Low-density and low-heat-conduction-rate polyurethane foam and preparation method thereof

A technology of polyurethane foam and low thermal conductivity, applied in the field of materials, can solve the problems of unfriendly polyurethane foam, high GWP value, low thermal conductivity, etc., and achieve good compressive strength and dimensional stability, uniform density distribution, and low gas-phase thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

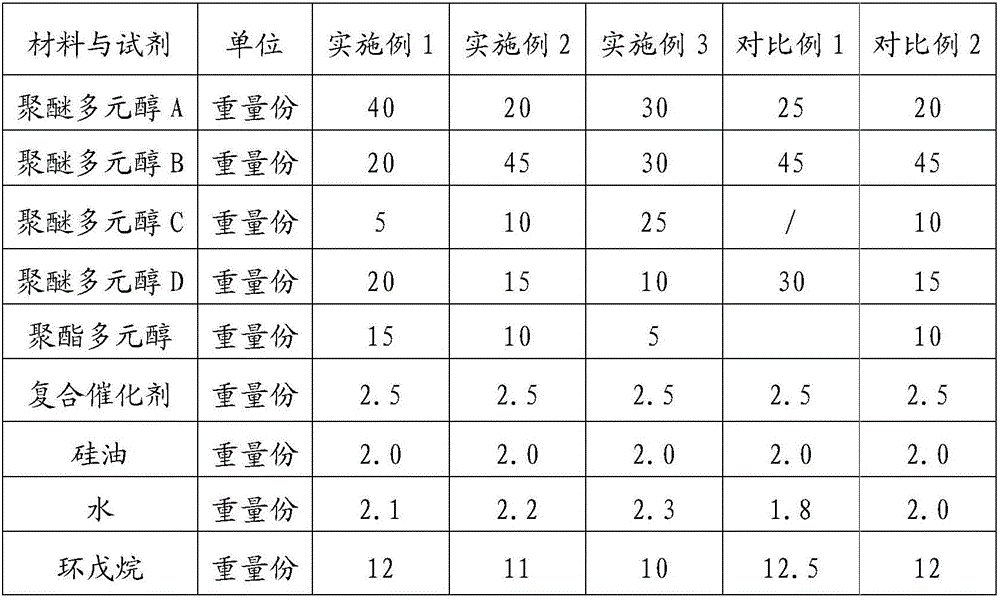

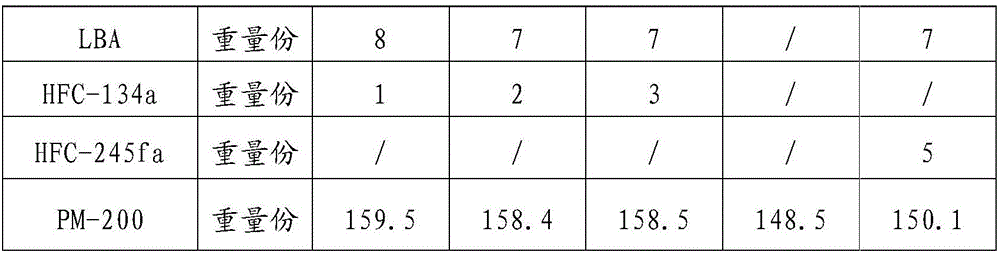

[0055] In Examples 1-3, changing the components of the CP / LBA / HFC-134a mixed blowing agent can prepare polyurethane foams with low density and low thermal conductivity, see Table 1 for details, wherein, the preparation method of the polyurethane foams Include the following steps:

[0056] Table 1 implements the raw material components and content of 1-3 and comparative example 1-2

[0057]

[0058]

[0059] 1) Add the weighed polyol composition into the mixing tank, add the weighed composite catalyst, foam stabilizer and water, pressurize to 0.5-1.5MPa at 25±5°C for physical mixing, and stir for 0.5-1.5 hours, the primary mixture was obtained;

[0060] 2) Using multi-stage static premixing equipment, mix LBA and HFC-134a with the above-mentioned primary mixture at a pressure of 0.7-2.0 MPa for 0.5-1.5 hours, then add cyclopentane and carry out secondary mixing under a pressure of 2.0-4.0 MPa. Grade mixing to obtain a pre-mixture;

[0061] 3) The organic polyisocyanate...

Embodiment 2

[0072] Compared with the foam of Comparative Example 1 in Example 2, it can be seen that the former foam has better fluidity, the molded core density is reduced by 19.9%, the thermal conductivity is reduced by 8.4%, the minimum filling weight is reduced by 19.2%, the expansibility is reduced, and the exfoliation is reduced. The modulus performance is improved.

[0073] Compared with Comparative Example 2, the thermal conductivity and expansion rate of Example 2 are close, the molded core density has decreased by 9.6% compared with Comparative Example 2, and the minimum filling weight has decreased by 9.5%. The foaming material of the product prepared by using this foam The consumption is reduced, the cost is reduced, and the blowing agent consumption of Example 2 is less than that of Comparative Example 2, and the cost is low, which further reduces the production cost.

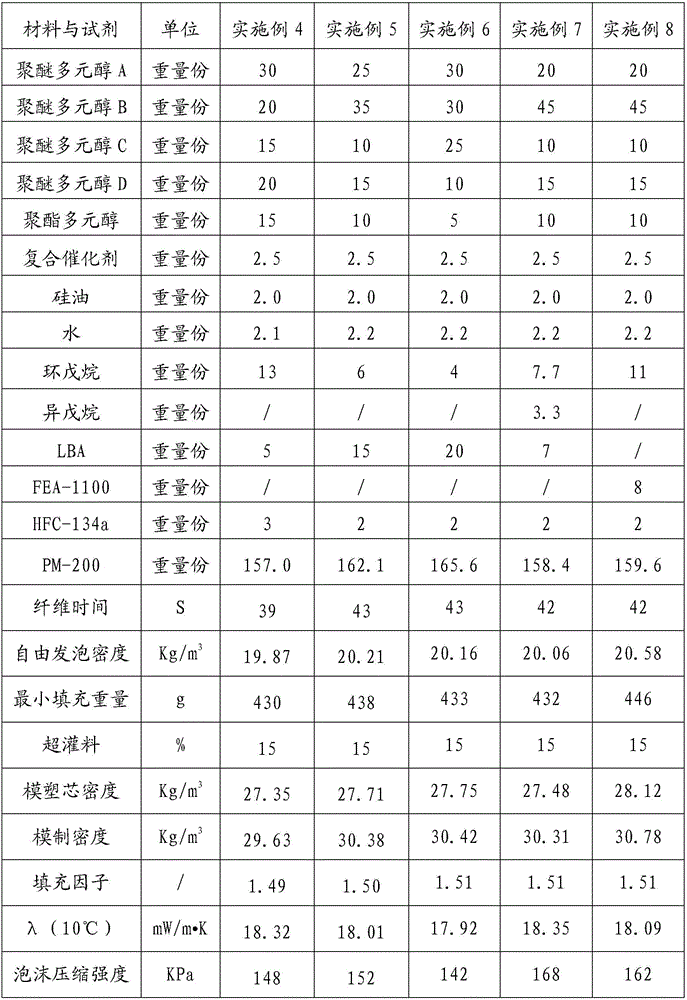

[0074] In Examples 4-8, by changing the ratio of blowing agents cyclopentane, LBA, HFC-134a and choosing cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com