Low-thermal-conductivity rigid polyurethane foam taking cyclopentane as main body and manufacturing method and applications thereof

A technology of rigid polyurethane foam and cyclopentane, which is applied in the field of rigid polyurethane foam, can solve the problems of low thermal conductivity and high thermal conductivity, and achieve the effects of low thermal conductivity, reduced thermal conductivity, and reduced foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with the examples. These examples are only typical descriptions of the present invention, but the present invention is not limited thereto.

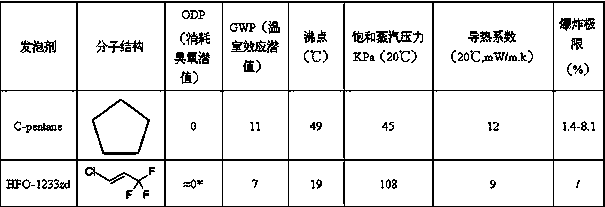

[0070] The raw materials used in the present invention are described as follows:

[0071] Polyether A: sucrose as the initiator, polymerized with oxyalkylene, functionality 8, hydroxyl value 370-415mg / KOH / g;

[0072] Polyether B: sucrose, glycerin as the initiator, polymerized with oxyalkylene, functionality 5~6, hydroxyl value 360~390mg / KOH / g;

[0073] Polyether C: Sorbitol is used as the initiator, polymerized with oxyalkylene, functionality 6, hydroxyl value 480-500mg / KOH / g;

[0074] Polyether D: Methylphenylenediamine as the initiator, polymerized with oxyalkylene, functionality 4, hydroxyl value 400-420mg / KOH / g;

[0075] Polyether E: Ethylenediamine is used as an initiator, and it is polymerized with oxyalkylene, with a functionality of 4 and a hydroxyl v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com