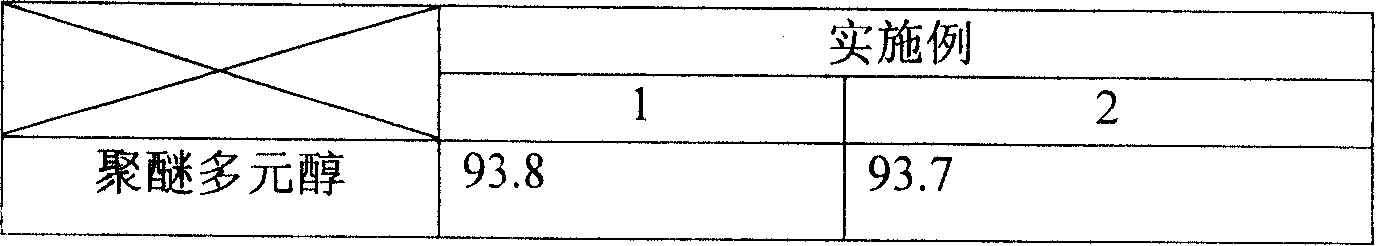

Low-thermal-conductivity rigid polyurethane foam taking cyclopentane as main body and manufacturing method and applications thereof

The invention discloses a low-thermal-conductivity rigid polyurethane foam taking cyclopentane as a main body and a manufacturing method and applications thereof. The invention relates to the technical field of rigid polyurethane foams, and specifically relates to a rigid polyurethane foam which is prepared from the following raw materials in parts by weight through a hybrid reaction: 135-165 parts of polyisocyanate, 100 parts of polyol composition, 10-16 parts of cyclopentane, 1.8-2.3 parts of catalyst, 1.8-2.5 parts of silicone oil, 1.6-2.4 parts of water, and 1-chlorine-3,3,3-trifluoropropene with a weight accounting for 1-3% of the total weight of the raw materials. The invention also relates to a preparation method of the rigid polyurethane foam and the application of the rigid polyurethane foam in refrigerator and freezer industries. Cells of the rigid polyurethane foam disclosed by the invention are smaller and more uniform, so that the thermal conductivity (minimum: below 0.01800 W / m.K) is greatly reduced, and the strength of the foam is increased; the rigid polyurethane foam reduces the energy consumption and is good in environmental friendliness; the rigid polyurethane foam disclosed by the invention has a positive role in promoting the upgrading and updating of an existing cyclopentane foaming technology for refrigerators.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

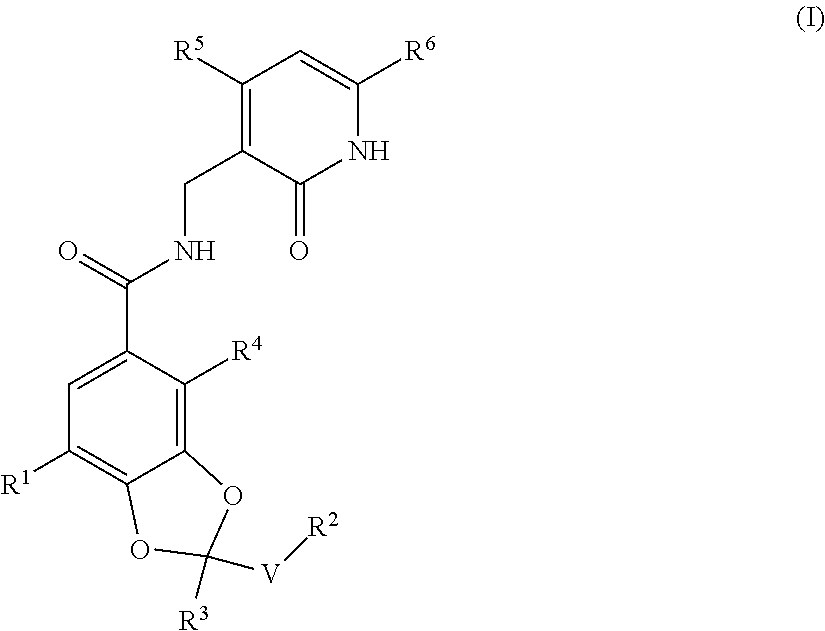

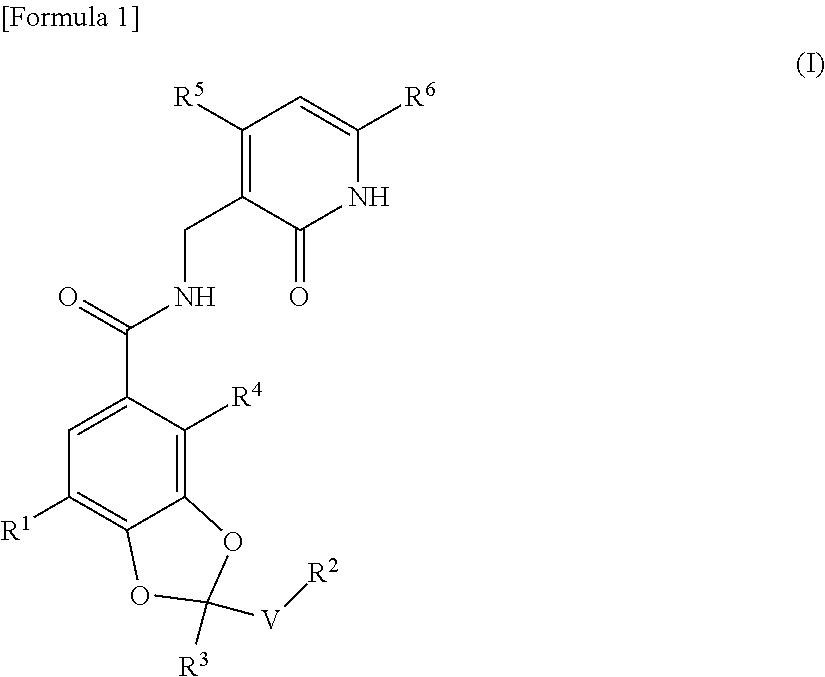

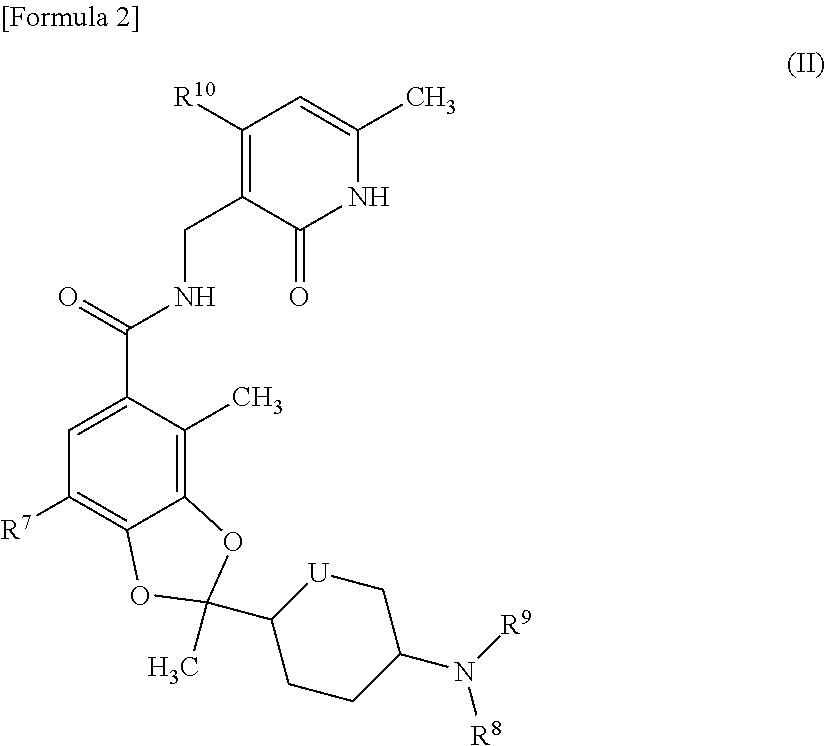

1,3-benzodioxole derivative

ActiveUS20170073335A1High activityInhibit cell growthOrganic active ingredientsOrganic chemistryBenzeneChemical structure

The present invention provides a compound having a particular chemical structure or a pharmacologically acceptable salt thereof which has an excellent inhibitory effect on EZH1 and / or EZH2 activity. The present invention provides a compound having a 1,3-benzodioxole structure represented by the general formula (I) or a pharmacologically acceptable salt thereof, or a pharmaceutical composition comprising the compound (wherein R1, R2, R3, R4, R5, R6, and V in the formula (I) are each as defined in the present specification).

Owner:DAIICHI SANKYO CO LTD

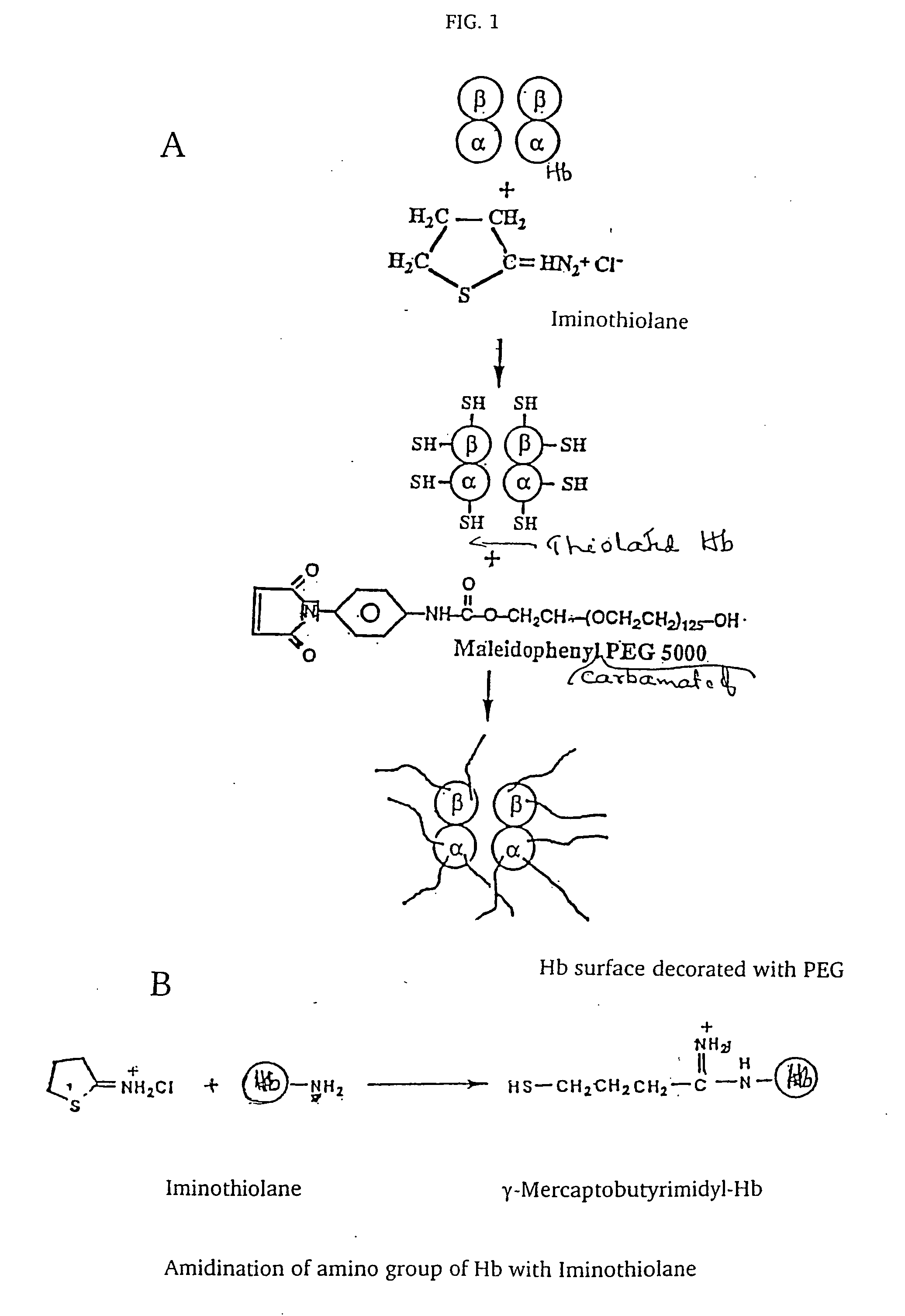

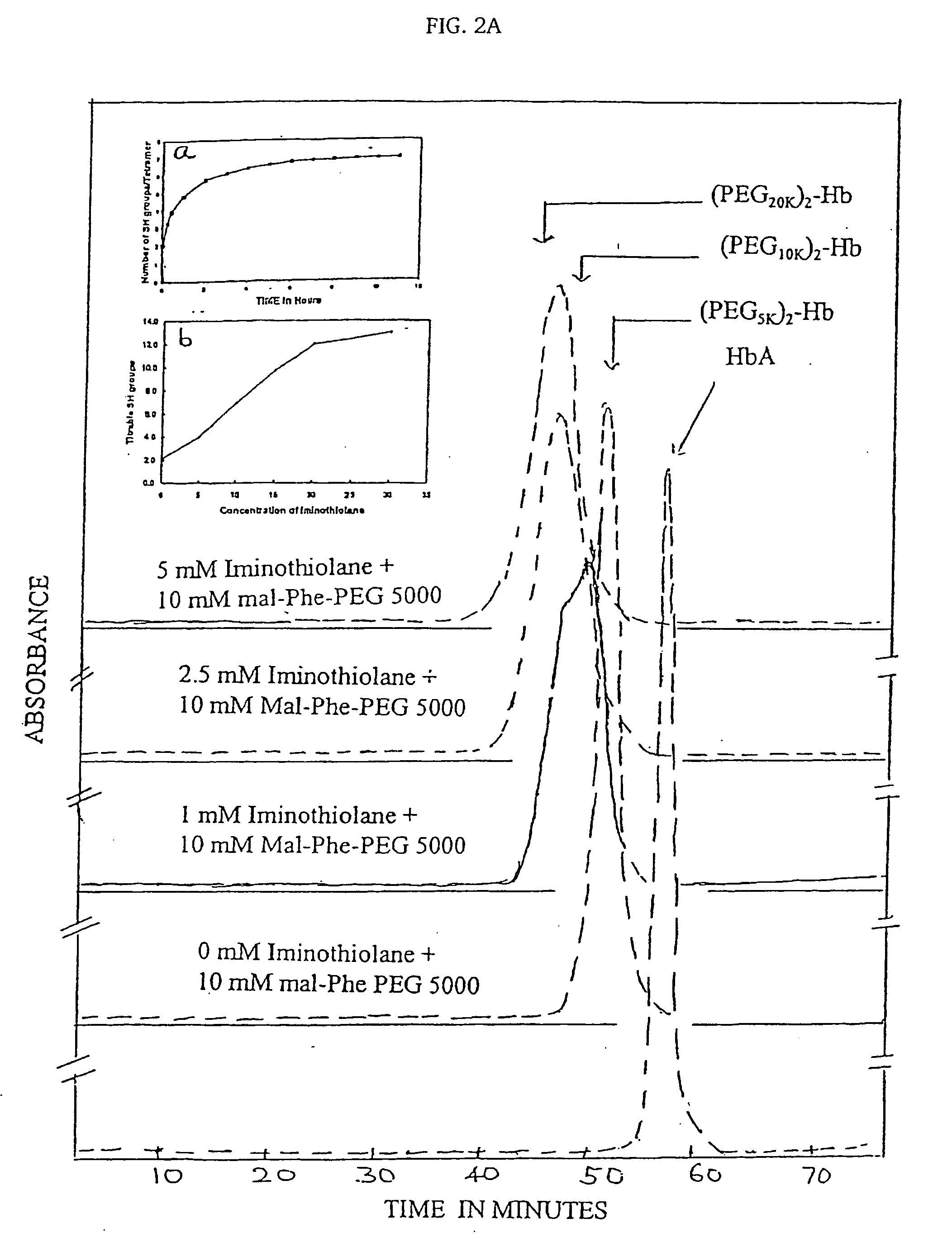

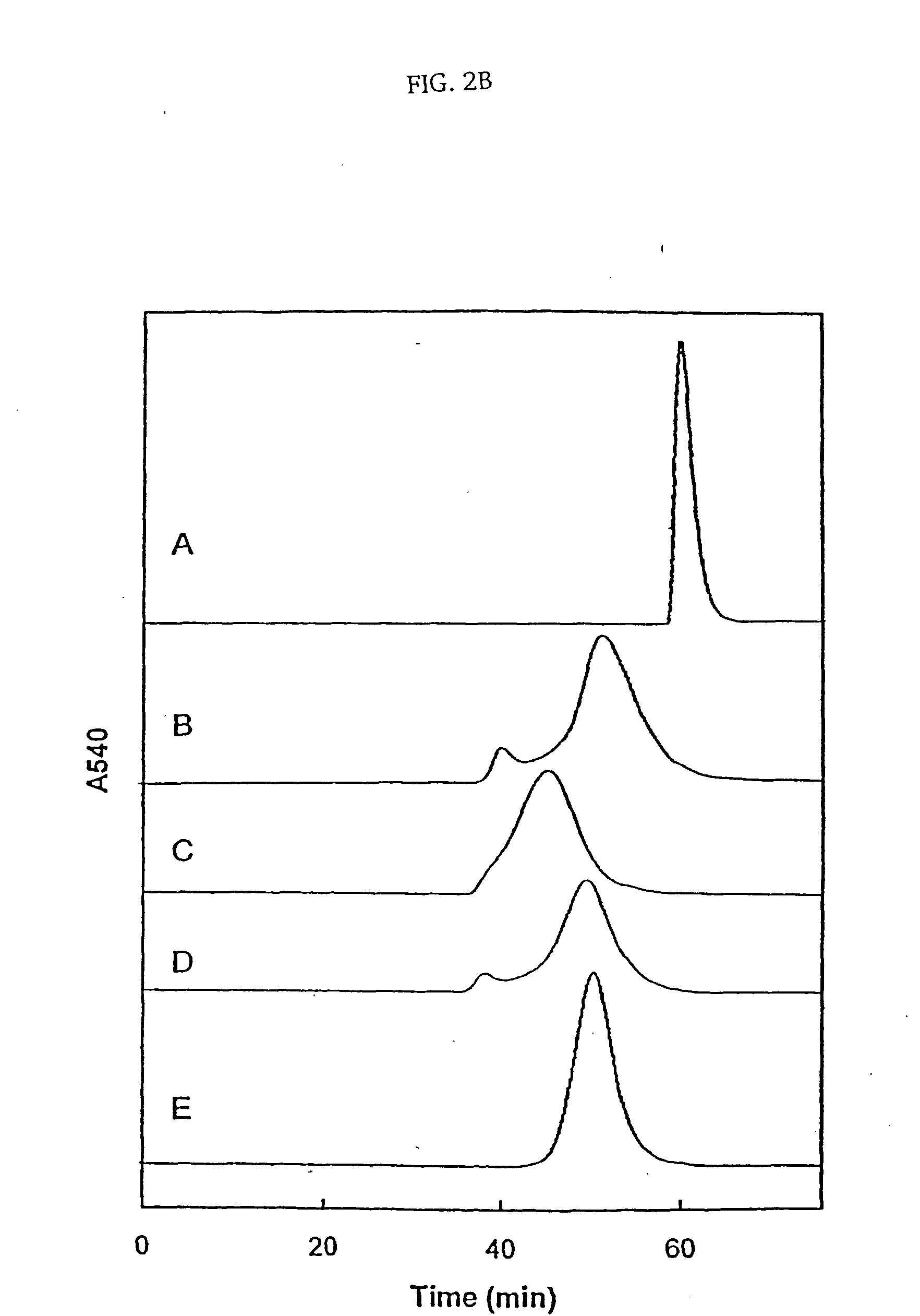

Modified hemoglobin and methods of making same

InactiveUS20060135753A1Enhanced molecular volumeHigh viscosityPeptide/protein ingredientsHaemoglobins/myoglobinsSulfurHemeprotein

The present invention provides a hemoglobin molecule (Hb) having six±one PEG chains, wherein two of said PEG chains are bound to Cys-93 (β) of Hb, and the remaining PEG chains are bound to thiol groups introduced on ε-NH2 of Hb. The present invention also provides a process for preparing a modified hemoglobin molecule (Hb), comprising the steps of: (a) reacting Hb with 8-15 fold excess of iminothiolane to form thiolated Hb; and (b) reacting the thiolated Hb with 16-30 fold excess of PEG functionalized with a maleimide moiety, to form the modified Hb.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIV

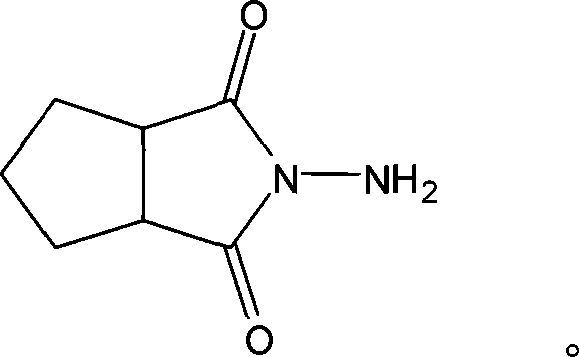

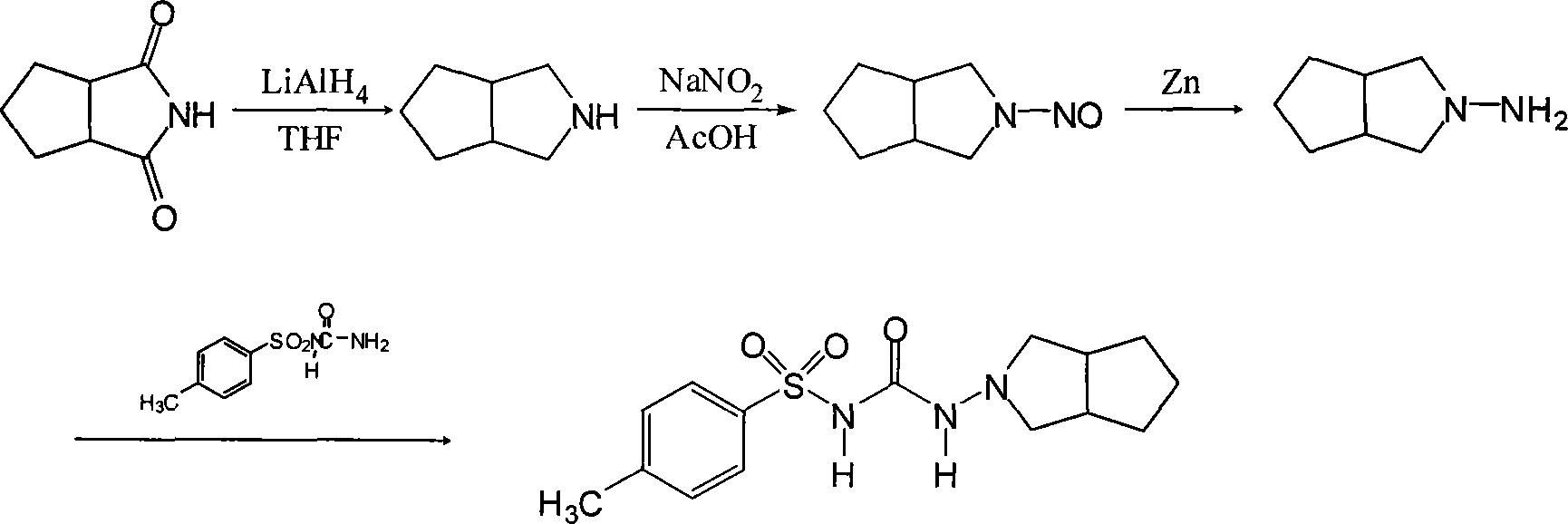

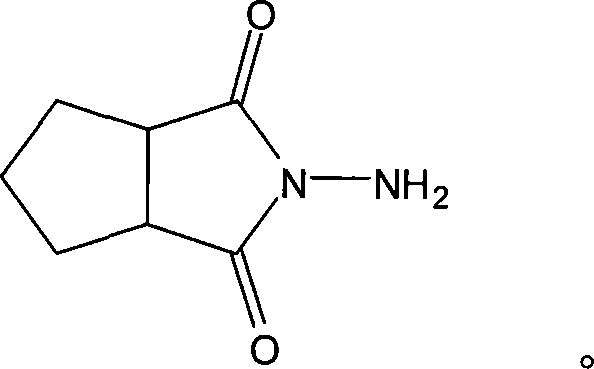

N-amino-1,2-cyclopentanediformylimine and preparation method thereof

InactiveCN101235011AFew reaction stepsReduce manufacturing costOrganic chemistryImideCombinatorial chemistry

The invention discloses an N-amino-1, 2-cyclopentane dicarboximide whose formula is represented as right. The invention also discloses a corresponding preparation method which comprises using cyclopentane ortho-anhydride as raw material, carrying out hydrazine hydrate in solvent for refluxing reaction for 0.5-12h while the mol ratio of cyclopentane ortho-anhydride and hydrazine hydrate is 1:1-2.5, removing solvent after reaction, and drying to obtain N-amino-1, 2-cyclopentane dicarboximide. The N-amino-1, 2-cyclopentane dicarboximide can be used as the intermediate of gliclazide, thereby reducing the reaction route of gliclazide to reduce waste.

Owner:ZHEJIANG UNIV

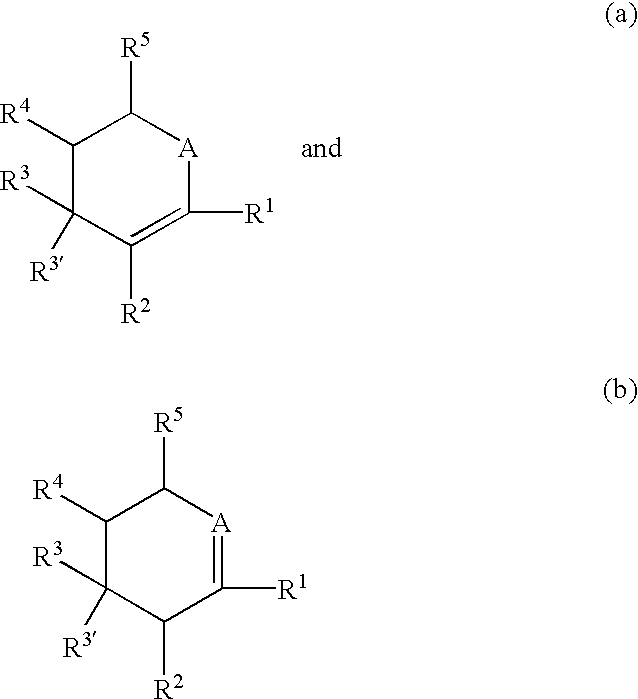

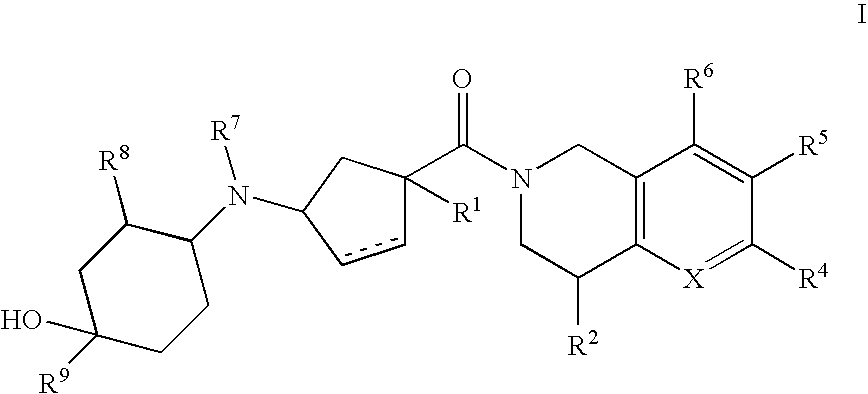

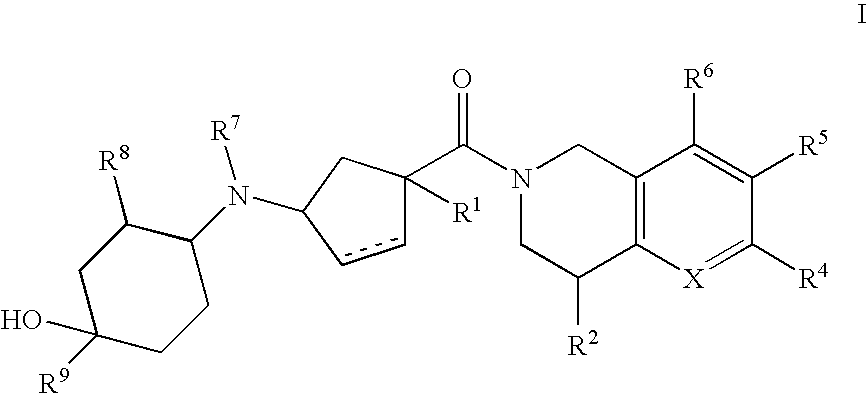

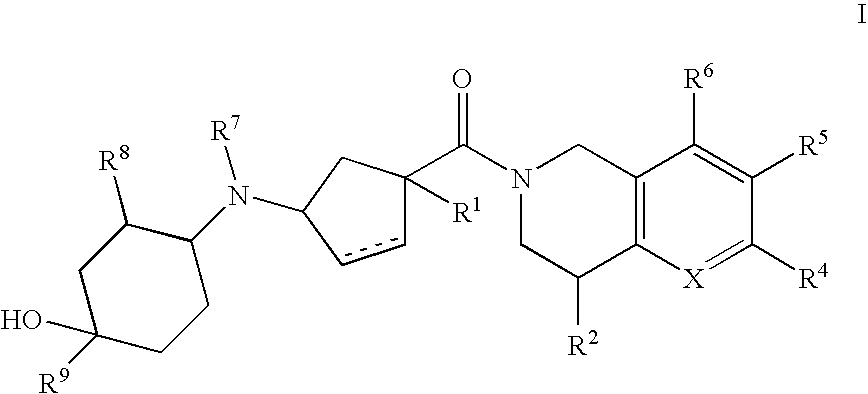

3-(4-heteroarylcyclohexylamino)cyclopentanecarboxamides as modulators of chemokine receptors

Owner:INCYTE HLDG CORP

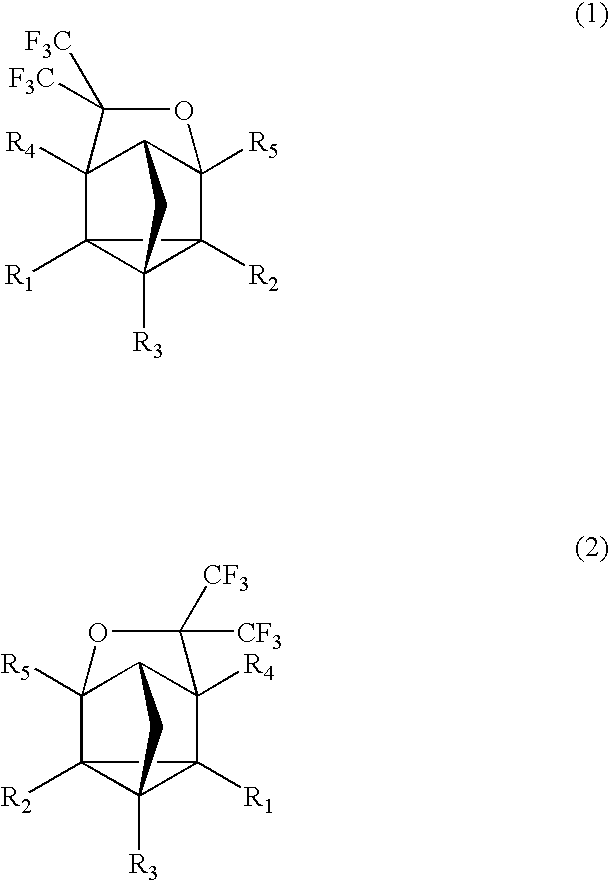

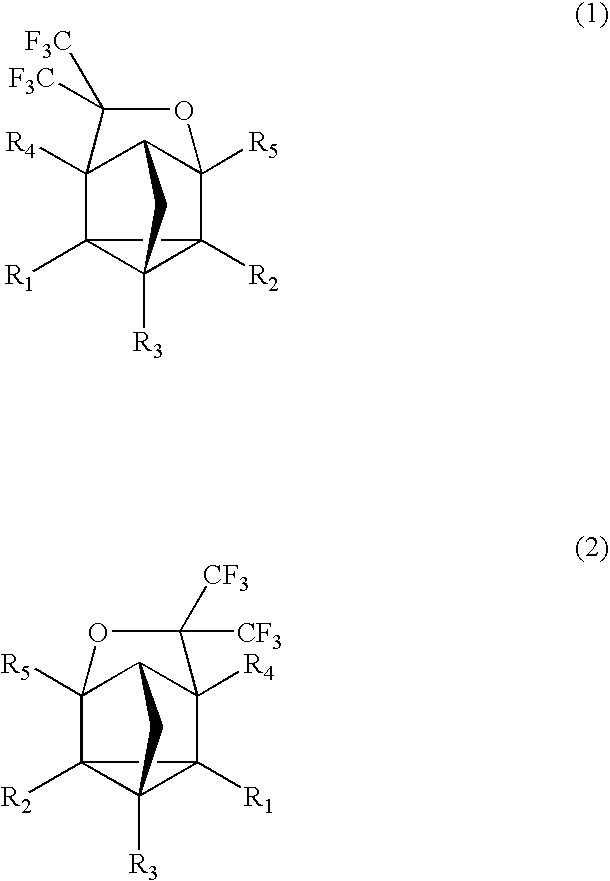

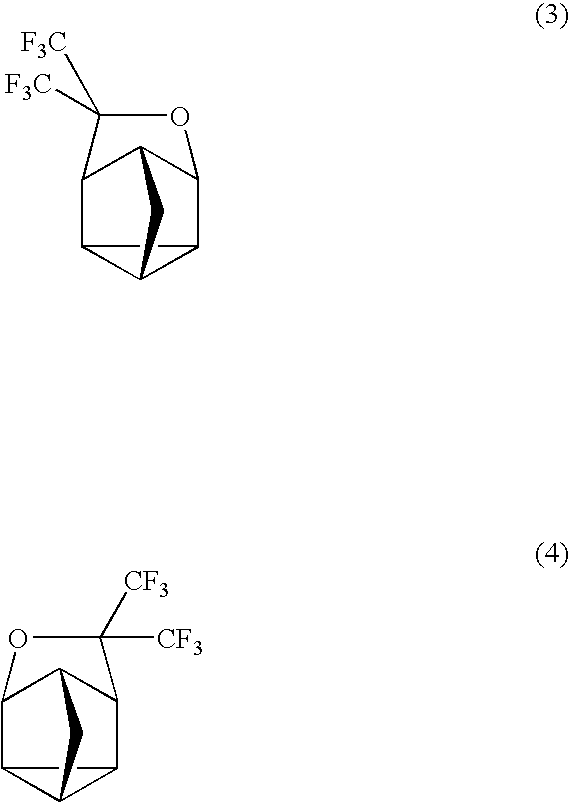

Fluorinated cyclic compound, polymerizable fluoromonomer, fluoropolymer, resist material comprising the same, and method of forming pattern with the same

InactiveUS20060135744A1High transparencyIncrease resistanceOrganic chemistryPhotosensitive materialsPolymer scienceFluoropolymer

The present invention relates to a novel fluorine-containing cyclic compound that is derived from a norbornadiene and hexafluoroacetone and has an oxacyclopentane or oxacyclobutane structure. This compound may be represented by the following formula (1) or (2). Furthermore, the present invention relates to a fluorine-containing high-molecular compound prepared by a polymerization or copolymerization using this fluorine-containing cyclic compound or its derivative. By using such fluorine-containing high-molecular compound, it is possible to provide a superior resist material and a fine pattern forming process using the same.

Owner:CENT GLASS CO LTD

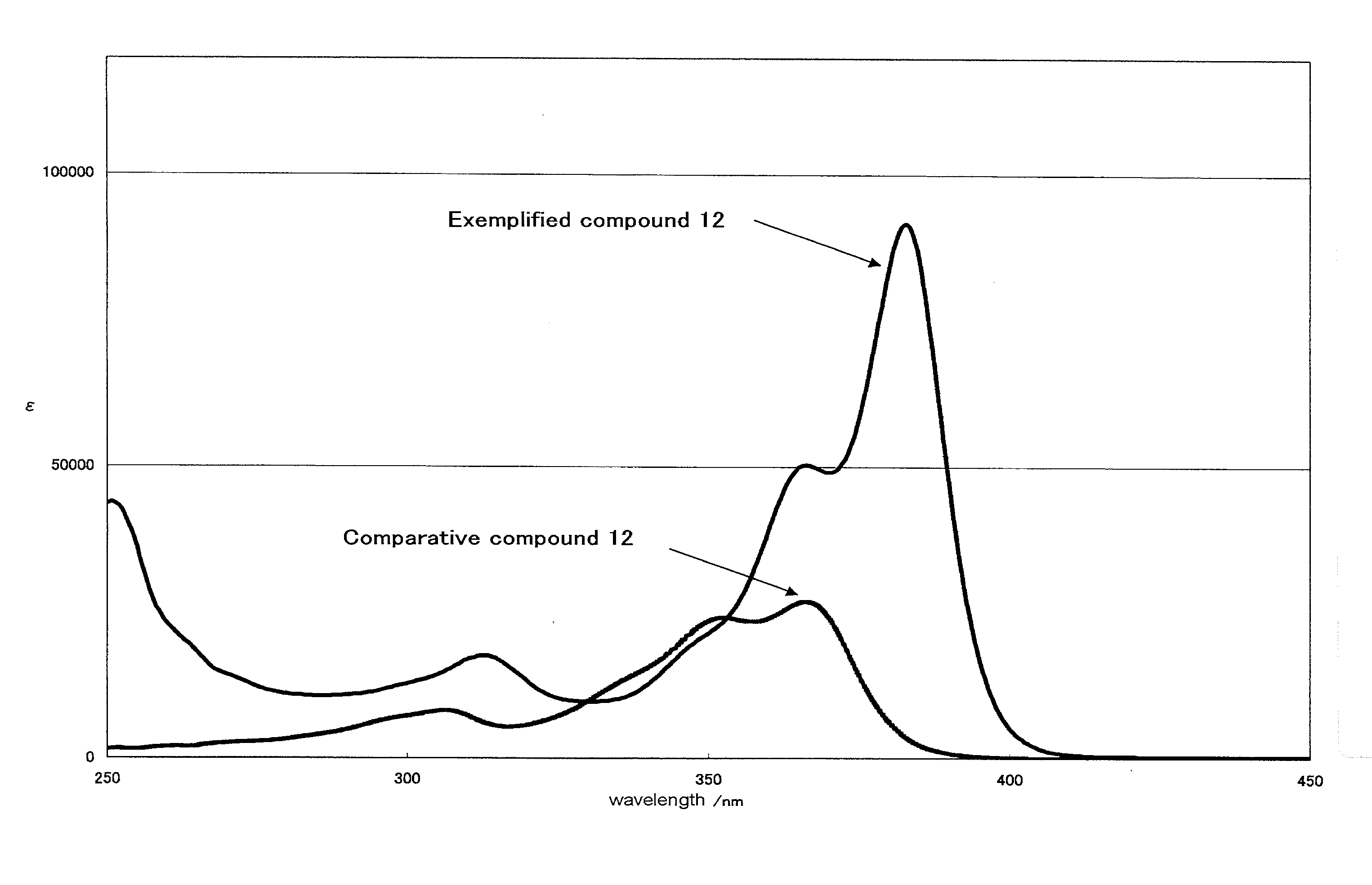

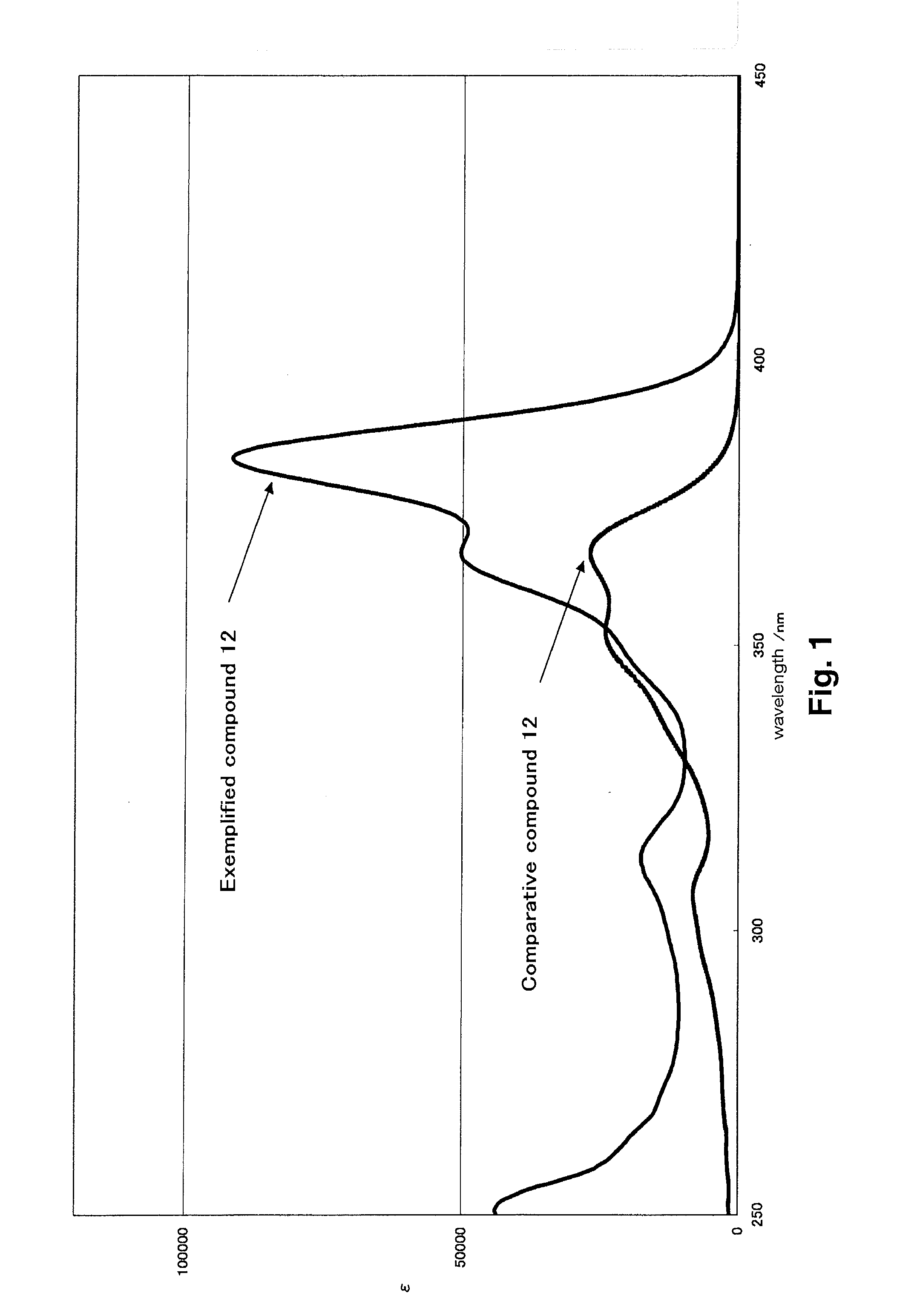

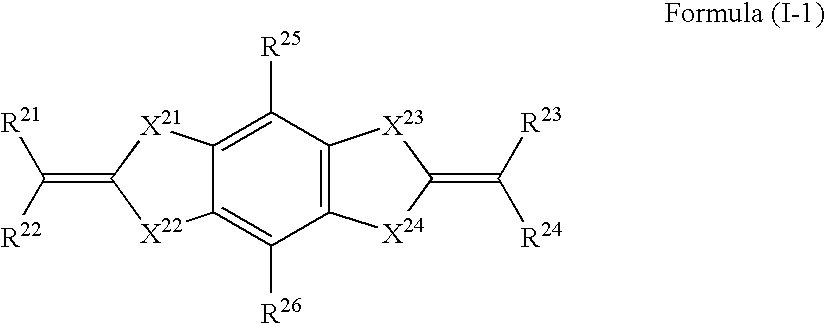

Heterocyclic compound, ultraviolet absorbent and composition containing the same

ActiveUS20100210762A1Improves UV resistancePrevent unstable compoundCosmetic preparationsGroup 4/14 element organic compoundsSulfurylPolymer chemistry

A compound represented by formula (I-1):wherein R21, R22, R23 and R24 each independently represent a hydrogen atom or a monovalent substituent, with the proviso that compounds, in which R21, R22, R23 and R24 each are an alkylthio group, are excluded; R21 and R22 and / or R23 and R24 each may bond to each other to form a ring, with the proviso that compounds, in which the formed ring is a dithiol ring or a dithiolane ring, are excluded;R25 and R26 each independently represent a hydrogen atom or a monovalent substituent;X21, X22, X23 and X24 each independently represent a hetero atom;compounds, wherein R21, R22, R23 and R24 each represent a cyan group; X21, X22, X23 and X24 each represent a sulfur atom; and R25 and R26 each represent a hydroxyl group or a hydrogen atom, are excluded; andcompounds, wherein R21 and R23 each represent a hydrogen atom; R22 and R24 each represent an arylcarbonyl group; X21, X22, X23 and X24 each represent a sulfur atom; and R25 and R26 each represent a hydroxyl group, are excluded; and an ultraviolet absorbent, which has molecular weight of 10,000 or less and molar extinction coefficient at the maximum absorption wavelength of the ultraviolet absorbent of 80,000 or more.

Owner:FUJIFILM CORP

Method for preparing ticagrelor key intermediate

InactiveCN106279095AReduce pressure on environmental protectionSuitable for large-scale industrial productionOrganic chemistryBulk chemical productionChemical synthesisPalladium on carbon

The invention relates to a chemical synthesis method of ticagrelor key intermediate 2-[[(3aR, 4S, 6R, 6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4-yl] oxy]ethanol (a key intermediate A). The method comprises the following steps: taking D-ribose as a raw material, and carrying out ten chemical reaction steps of 1-locus methylation and 2,3-loci isopropylidene protection, 4-locus derivatization, iodination, furan ring-opening, hydroxylamine reaction, palladium on carbon catalytic hydrogenation, amino Cbz protection, hydroxy protection, sodium borohydride reduction ester, Cbz removal protection and the like, thereby obtaining the key intermediate A. The raw materials are cheap and readily available, the preparation process is high in operability, steps of optical resolution, chiral induction and the like are avoided, the total yield is relatively high, and the product quality is better; particularly due to the use of sodium borohydride reduction ester, the preparation cost of ticagrelor is greatly reduced; and the method is suitable for large-scale industrial production.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

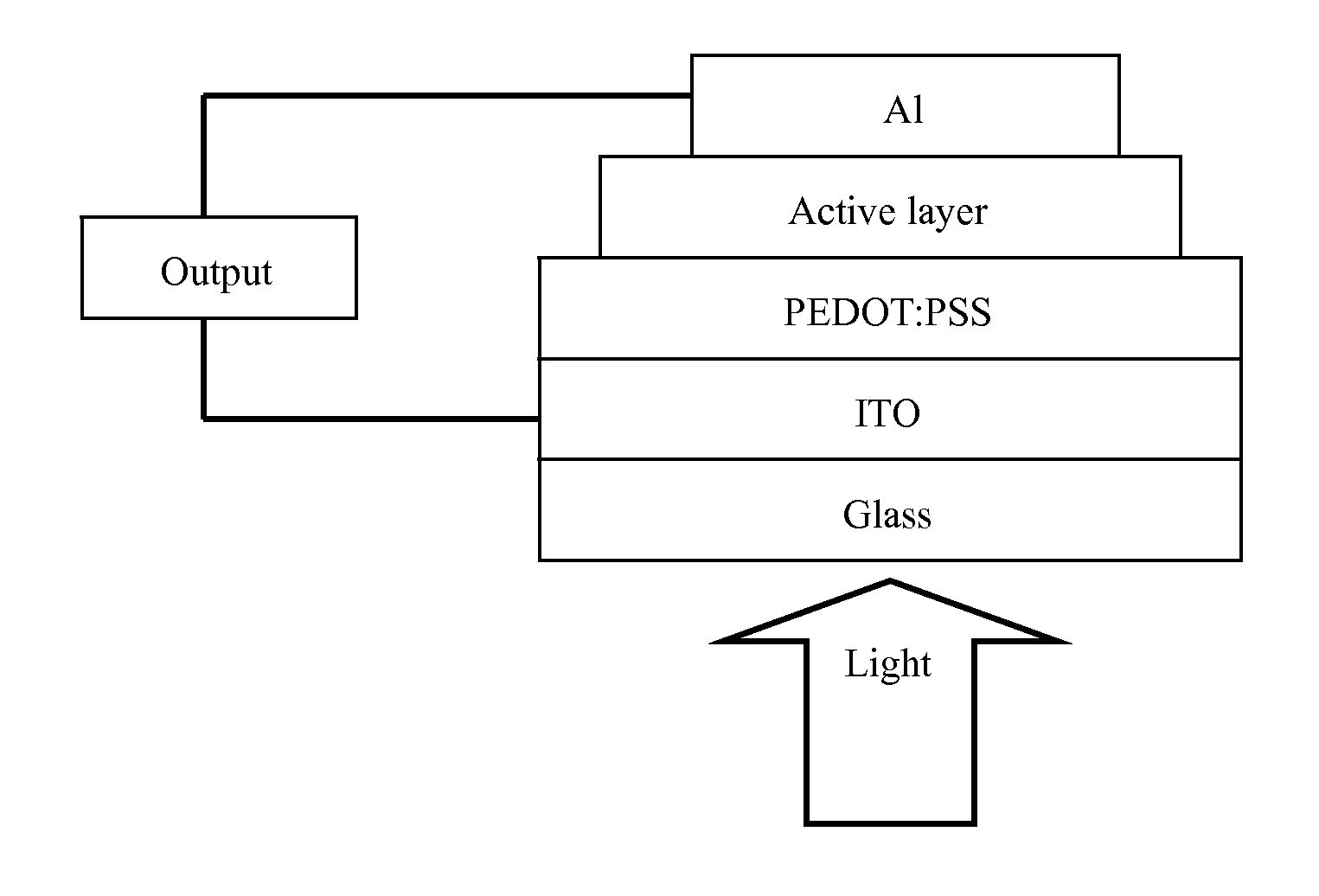

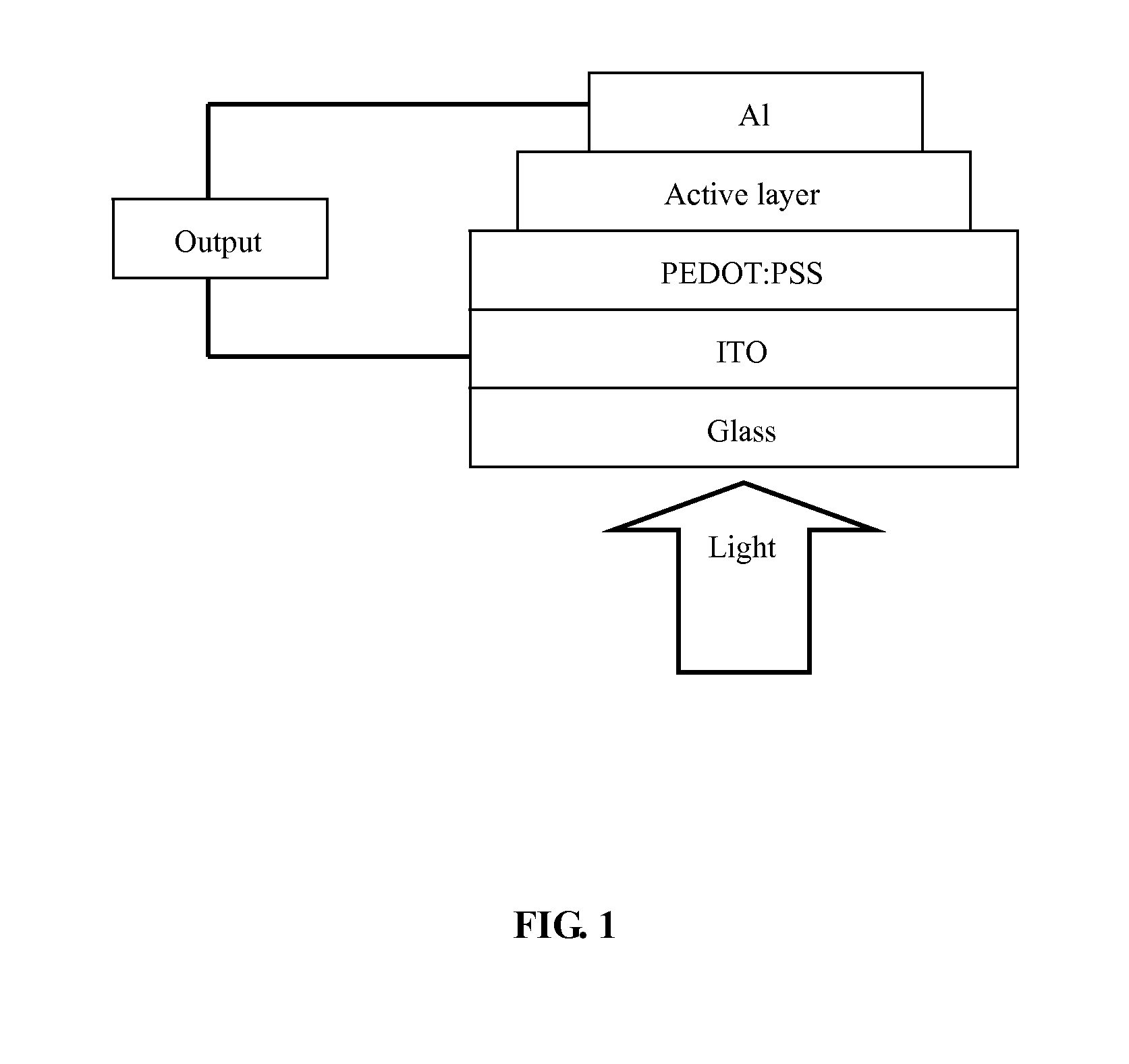

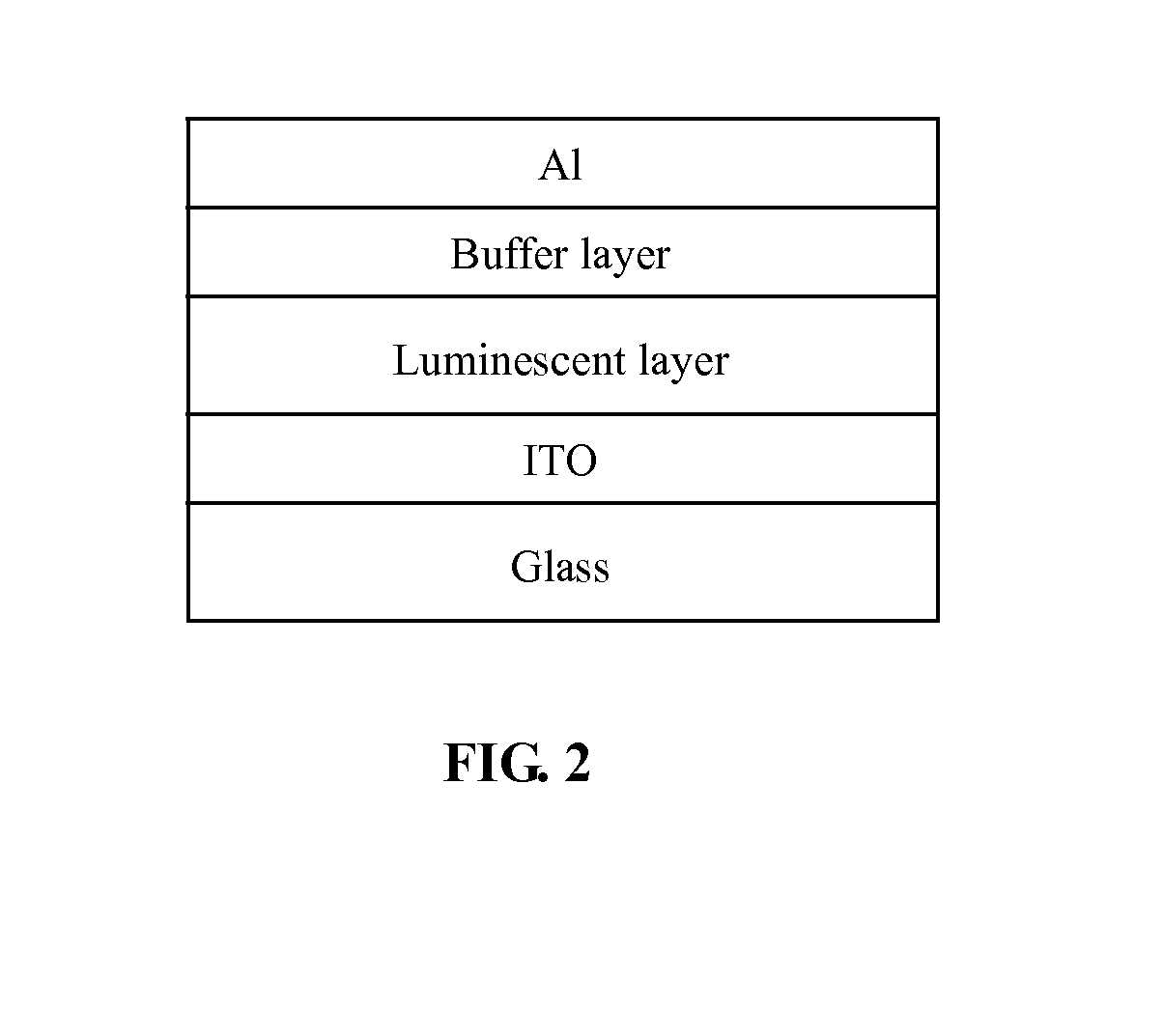

Polymer containing units of fluorene, anthracene and benzothiadiazole, preparation method thereof and application thereof

InactiveUS20130090446A1Improve stabilityWide finger peak absorptionSolid-state devicesOrganic dyesAnthracenePtru catalyst

A polymer containing units of fluorene, anthracene and benzothiadiazole with the following formula is provided:2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolanyl)-9,9-dialkylfluorene, 9,10-dibromoanthracene or its or derivatives and 4,7-bis(5′-bromo-2′-thienyl)-2,1,3-benzothiadiazole or its derivatives are added to solvent, after the catalyst and base solution are added to the solution, the compounds in the solution are processed by Suzuki coupling reaction to obtain polymer. This kind of polymer containing units of fluorene, anthracene and benzothiadiazole have low energy gap, high mobility of the carriers, wide range of spectral absorption and have a broad prospect of application in the field of photoelectric.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

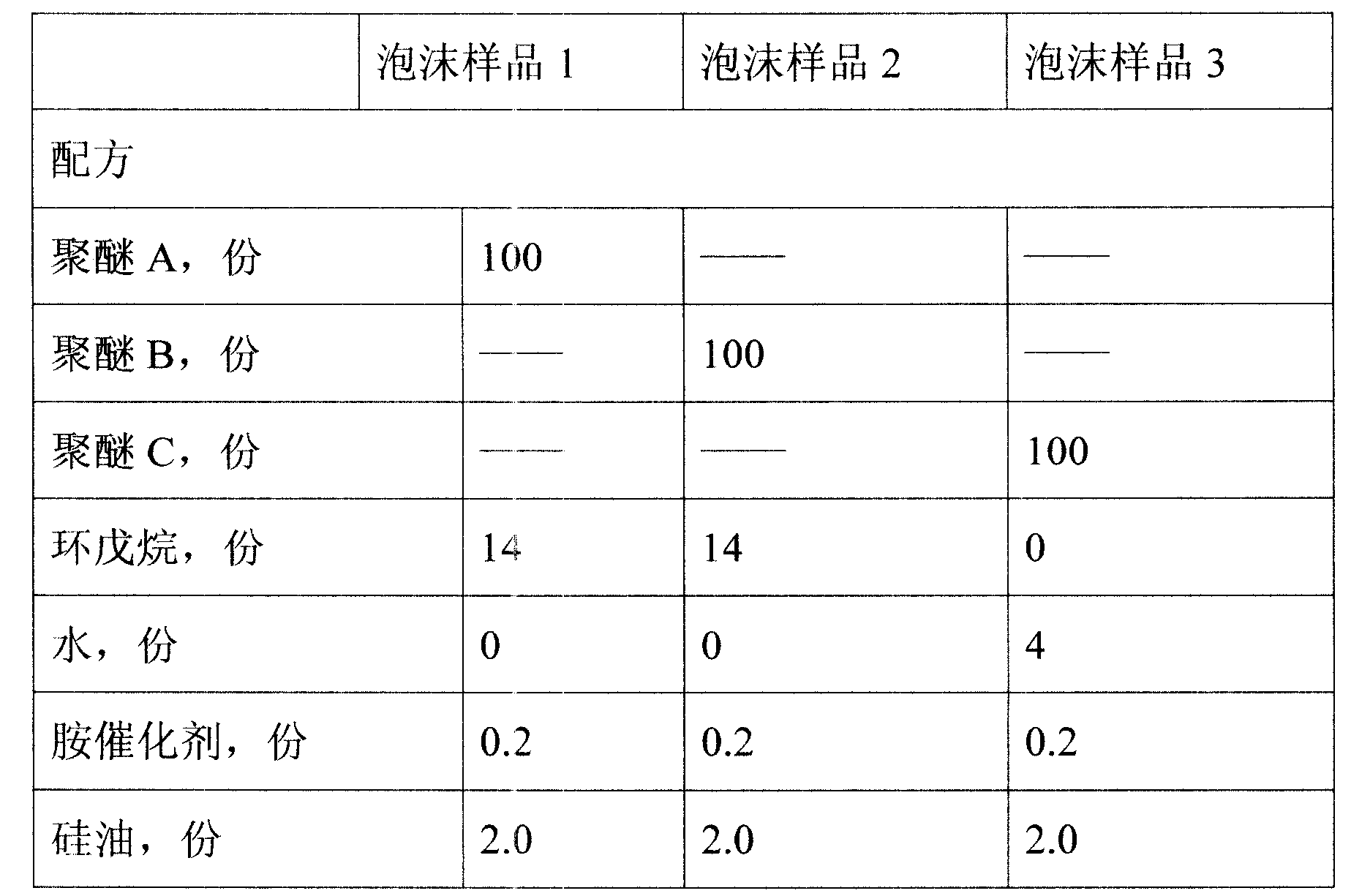

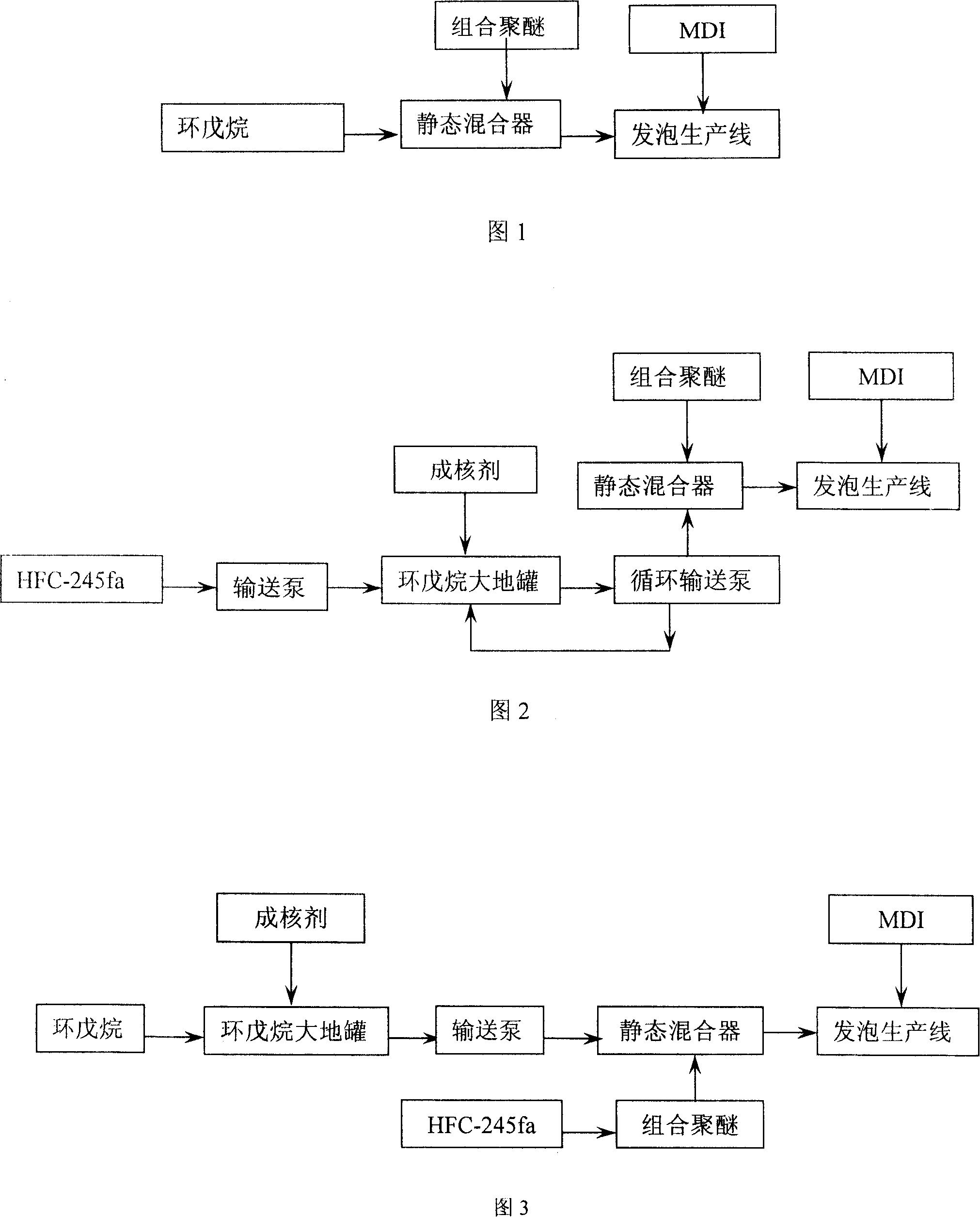

Hard polyurethane foam plastic and producing method thereof

InactiveCN101125910AGood compressive strength and dimensional stabilityReduce the amount of foaming raw materialsIsocyanateChemistry

The invention relates to a pyrex polyurethane foam plastic and the production method thereof. The raw materials are polyisocyanate, conjugate polyether and blowing catalyst, wherein the blowing catalyst consists of HFC-245fa, pentamethylene and nucleating agent; portions of raw materials by weight are: 100 portions of conjugate polyether, 1 to 10 portions of HFC-245fa, 6 to 12 portions of pentamethylene, 0.1 to 2.2 portions of nucleating agent, 100 to 130 portions of polyisocyanate. The steps of the production method are: a) the HFC-245fa, the pentamethylene and the nucleating agent are put into circularly transferring pump to mix with circularly; b) polyether glycol monomer, water, catalyst and stabilizer are mixed to prepare conjugate polyether; c) the mixture of the blowing catalyst and the nucleating agent and the conjugate polyether are fed into a static mixer; d) the mixture obtained from the step reacts with polyisocyanate that yields effervescence. The foam plastic of the invention has the advantages of environmental protection and low cost, and comprehensive properties thereof equivalent to the foaming ability of CEC-11. The invention opens up a novel shortcut for the application of HFC-245fa, erases the cost burden while is used alone, thus HEC-245fa can be largely popularized and used.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

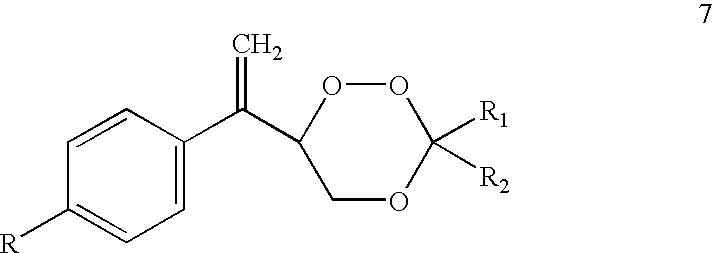

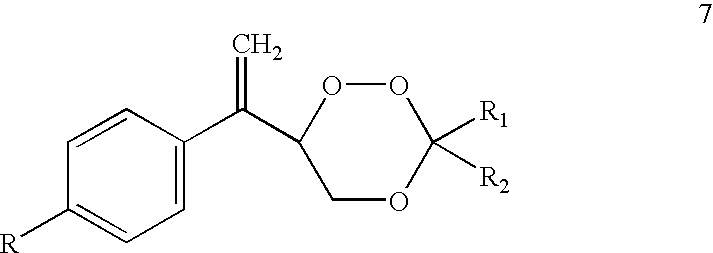

Substituted 1,2,4-trioxanes useful as antimalarial agents and a process for the preparation thereof

Owner:COUNCIL OF SCI & IND RES

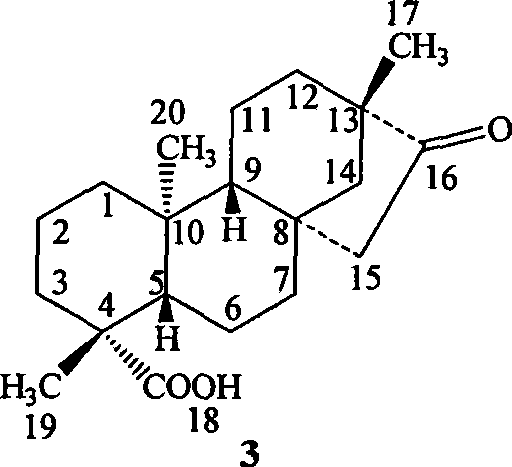

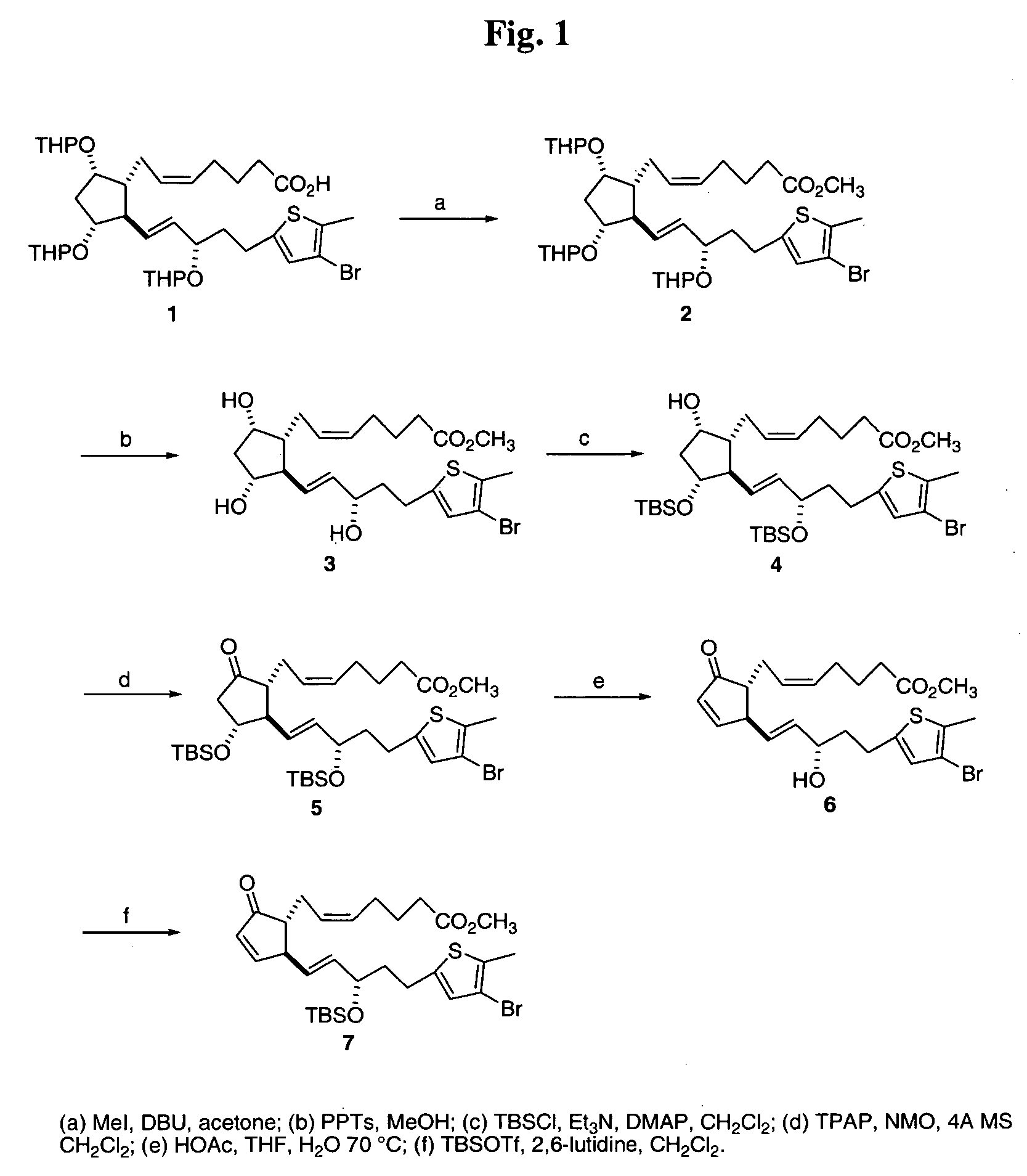

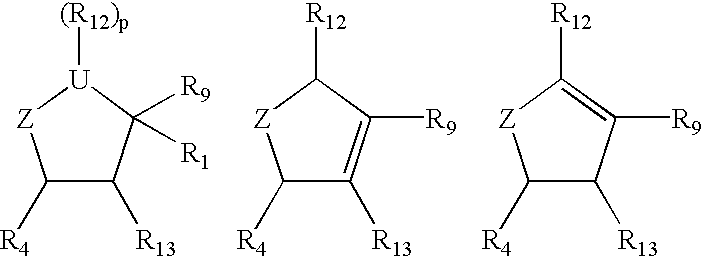

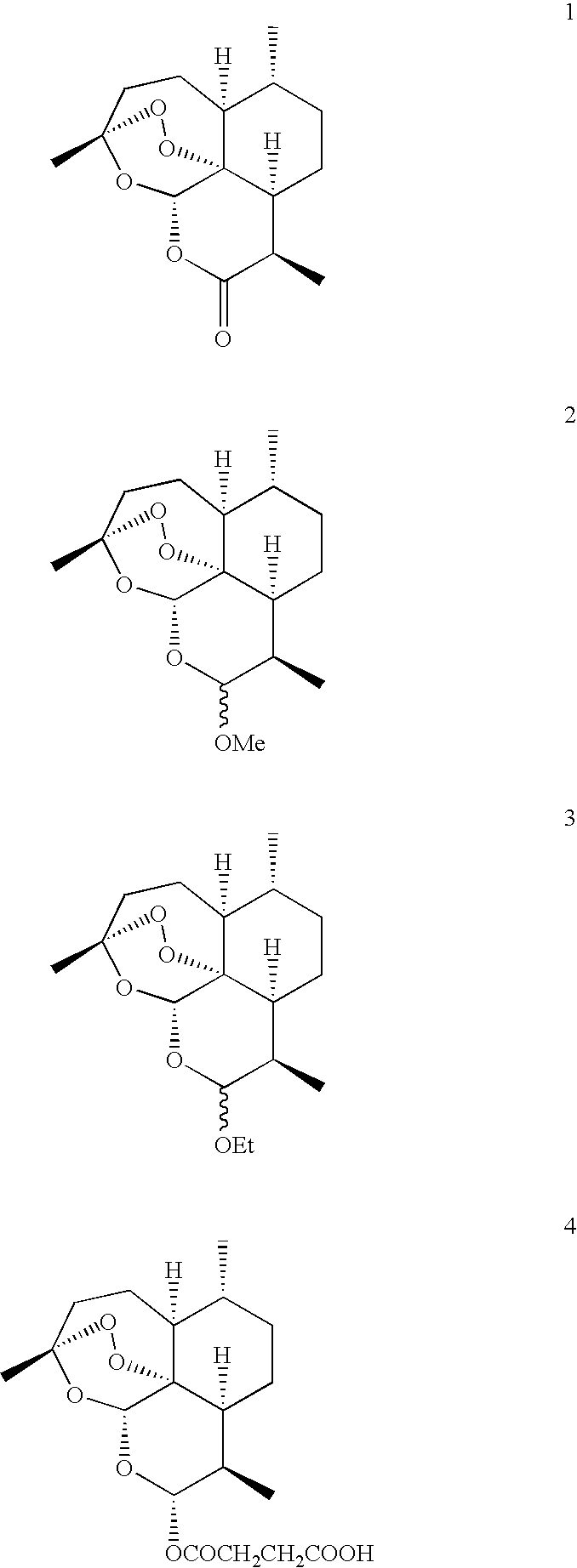

Antioxidant nanosphere comprising [1,2]-dithiolane moieties

The present invention is directed to multiple a-lipoic acid-containing hydrophobic compounds (mALAs) capable of acting as scavengers of free radicals, metals and reactive oxygen species (ROS). Methods of synthesizing novel antioxidant mALAs, spontaneous emulsification or nanoprecipitaion thereof to produce antioxidant nanospheres and their use in preventing or treating diseases or conditions caused by oxidative stress and other free radical mediated conditions are also described. Another aspect of this invention is the use of these antioxidant nanospheres for the preparation of antioxidant particulate delivery system of therapeutic agents.

Owner:CEDARS SINAI MEDICAL CENT

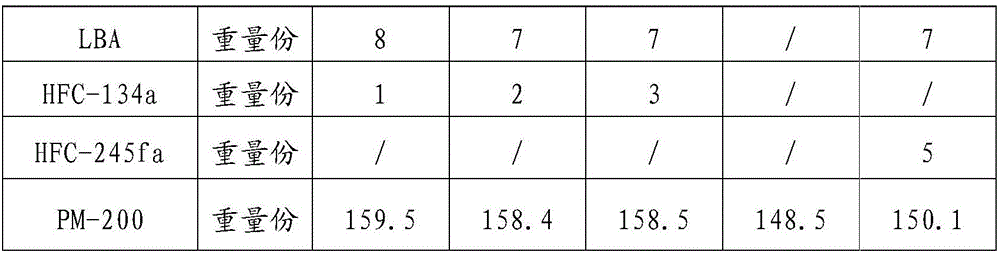

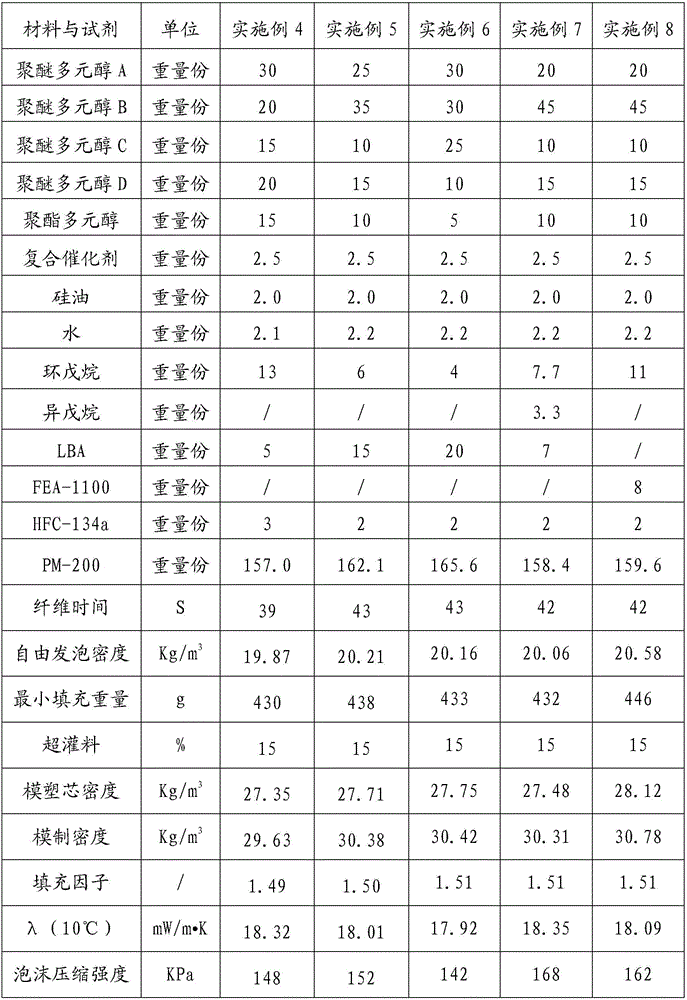

Low-density and low-heat-conduction-rate polyurethane foam and preparation method thereof

The invention relates to low-density and low-heat-conduction-rate polyurethane foam and a preparation method thereof. The polyurethane foam is prepared from the following raw materials in parts by weight: 100 parts of a polyatomic alcohol composition, 1 to 30 parts of a low-gas-phase heat conductivity coefficient foaming agent, 0.5 to 6 parts of HFC-134a, 5 to 20 parts of pentane, 0.5 to 3.0 parts of water, 1.0 to 3.5 parts of a catalyst and 1.0 to 4.0 parts of a foam stabilizer, wherein the ratio of the use amount of organic polyisocyanate to the total mass of the raw materials is 1.15 to 1.35. The polyurethane foam prepared by the method has a low GWP value; when the polyurethane foam is used, gas which damages an ozone layer is not released; the molding density of the foam is low and is reduced by 19 percent or more when being compared with that of a common cyclopentane system; the polyurethane foam is good in dimensional stability and low in heat conduction coefficient; the total weight of a product can be reduced and the comprehensive cost is low; the polyurethane foam has extremely good economic benefits in a heat preservation industry of high-end products.

Owner:HEFEI HUALING CO LTD +3

Hard polyurethane foam for ultralow-temperature insulation and preparation method thereof

InactiveCN104788642AGood dimensional stabilityThe preparation method is simple and reliableFoaming agentSteam pressure

The invention discloses a hard polyurethane foam for ultralow-temperature insulation, which is prepared by independently foaming trans-1,3,3,3-tetrafluoropropylene or foaming the trans-1,3,3,3-tetrafluoropropylene with cyclopentane. By utilizing the characteristic that HFO-1234ze has higher steam pressure at low temperature, the polyurethane foam has favorable dimensional stability at ultralow temperature, and is applicable to the field of ultralow-temperature insulation. The hard polyurethane foam for ultralow-temperature insulation is prepared by mixing composite polyethers and poly MDI (methylenediphenyl diisocyanate) in a mass ratio of 1:(1.1-1.3), wherein the composite polyethers contain a physical foaming agent and a chemical foaming agent; the physical foaming agent is HFO-1234ze or an HFO-1234ze-cyclopentane mixture; and the chemical foaming agent is water.

Owner:NANJING FORESTRY UNIV

Methanol diesel oil additive and methanol diesel oil

ActiveCN101033414ASolve power problemsSolve emulsification problemsLiquid carbonaceous fuelsOil additiveN-Butyl Alcohol

This invention relates to methyl alcohol diesel oil and its additive, in which, the additive is prepared in the volume ratio of the following raw materials: MTBE 10-15%, normal actane 5-10%, isopropyl acetone 15-20%, n-butyl alcohol 25-30% and methyl cyclopentane 10-35%, and said methyl alcohol is prepared in the volume ratio of the following materials: methyl alcohol 10-25%, diesel oil 70-88% and its additive 2-5%, which solves the technical problems of causticity, swellingness, difficulty of cold starting up, hot air-blocking, separation when meeting water, power reduction, fluidity and emulsification met when using the present methyl acohol.

Owner:CRPC INNOVATION ENERGY

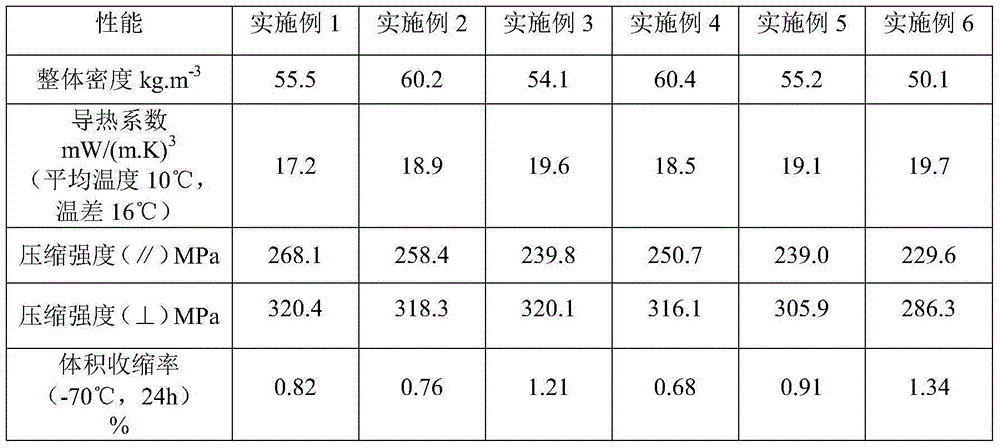

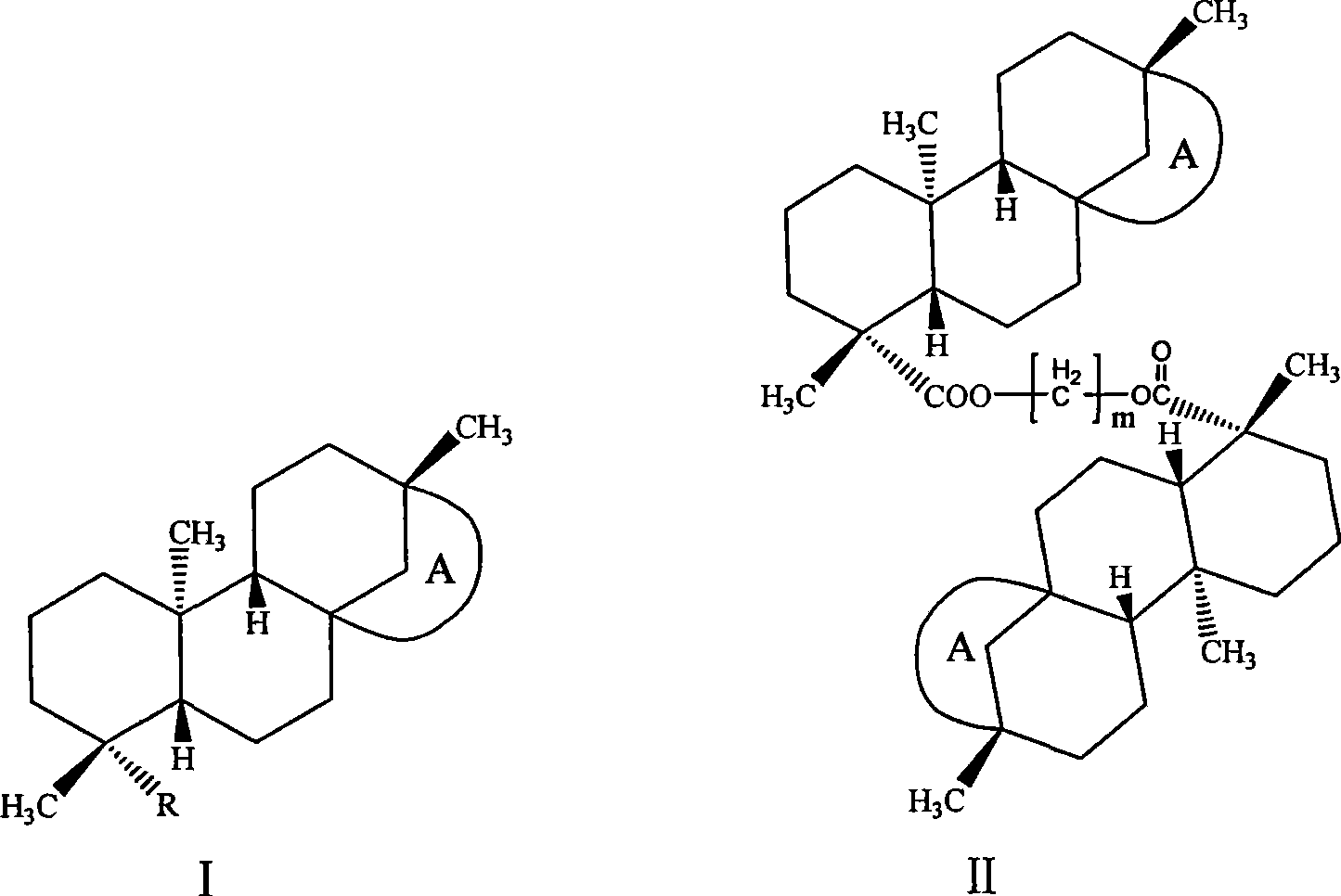

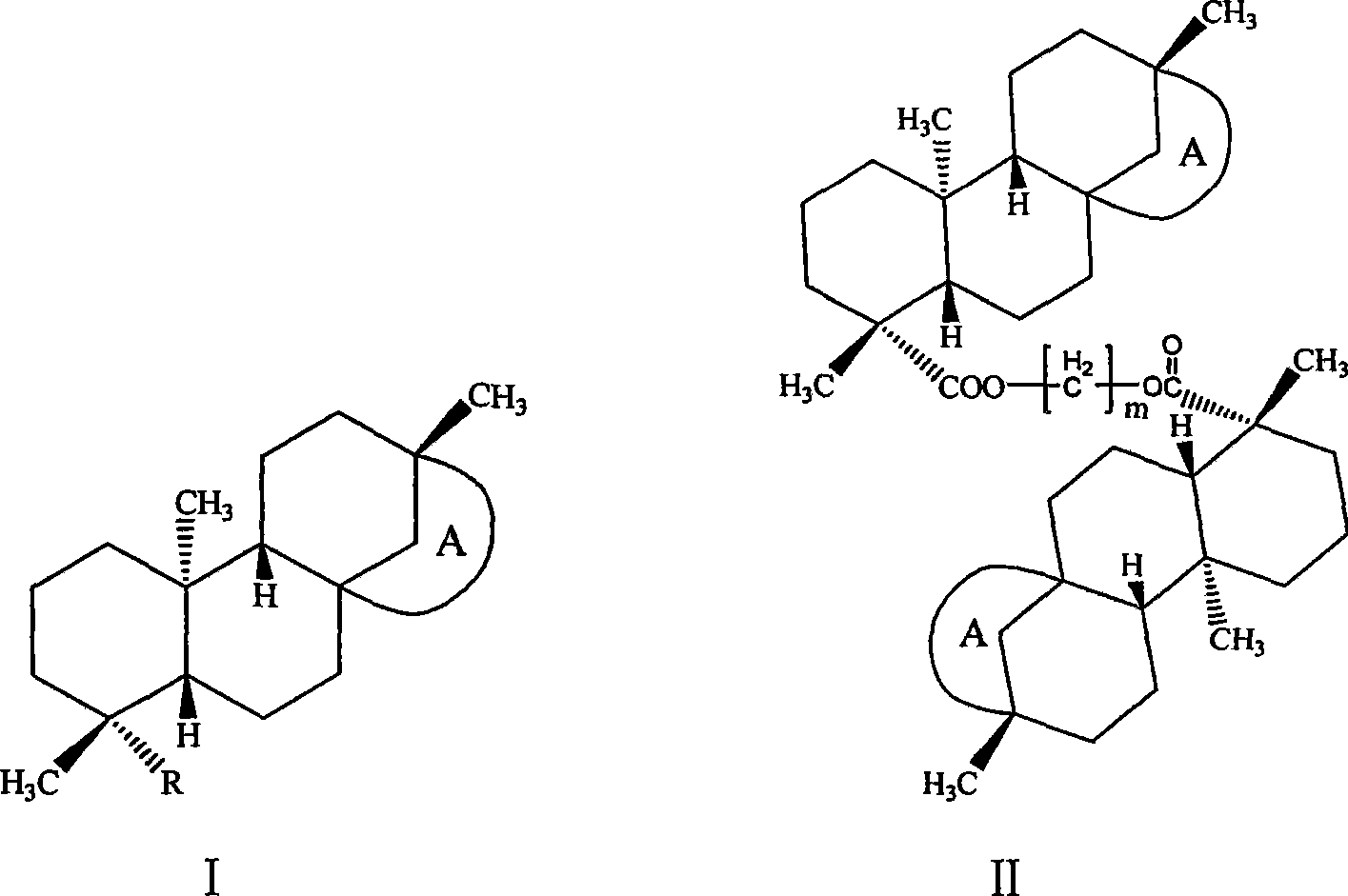

Isosteviol derivant and application thereof

The invention discloses isosteviol derivant and the application thereof, wherein, as shown in formula (I) or formula (II), A is cyclopentane, cyclopentanone, valerolactam, substituted cyclopentane, substituted cyclopentanone or substituted valerolactam; R is alkyl, substituted alkyl, -COOR2 or -COO(CH2)n-O-R4; R2 is alkyl or substituted alkyl; R4 is alkyl acyl, nitryl, heterocyclic acyl, substituted heterocyclic acyl, aromatic acyl or substituted aromatic acyl; and n or m is respectively integral numbers from 1 to 6. The compound has the effects of regulating blood sugar and treating cardiovascular diseases.

Owner:SOUTHEAST UNIV

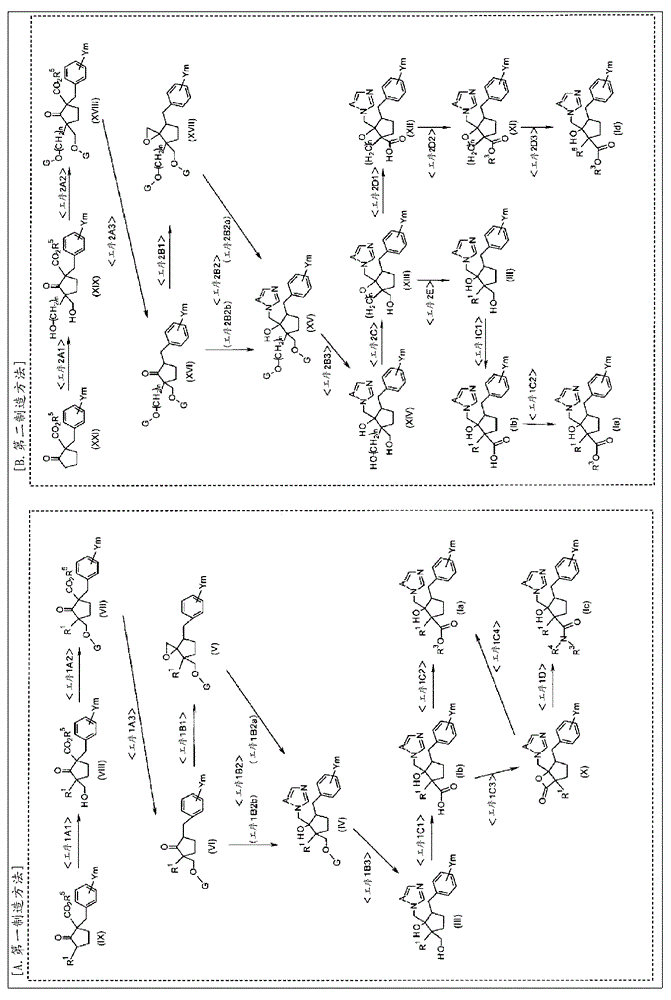

Azole derivative, method for producing same, intermediate compound, and agricultural or horticultural chemical agent and industrial material protecting agent

InactiveCN103562187AImprove the bactericidal effectImprove the effect of prevention and controlBiocideOrganic chemistryBULK ACTIVE INGREDIENTPhenyl group

Provided is an azole derivative which can be contained as an active ingredient in an agricultural or horticultural chemical agent having an excellent disease control effect. This azole derivative is represented by general formula (I). (In formula (I), R1 represents a C1-C6 alkyl group which may be substituted; R2 represents a functional group containing a carbonyl group, wherein a carbon atom in the carbonyl group is bonded to both a carbon atom substituted by R1 in the cyclopentane ring and any one selected from a hydrogen atom, a hydroxyl group, R3, OR3 and NR3R4; R3 and R4 independently represent a C1-C6 alkyl group, a C2-C6 alkenyl group or a C2-C6 alkynyl group; Y represents a halogen atom, a C1-C4 alkyl group, a C1-C4 haloalkyl group, a C1-C4 alkoxy group, a C1-C4 haloalkoxy group, a phenyl group, a cyano group or a nitro group; m represents 0-5; and A represents a nitrogen atom or a methine group.).

Owner:KUREHA KAGAKU KOGYO KK

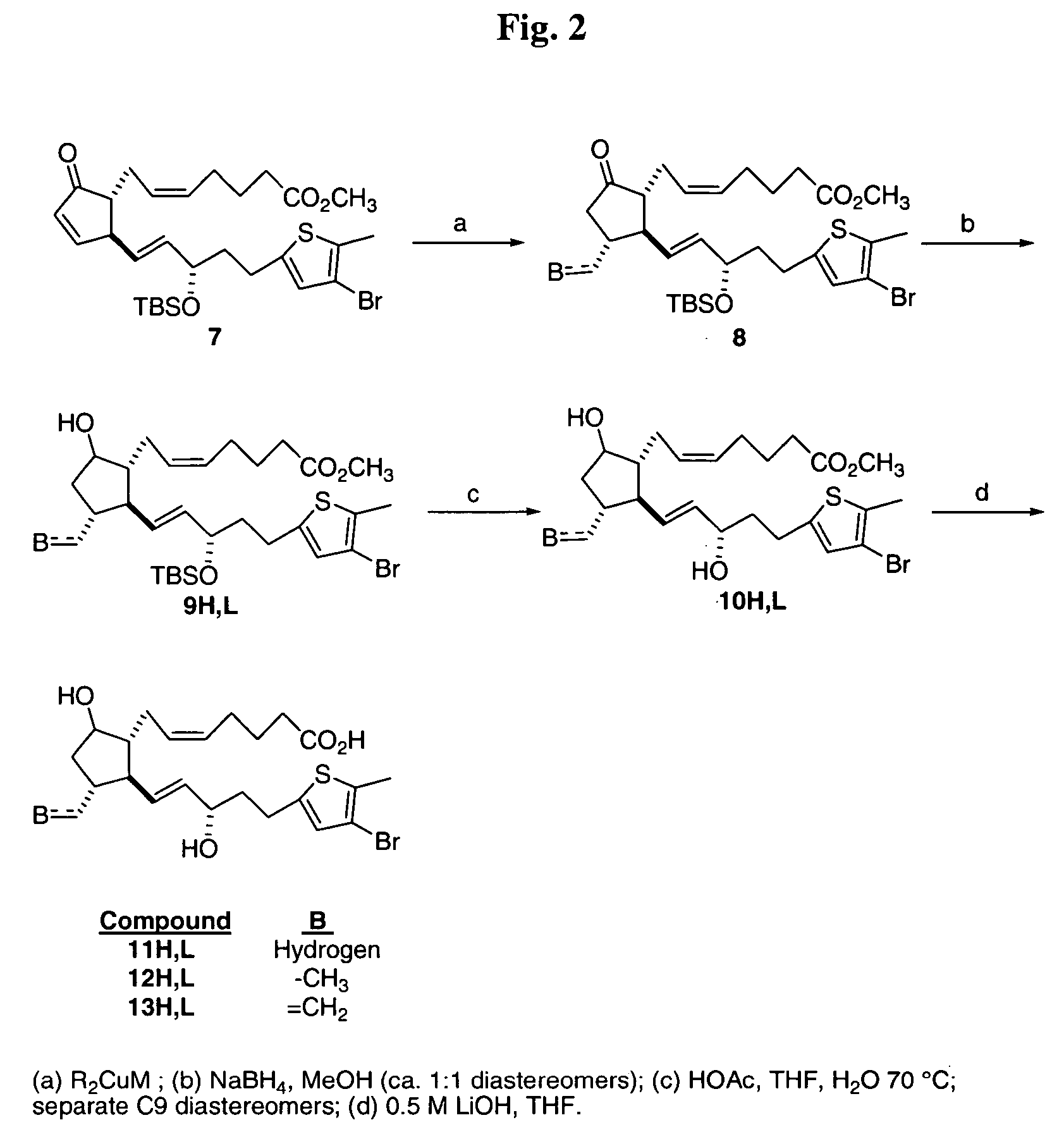

Cyclopentane heptan(ENE)OIC acid, 2-heteroarylalkenyl derivatives as therapeutic agents

A compound comprising or a pharmaceutically acceptable salt or a prodrug thereof, having the groups described in detail herein is disclosed. Also disclosed herein are compounds comprising or derivatives thereof, or pharmaceutically acceptable salts, tetrazoles, or prodrugs of compounds of the structure or derivatives thereof, said derivatives being described in detail herein. Also disclosed herein are methods of treating diseases or conditions, including glaucoma and elevated intraocular pressure. Compositions and methods of manufacturing medicaments related thereto are also disclosed.

Owner:ALLERGAN INC

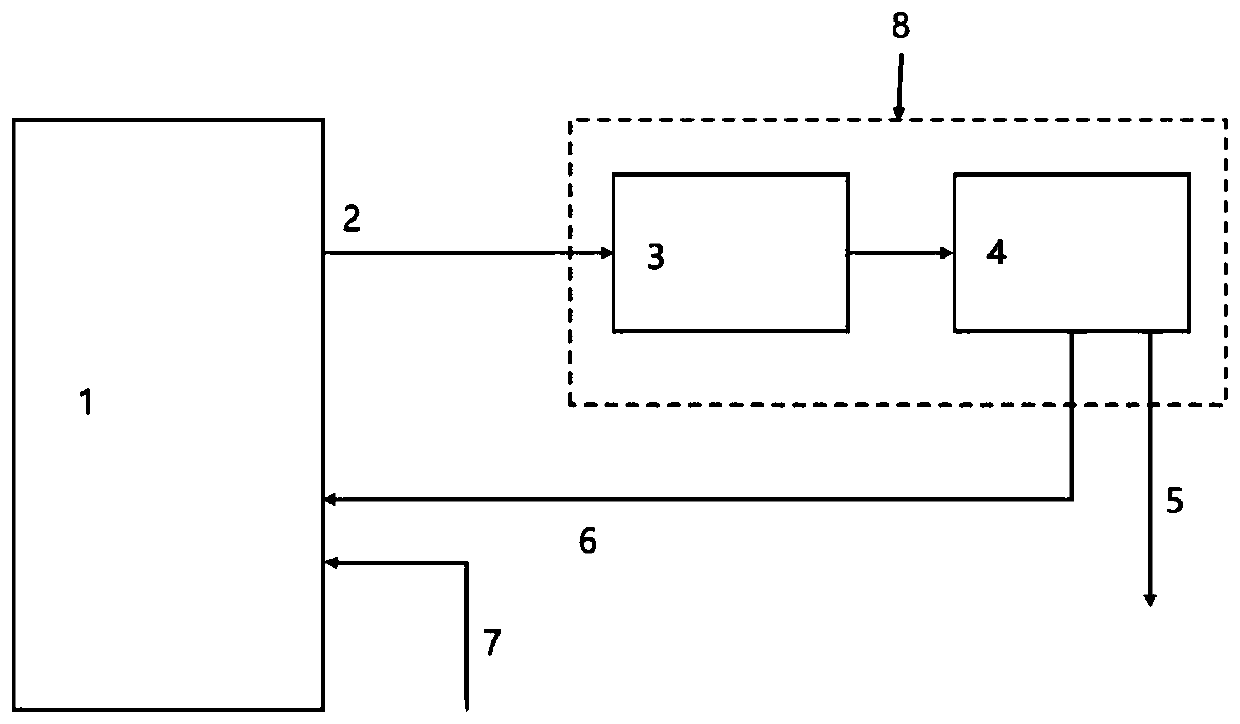

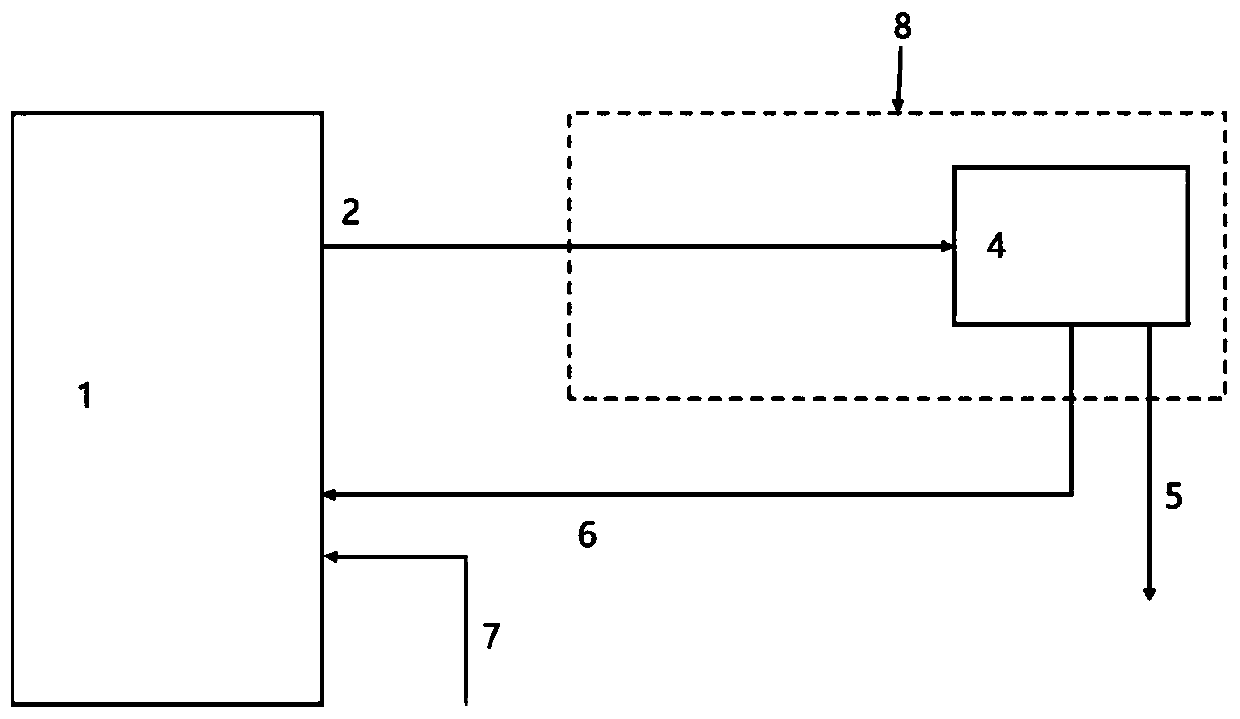

Safe solution spinning method

ActiveCN111286790AEmission reductionImprove production safetySpinnerette packsArtificial filament recoverySpinningNitrogen gas

The invention relates to a safe solution spinning method. The method is characterized in that in the solution spinning process, the oxygen content of mixed gas in a spinning box is controlled to be below 18vol%. By means of the method for introducing incombustible gas into the spinning box to reduce the oxygen content, the explosion risk in the solution spinning process is avoided, and the production safety is improved. The requirement for solvents can be reduced, the selection range of the solvents in the solution spinning process can be wider, the solvents are not limited to hydrocarbon solvents containing halogen, and hydrocarbon solvents (such as cyclopentane and cyclohexane) which have low flash points and only contain carbon atoms and hydrogen atoms can be adopted. In addition, by arranging a VOC-rich tail gas treatment system 8, the content of organic compounds in VOC-rich tail gas can be effectively reduced, and therefore low-VOC nitrogen is obtained, the tail gas in the spinning box can be recycled, and the production cost is reduced.

Owner:JIANGSU QINGYUN NEW MATERIAL TECH CO LTD

Modified cardanol-based polyether polyol and high-fire-resistant hard polyurethane foam prepared by modified cardanol-based polyether polyol and preparation method thereof

The invention discloses a modified cardanol-based polyether polyol and high-fire-resistant hard polyurethane foam prepared by the modified cardanol-based polyether polyol and a preparation method thereof. The polyether polyol takes cardanol, paraformaldehyde, diethanolamine, diethylenetriamine, tribromoaniline, melamine, oxirane and epoxypropane as raw materials, the raw materials are reacted for synthesis of cardanol Mannich polyether polyol, a hydroxyl value is 200-700mg / gKOH, the moisture is less than or equal to 1.0%, the viscosity is 1000-12000 mPa.s (at 25 DEG C), and the cardanol-based polyether polyol can be taken as a polyhydric alcohol component which can be used in the hard polyurethane foam. The product has advantage of adjustable functionality, contains a flame-retardant group, and has good compatibility with a cyclopentane foaming agent.

Owner:滕州市科米特新材料有限责任公司

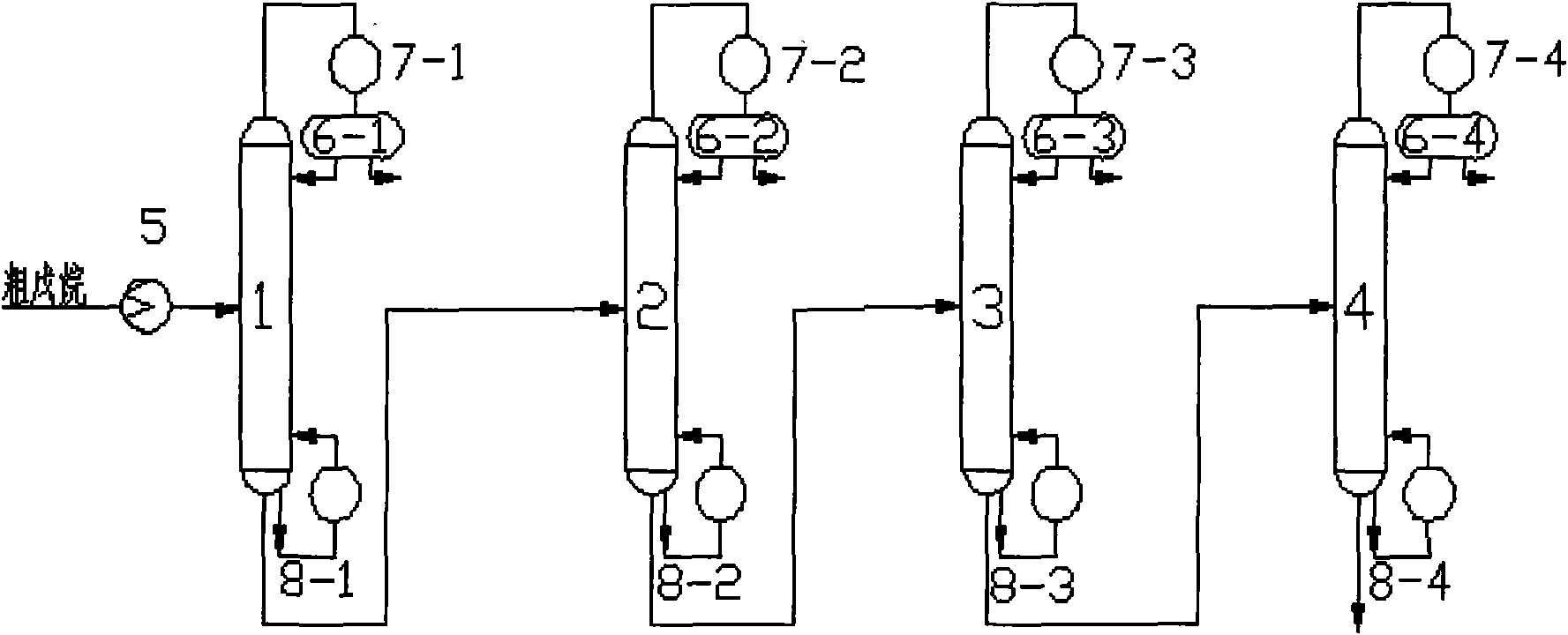

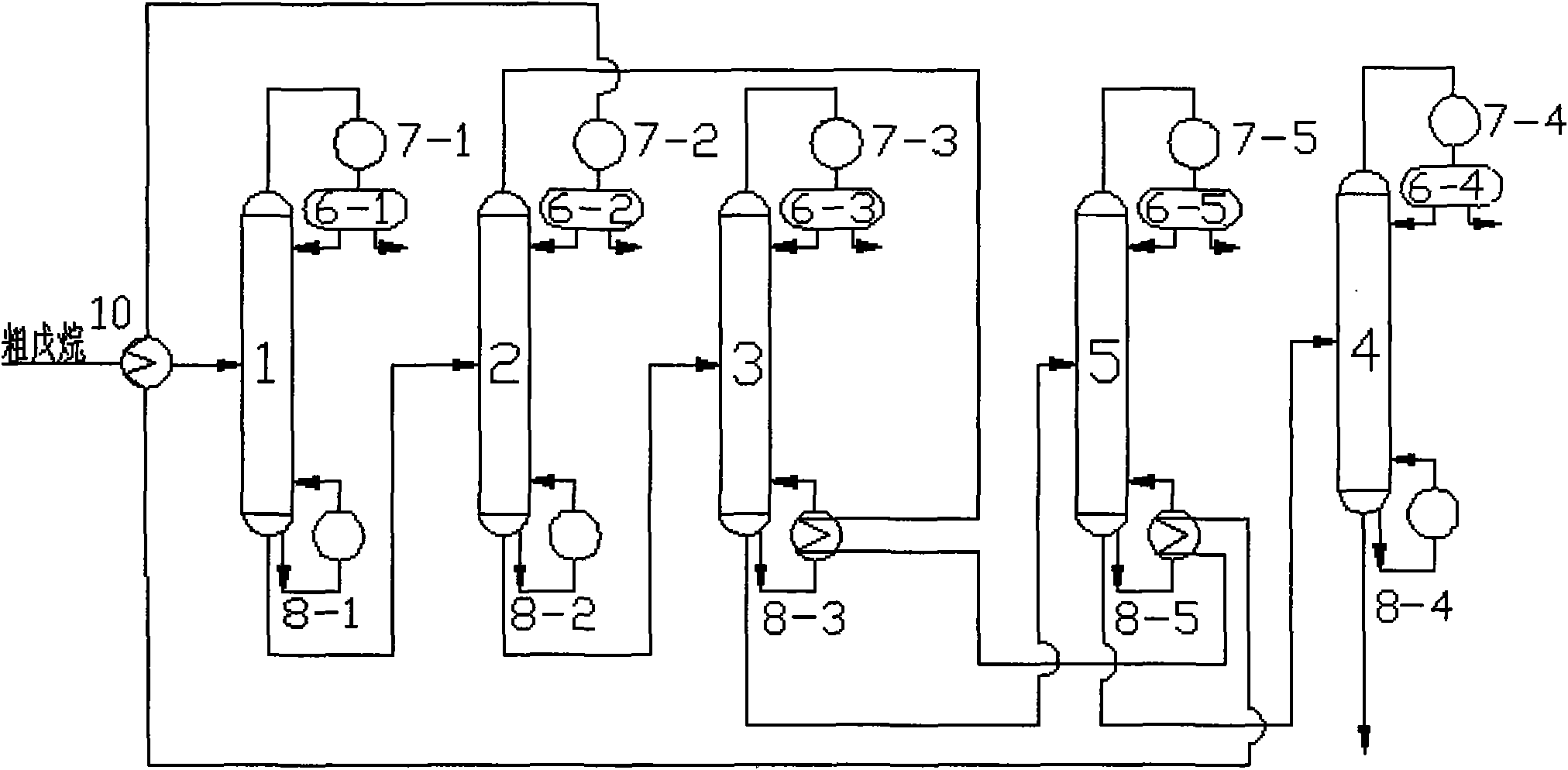

Double-effect rectification method and system thereof for finely separating hybrid pentane isomer

ActiveCN101602641AImprove product qualityReduce consumptionDistillation purification/separation2-methylbutaneReboiler

The invention discloses a double-effect rectification method for finely separating hybrid pentane isomer, which comprises the following steps: introducing a crude pentane raw material into a condensation preheater, a dehydrogenation tower of which the top is connected with a condenser and a reflux tank and the bottom is connected with a reboiler, an isopentane tower, an n-pentane tower, an azeotrope tower and a cyclopentane tower in turn to be rectified and separated, feeding total vapor at the tower top of the isopentane tower into the n-pentane tower and the reboiler as heat sources thereof, condensing the vapor into a two-phase mixture of vapor and liquid after heat exchange, then feeding the mixture to the azeotrope tower and the reboiler to exchange heat, re-preheating the crude pentane raw material by the waste heat after heat exchange, and finally beating the liquid to the isopentane tower as reflux liquid by a reflux pump of the isopentane tower. The method has the advantages of high product purity and low energy consumption and water consumption; and the product can be flexibly controlled according to the requirement.

Owner:TIANJIN UNIV

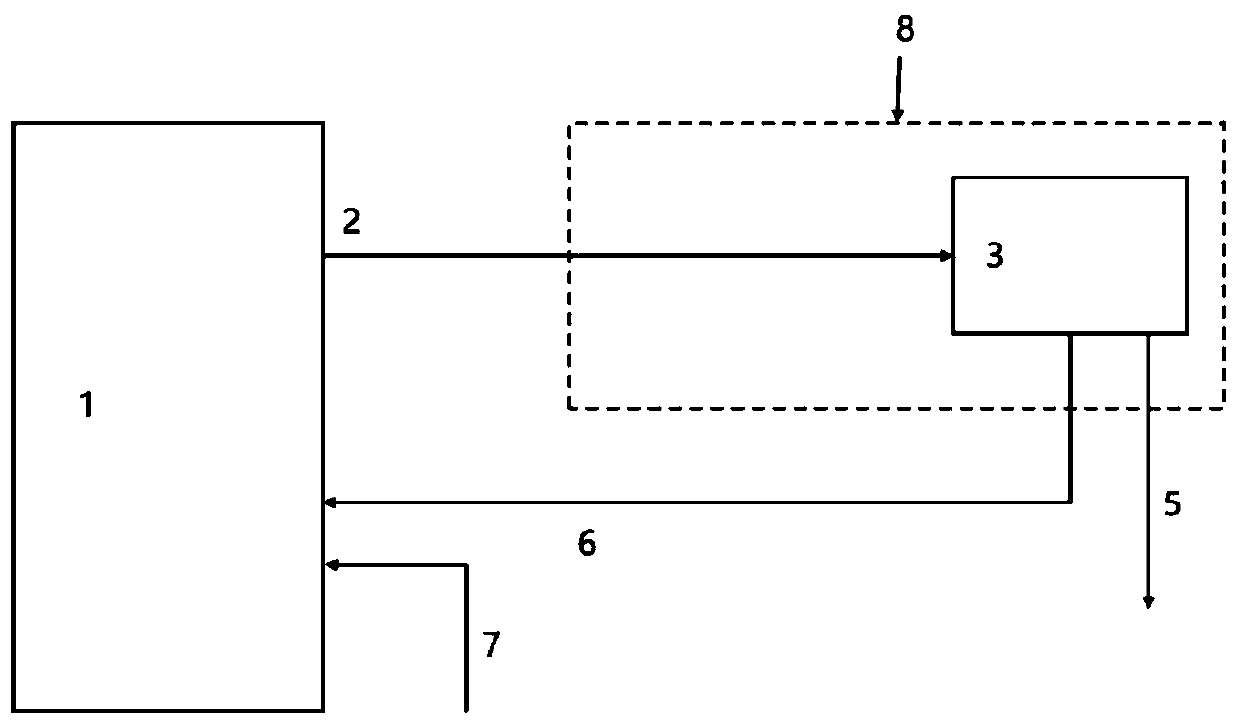

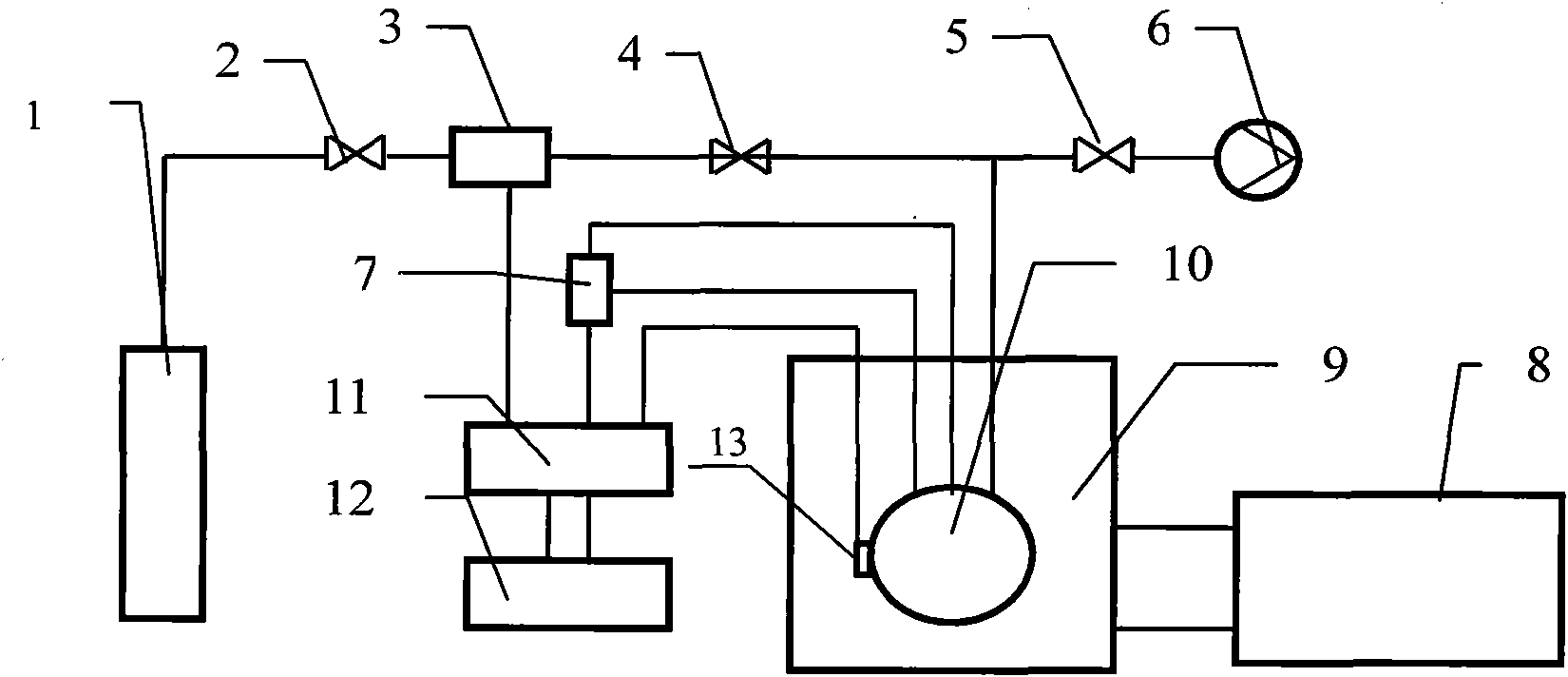

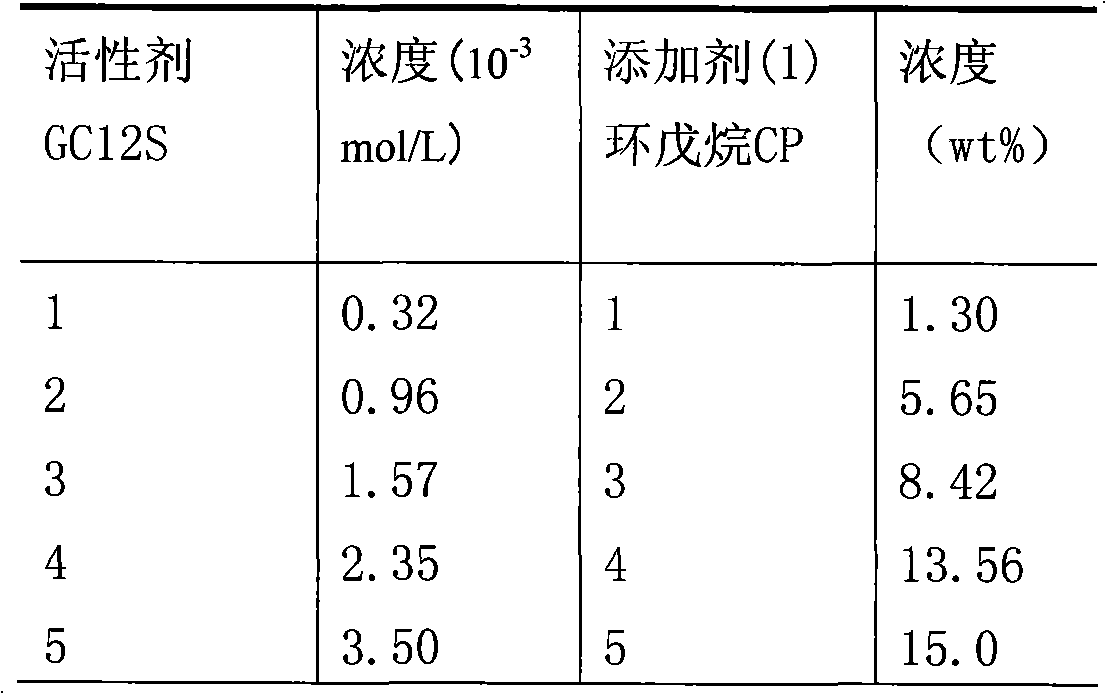

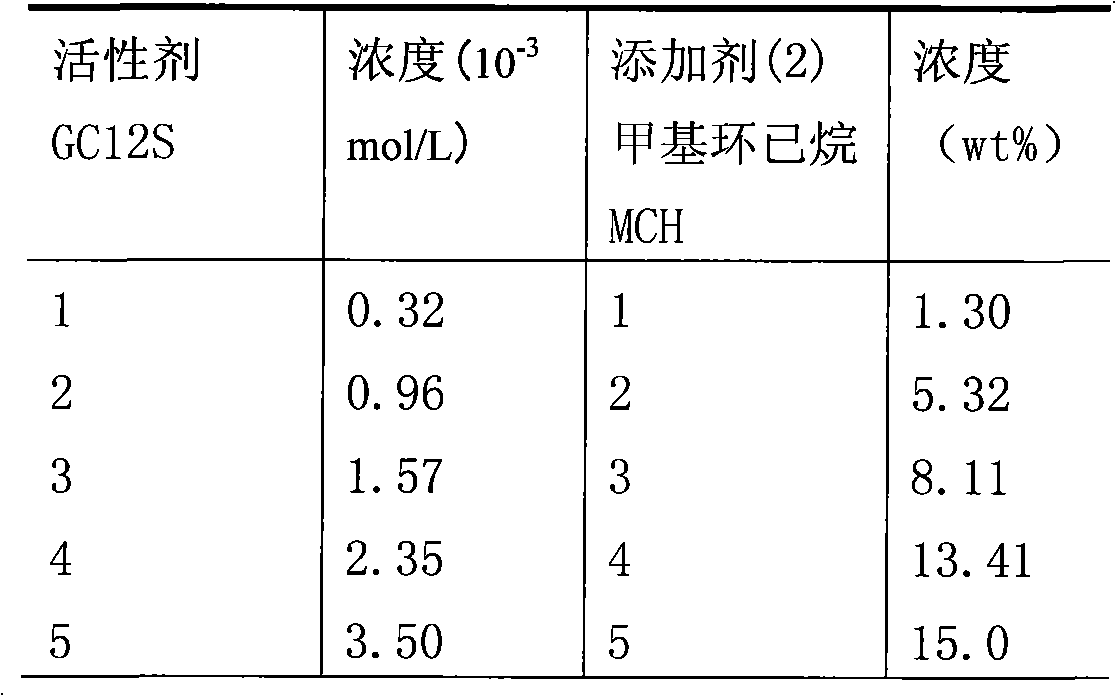

Method for preparing composite hydrate accelerant

The invention relates to a method for preparing a composite hydrate accelerant. The composite accelerant is characterized by being prepared by mixing cyclopentane or methyl cyclohexane serving as a kinetic accelerant and 2-butyl octyl sodium sulfate serving as a surfactant, wherein the percentage by mass of the cyclopentane or methyl cyclohexane in a solvent is 1.3 to 15.0, and the concentration of the surfactant 2-butyl octyl sodium sulfate in the solvent is 0.32*10<-3> to 9.5*10<-3> mol / L; and 0.02 to 0.78 mass percent of sodium chloride is added into the mixture. In the method, a high-pressure gas cylinder is taken as a gas source, a pressure is properly adjusted through a pressure adjustment valve, consumed gas is metered by a mass flow meter, a temperature and the pressure in a reactor are monitored by pressure and temperature transducers, and the temperature of liquid in a water tank is controlled by means of a thermostatic water bath, so that the temperature in the reactor is adjusted; and data is acquired by a data acquisition system and a computer, and the forming condition of a hydrate in the reactor is monitored by a photoelectric lens. The method for preparing the composite hydrate accelerant not only can reduce the forming condition of the hydrate, but also can shorten the formation time of the hydrate and improve the gas storage capacity of the hydrate.

Owner:溧阳常大技术转移中心有限公司

Rigid cellular plastic with improved property and preparation method thereof

The invention relates to a polyurethane rigid cellular plastic with improved property, which is prepared by the raw materials that are fully mixed in a high pressure foaming machine for reaction according to the ratio of parts by weight: composite polyether:mixed foaming agent:isocyanate = 100:7-27:110-150. The composite polyether is prepared by the components according to the ratio of parts by weight: composite polylols:foam stabilizer:catalyst:water:emulsifying agent= 100:1.0-4.0:0.5-5.0:0.5-3.5:0.5-10, wherein, the composite polylols comprise two or more polylols. Compared with cyclopentane foam and hydroflurocarbon foam, the heat conductivity coefficient of the foam prepared by the invention is obviously reduced; in the process of reaction between isocyanate and composite material, wider operating range can be obtained. The sensibility of the reaction towards parameters such as materials, mould, condition of circumstance and the like can be reduced.

Owner:HONGBAOLI GRP CO LTD

High-temperature rigid polyurethane spray foam for pipe insulation

The present invention provides a rigid polyurethane spray foam, which is made using cyclopentane as the blowing agent and which is useful for pipe insulation because of its ability to withstand high-temperatures (>250 DEG F.). The inventive foams may be sprayed with existing foam spraying equipment because the foams are reacted at about a 1:1.25 polyol to isocyanate ratio.

Owner:BAYER MATERIALSCIENCE AG

Polyether polyvalent alcohol for preparing no-freon polyurethane hard foam plastic and preparation method thereof

InactiveCN101161699ANo pollution in the processGood dimensional stability at low temperatureProcess systemsPolymer science

The present invention relates to a polyether glycol for preparing fluorin-free rigid PU foam and a preparation method thereof. The invention obtains the polyether glycol, at the condition of mixing initiator and using KOH as a catalyst, by adding the mixture into the high-pressure reaction kettle, stirring to displace by the nitrogen, evacuating and dehydrating, controlling the temperature and the pressure of the kettle, dripping oxyalkylene continuously into the kettle until the hydroxyl value meets the need of polyether to ring-opening polymerize with oxyalkylene. The mixing initiator comprises, a) at least one active hydrogen compounds with the functionality more than 3; b) one active hydrogen compound with an aromatic ring structure or heterocycle structure; c) at least one active hydrogen compound with a functionality not more than 3 different from a) and b). The foam after foaming of the polyether by cyclopentane or full-water has an excellent high and low temperature dimensional stability and an excellent compressive strength, capable of replacing the traditional foaming process system and being used in the fields of refrigeratory, deep freezer, heat preservation of the underground conduit and the solar energy water heater, building materials, etc.

Owner:李颂兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Antioxidant nanosphere comprising [1,2]-dithiolane moieties Antioxidant nanosphere comprising [1,2]-dithiolane moieties](https://images-eureka.patsnap.com/patent_img/7638ee01-2a0a-47ec-a6db-48cf0bd0b780/US20100291222A1-20101118-D00000.png)

![Antioxidant nanosphere comprising [1,2]-dithiolane moieties Antioxidant nanosphere comprising [1,2]-dithiolane moieties](https://images-eureka.patsnap.com/patent_img/7638ee01-2a0a-47ec-a6db-48cf0bd0b780/US20100291222A1-20101118-D00001.png)

![Antioxidant nanosphere comprising [1,2]-dithiolane moieties Antioxidant nanosphere comprising [1,2]-dithiolane moieties](https://images-eureka.patsnap.com/patent_img/7638ee01-2a0a-47ec-a6db-48cf0bd0b780/US20100291222A1-20101118-D00002.png)